A fuel cell metal bipolar plate and its welding method

A technology of metal bipolar plates and welding methods, which is applied to fuel cell parts, welding equipment, laser welding equipment, etc., can solve problems such as increased resistance and poor operating performance, and achieve reduced deformation, improved performance, and smoothness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

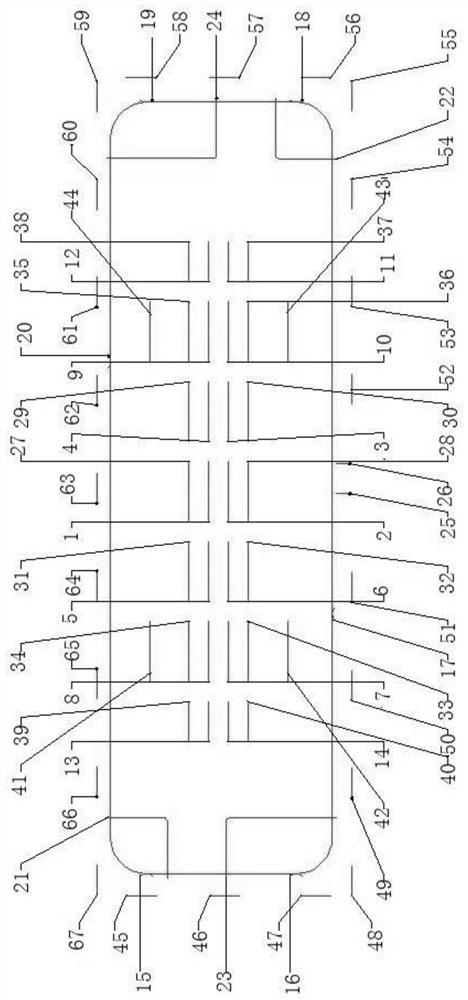

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0028] A method for welding a metal bipolar plate of a fuel cell provided by the present invention improves the flatness of the metal bipolar plate of a fuel cell, comprising the following steps:

[0029] 1. Place the two unipolar plates (anode plate and cathode plate) of the metal bipolar plate on the jig for positioning. The anode plate is on the upper layer and the cathode plate is on the lower layer. Keep the anode plate, cathode plate and welding tooling The relative position of the anode plate remains unchanged, and the compression tooling is placed to make the anode plate flow channel and the cathode plate flow channel closely fit.

[0030] Use the laser beam to carry out relative displacement along the welding track in the middle of the metal bipolar pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com