Semicircular bolt forming equipment and process thereof

A technology for forming equipment and bolts, which can be used in bolts, metal processing equipment, heating/cooling equipment, etc., and can solve problems such as high height, easy to slip, and unstable dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

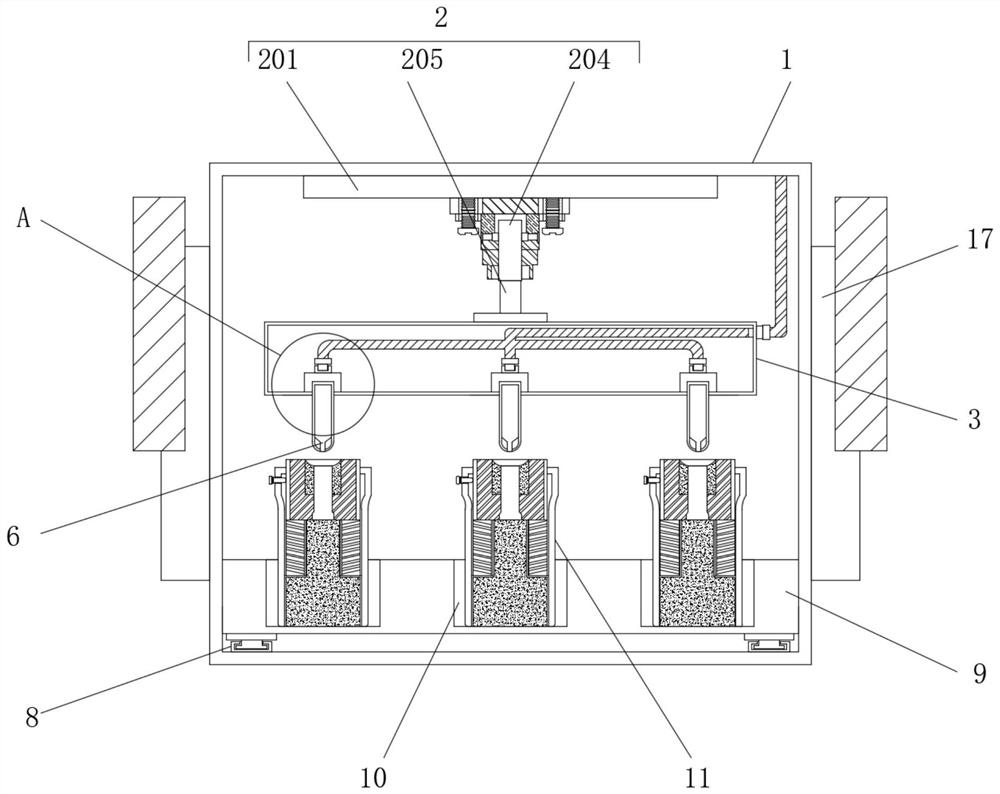

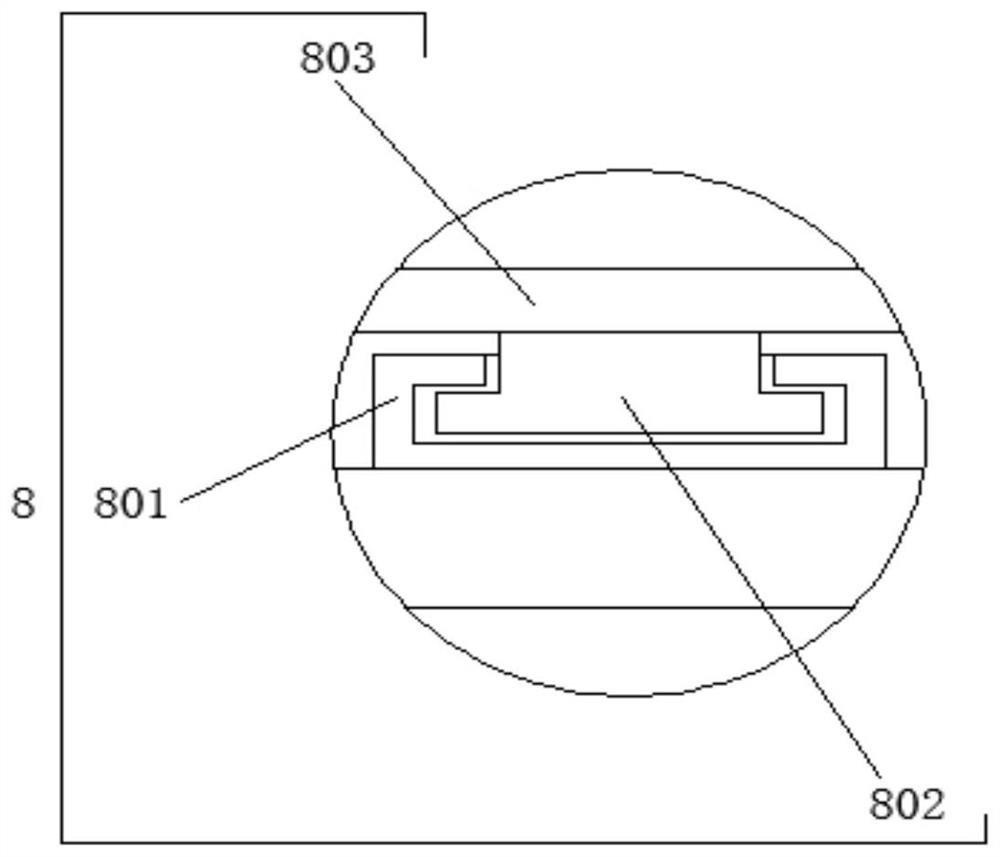

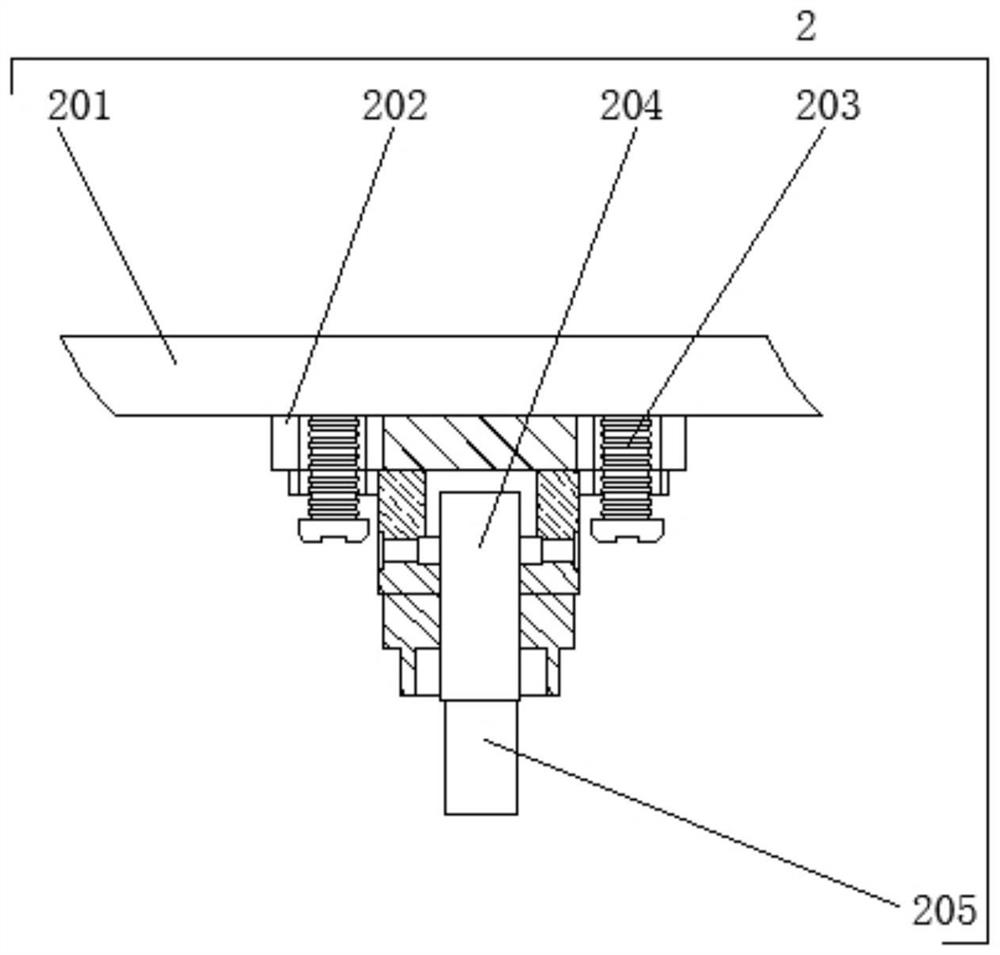

[0034] see Figure 1-6 , in this embodiment: a semicircular bolt forming equipment, including a box body 1, a hydraulic mechanism 2 is connected with a screw on the inner top of the box body 1, and a fixing frame 3 is installed under the hydraulic mechanism 2, and a fixing frame 3 is arranged below the inner side Connecting seat 4, and the movable punch 5 is installed under the connecting seat 4, the inner side of the movable punch 5 is provided with a discharge hole 6, the top of the connecting seat 4 is provided with a feeding mechanism 7, and the inner bottom of the box body 1 is installed Sliding mechanism 8 is arranged, and workbench 9 is arranged on the top of sliding mechanism 8, and the upper surface of workbench 9 is provided with fixed groove 10, and the inner side of fixed groove 10 is provided with dynamic punching shell 11, and the inner bottom end of dynamic punching shell 11 A T-shaped pad 12 is installed, and the outer wall of the T-shaped pad 12 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com