Frame-type single-stranding machine and working method thereof

A single stranding machine and frame type technology, applied in the field of frame type single stranding machine, can solve the problems of complicated programming control, limited torque control range of servo motor, and inability to control the winding speed in real time, etc. Effects precisely matched to winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

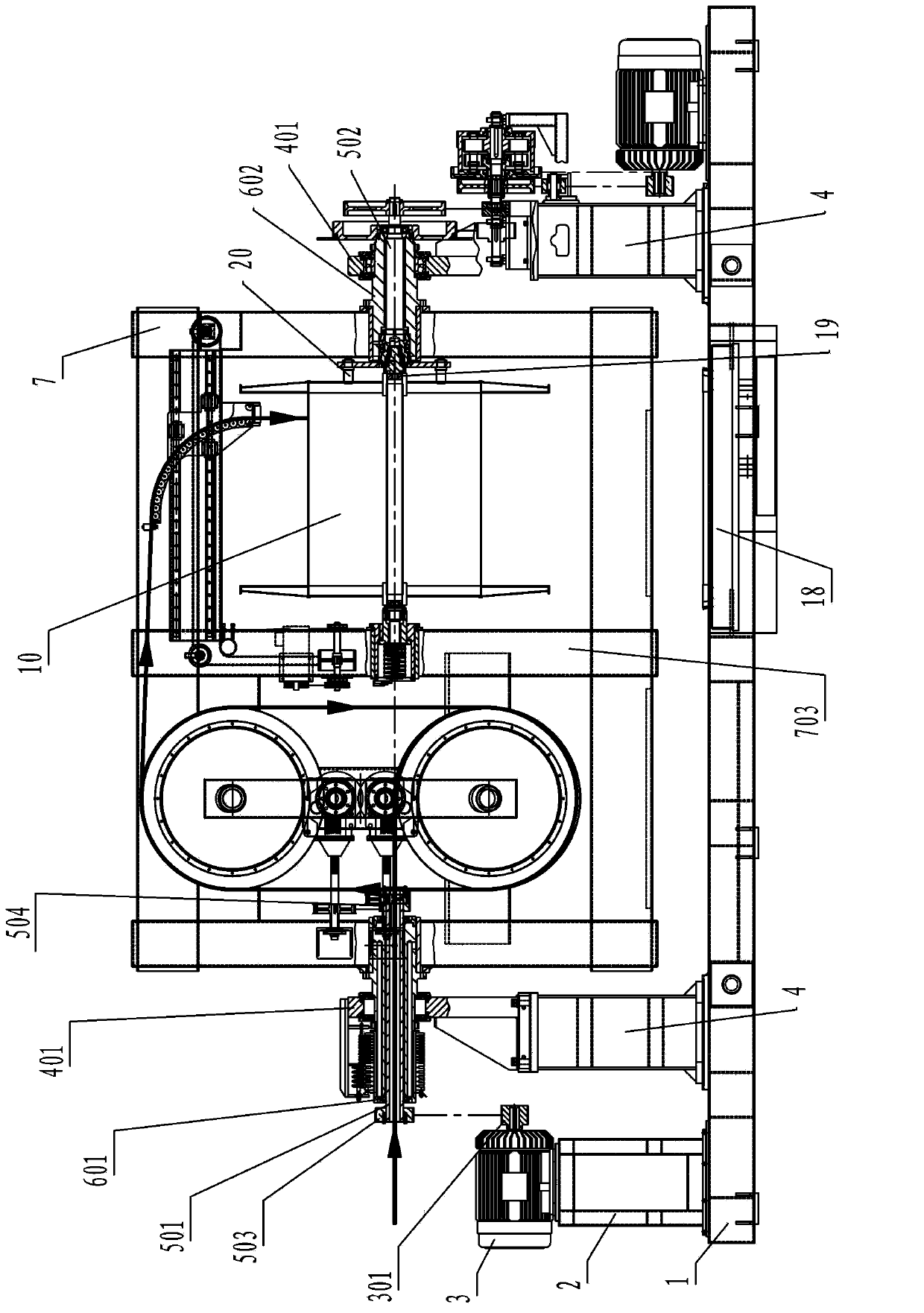

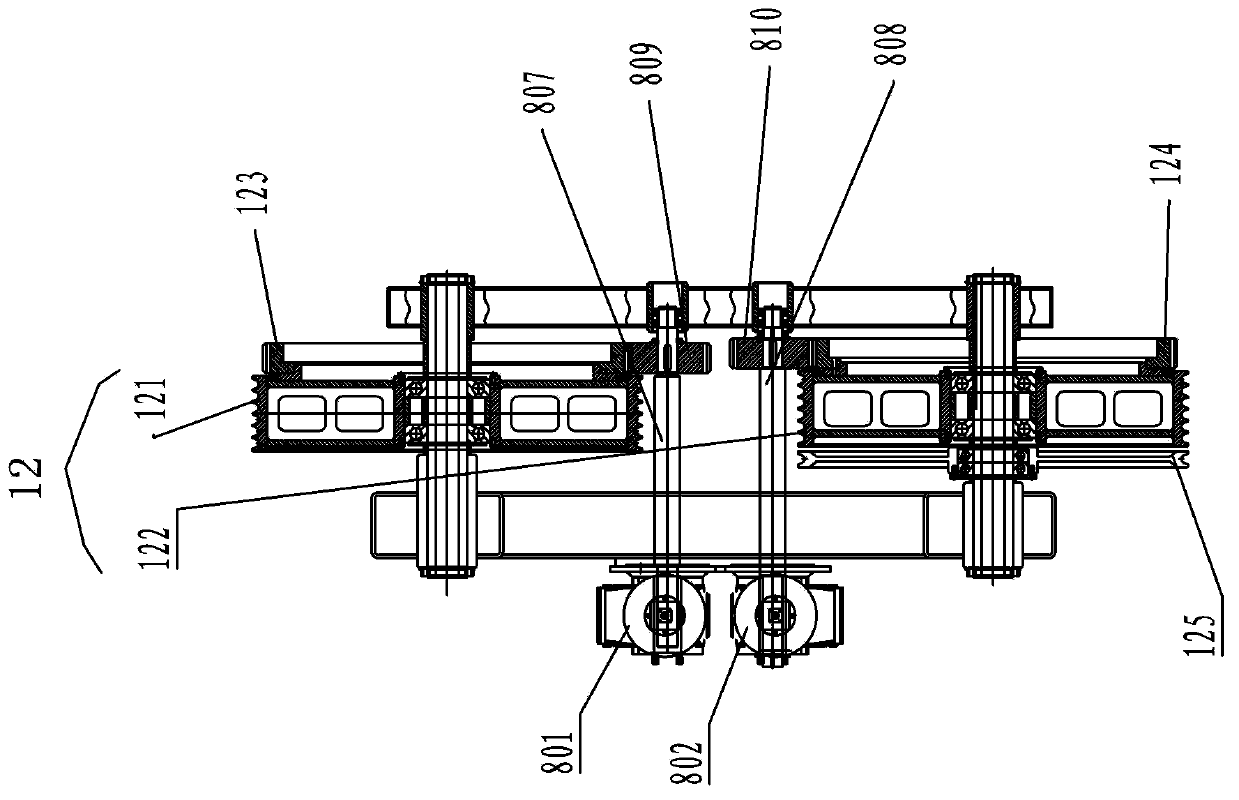

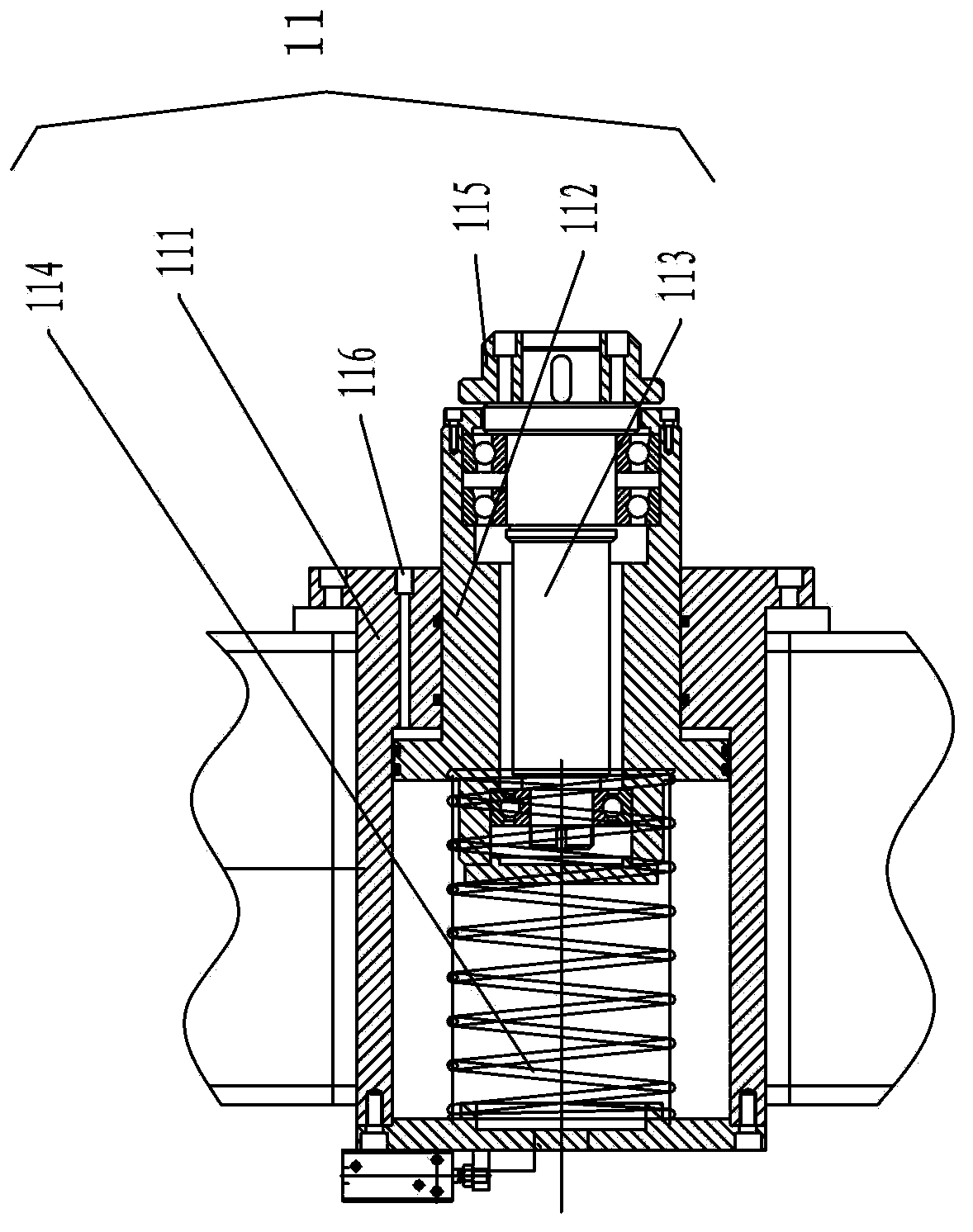

[0030] like figure 1 As shown, the single twisting machine of the present invention includes: base 1, support one 2, motor one 3, support two 4, left inner shaft 501, right inner shaft 502, left outer shaft 601, right outer shaft 602, frame 7, turbine Reducer 8, cable arrangement mechanism 9, wire reel 10, top cone mechanism 11, lead wheel 12, motor 2 13, motor 3 14, traction pulley 15, differential mechanism 16, power distribution mechanism 17, hydraulic lift 18 .

[0031] Described base 1 left end is provided with support one 2, and support is provided with motor one 3, and base middle part is provided with a pair of support two 4, and this support two 4 is provided with a pair of bearing seat one 401; The outer shaft 601 is fixedly connected, and its right end is fixedly connected with the hollow right outer shaft 602; the left outer shaft 601 and the right outer shaft 602 are respectively rotated and fitted on the pair of bearing seats 401 through bearings, and the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com