Large automatic winding machine for amorphous and ultrafine-crystalline thin strips

A technology of ultra-microcrystalline and winding machines, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc. It can solve the problems of high defective rate and difficult control of product quality, so as to improve product quality and ensure smoothness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

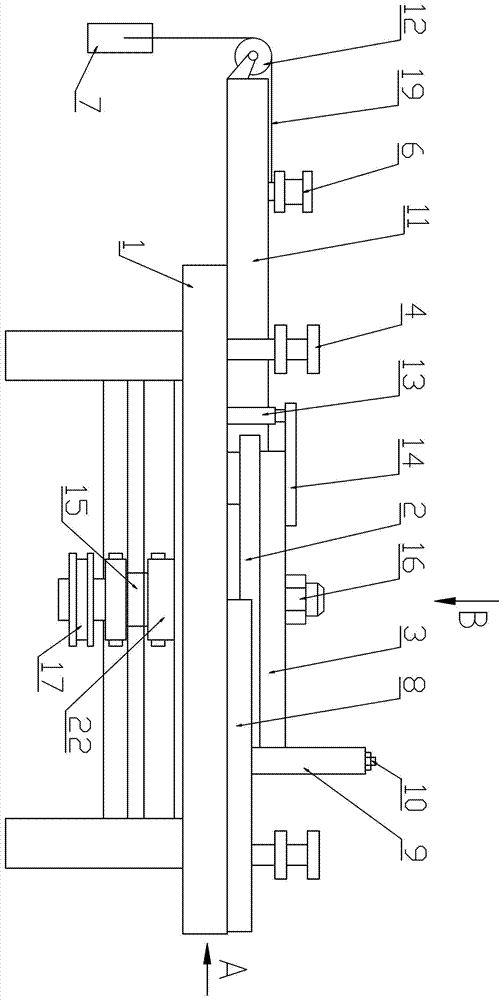

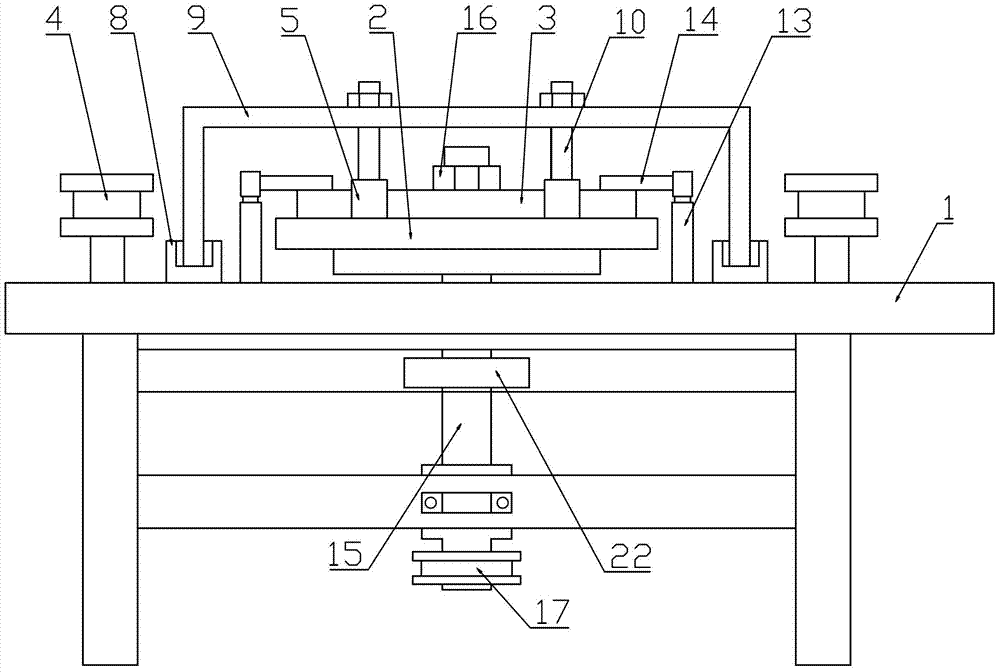

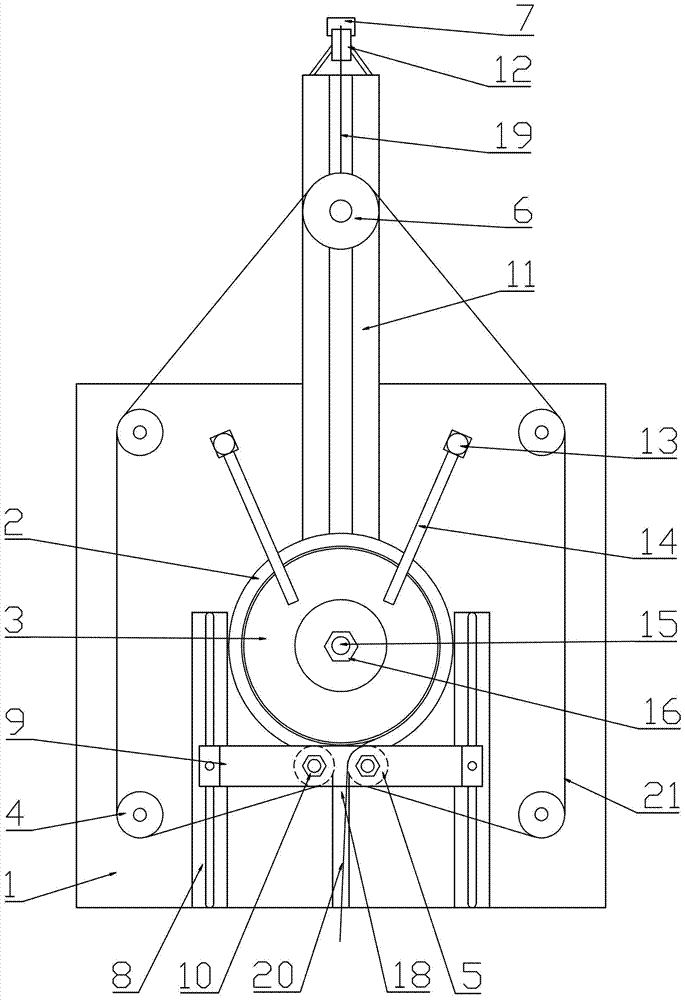

[0022] As attached to the manual figure 1 , 2 As shown, a large-scale automatic winding machine for amorphous and ultramicrocrystalline thin strips includes a frame 1, a motor-driven rotating disk 2 is provided on the central plane of the frame 1, and a rotating disk 2 for winding is provided on the rotating disk 2. The rotating inner core 3 of the winding belt 20 is linked and concentric with the rotating disk 2. The automatic winding machine also includes a vertically arranged rotating shaft 15, and a rotating shaft fixing seat 22 sleeved on the rotating shaft 15 is provided under the frame 1. One end of the rotating shaft 15 runs through the frame 1, the rotating disk 2 and the rotating inner core 3, and is connected with a fixed nut 16, and the other end of the rotating shaft 15 is provided with a pulley 17, which is connected with the output shaft of the motor through a transmission belt, as shown in the attached manual image 3 As shown, the frame 1 is fixed with four f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com