Yarn bobbin device for textile machinery

A technology for textile machinery and bobbins, which is applied in the field of bobbin devices for textile machinery, which can solve the problems that the yarn cannot be rotated and wound evenly back and forth, and achieve the effect of convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

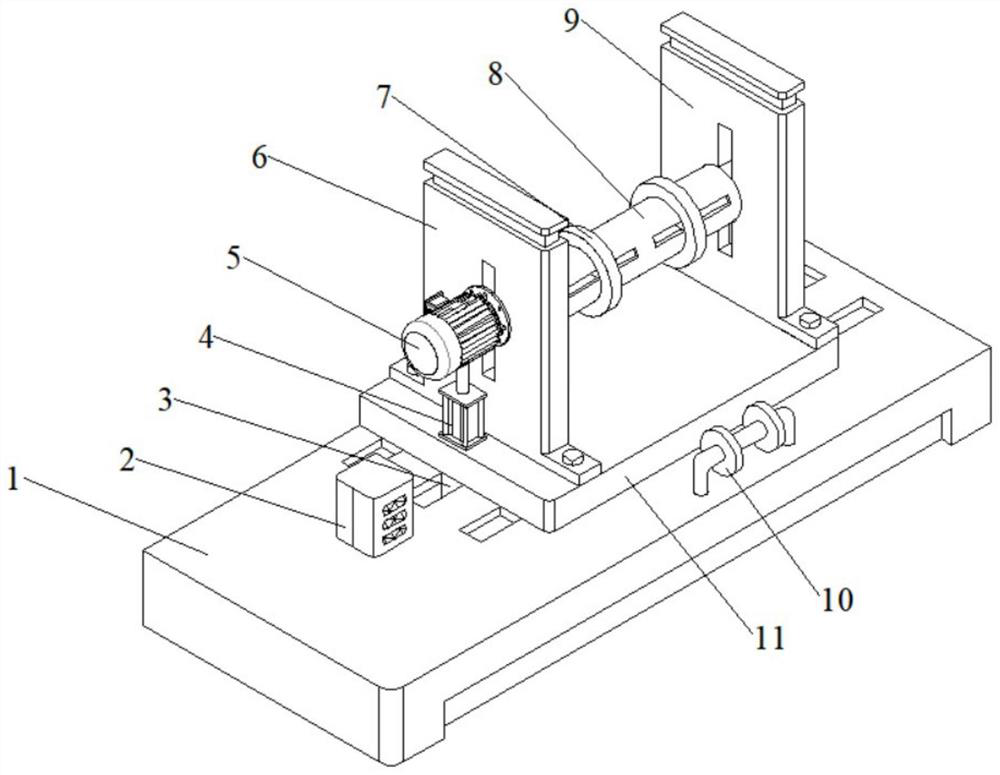

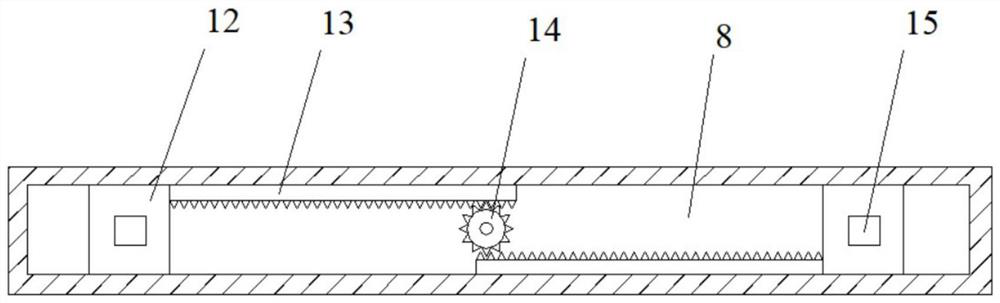

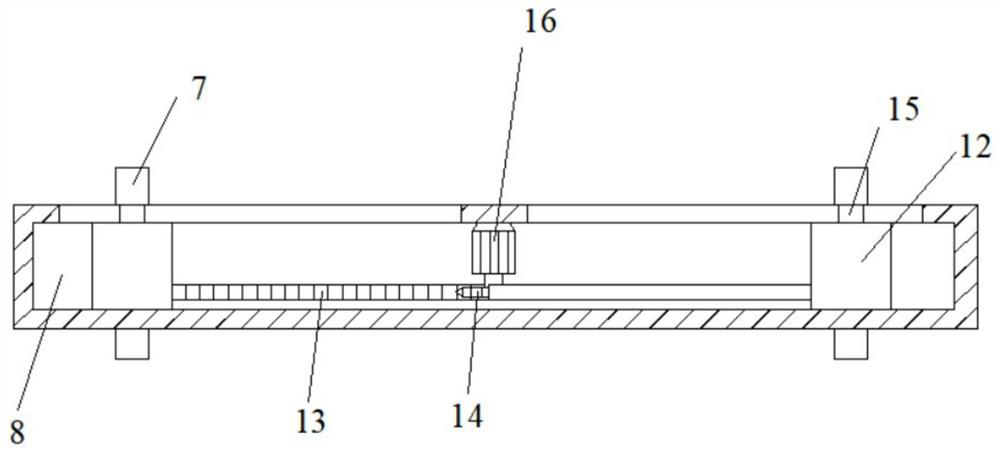

[0027] Attached below Figure 1-5 The present invention is further described with embodiment:

[0028] A yarn bobbin device for textile machinery, comprising a base 1 and a workbench 11, a first vertical board 6 and a second vertical board 9 are installed vertically on both sides of the top of the workbench 11, and the first vertical board 6 and the second vertical board The horizontal rotation between the plates 9 is connected with the yarn bobbin 8, the side of the first vertical plate 6 is provided with a drive mechanism to drive the yarn bobbin 8 to rotate and lift, and the inside of the second vertical plate 9 is provided with a supporting structure for supporting the yarn bobbin 8. Both ends of the tube 8 are sleeved with limit discs 7, and the interior of the yarn tube 8 is provided with a moving mechanism that drives the movement of the two limit discs 7. Both sides of the bottom of the workbench 11 are welded with moving columns 3 vertically, and the two moving column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com