Sealing structure for sealing box

A technology of sealing structure and sealing box, applied in the direction of engine sealing, sealing shell, connecting components, etc., can solve the problems of communication cable, signal equipment explosion, insufficient protection level of sealing box, and low insulation level of sealing box, etc. High grade, good elasticity, and the effect of preventing rainwater leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

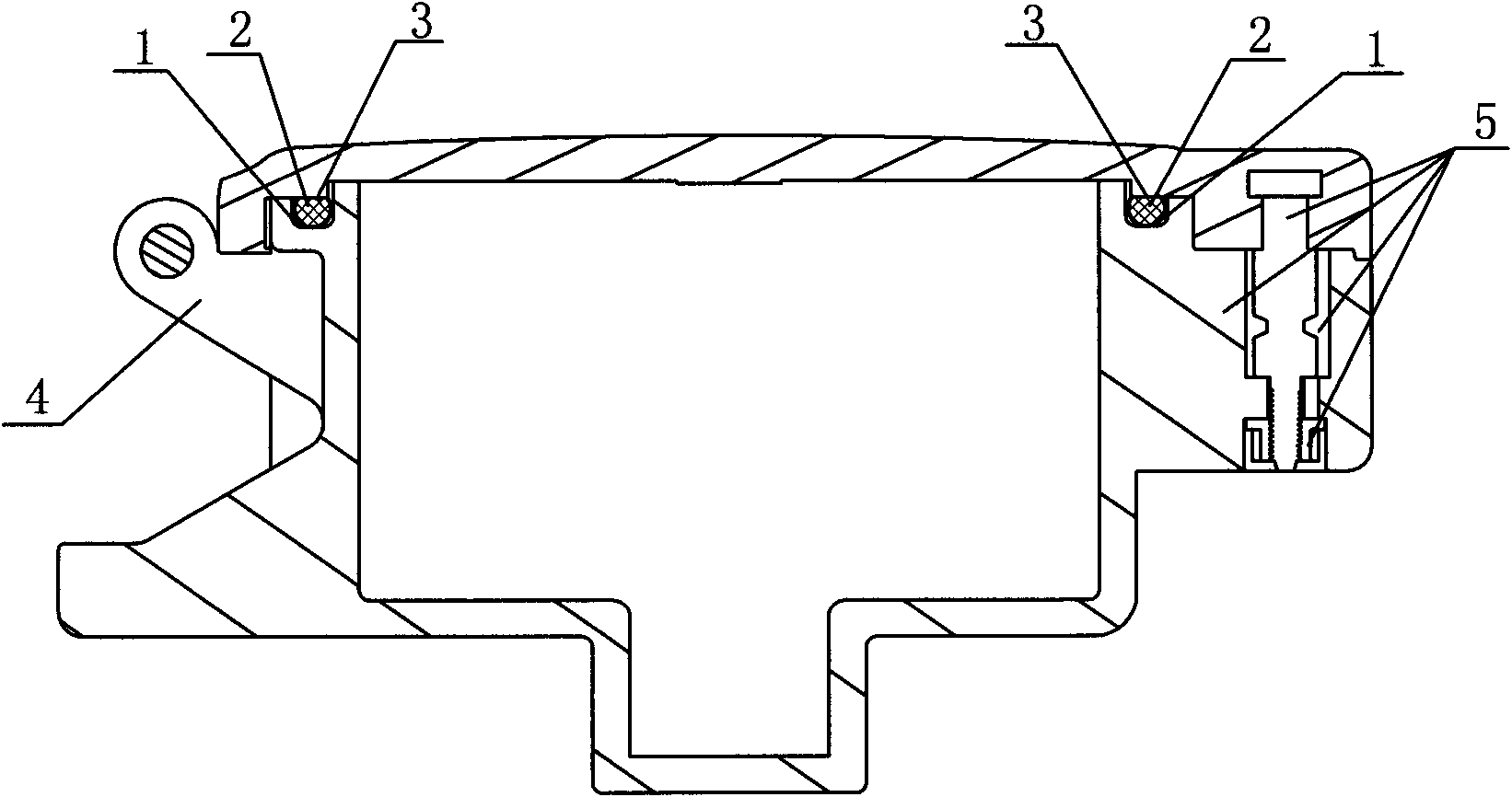

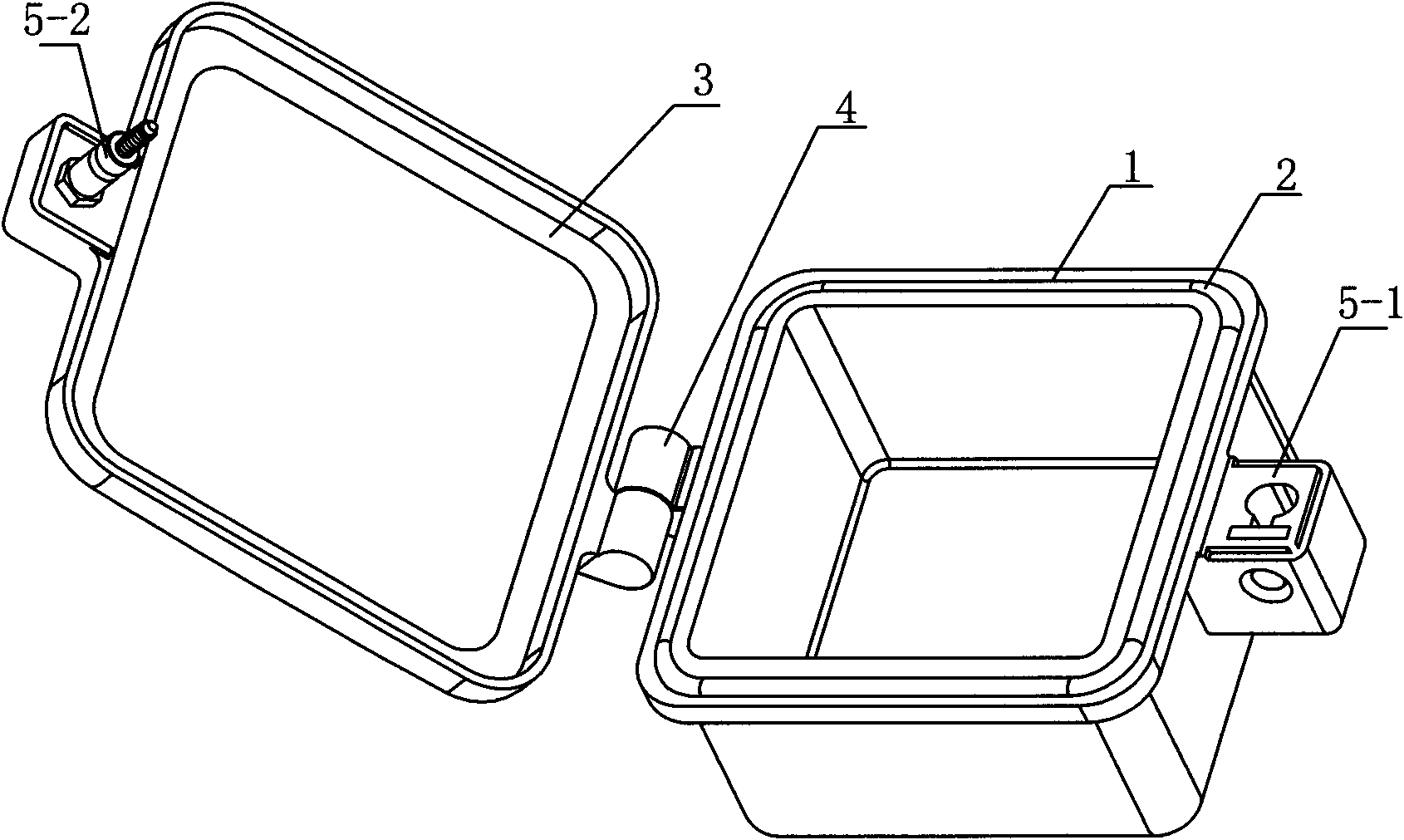

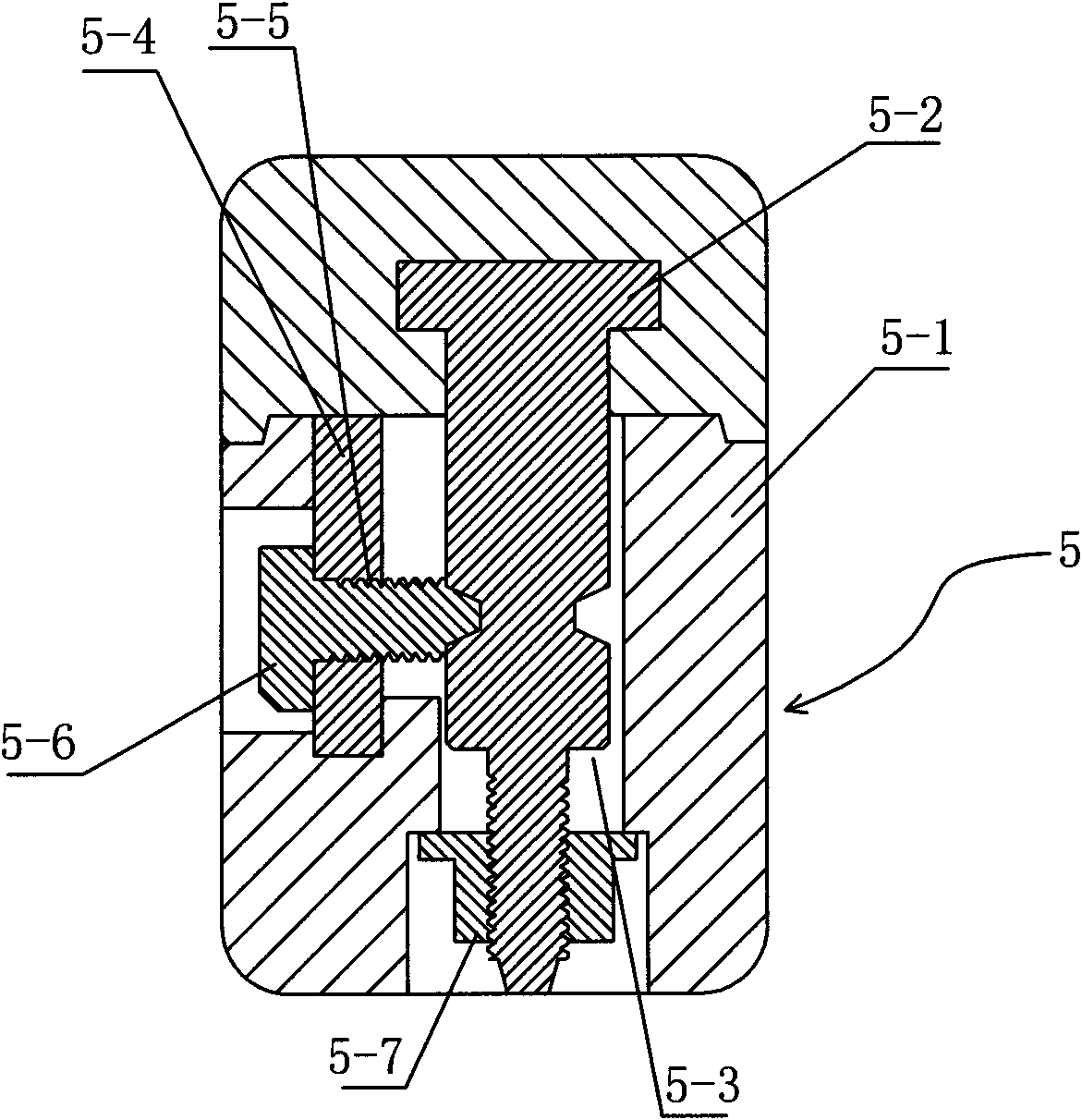

[0016] As shown in the figure, the sealing structure of the sealed box of the present invention includes an accommodation groove 1 located on the upper edge of the box body, an elastic seal 2 accommodated in the accommodation groove 1, and an elastic seal arranged on the box cover for pressing against the elastic seal. The abutment plate 3 of 2, the contact surface of the abutment plate 3 and the elastic seal 2 is a plane, and the elastic seal 2 and the abutment plate 3 are pressed against each other through the pressing device arranged on the box body and the box cover. The hardness of the elastic sealing member 2 is 45-50°, the compression amount of the elastic sealing member 2 is 1-1.5 mm, and the surface flatness of the abutting plate 3 is not greater than 0.4.

[0017] The section of the receiving tank 1 is semicircular, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com