Rapid winding device for nylon yarns

A technology of winding device and nylon yarn, which is applied in the field of nylon yarn winding device and textile equipment, which can solve the problems of less nylon filaments, increased difficulty of nylon filaments, uneven center distribution, etc., and achieve fast winding speed , Improve efficiency, even winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

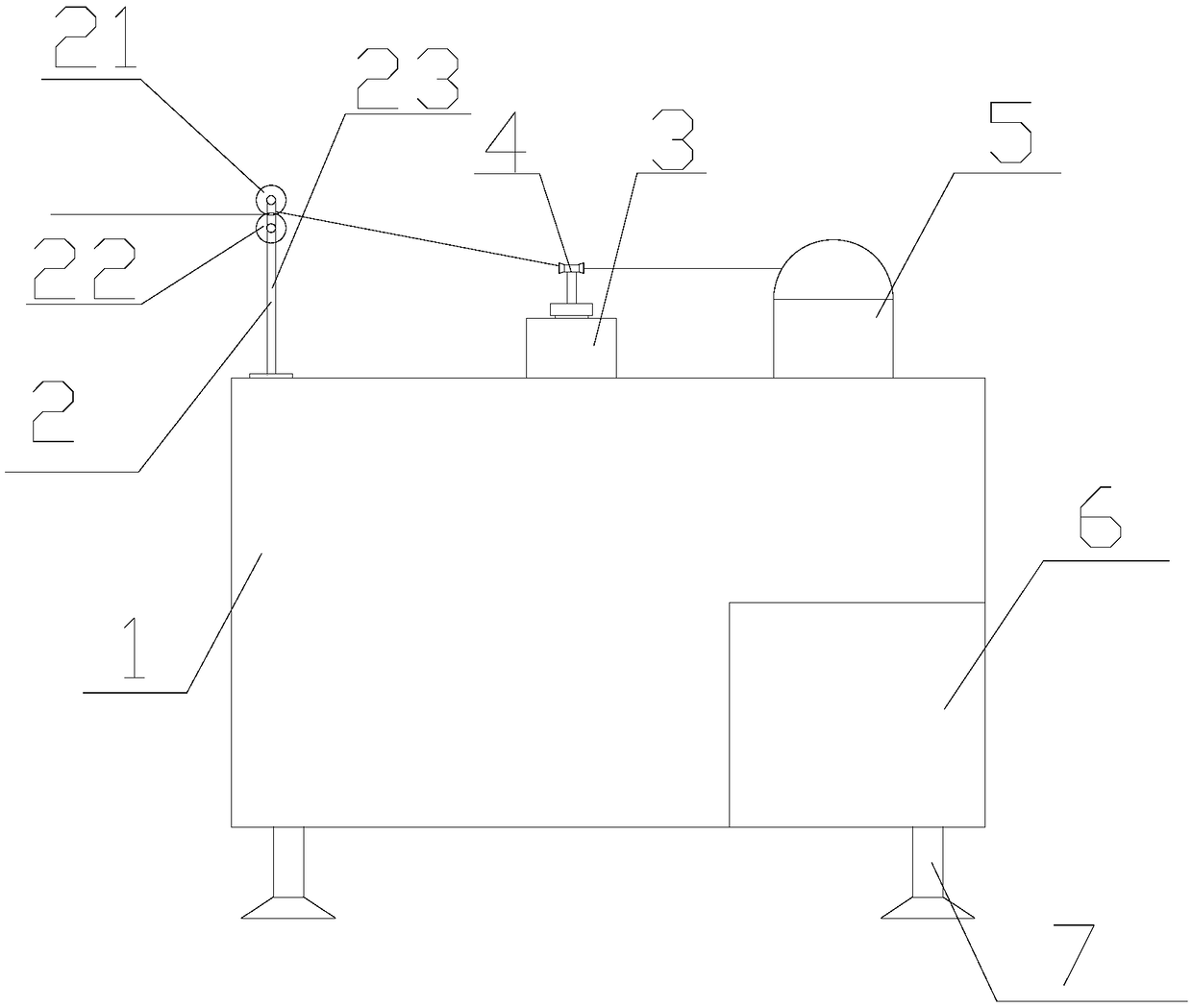

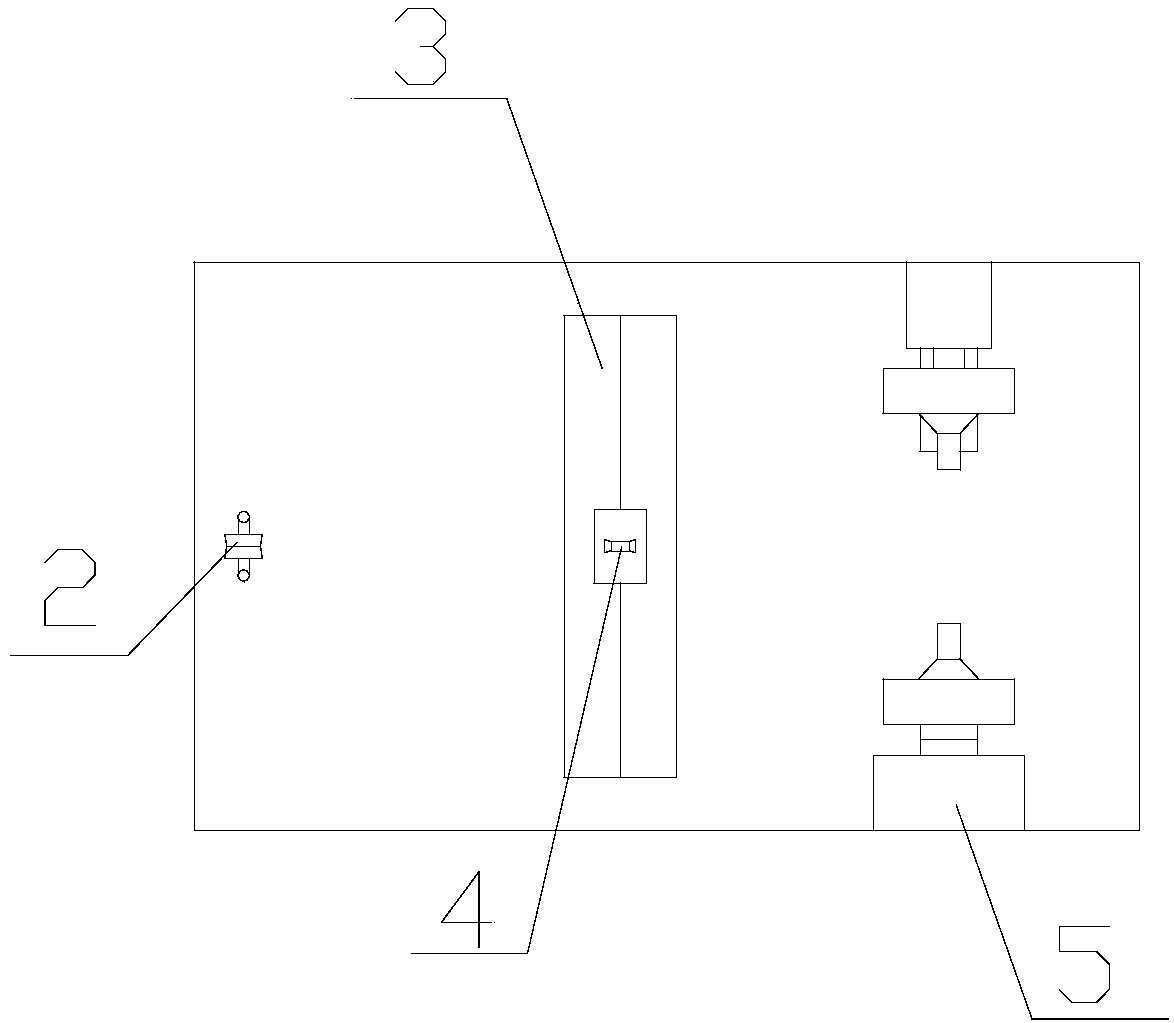

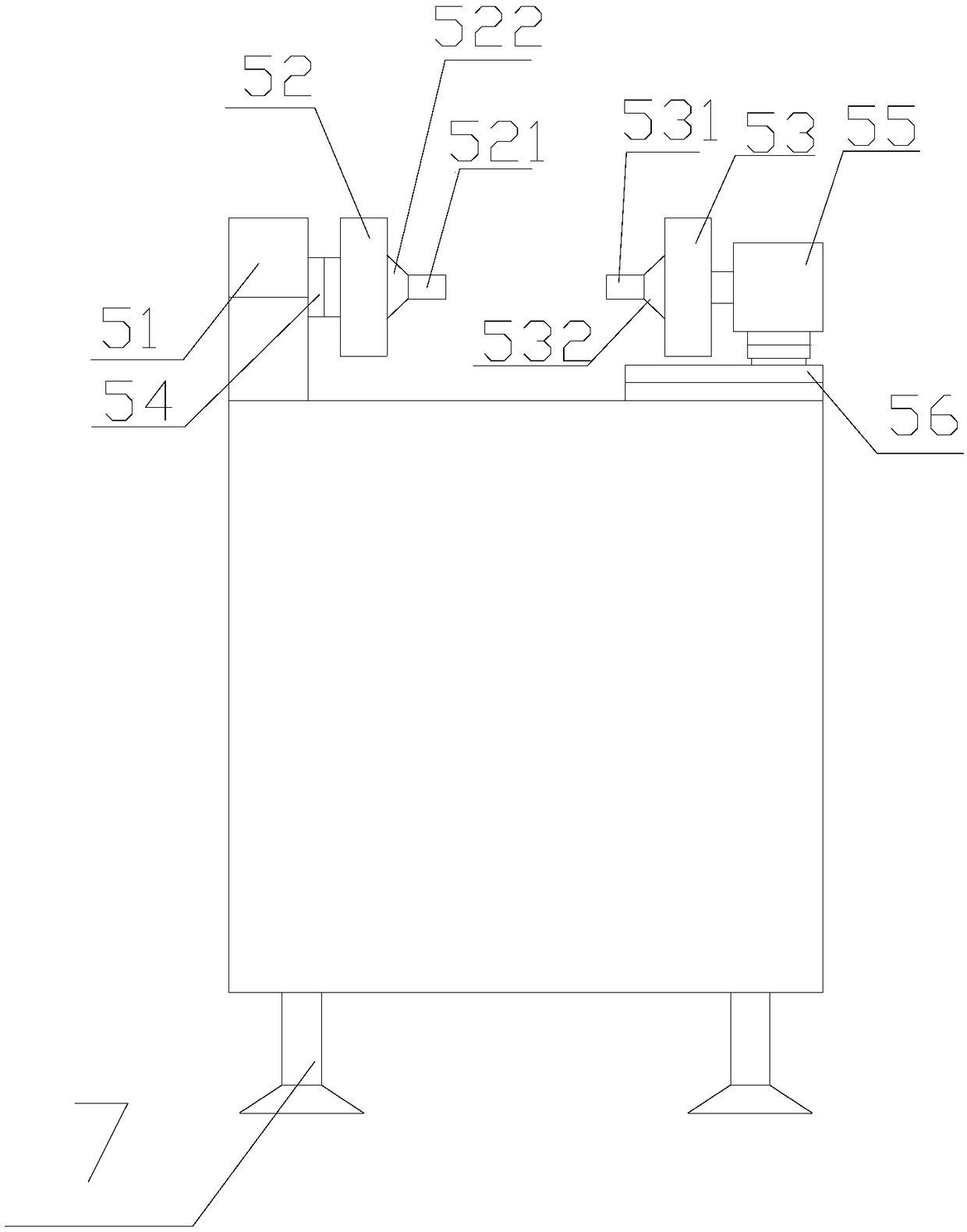

[0016] refer to figure 1 , figure 2 ,and image 3 , a nylon silk fast winding device of the present invention, comprising a frame base 1, a wire passing wheel set 2, a first electric cylinder 3, a wire passing nozzle 4, a silk winding device 5, and a control electric box 6. The machine The frame base 1 is provided with a control electric box 6, and the upper left side of the frame base 1 is provided with a wire passing wheel group 2, and the wire passing wheel group 2 is detachably connected with the frame base 1. The upper end of the right side of the frame base 1 is provided with a silk thread winding device 5, and a first electric cylinder 3 is arranged between the silk thread winding device 5 and the wire passing wheel group 2, and the first electric cylinder 3 and the frame base 1 fixed connection, the sliding part of the first electric cylinder 3 is provided with a wire nozzle 4, the first electric cylinder 3 is electrically connected to the control electric box 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com