Device for evenly winding spinning yarn

A kind of winding and uniform technology, applied in spinning machines, textiles and papermaking, continuous winding spinning machines, etc. Winding quality and other issues, to avoid winding knots, uniform winding, and improve winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

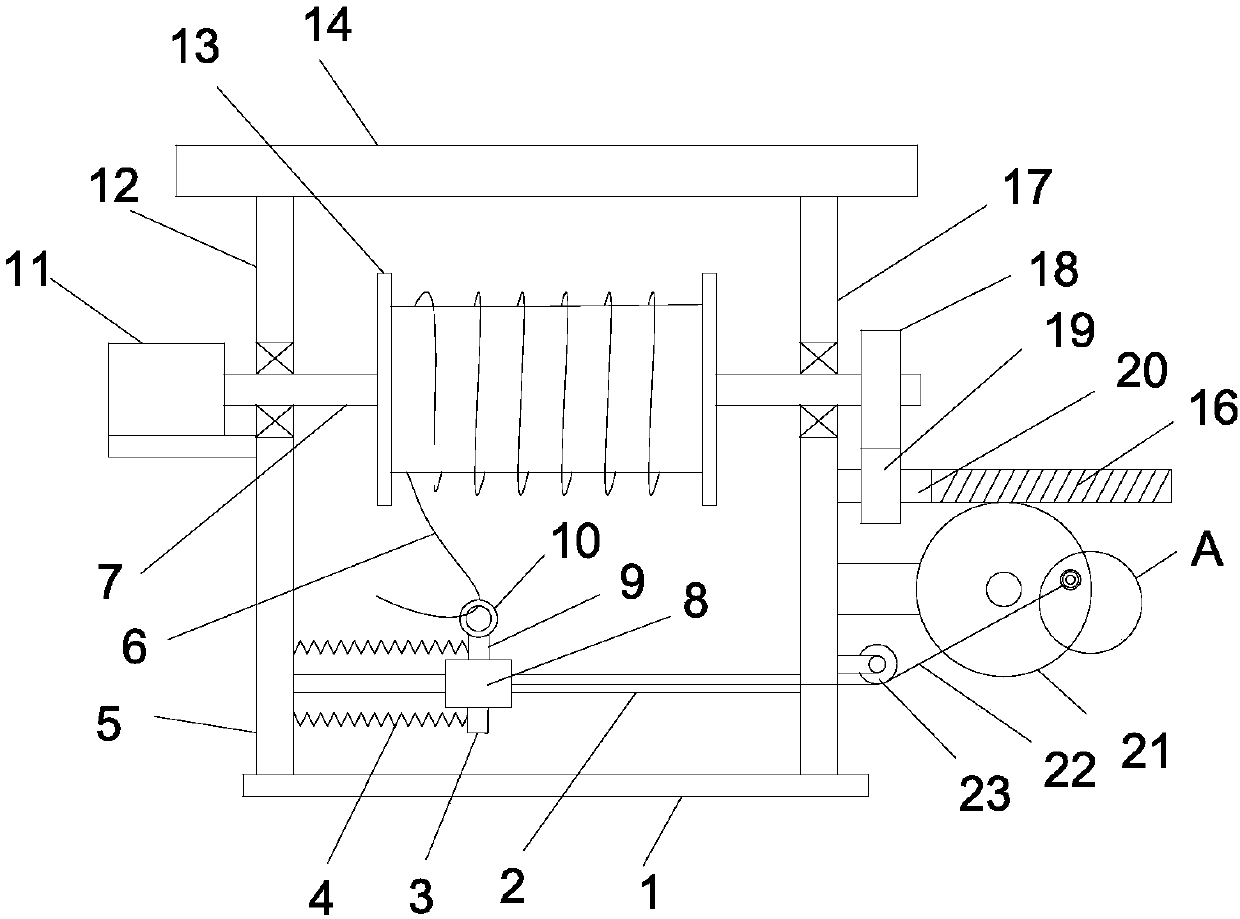

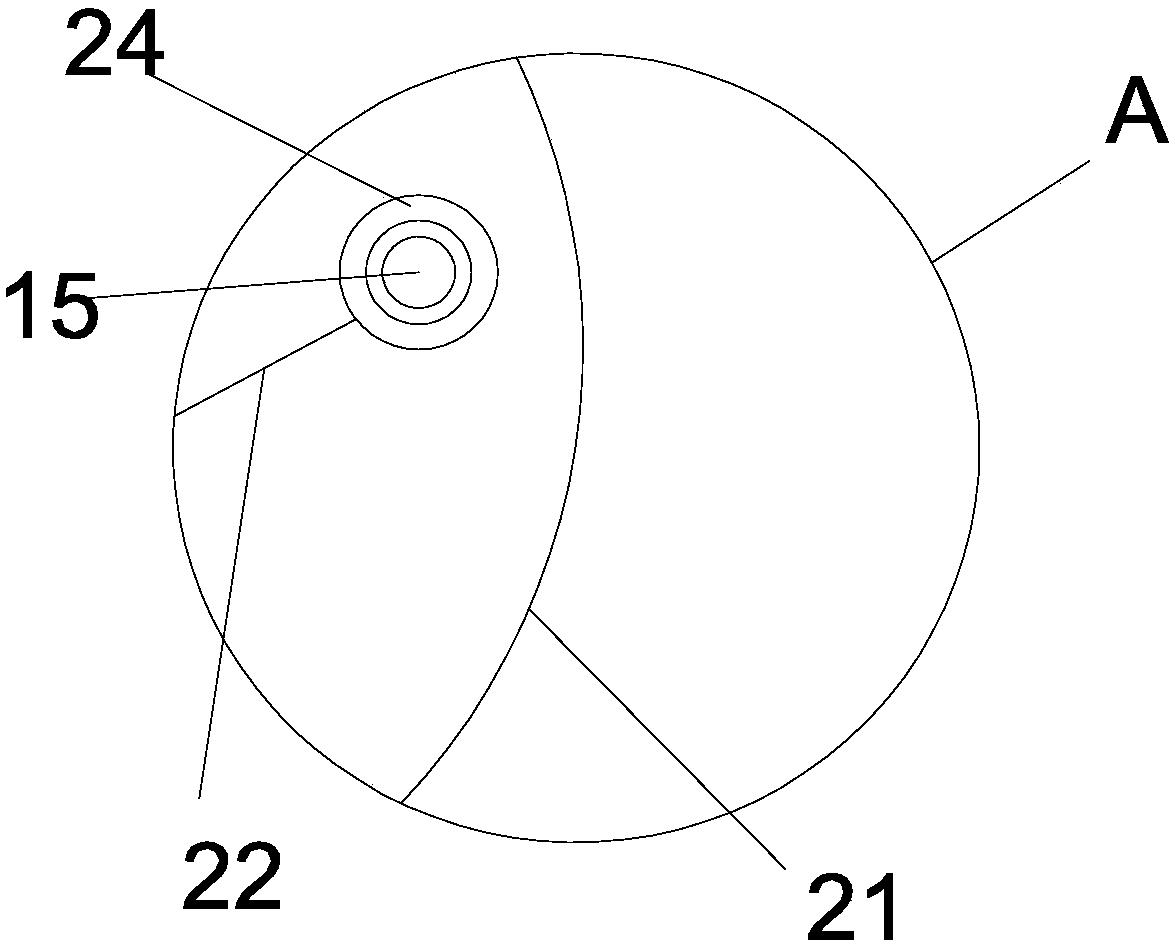

[0018] see Figure 1-2 , a kind of spun yarn uniform winding device, comprising a base plate 1, a left vertical plate 12 and a right vertical plate 17 are vertically and fixedly installed on the bottom plate 1, and a top plate 14 is vertically and fixedly installed on the left vertical plate 12 and the right vertical plate 17, The left side of the left vertical plate 12 is provided with a drive motor 11, and the output shaft of the drive motor 11 is coaxially fixedly equipped with a drive shaft 7, and the drive shaft 7 horizontally rotates to the right and runs through the left vertical plate 12 and the right vertical plate 17. The drive shaft 7 is sleeved and fixedly installed with a winding roller 13, and the winding roller 13 is wound with a spinning thread 6; the right end of the drive shaft 7 is coaxially fixed with a driving gear 18, and the right v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com