Bag outputting mechanism of automatic plastic bag selling machine

A plastic bag, automatic technology, used in thin material handling, strip winding, transportation and packaging, etc., can solve problems such as uncontrollable tightness, limited space for material rollers, clogging of plastic bags, etc., to enhance environmental protection awareness, Compact structure, the effect of eliminating the difference in inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

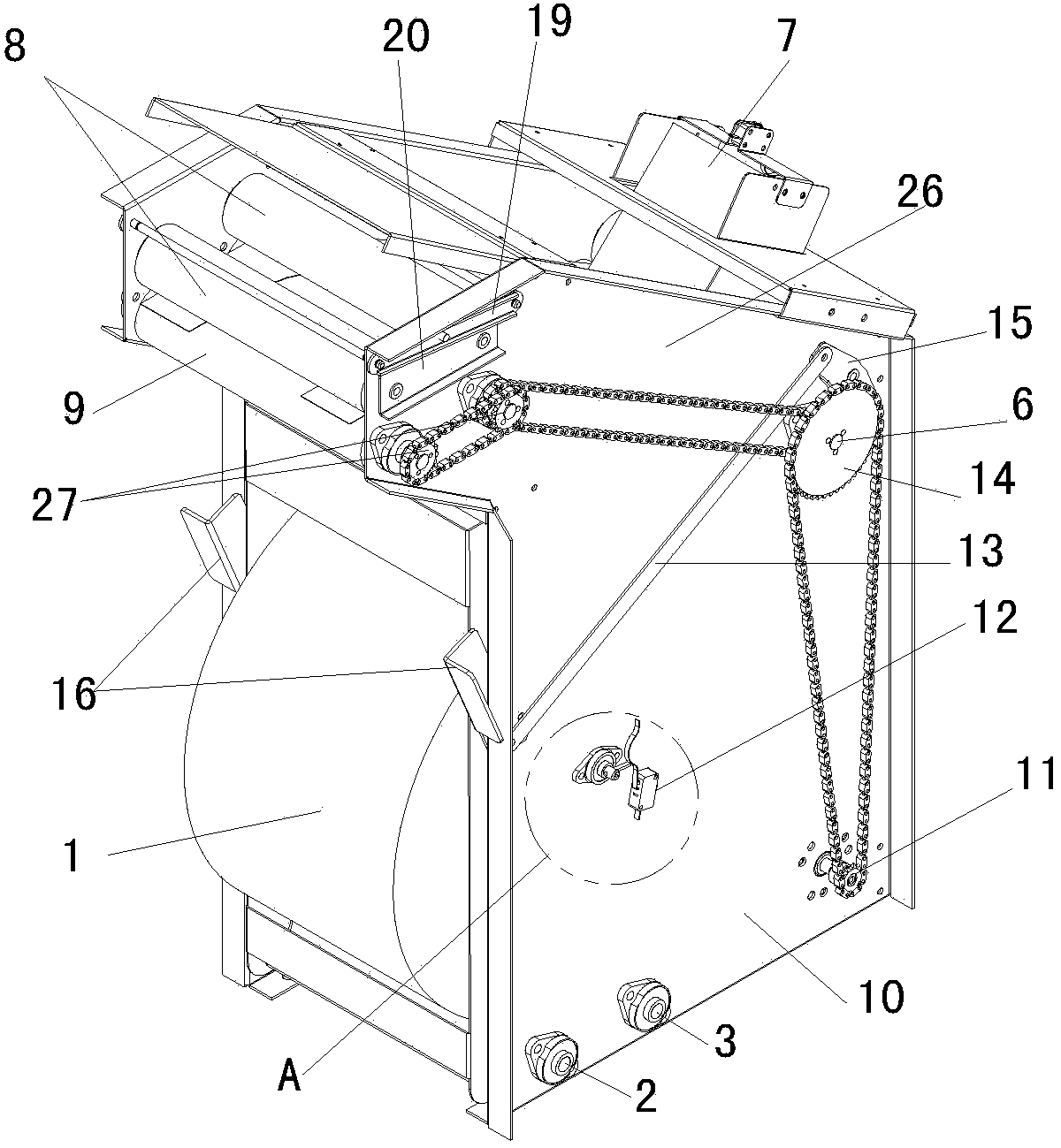

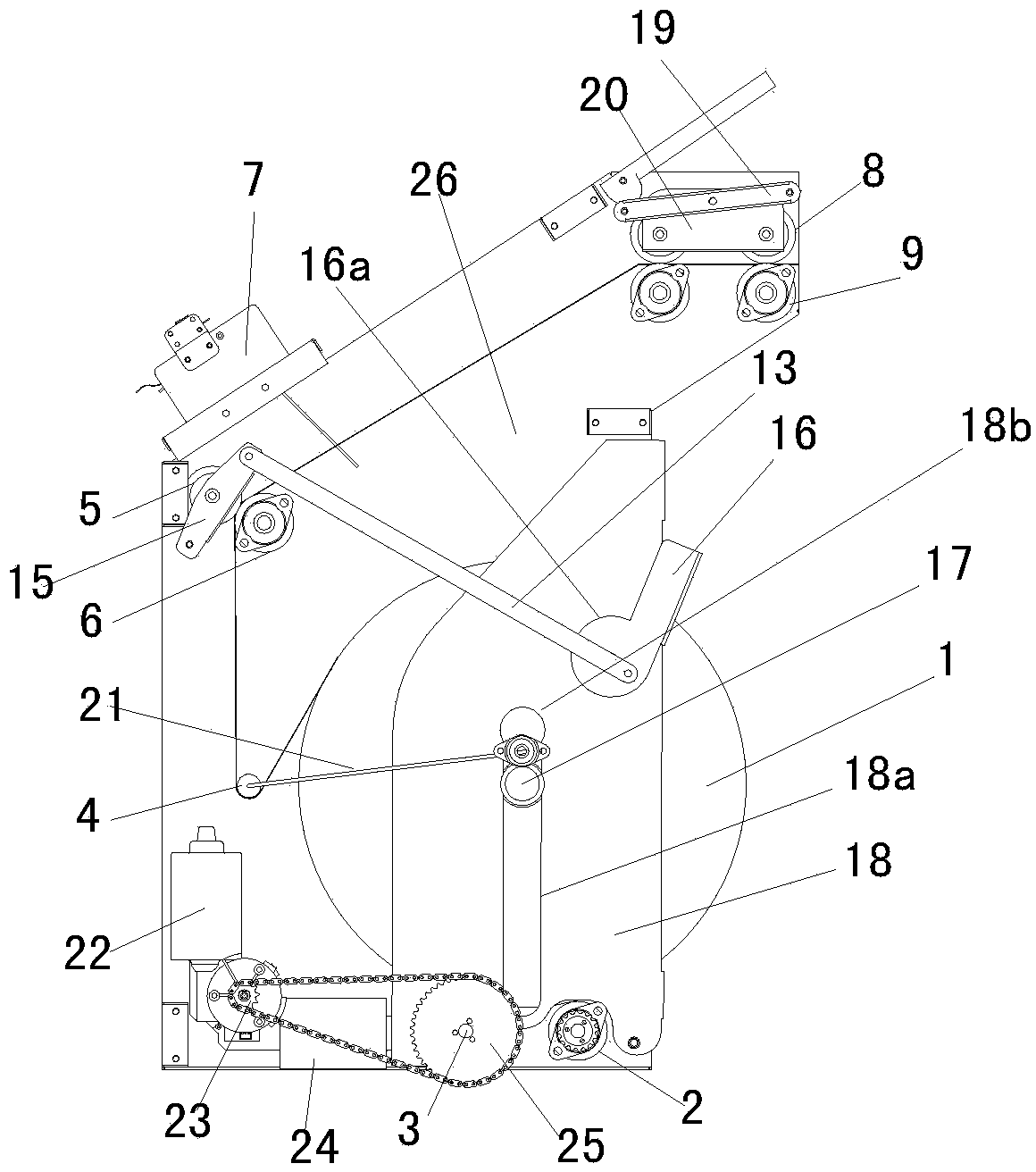

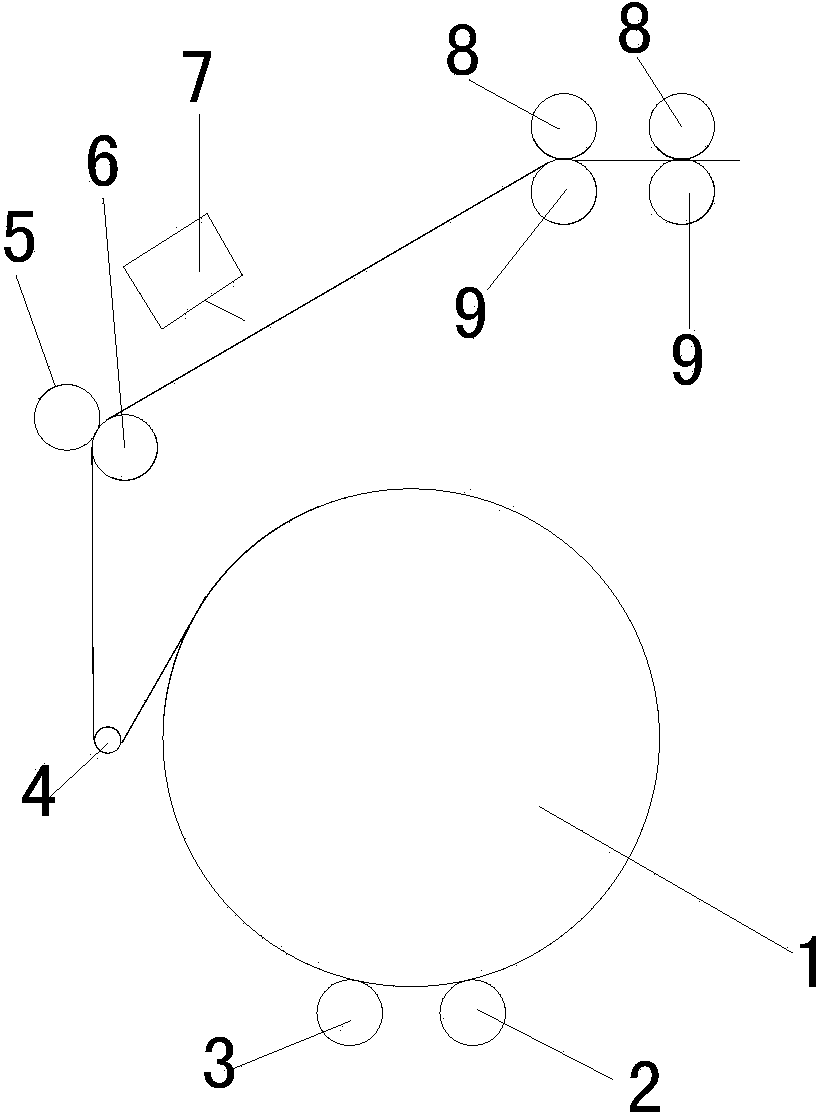

[0019] Embodiment 1: refer to Figure 1~5 . A bag discharging mechanism of an automatic plastic bag vending machine, comprising a frame 10, an active bag feeding roller 3, a driven bag feeding roller 2, and a reel 17 for taking plastic bag rolls 1. The base 18 is provided with vertical guide grooves 18a respectively, the two ends of the reel 17 are connected in the vertical guide grooves 18a, and the two sides below the reel 17 are provided with active bag feeding rollers 3 driven by motors. And the driven bag-feeding roller 2 that is positioned at one side of the active bag-feeding roller 3, and the axial ends of the active bag-feeding roller 3 and the driven bag-feeding roller 2 are respectively connected to the base 18 through bearing seats, and the bases 18 on both sides There are brackets 26 respectively on the top, and at least one group of lead-out rollers is arranged between the tops of the two sides of the brackets 26. The lead-out rollers are composed of two driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com