Wire adjusting mechanism of winding machine for winding fan housing

A technology of adjusting mechanism and winding machine, applied in the field of components for winding machines, can solve the problems of reduced production efficiency, dangerous operator personal safety, complicated processing procedures, etc., to reduce production costs, avoid jumper phenomenon, ensure The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

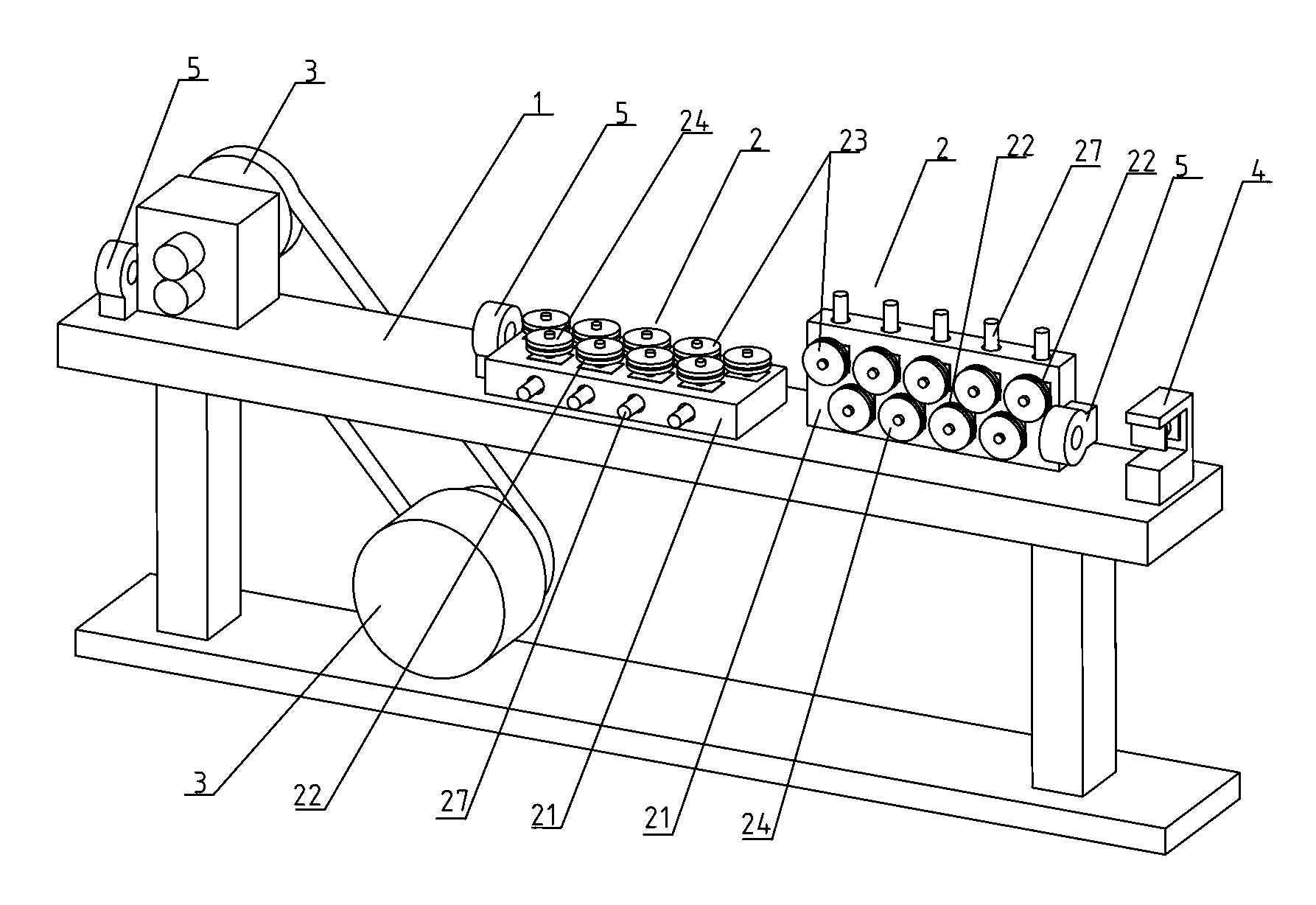

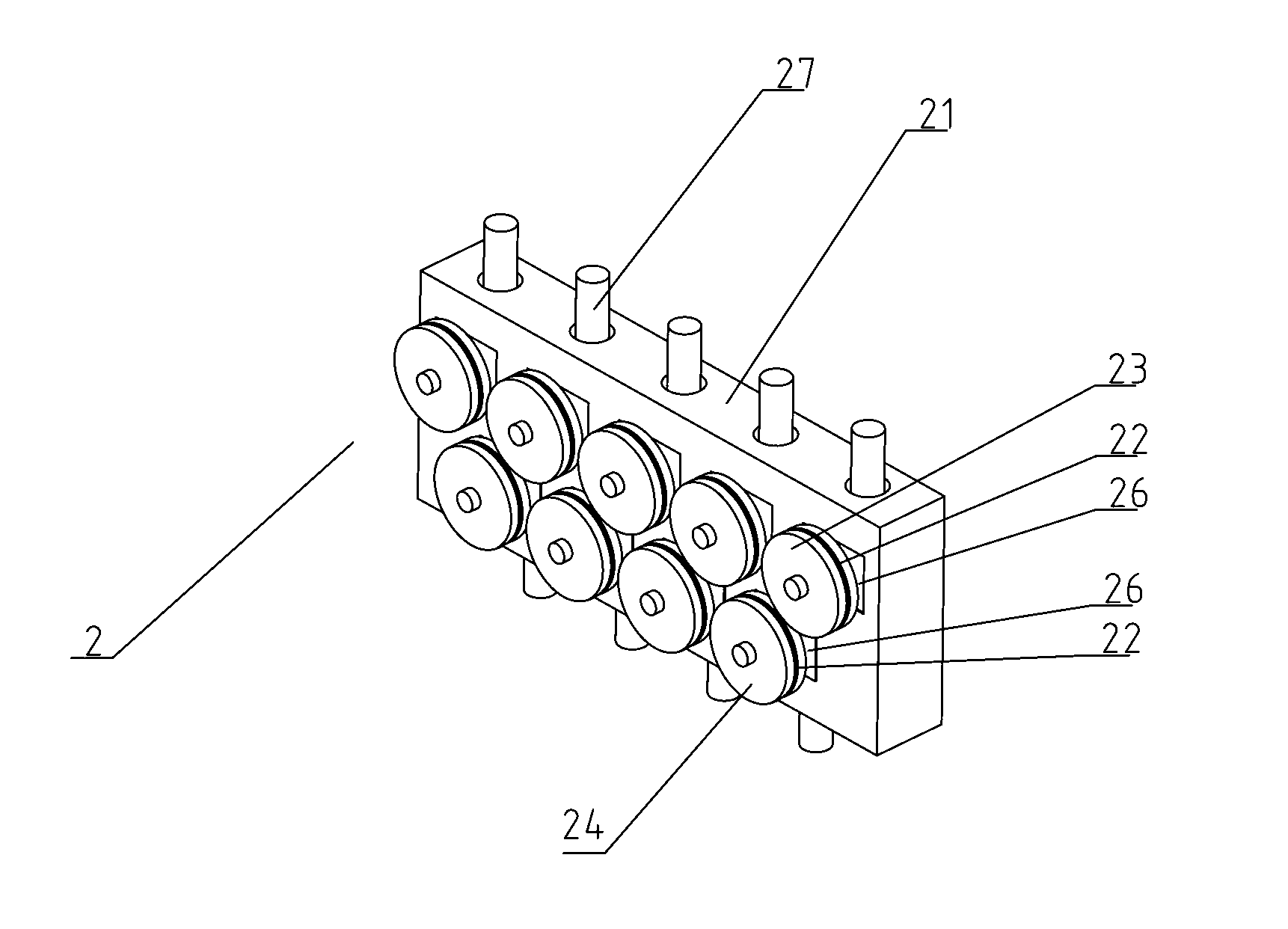

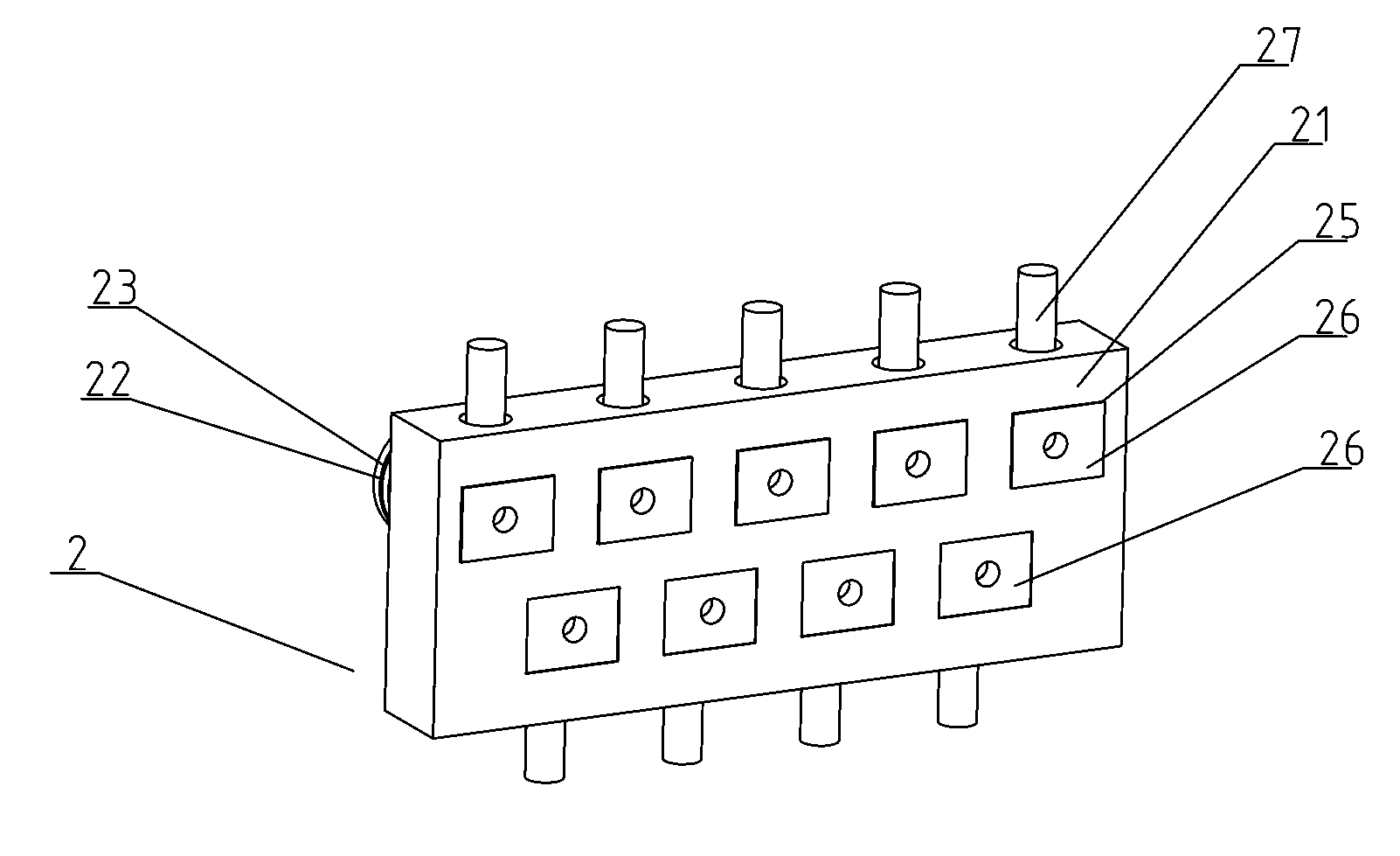

[0028] according to figure 1 As shown, the wire adjustment mechanism of the winding machine used for winding the fan cover according to the present invention includes a frame 1 on which a power mechanism 3, a feeding sleeve 4 and a straightening device 2 are arranged. The material sleeve 4 is arranged in front of the straightening device 2 , and the power mechanism 3 is arranged in the rear of the straightening device 2 . And straightening device 2 is arranged between feeding sleeve 4 and power mechanism 3, and the quantity of this straightening device 2 is provided with more than two groups, namely two groups, three groups, four groups or more than four groups. However, more than two sets of straightening devices 2 are arranged on the frame 1 at 15 degrees, 45 degrees, vertically, 60 degrees, 75 degrees or horizontally relative to the horizontal plane of the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com