Winding device for transformer core

A transformer core and winding technology, applied in the field of transformers, can solve problems such as uneven distribution of copper wires, inability to fix the iron core, and easy quality problems of the iron core, and achieve simple and convenient operation, improved production quality, and simple and convenient clamping hold a fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

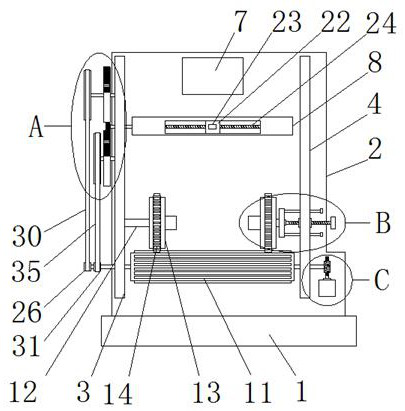

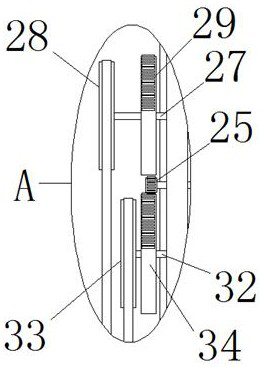

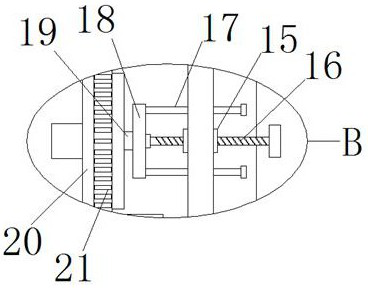

[0027] refer to Figure 1-5 , a winding device for a transformer core, including a base 1, the top of the base 1 is fixedly connected with a riser 2 by welding, and the riser 2 is fixedly connected with a left side plate 3 and a right side plate 4 through welding, and the left side plate 3 The same winding mechanism is set on the right side plate 4, the motor 5 is fixedly installed on the vertical plate 2 by bolts, the output shaft of the motor 5 is welded with a worm 6, the worm 6 cooperates with the winding mechanism, and the left side plate 3 The top is provided with a rotation limiting mechanism, and the right side plate 4 is provided with a rotation extrusion mechanism, the rotation limitation mechanism and the rotation extrusion mechanism cooperate with the winding mechanism, and the vertical plate 2 is fixedly connected with a placement box 7 and a horizontal The plate 8 and the horizontal plate 8 are provided with a reciprocating positioning mechanism, and the reciproc...

Embodiment 2

[0037] The difference from Embodiment 1 is that it includes a base 1, a riser 2 is fixedly connected to the top of the base 1, a left side board 3 and a right side board 4 are fixedly connected to the riser 2, and the left side board 3 and the right side board 4 is provided with the same winding mechanism, a motor 5 is fixedly installed on the vertical plate 2, and a small bevel gear is welded on the output shaft of the motor 5, and the small bevel gear cooperates with the winding mechanism, and the left side plate 3 is provided with a rotating Limiting mechanism, the right side plate 4 is provided with a rotating extrusion mechanism, the rotating limiting mechanism and the rotating extrusion mechanism cooperate with the winding mechanism, the vertical plate 2 is fixedly connected with a placement box 7 and a horizontal plate 8, and the horizontal plate 8 A reciprocating positioning mechanism is arranged on the top, and the reciprocating positioning mechanism indirectly coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com