Efficient winding device for optical fiber gyroscope production

A fiber optic gyroscope and winding device technology, which is applied in measuring devices, instruments, transportation and packaging, etc., can solve problems such as wire damage and affect production efficiency, and achieve the effect of reducing tension and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

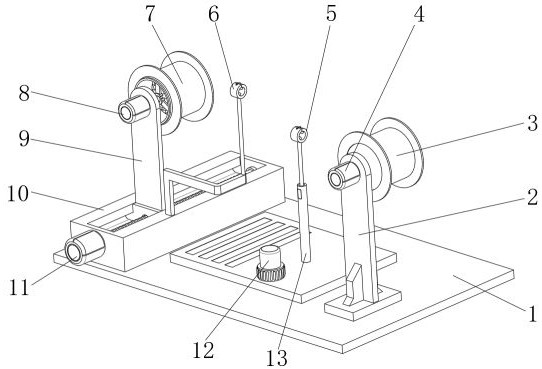

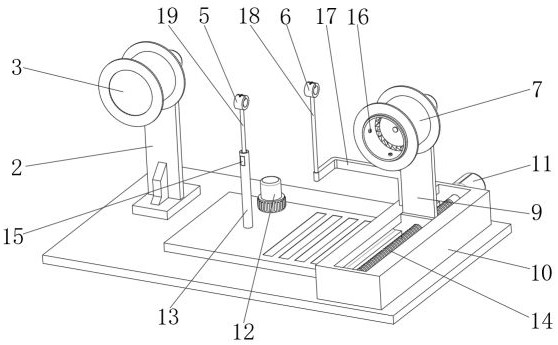

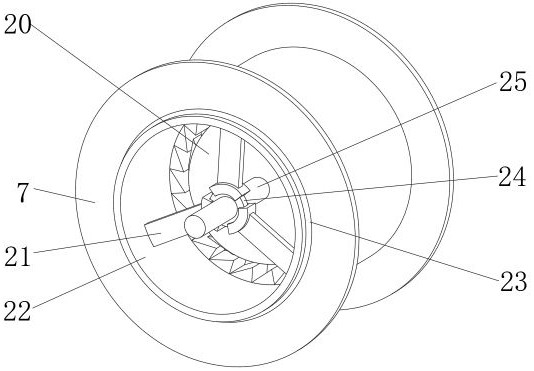

[0033] A high-efficiency winding device for fiber optic gyroscope production, such as Figure 1-6 As shown, it includes a mounting table 1, the outer wall of the top of the mounting table 1 is fixed with a mounting frame 2 by screws, and the outer wall of one side of the mounting frame 2 is fixed with a pay-off motor 4 through screws, and the output end of the pay-off motor 4 is connected to a pay-off motor in rotation. Wheel 3, wire rod is wound on the pay-off wheel 3; the outer wall of the top of the installation table 1 is provided with a translation mechanism, and the movable frame 9 is movably connected in the translation mechanism, and the outer wall of one side of the movable frame 9 is fixed with a winding motor by screws 8. The output end of the winding motor 8 is rotatably connected to a winding main shaft 25, the outer wall of the winding main shaft 25 is integrally provided with a limit ring 24, and the outer wall of the limit ring 24 is slidably connected with two ...

Embodiment 2

[0043] A high-efficiency winding device for fiber optic gyroscope production, such as Figure 4 As shown, in order to improve the reliability of winding; the present embodiment makes the following improvements on the basis of Embodiment 1: the number of the movable teeth 30 is more than three, and the three movable teeth 30 and the meshing teeth 27 are formed over time. Change staggered mesh structure.

[0044] This embodiment has been proved by many tests, because the movable teeth 30 with a staggered meshing structure are provided, the dislocation rotation between the rotating cylinder 22 and the mounting plate 20 can be made more gentle, so that the tightness of the wire winding process is more even, Thereby improving product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com