Copper wire winding device with cleaning function

A technology of copper wire and function, applied in the field of copper wire winding device with cleaning function, can solve the problems of time-consuming adjustment, easy adhesion of dust and debris to copper wire, uneven winding of copper wire, etc., to achieve good dust removal effect, improve The effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

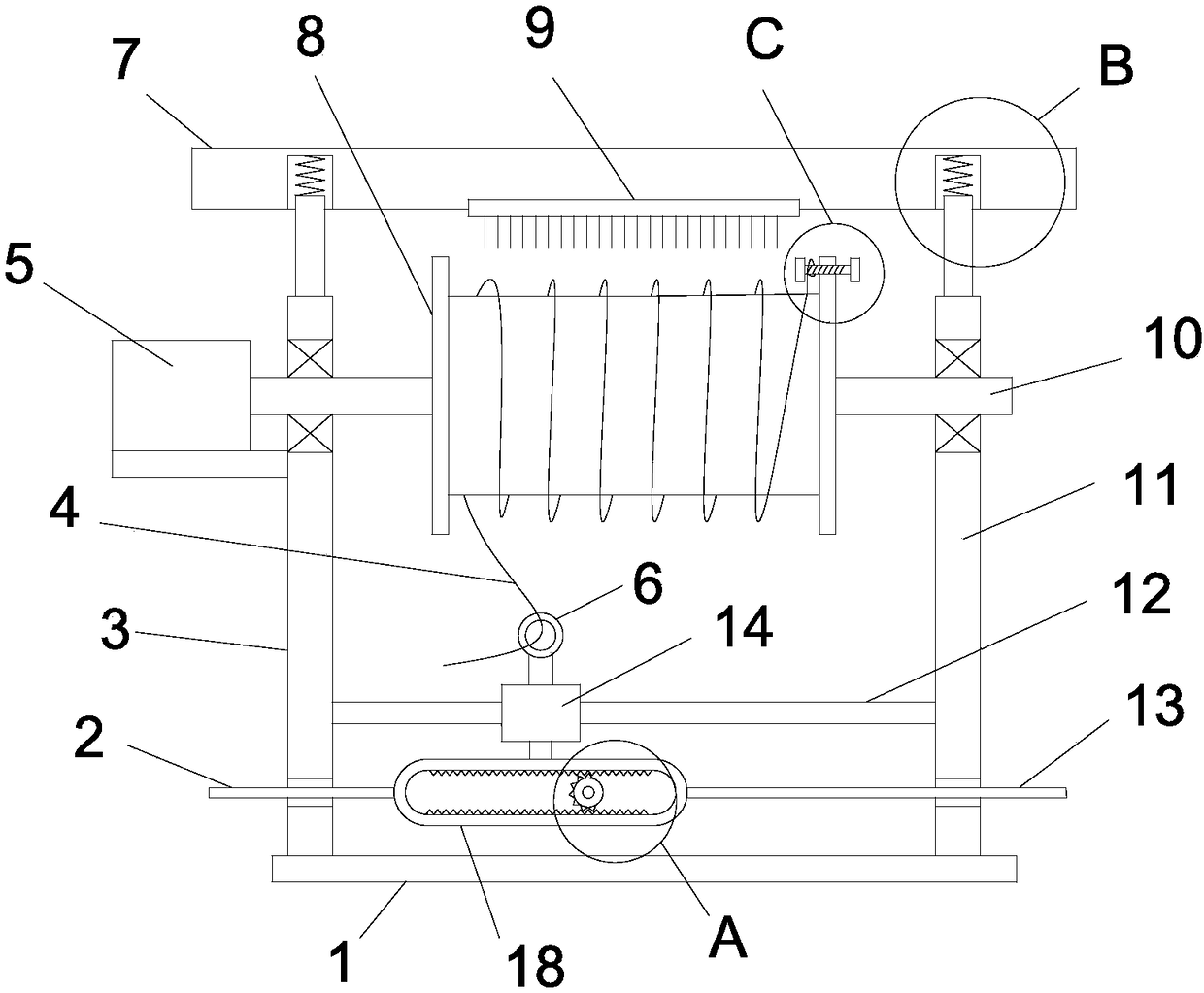

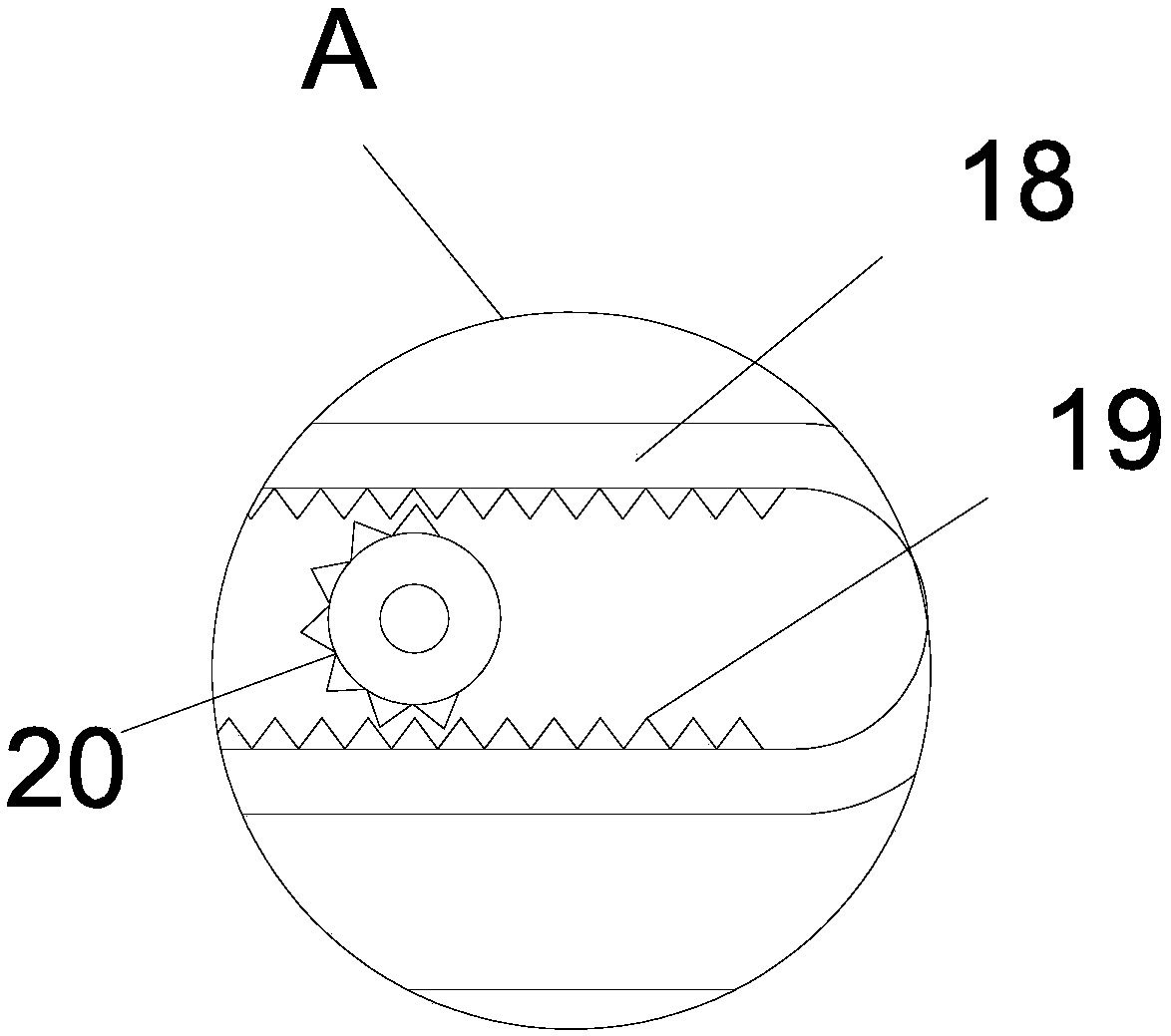

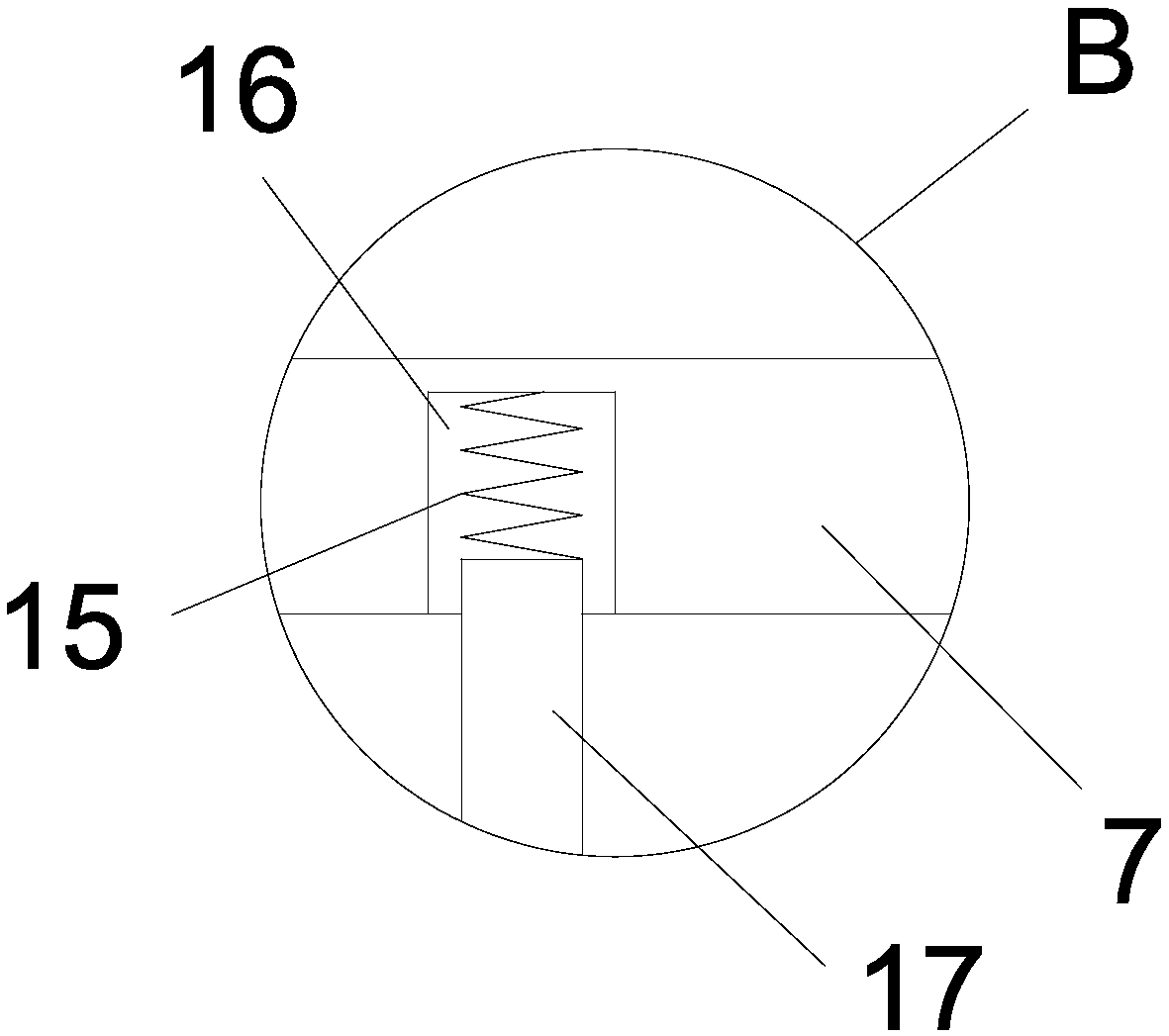

[0021] see Figure 1-4 , a copper wire winding device with a cleaning function, comprising a base plate 1, a left vertical plate 3 and a right vertical plate 11 are vertically fixedly installed on the bottom plate 1, and the upper ends of the left vertical plate 3 and the right vertical plate 11 are vertical A vertical shaft 17 is fixedly installed, and a pressure plate 7 is horizontally provided above the left vertical plate 3 and the right vertical plate 11, and the pressure plate 7 is provided with a slide chamber 16 slidingly matched with the vertical shaft 17, and a limit spring 15 is provided in the slide chamber 16; The left side of the vertical plate 3 is provided with a motor 5, and the output shaft of the motor 5 is coaxially fixedly installed with a drive shaft 10 that runs through the left vertical plate 3 and the right vertical plate 11 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com