Patents

Literature

41results about How to "Guaranteed horizontal position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

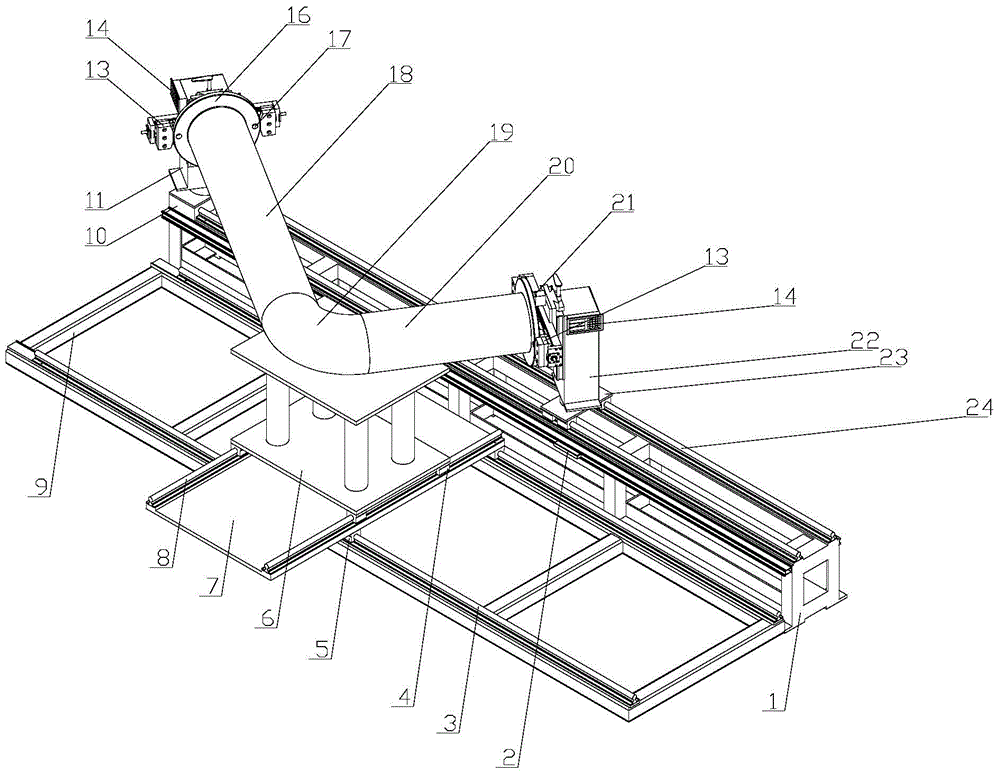

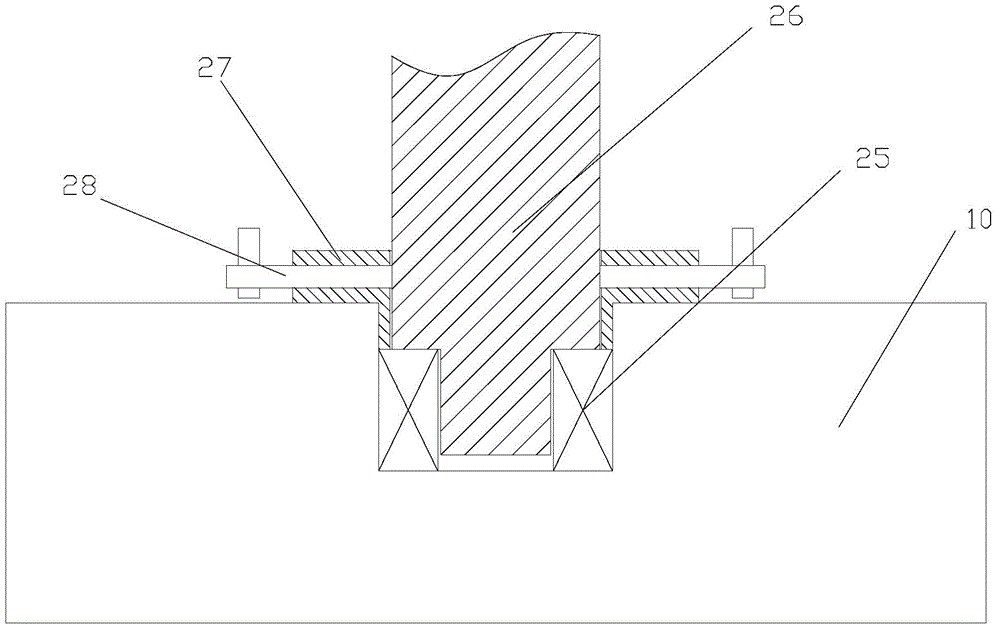

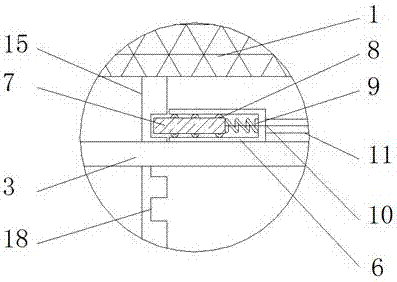

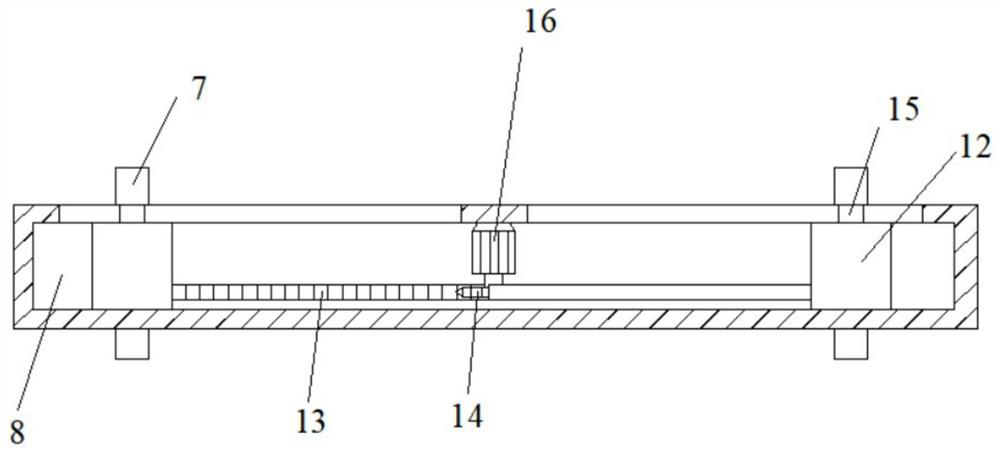

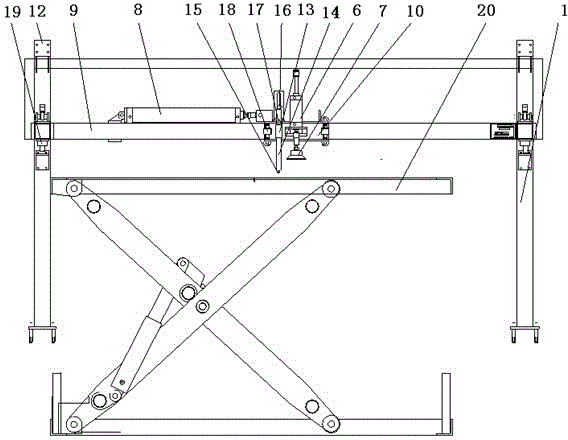

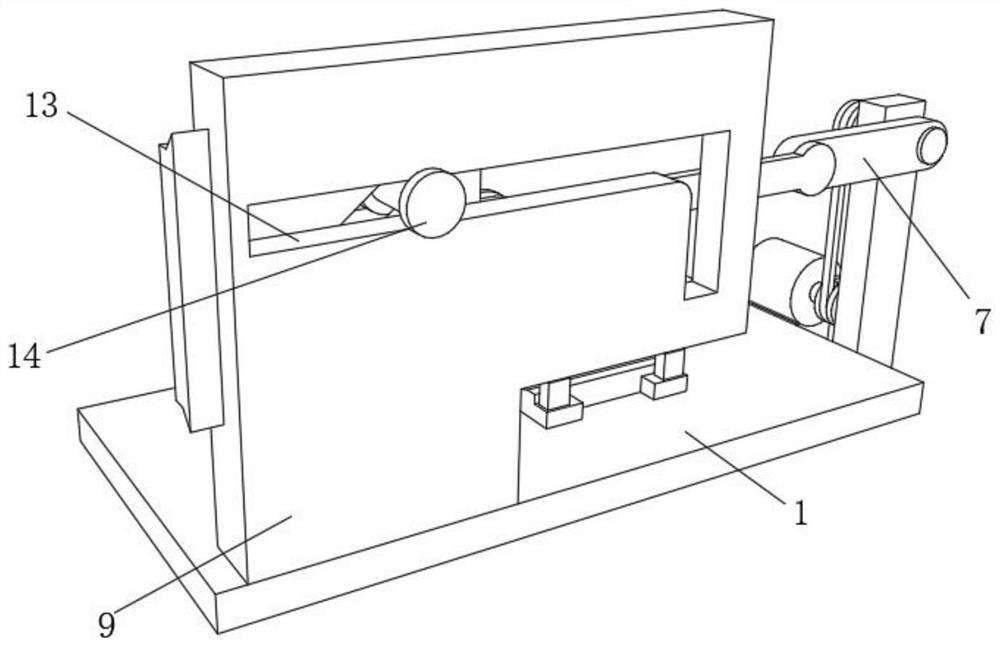

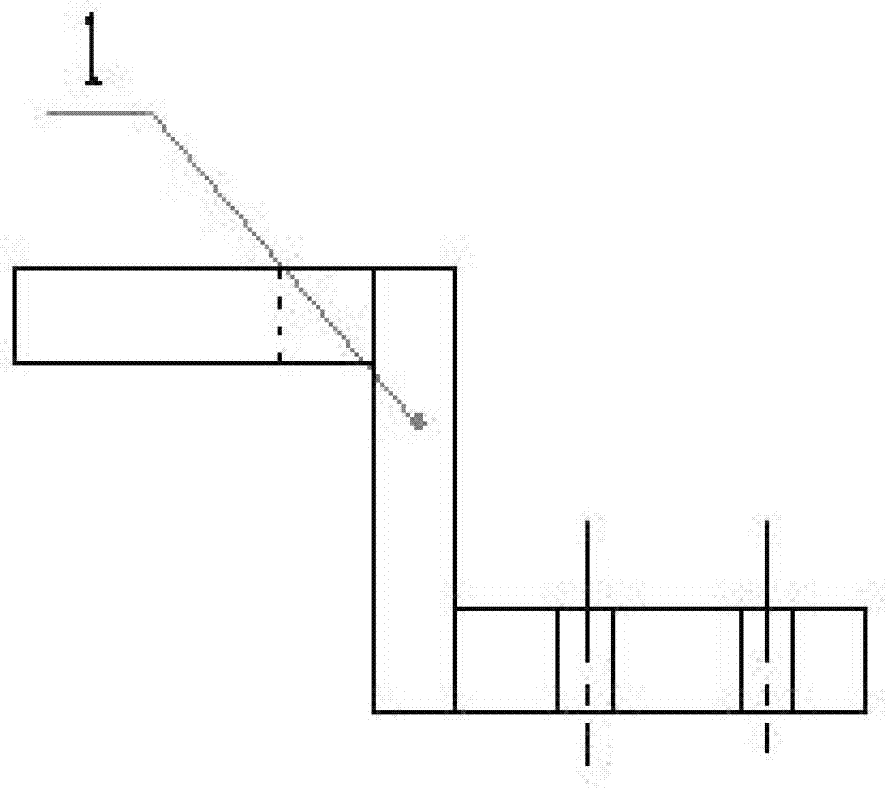

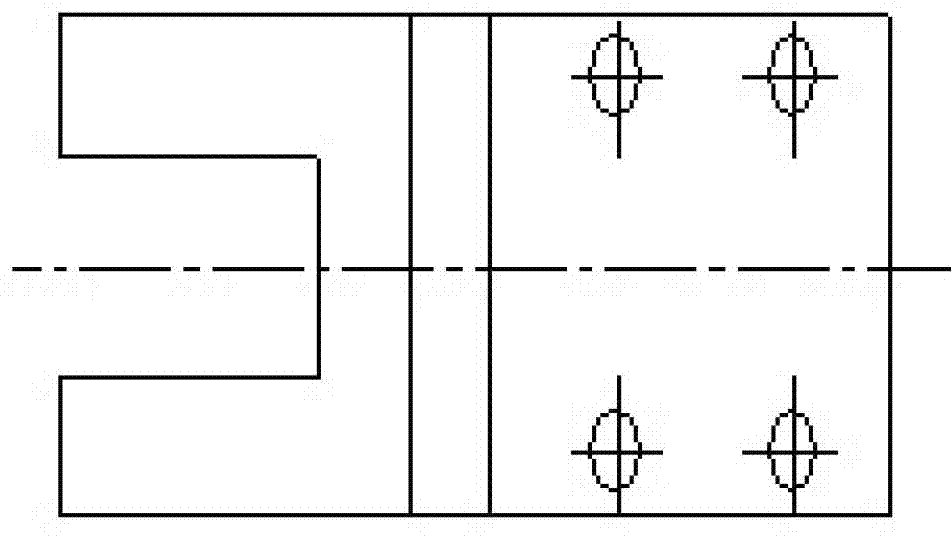

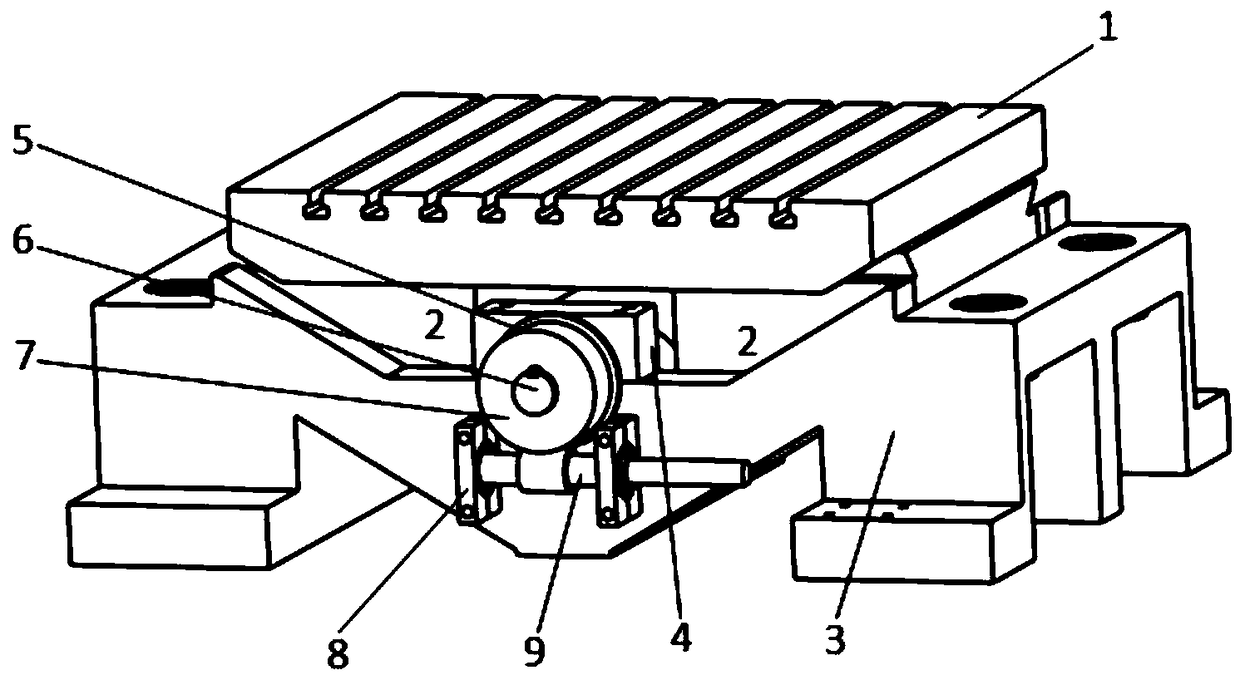

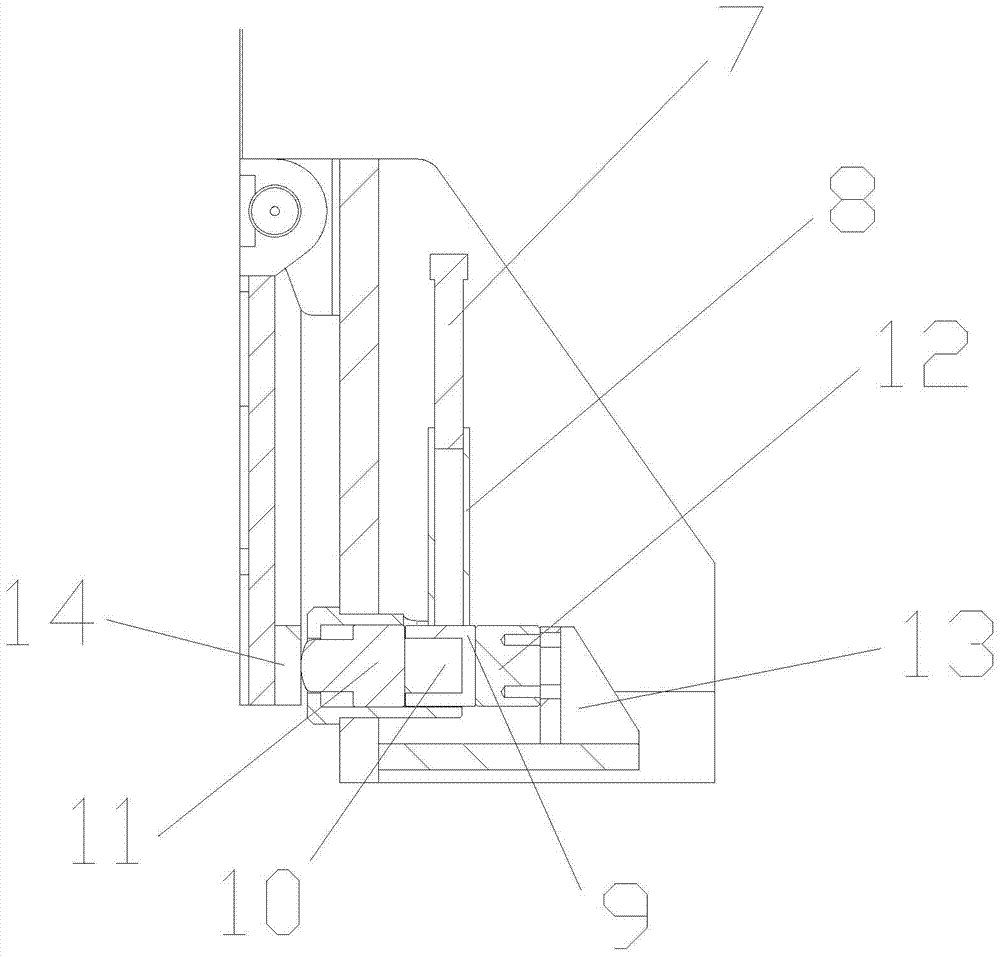

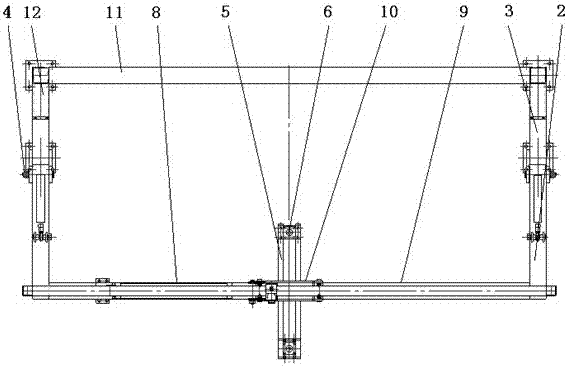

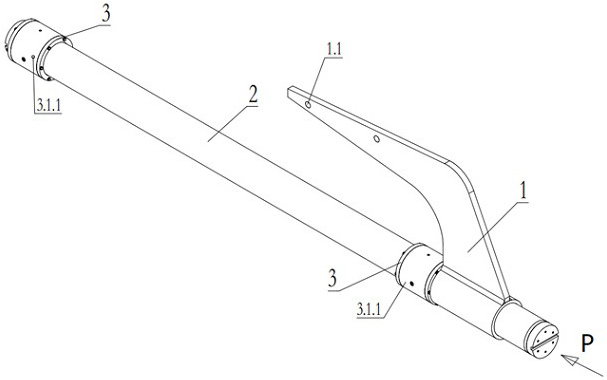

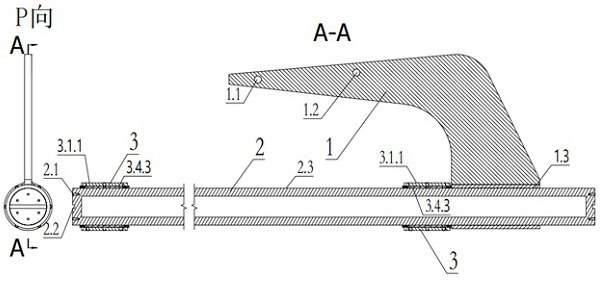

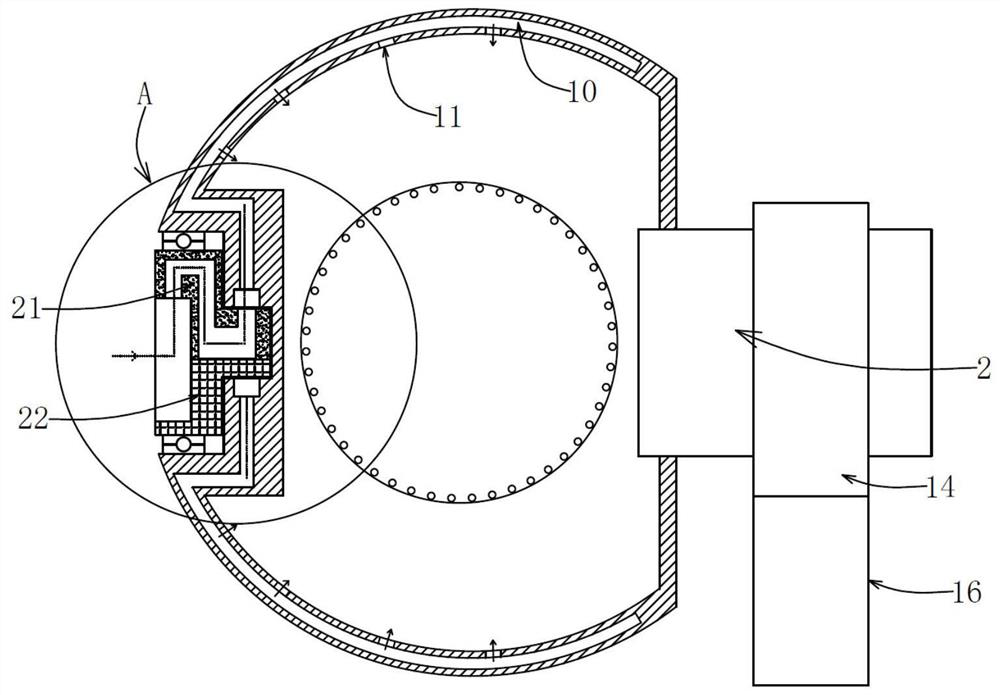

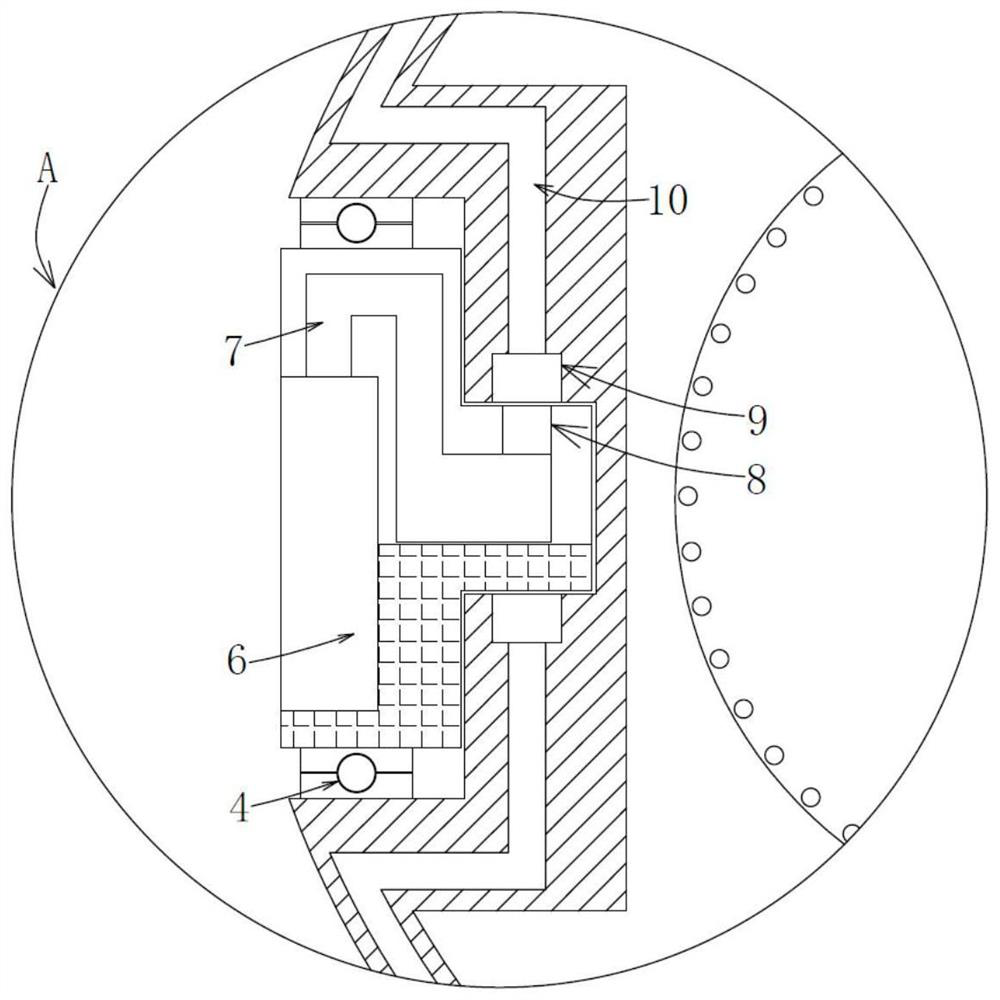

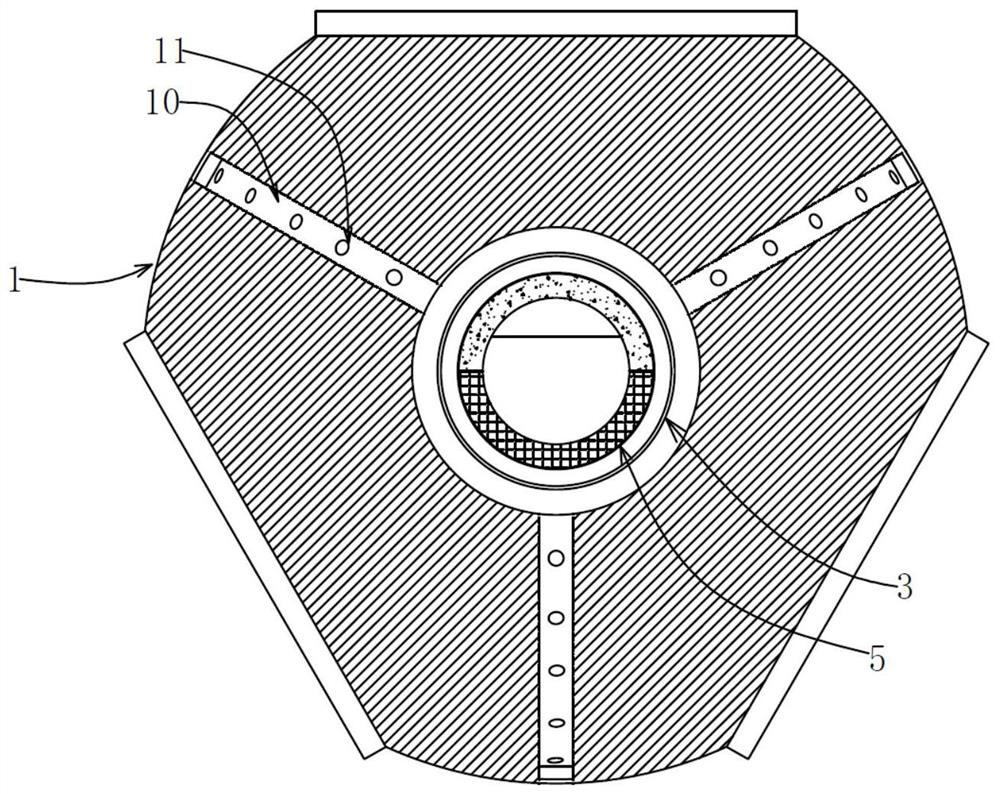

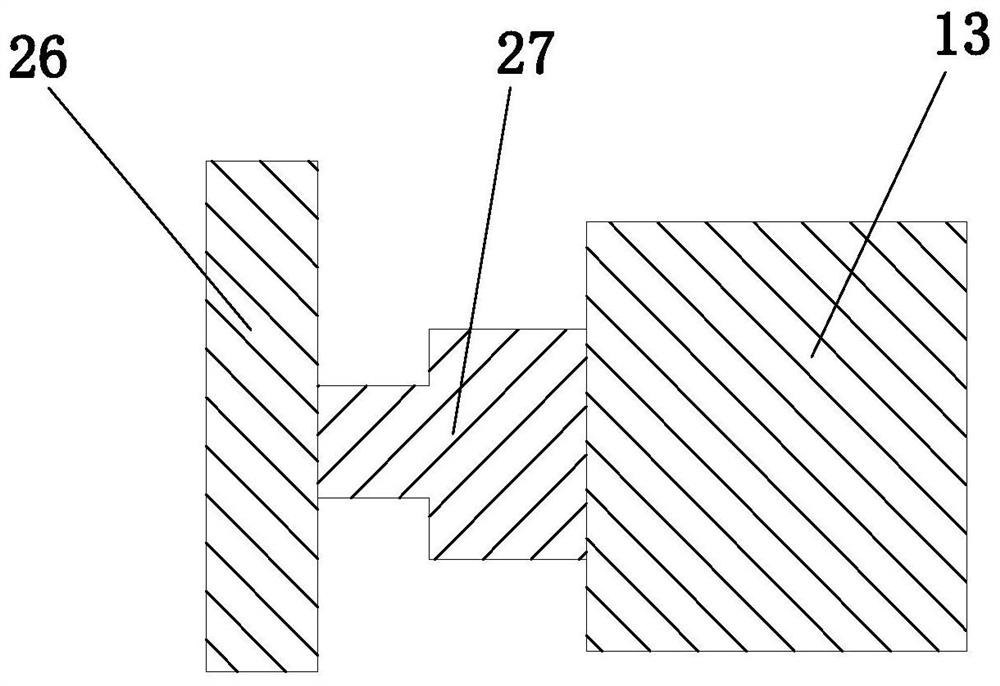

Bending pipe correction tooling platform and pipe correction method

ActiveCN104913751AEasy to adjustGuaranteed horizontal positionMeasurement devicesWelding/cutting auxillary devicesGratingEngineering

The invention discloses a bending pipe correction tooling platform and a pipe correction method. The platform comprises a frame, a fixed headstock and a movable tailstock, and is characterized in that a fixed base is arranged between the fixed headstock and the movable tailstock, the fixed base is provided with a first groove, the first groove is internally provided with a first bearing, the bottom part of the fixed headstock is provided with a stepped first rotating shaft, the first rotating shaft is arranged on the first bearing in a sleeved mode, the first rotating shaft is provided with a first bearing cover in a sleeved mode, and the first bearing cover is provided with a first locking device; the frame is provided with a first guide rail and a second guide rail which are parallelly arranged, the movable tailstock is located at the first guide rail and can move along the first guide rail, the first guide rail is provided with a magnetic grating ruler, and the second guide rail is provided with a movable supporting device which supports a bending pipe. According to the invention, an angle of a flange is adjusted conveniently through the rotatable fixed tailstock and the rotatable movable tailstock, the flange is enabled to be attached to both ends of the bending pipe, a horizontal position of the bending pipe and a height position of the flange are guaranteed through a vertical sliding block and a horizontal clamping block, and the bending pipe correction accuracy is ensured.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

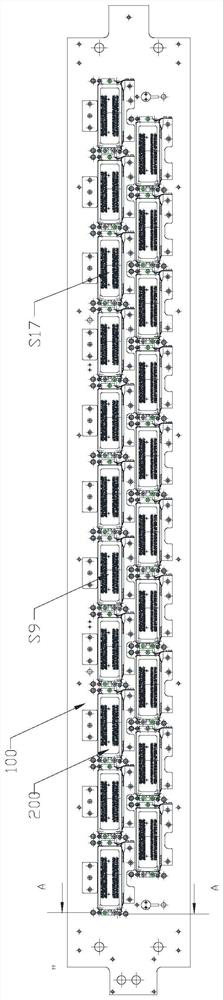

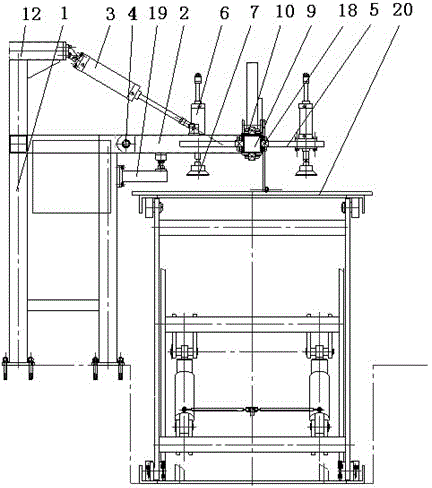

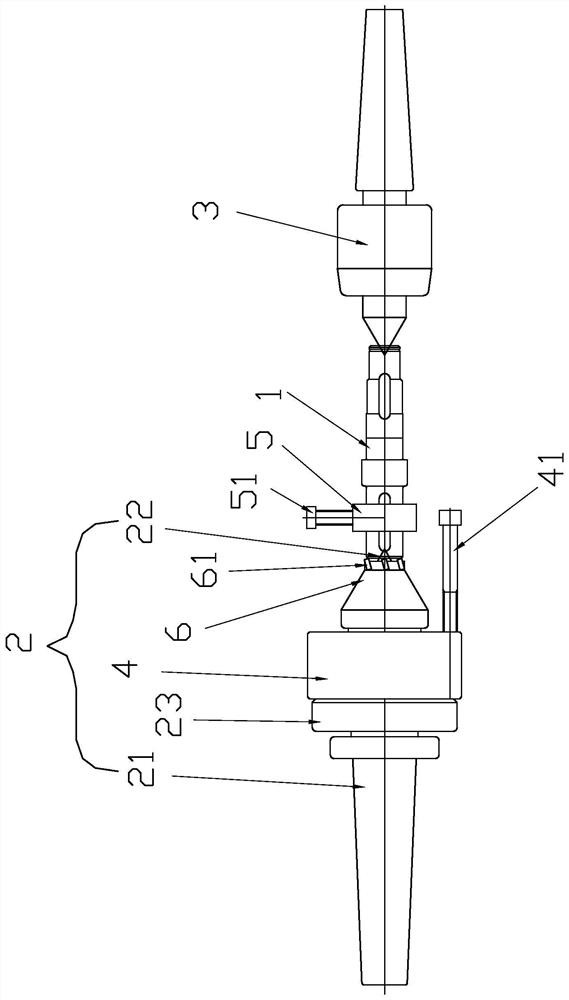

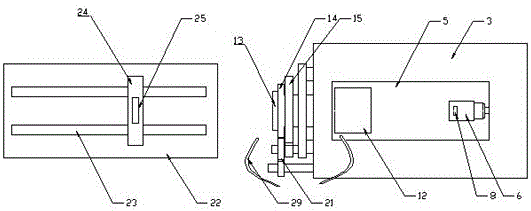

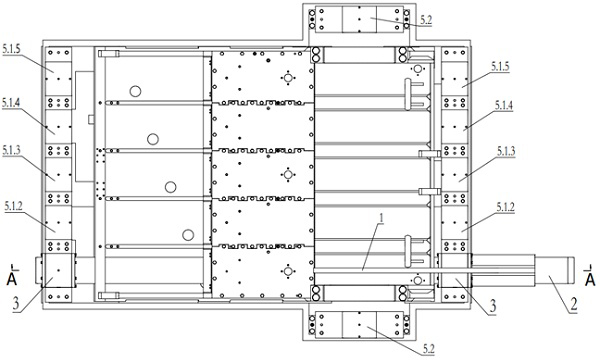

Spray head adjustment system of digital ink-jet printer

PendingCN111674157AGuaranteed horizontal positionGuaranteed printing qualityPower drive mechanismsComputer printingInk printer

The invention discloses a spray head adjustment system of a digital ink-jet printer. The spray head adjustment system comprises multiple spray head plates, wherein the spray head plates are parallel with one another. Each spray head plate is provided with multiple spray heads. Part of the spray heads are fixed to the spray head plates, and spray head adjustment mechanisms are arranged on the sprayhead plates adjacent to the remaining spray heads. A horizontal adjustment mechanism is arranged between the spray head plates and an equipment frame, wherein the horizontal adjustment mechanism is used for adjusting horizontal positions of the spray head plates. A height adjustment mechanism is arranged between the spray head plates and a color stripe frame. The spray head adjustment system canachieve multi-directional adjustment, and printing quality of the spray heads is guaranteed.

Owner:西斯特姆(中国)科技有限公司

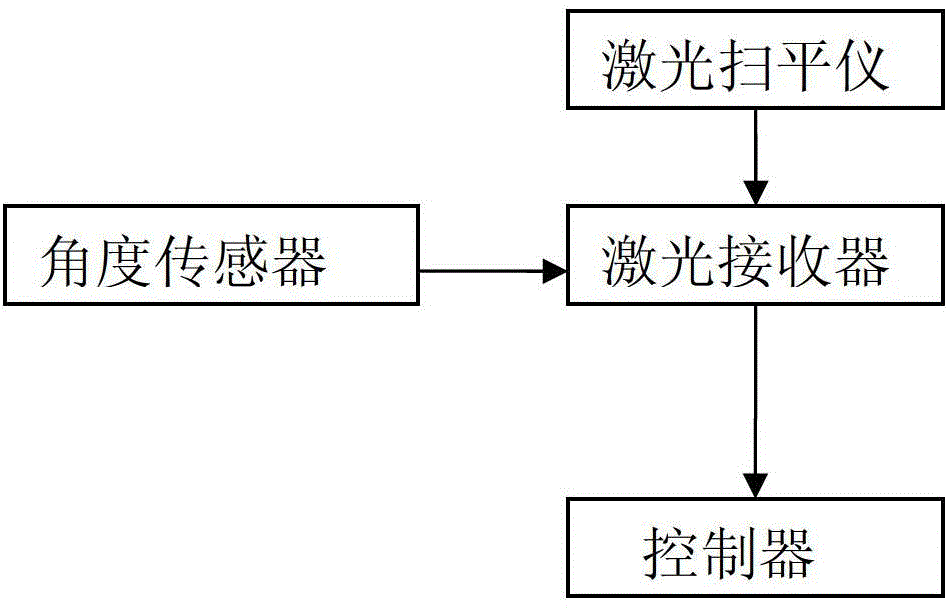

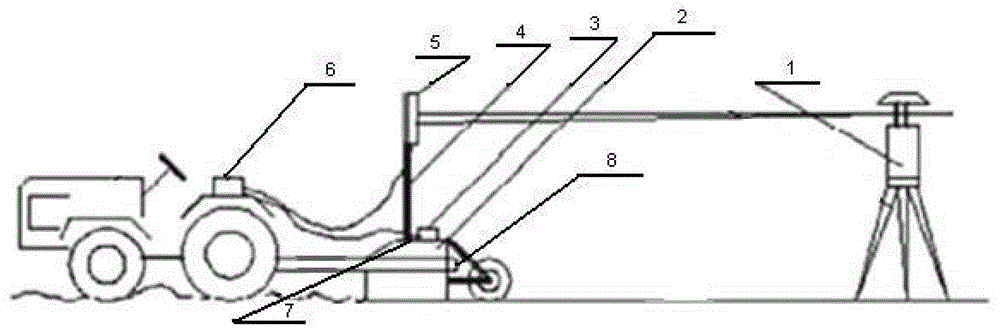

Laser land leveler and control system thereof

InactiveCN103931290AImprove working precisionImprove work efficiencySoil-working equipmentsLaser transmitterControl system

The invention discloses a laser land leveler and a control system thereof. The laser land leveler comprises a laser emitter, a laser receiver, an angle sensor, a controller, a mast, a hydraulic system and an actuating device, wherein the laser receiver and the angle sensor are arranged on the mast to send instructions to the controller, the hydraulic system can drive the actuating device to adjust the position of a land leveling shovel according to the operation instructions sent by the controller, and the actuating device can adjust the horizontal position of the land leveling shovel to enable the laser land leveler to have a function of automatically adjusting the horizontal position of the land leveling shovel. By means of the technical scheme, the levelness of an operating face of the laser land leveler can be automatically or manually adjusted to guarantee that the laser land leveler always keeps horizontal in different work states.

Owner:CHANGZHOU HUADA KEJIE OPTO ELECTRO INSTR

Garden lawn trimmer with height adjustable

The invention relates to the technical field of garden equipment, and discloses a garden lawn trimmer with height adjustable. The garden lawn trimmer comprises a fixing plate, fixing legs are fixedly connected to the bottoms of both sides of the fixing plate, a placing plate is fixedly connected to one sides of the fixing legs, and moving wheels are connected to the bottoms of the other sides of the fixing legs in a rotating mode through rotary shafts; a clamping connection device is fixedly connected to the top of the placing plate, a movable column is connected in the fixing plate in a penetrating mode, a clamping opening is formed in the right side of the movable column, the clamping opening is located on the left side of the clamping connection device, and a mower is fixedly connected to the bottom end of the movable column. According to the garden lawn trimmer with the height adjustable, through cooperation of the placing plate, the clamping connection device, the movable column, a pulling block, the clamping opening and the mower, the trimming height of the lawn trimmer can be adjusted, so that the lawn trimmer is applicable to lawn trimming of all terrains, it is unnecessary to replace different lawn trimmers during trimming of different lawns, the purpose of saving manpower and material resources is achieved, and more time is saved.

Owner:陈慧

Yarn bobbin device for textile machinery

The invention relates to the technical field of textile machinery, in particular to a bobbin device for textile machinery, which comprises a base and a worktable, a first vertical plate and a second vertical plate are vertically mounted on two sides of the top of the worktable respectively, a bobbin is horizontally and rotatably connected between the first vertical plate and the second vertical plate, and a driving mechanism is arranged on the side surface of the first vertical plate. A supporting structure is arranged in the second vertical plate, the two ends of the spool are sleeved with limiting discs, a moving mechanism is arranged in the spool, moving columns are vertically welded to the two sides of the bottom of the workbench, pulleys are installed at the bottoms of the two moving columns, and a reciprocating moving mechanism for driving the workbench to move left and right is arranged in the base. According to the device, the defects in the prior art are overcome, the bobbins can be adjusted through the moving mechanism, the driving mechanism and the reciprocating moving mechanism, the diameters of the bobbins are the same all the time, the tensioning force can be adjusted, and yarn can be evenly wound on the bobbins in a left-right back-and-forth rotating mode.

Owner:苏州绿杰纺织有限公司

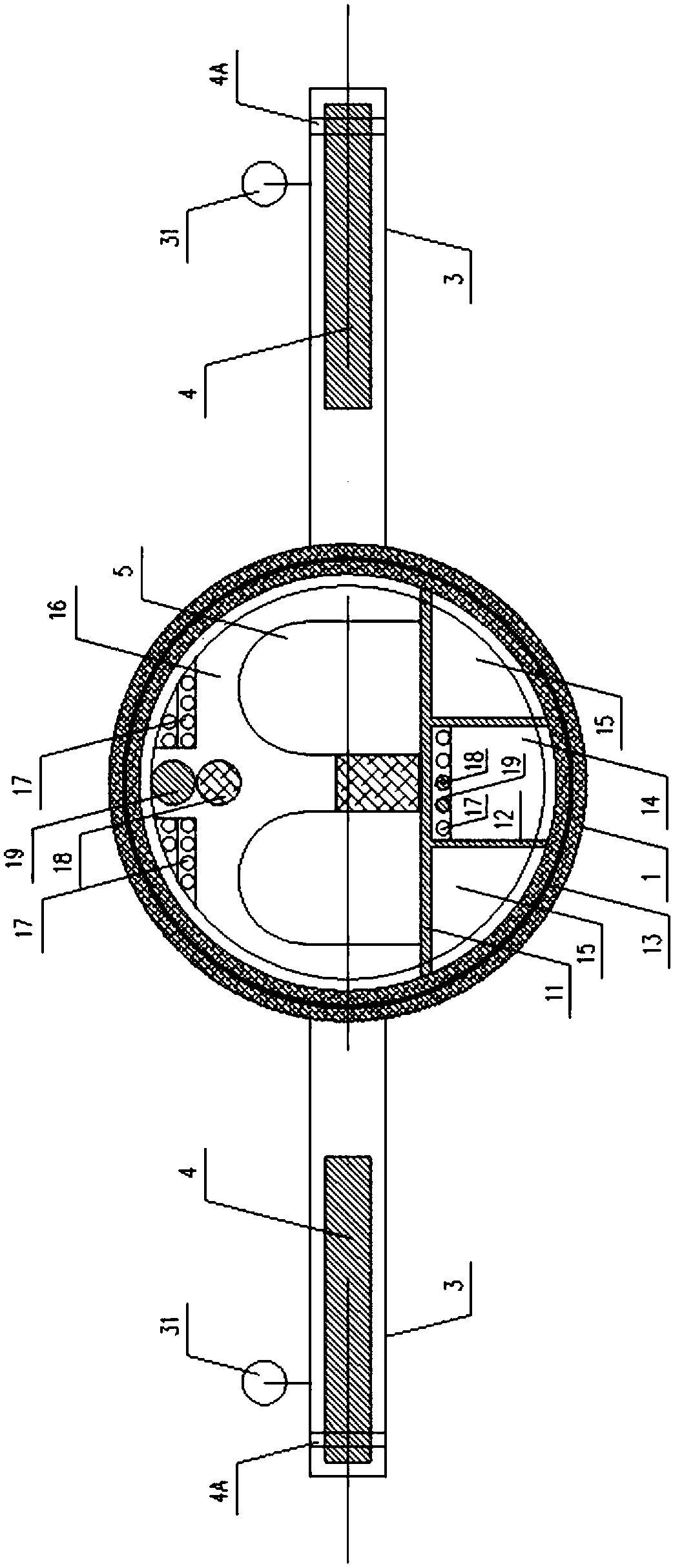

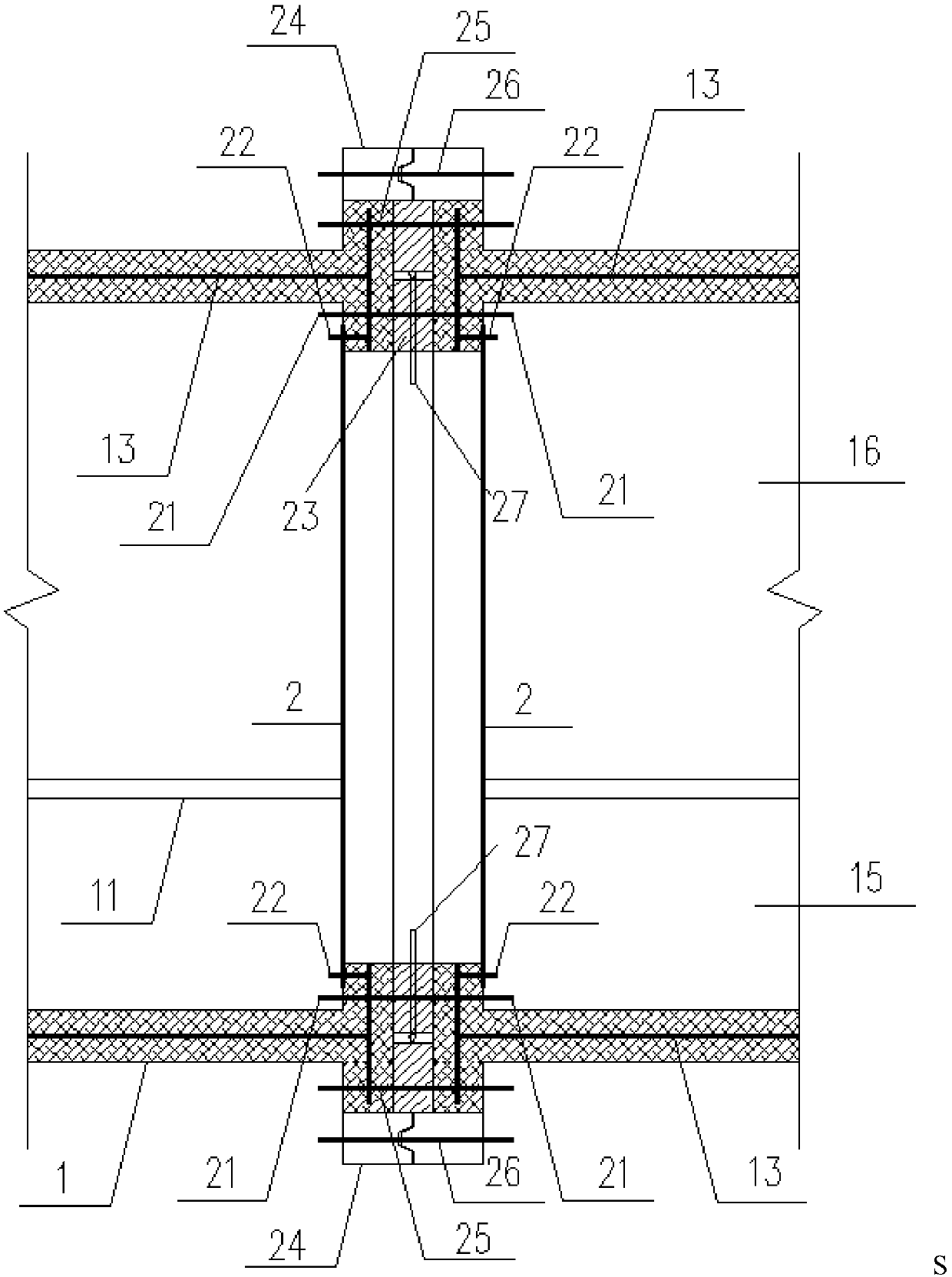

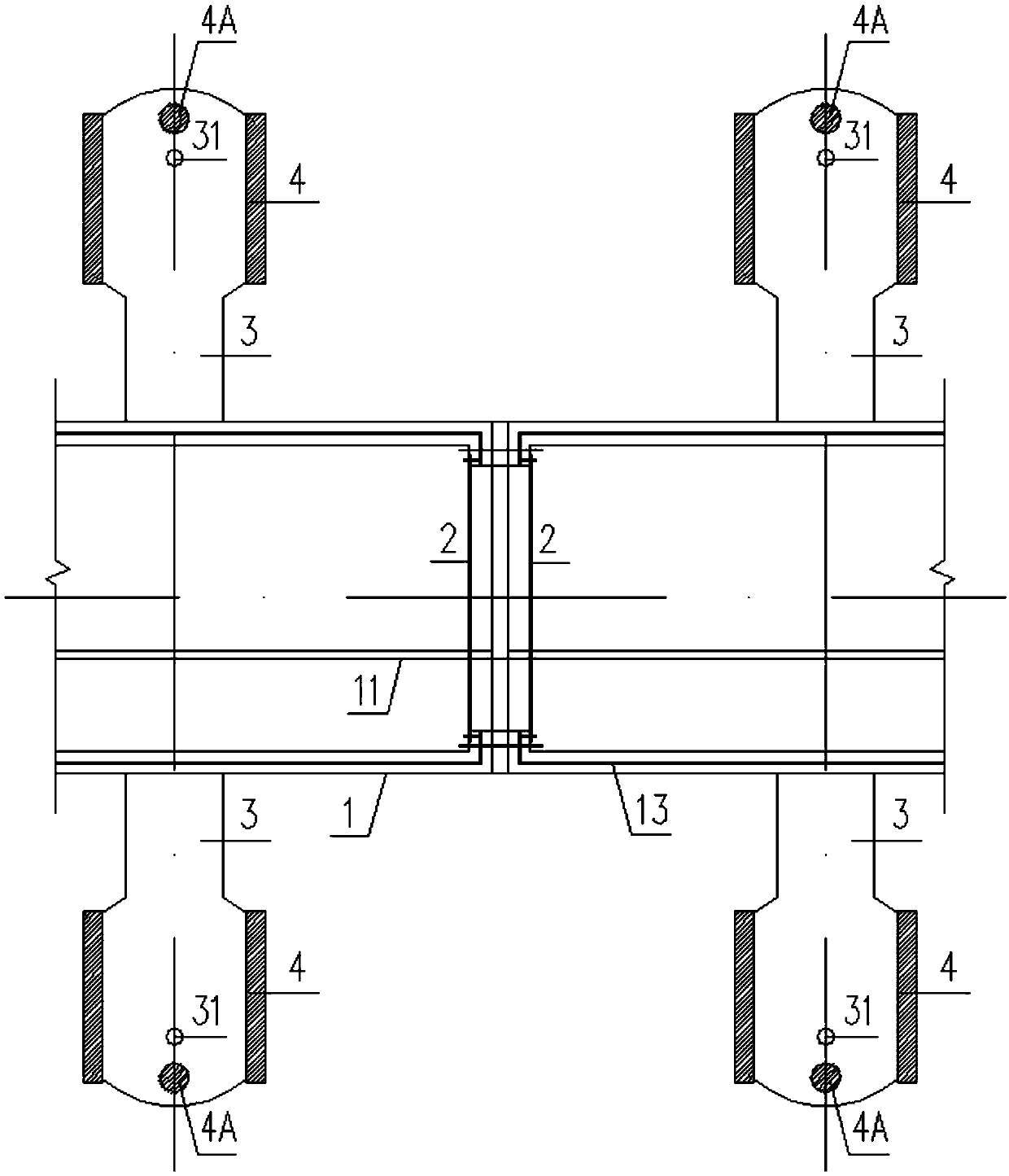

Sea-crossing water suspended high-speed rail tunnel structure, construction method thereof, and control method

InactiveCN109610511AGuaranteed horizontal positionEnsure stabilityArtificial islandsUnderwater structuresReinforced concreteRebar

The invention discloses a sea-crossing water suspended high-speed rail tunnel structure, a construction method thereof, and a control method. The sea-crossing water suspended high-speed rail tunnel structure comprises a pipe body which can be suspended in water, and the pipe body is formed by a plurality of pipe sections which are fixedly connected; a reinforced concrete horizontal partition platefor partitioning each pipe section into an upper cabin and a lower cabin is fixed into the pipe section; two closed tunnels which are arrayed along the length of the pipe body are arranged in each upper cabin, and reinforced concrete fins are symmetrically arranged in the horizontal direction outside the pipe sections; steel closed tunnel shells fixed to the reinforced concrete horizontal partition plates are arranged in the upper cabins, and track beds are arranged in the steel closed tunnel shells; and transversely-arranged electromagnetic adjustment devices are fixedly connected between the two sides of the track beds and the steel closed tunnel shells, and vertically-arranged electromagnetic adjustment devices are fixedly connected between the two sides of the lower parts of the trackbeds and the reinforced concrete partition plates. The problems of design and construction of sea-crossing water suspended tunnels, the stability, durability and safety of the tunnels, and precise control over high-speed rail tracks in the tunnels are solved.

Owner:黄夏羿

Automatic single plate feeding machine

The invention discloses an automatic single plate feeding machine which is characterized by comprising a fixing framework, a turning-over rod, a control system, a turning-over air cylinder, a rotating shaft, sucker supports, a lifting air cylinder, a vacuum sucker, a moving air cylinder, an induction support, contact idler wheels, a contact switch, a fixing guide rail frame and a sliding sleeve. The fixing framework is composed of a supporting leg frame and a connecting rod. One side of the supporting leg frame is connected with the connecting rod. The two ends of the other side of the supporting leg frame are hinged to the turning-over rod. One end of the turning-over air cylinder is connected with the connecting rod, and the other end of the turning-over air cylinder is connected with the turning-over rod. The other end of the turning-over rod is connected with the fixing guide rail frame. The fixing guide rail frame is sleeved with the sliding sleeve in a sliding mode. The moving air cylinder is arranged on the portion, at one side of the sliding sleeve, of the fixing guide rail frame. One end of the moving air cylinder is connected with the fixing guide rail frame, and the other end of the moving air cylinder is connected with the sliding sleeve. The sucker supports are arranged at the two sides of the sliding sleeve respectively. The lifting air cylinder is fixed to the sucker supports. The lower end of the lifting air cylinder is connected with the vacuum sucker. The automatic single plate feeding machine has the advantages of being novel in structure, high in working efficiency, low in labor intensity, high in automation degree, stable in operation and the like.

Owner:SHANDONG BAISHENGYUAN GRP

Vacuum package flattening device for quick-frozen food processing

PendingCN114348379APress evenlyQuality improvementPackaging under special atmospheric conditionsSlide plateFood packaging

The invention discloses a vacuum packaging and flattening device for quick-frozen food processing, and relates to the technical field of quick-frozen food processing. In order to ensure the packaging and flattening completeness of quick-frozen food; the device specifically comprises a base, a motor is fixed to the outer wall of one side of the base through a supporting block, a support is arranged on the outer wall of the side, close to the motor, of the base, a guide connecting shaft is arranged at the output end of the motor and connected with the support through a bearing, and a connecting shaft is fixed to one side of the top of the support through a bearing; the circumferential outer walls of the connecting shaft and the guide connecting shaft are sleeved with transmission wheels correspondingly, the circumferential outer walls of the two transmission wheels are sleeved with the same transmission chain, a supporting plate is arranged on one side of the top of the base, a sliding groove is formed in one side of the front face of the supporting plate, a sliding plate is slidably connected into the sliding groove, and a sliding lifting mechanism is arranged between one side of the sliding plate and the connecting shaft. And an inclined sliding hole is formed in one side of the sliding plate. According to the vacuum flattening device, it is guaranteed that vacuum flattening of packaging bags is completed under the condition that quick-frozen food is not damaged.

Owner:安徽靖童科技农业发展有限公司

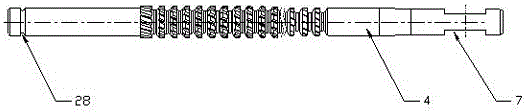

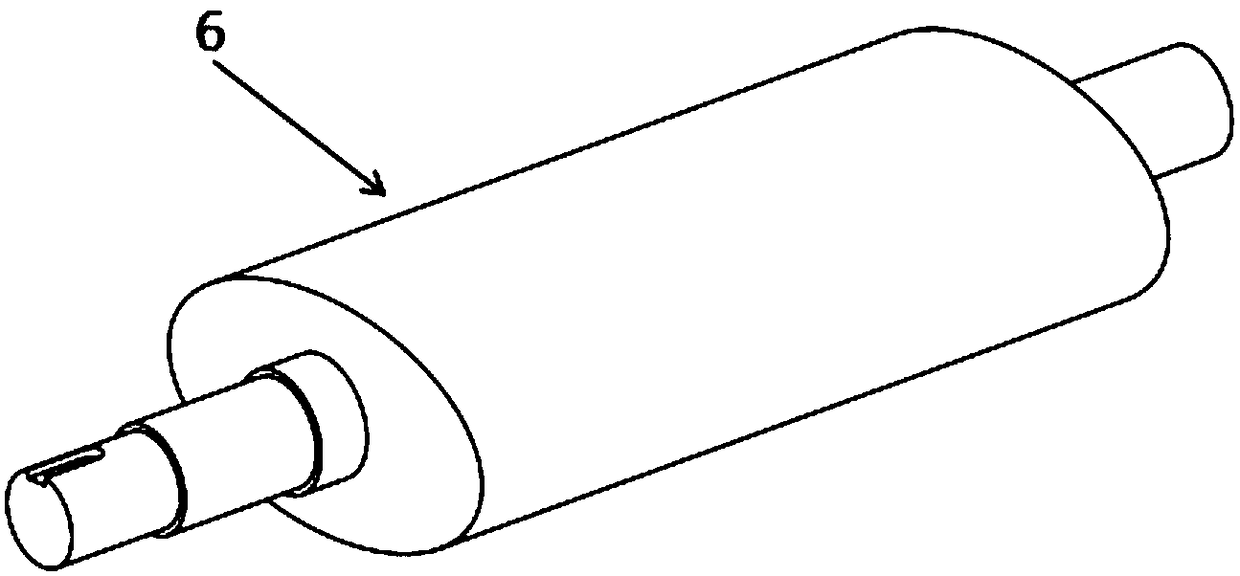

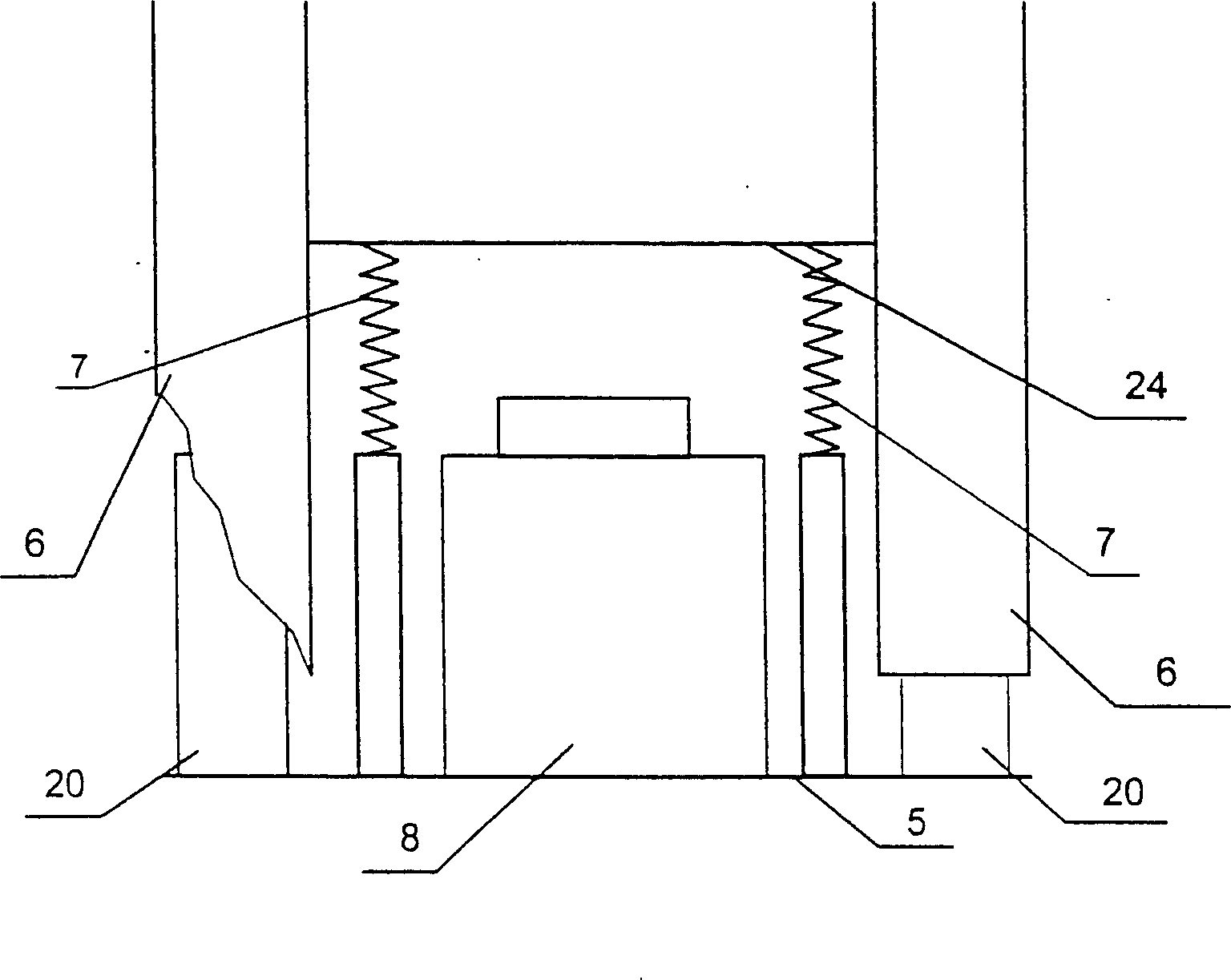

Carrier roller

The invention discloses a carrier roller which is long in service life and low in noise. The carrier roller comprises an installation seat and a roller movably arranged on the installation seat, wherein two sides of the lower surface of the installation seat are respectively provided with a bracket, each bracket comprises a base, an installation hole is formed in the base, a strut is movably arranged in the installation hole in a penetrating way, a limiting plate is arranged at the top of the strut, a spring is sheathed between the limiting plate and the installation seat on the strut, the limiting plate is connected with the installation seat through a connecting block, threads are arranged in the installation hole in the base, the base is connected with an adjusting seat through the threads, a through hole is formed in the adjusting seat, the strut is arranged in the through hole in a penetrating way, and the spring is positioned between the limiting plate and the adjusting seat.

Owner:张家港优尼克五金工具有限公司

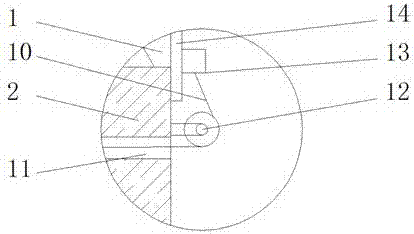

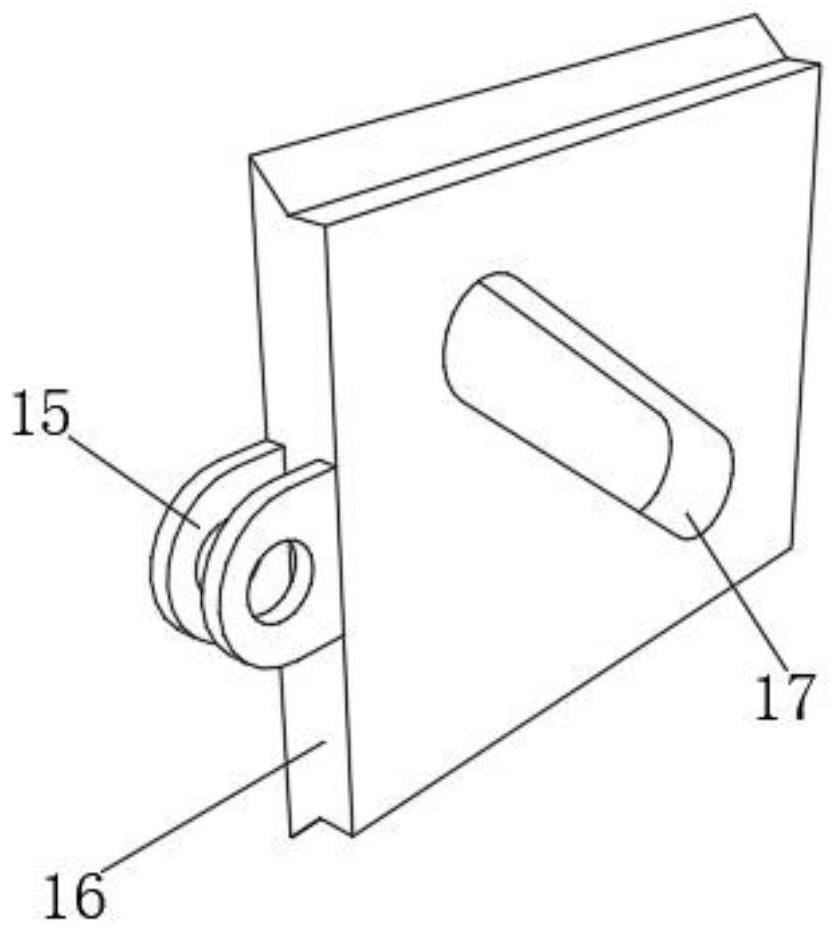

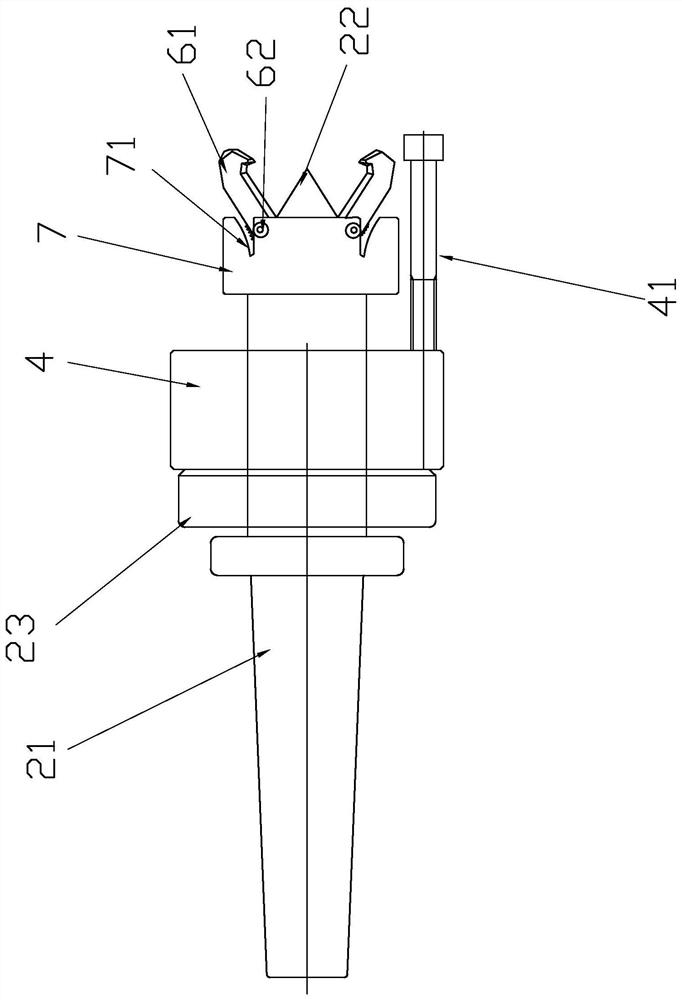

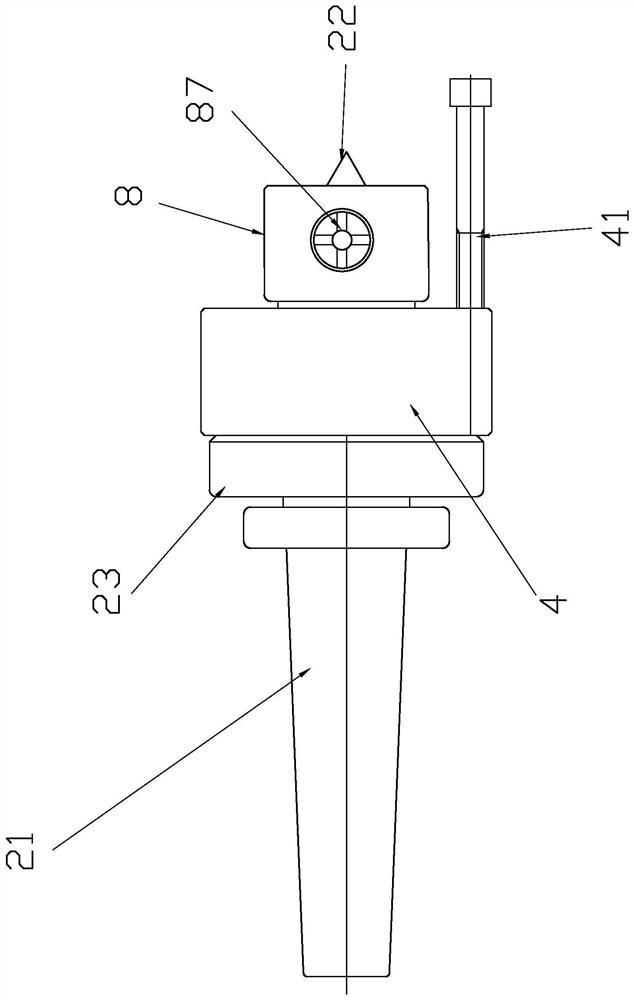

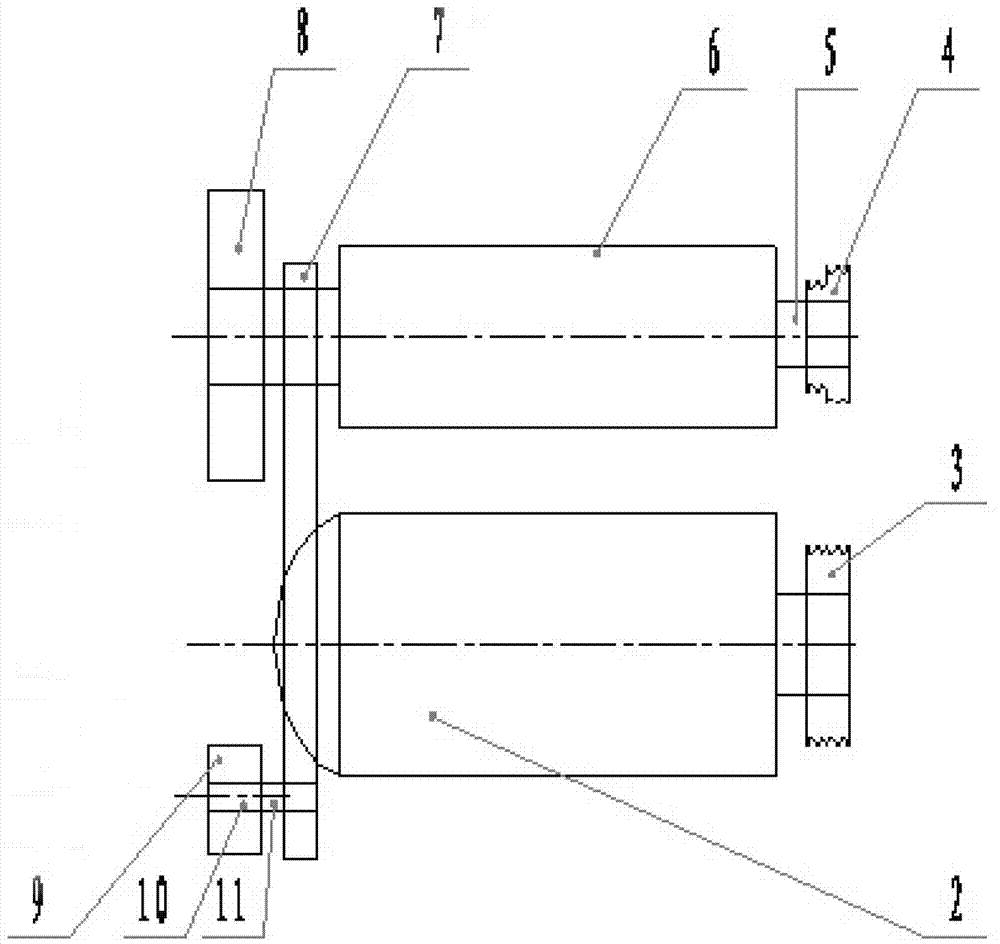

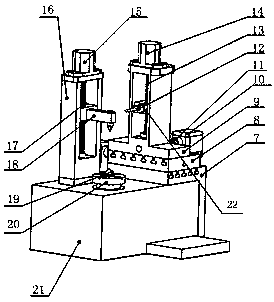

Clamping tool for machining Hawking metal surface

PendingCN113333794AGuaranteed horizontal positionImprove installation efficiencyTailstocks/centresPositioning apparatusEngineeringTailstock

The invention relates to a clamping tool for machining a Hawking metal surface. A front tip and a rear tip abut against center holes in the two ends of an output shaft, and the horizontal position of a workpiece is guaranteed; a driven tip is installed on a pneumatic lathe tailstock, manual tightening of a common tailstock is replaced, and the installation efficiency is improved; a first fastener on the end face of a first shaft sleeve abuts against and makes contact with a second fastener on the top of a second shaft sleeve, a clamping mechanism makes contact with the end face of the workpiece, and therefore the workpiece is driven to rotate for machining, and rapid clamping is achieved; and rapid clamping of parts can be achieved only by hydraulically driving the tips and the pneumatic tip. The tool can flexibly deal with output shafts of different specifications and sizes, and the production efficiency can be better improved in a large batch.

Owner:ZHEJIANG TONGLI HEAVY GEAR

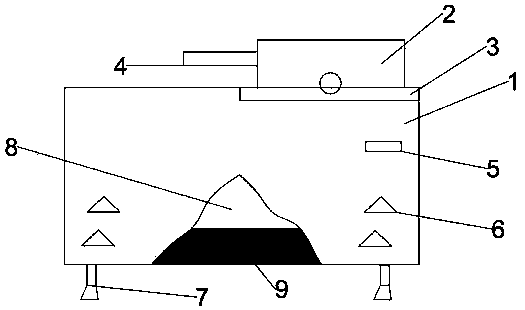

Anti-vibration aluminum profile cutting lathe

InactiveCN107755713AGuaranteed accuracyGuaranteed horizontal positionAuxillary equipmentMeasurement/indication equipmentsWave shapeEngineering

The invention relates to an anti-vibration aluminum profile cutting lathe. The anti-vibration aluminum profile cutting lathe comprises a lathe base and a workbench, a rail is arranged on the upper surface of the lathe base, a connecting portion matched with the rail is arranged on the workbench, the workbench is slidably arranged on the rail through the connecting portion, a cavity is formed in the lathe base and shaped like an isosceles triangle, three edges of the isosceles-triangle-shaped cavity are all shaped like waves, small plastic foam balls are arranged in the cavity, and a tool restis arranged on one side of the workbench. According to the anti-vibration aluminum profile cutting lathe, vibration is absorbed through the small plastic foam balls, and the machining precision is guaranteed. The height of the lathe base can be adjusted through hoof-shaped feet, and therefore it is guaranteed that the anti-vibration aluminum profile cutting lathe is located at the horizontal position in the machining process; the position of the lathe base can be monitored in real time through a level gauge, and then it is further guaranteed that the lathe is located at the horizontal position. The structure is simple, operation is convenient, and a guarantee can be effectively provided for the aluminum profile cutting precision.

Owner:JIANGSU BIGLE NON FERROUS METALS IND TECH

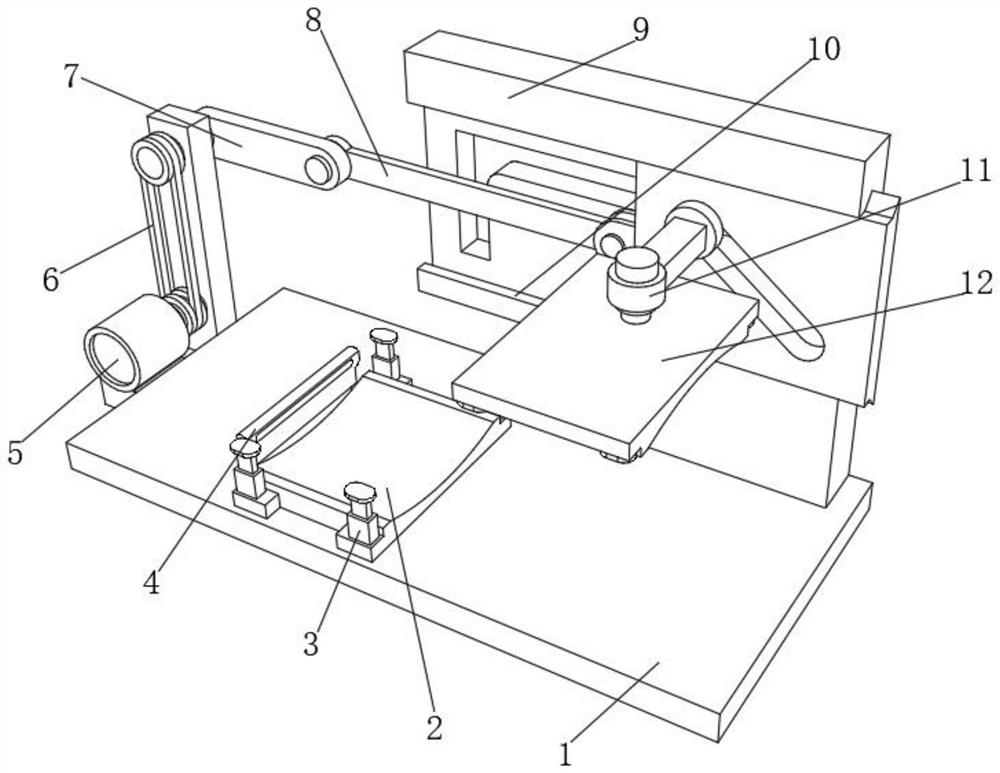

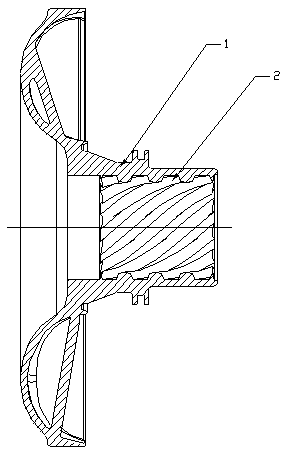

Slip-ring polishing tool

The invention discloses a slip-ring polishing tool which comprises a base, a transmission part and a polishing part. The transmission part comprises a motor, a large belt pulley, a small belt pulley, a transmission shaft and a casting shaft sleeve and is arranged on a machine tool cutter bracket; the polishing part comprises a driving wheel, a driven wheel, a pin shaft, a shaft sleeve and a fixing arm; the casting shaft sleeve, the motor and the base are mutually assembled together; the large belt pulley and the small belt pulley are connected by a V belt; the large belt pulley is arranged on the motor; the small belt pulley is arranged on one end of the transmission shaft; the other end of the transmission shaft is provided with the driving wheel and connected with one end of the fixing arm; the driven wheel is fixed through the pin shaft and the shaft sleeve and arranged on the other end of the fixing arm; the driving wheel and the driven are both provided with a grinding belt; and surface of the driven wheel is in an arc shape. The slip-ring polishing tool has the advantages that the operator can adjust the polishing amount and precision in real time and guarantee the roughness of the polished sip ring.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD

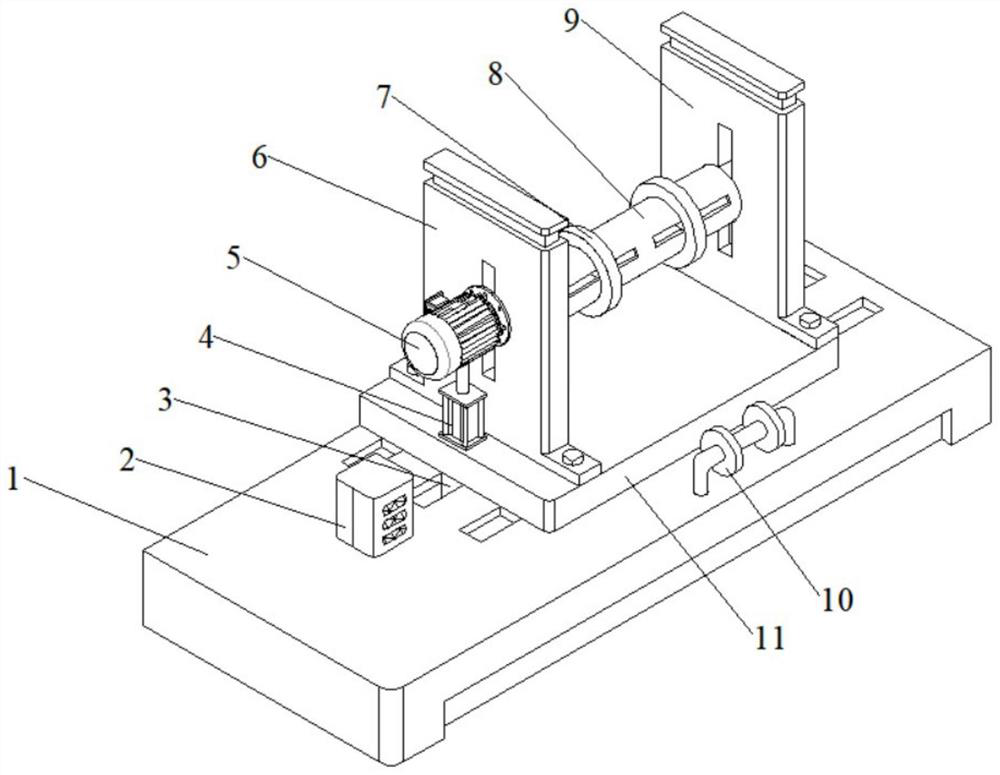

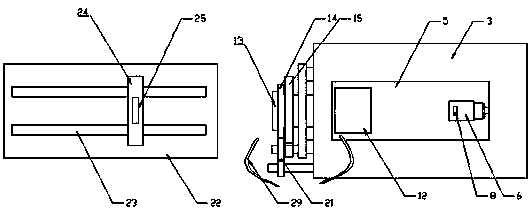

Machining method for impeller of hydraulic retarder of heavy truck

The invention relates to a machining method for an impeller of a hydraulic retarder of a heavy truck. The machining method includes the steps that an impeller workpiece to be machined is assembled in a special machining mechanism, and then a spiral broach is assembled; after the workpiece and the spiral broach are assembled, machining is started, a driving motor pulls a pull rod and drives the spiral broach to do linear motion towards the side far away from the workpiece, and when the spiral broach moves, a rotating assembly starts to work and drives a rotating disc to rotate so as to drive the workpiece to rotate in the clockwise direction; and after the machining, the workpiece is taken down from the machining mechanism, and the machining of spiral teeth of the impeller is completed. The machining method for the impeller of the hydraulic retarder of the heavy truck has the advantages that the special machining mechanism is coordinated, the parameters such as the column number, the size and the tooth number of machining teeth of the spiral broach, the speed of the spiral broach in the machining process and the rotating speed of the workpiece are reasonably and cooperatively designed, and therefore the spiral teeth of the impeller can be machined at a time, the machining precision of the spiral teeth can be guaranteed, and product scrapping or secondary machining caused by deviation can be avoided.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

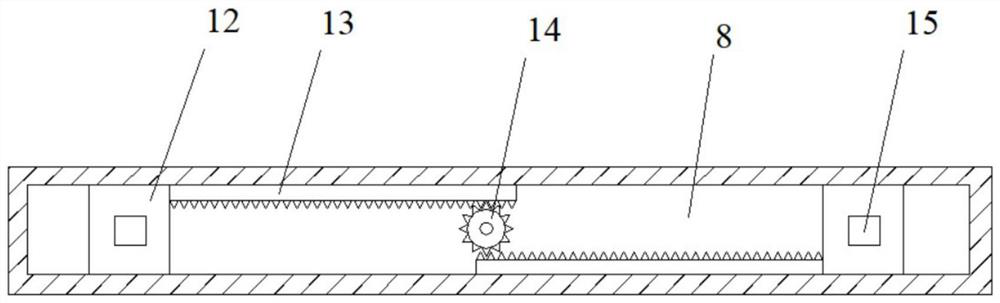

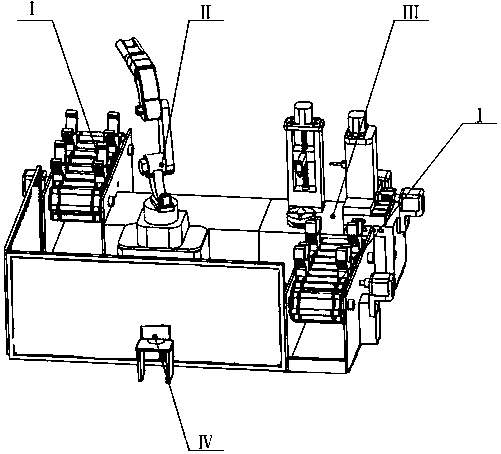

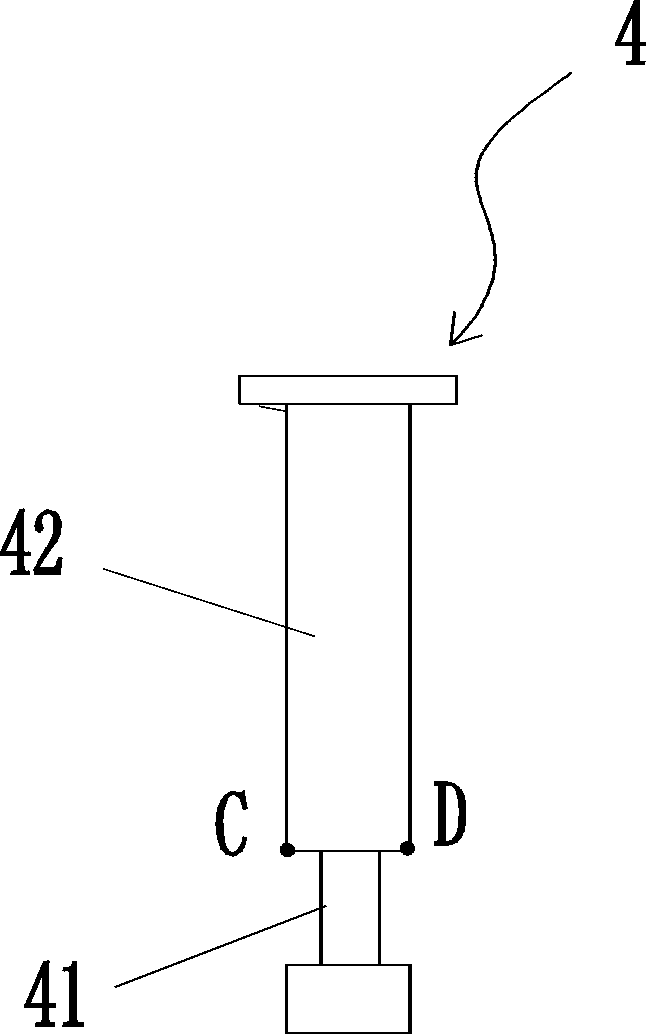

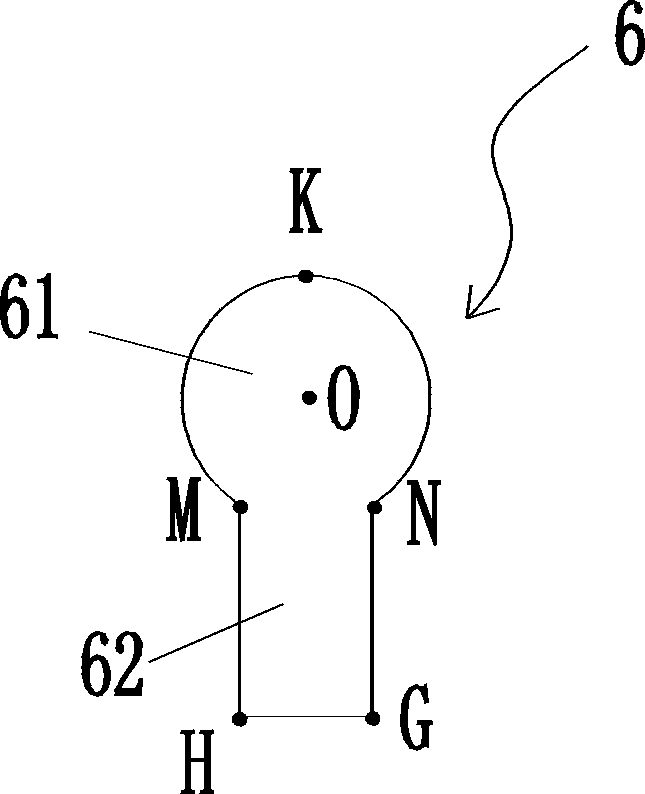

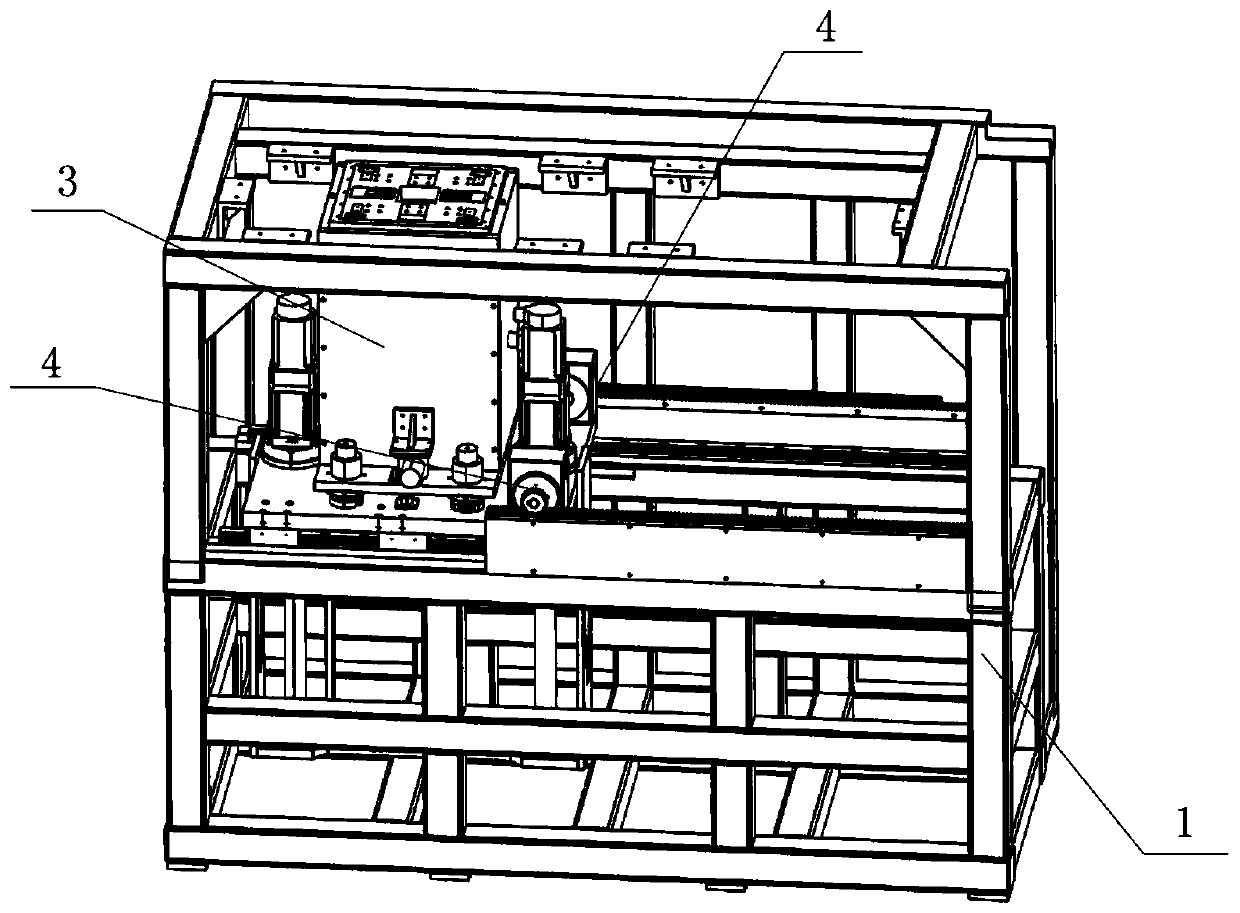

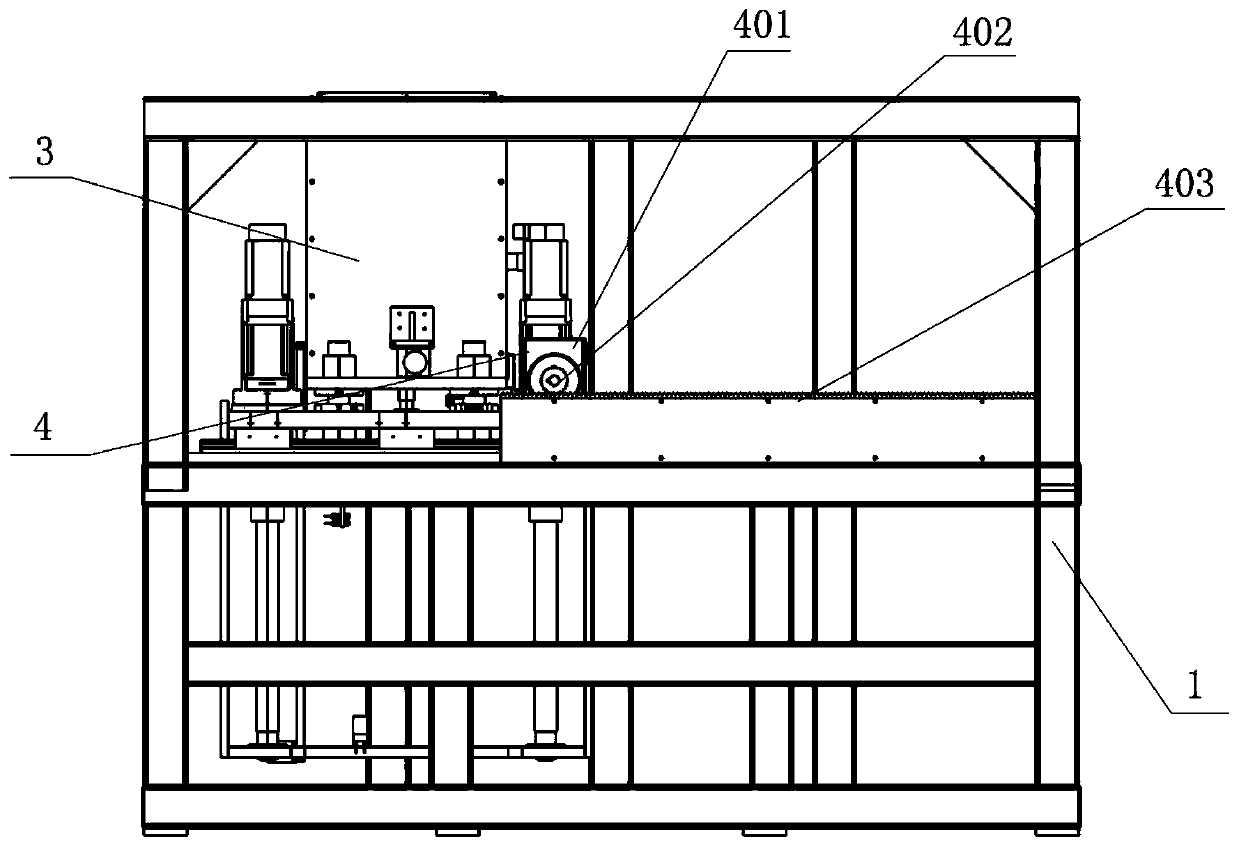

Automatic detection device of tooth face precision of gear shaft

PendingCN109238692AUpright positionGuaranteed horizontal positionMachine part testingDisplay deviceEngineering

The invention relates to an automatic detection device of tooth face precision of a gear shaft. The device comprises an automatic transportation device I, a manipulator II, a detection device III anda display device IV, wherein the automatic transportation device comprises a motor, a coupler, chain wheels, transportation claws, location sensors and bench bodies; the detection device comprises a workbench, motors, couplers, a flat key, an air cylinder, a pressure sensor, a lever mechanism, displacement measurement rulers, measurement frames, screw rods, an upper tip upright, an upper tip, a lower tip, screw nuts, an X sliding table, a Y sliding table, a Z sliding table, a detection upright, a probe, a rotating table and springs; the display device comprises a display screen and a display table; the manipulator comprises a gripper, a rotating arm, a small arm, a middle arm, a large arm and a base; during detection, the transportation device transports the gear shaft to a position abovethe location sensor; the manipulator puts the gear shaft on the detection device; the detection device fixes the gear shaft through the upper tip and the lower tip; the probe scans a tooth profile; detection information is transmitted to the display screen; and the detected gear shaft is placed by the manipulator on the automatic transportation device to be transported to a temporary storage area.

Owner:HARBIN UNIV OF SCI & TECH

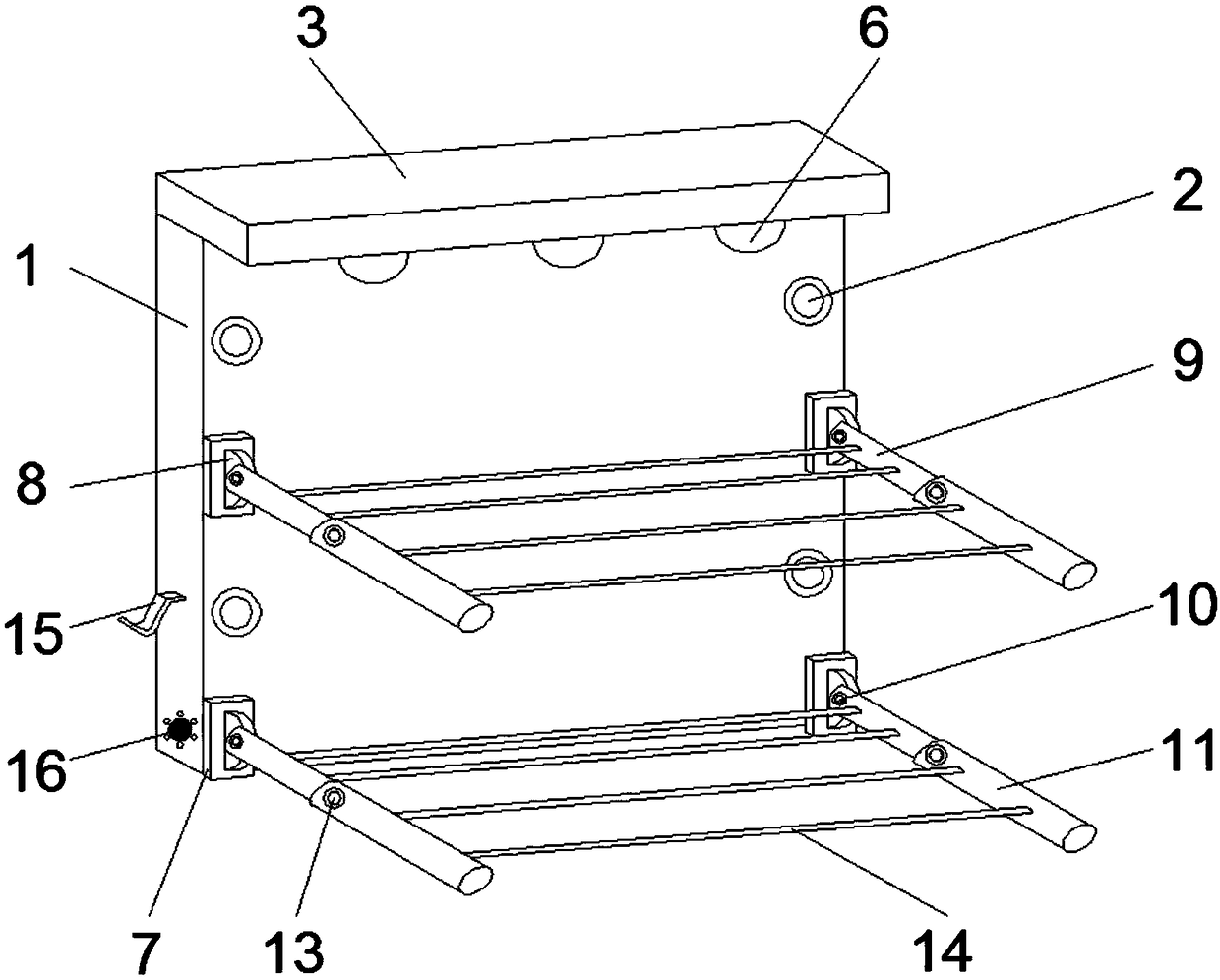

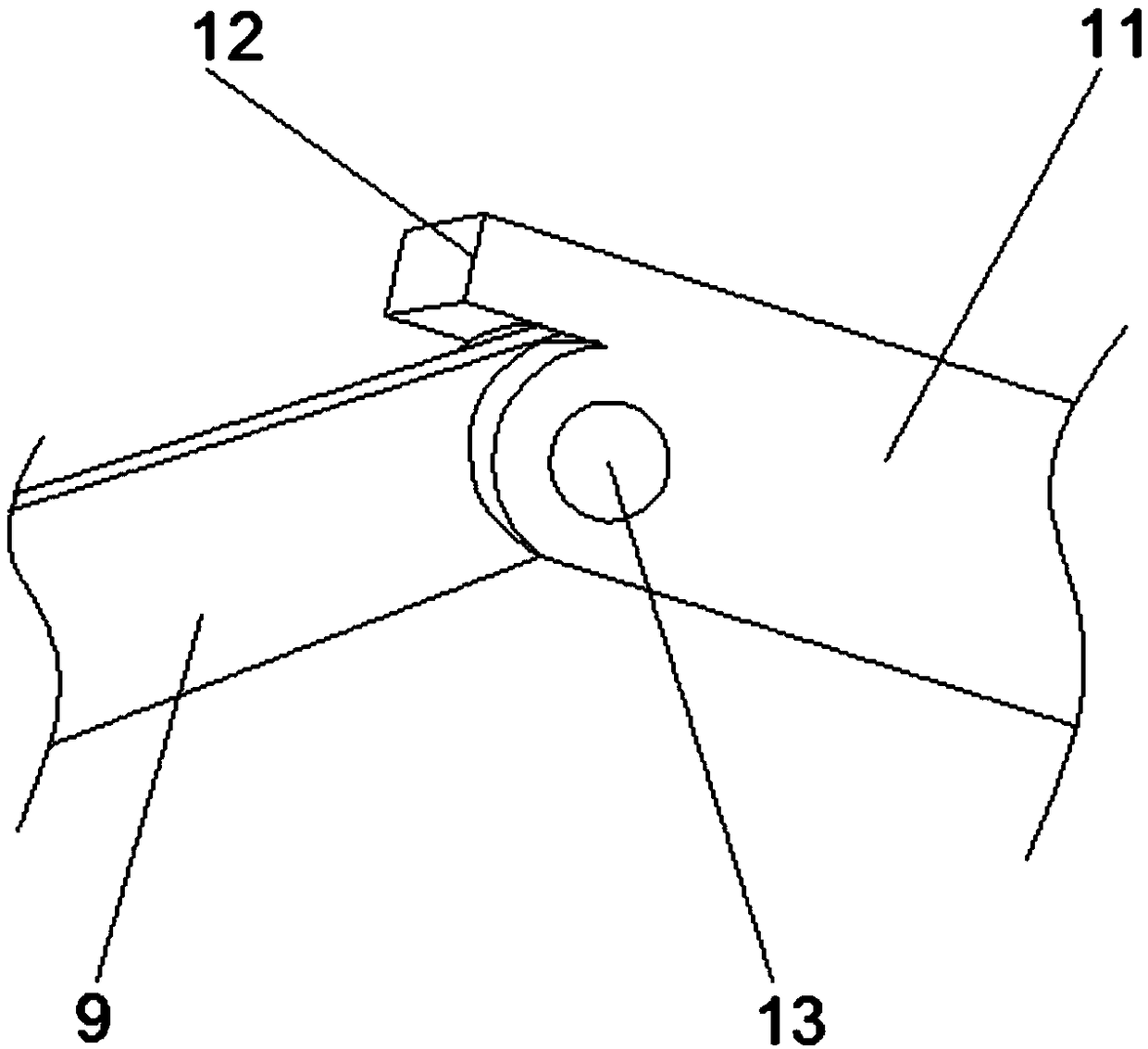

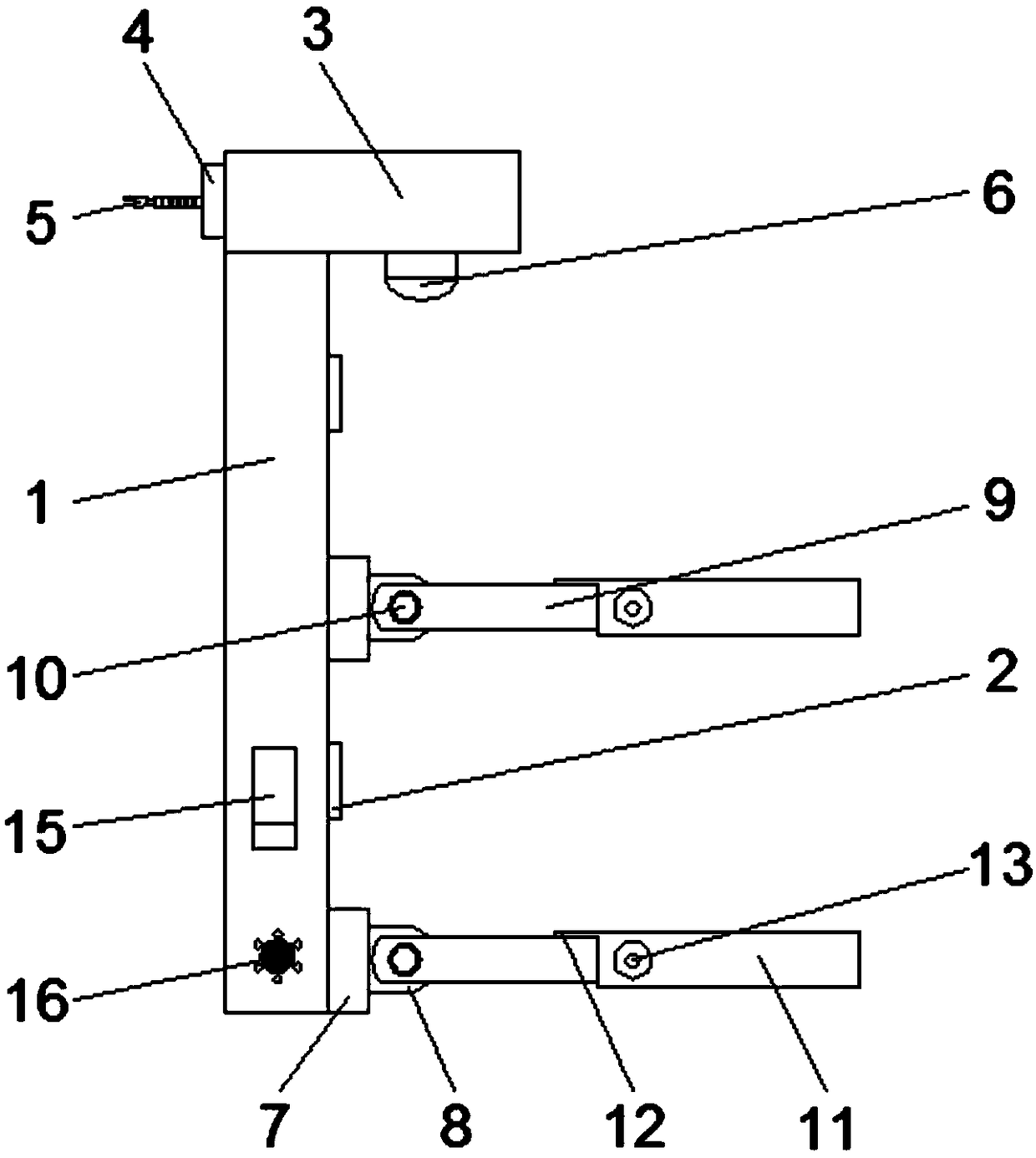

Household folding towel rack

InactiveCN108814382AGuaranteed horizontal positionSmall footprintDomestic applicationsEngineering management

Owner:池州市达宏信息技术有限公司

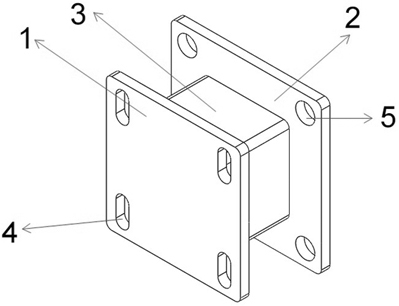

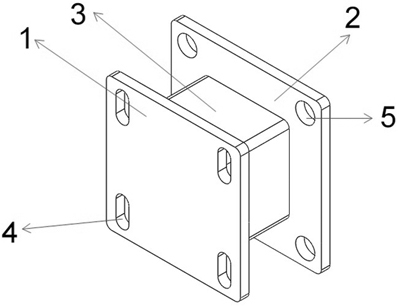

Basketball backboard connector

InactiveCN102416245AGuaranteed horizontal positionTroubleshoot Assembly Size MismatchesBall sportsEngineeringCantilever

The invention relates to a basketball backboard connector, belonging to the technical field of a sports apparatus. The basketball backboard connector comprises a front connecting plate and a rear connecting plate, the front connecting plate and the rear connecting plate in parallel are connected into a whole through a bracket, the front connecting plate is provided with a bolt connecting hole with the same size as the assembly size of a basketball backboard, and the rear connecting plate is provided with a bolt connecting hole with the same size as the assembly size of a cantilever head board. By adopting the basketball backboard connector, the problem of the mismatching assembly sizes of a hoop and the basketball backboard can be solved. Meanwhile, when a cantilever is arranged at the match height of 3150mm like the hoop, the depth of a bolt penetrating through the hole of the cantilever head board can be adjusted to ensure that the hoop is in a horizontal position.

Owner:WUXI SHUANGYING SPORTS EQUIP

Anti-arc installation structure of cable compartment door of ring network cabinet

ActiveCN110994434BPrevent blastingEnsure safetyElectric switchesArrangements with metal casingStructural engineeringElectric cables

An anti-arcing installation structure for a cable chamber door of a ring network cabinet, comprising a cabinet body of the ring network cabinet, a grounding switch is installed in the cabinet body, a cable room is arranged below the grounding switch, the grounding switch is provided with a grounding switch operating shaft, and the grounding switch operating shaft There is a cam fixedly connected to the coaxial; the cabinet body of the ring network cabinet is also equipped with movable iron pins that can move vertically, and the movable iron pins are driven by the cam to move vertically. The upper edge of the door leaf is provided with the first gap for the necking section of the movable iron pin to be embedded. The left and right sides of the door leaf are respectively provided with a plurality of T-shaped hook nails. Corresponding to the clamping holes, the cabinet body of the ring network cabinet is also equipped with fixed vertical fixing iron pins, and the upper edge of the door leaf is also correspondingly provided with a second gap for the vertical fixing iron pins to embed. The invention can prevent the door leaf from being exploded when an arc burning accident occurs, and the operation is convenient.

Owner:广东正超电气有限公司

A processing method for the impeller of the hydraulic retarder of the truck

The invention relates to a machining method for an impeller of a hydraulic retarder of a heavy truck. The machining method includes the steps that an impeller workpiece to be machined is assembled in a special machining mechanism, and then a spiral broach is assembled; after the workpiece and the spiral broach are assembled, machining is started, a driving motor pulls a pull rod and drives the spiral broach to do linear motion towards the side far away from the workpiece, and when the spiral broach moves, a rotating assembly starts to work and drives a rotating disc to rotate so as to drive the workpiece to rotate in the clockwise direction; and after the machining, the workpiece is taken down from the machining mechanism, and the machining of spiral teeth of the impeller is completed. The machining method for the impeller of the hydraulic retarder of the heavy truck has the advantages that the special machining mechanism is coordinated, the parameters such as the column number, the size and the tooth number of machining teeth of the spiral broach, the speed of the spiral broach in the machining process and the rotating speed of the workpiece are reasonably and cooperatively designed, and therefore the spiral teeth of the impeller can be machined at a time, the machining precision of the spiral teeth can be guaranteed, and product scrapping or secondary machining caused by deviation can be avoided.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

Ring main unit cable chamber door arcing-resistant installation structure

ActiveCN110994434AMany connectionsEven by forceElectric switchesArrangements with metal casingCamStructural engineering

A ring main unit cable chamber door arcing-resistant installation structure comprises a ring main unit body. A grounding switch is installed in the cabinet body, a cable chamber is arranged below thegrounding switch, the grounding switch is provided with a grounding switch operation shaft, and the grounding switch operation shaft is coaxially and fixedly connected with a cam. The ring main unit body is also provided with a movable iron pin which can move vertically. The movable iron pin is driven by the cam to move vertically. A necking section is formed at the lower part of the movable ironpin. The upper edge of the door leaf is correspondingly provided with a first notch for embedding the necking section of the movable iron pin. The left side edge and the right side edge of the door leaf are respectively provided with a plurality of T-shaped hook nails, the front face of the left door frame and the front face of the right door frame are provided with clamping holes corresponding tothe hook nails, the ring main unit body is further provided with a fixed vertical fixing iron pin, and the upper edge of the door leaf is further correspondingly provided with a second notch allowingthe vertical fixing iron pin to be embedded therein. According to the invention, the door leaf can be prevented from being exploded open when an arcing accident occurs, and the operation is convenient.

Owner:广东正超电气有限公司

An adjustable stand

ActiveCN103267209BGuaranteed horizontal positionThe overall structure is simple and reliableStands/trestlesSupport point

The invention relates to an adjustable support which is composed of a base plate, a main support, a supporting rod and an adjustment device. A three-point supporting method is adopted, each supporting point is connected with a supporting grounding plate through a ball head, and therefore the support can be ensured to be horizontal in any ground condition. An adjustment nut is arranged between the main support and the grounding plate, can adjust the horizontal state of the three supporting points and can be locked. The main support and a steel pipe are in external contacting connection and are locked through two bolts. The adjustable support ensures locking reliability and can effectively support work pieces.

Owner:浙江东煦材料科技有限公司

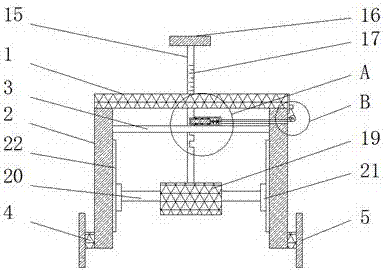

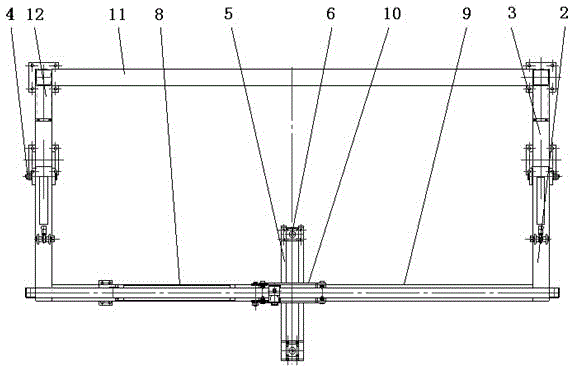

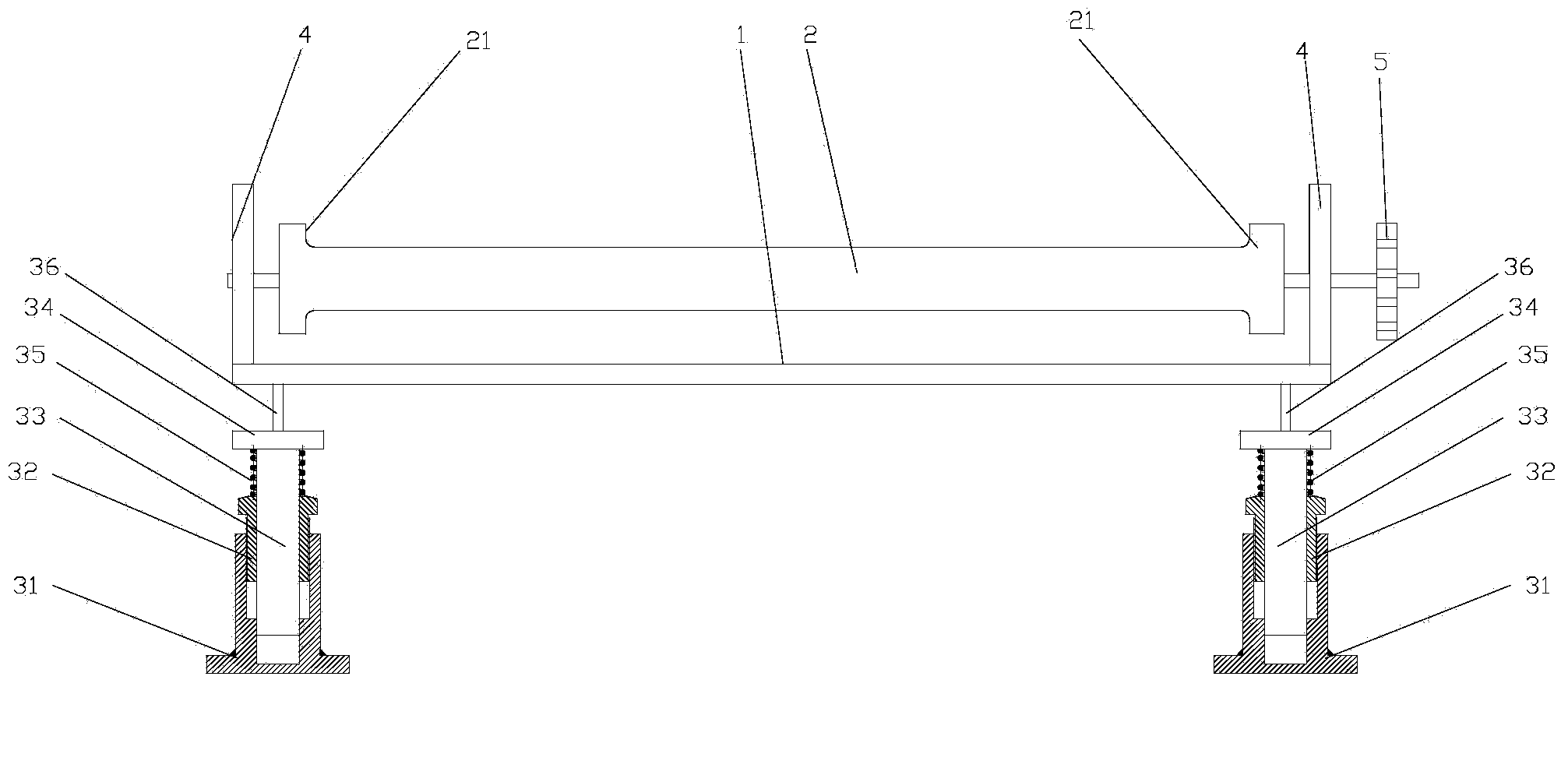

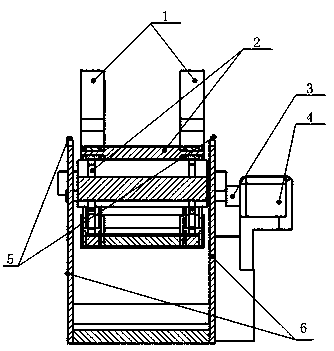

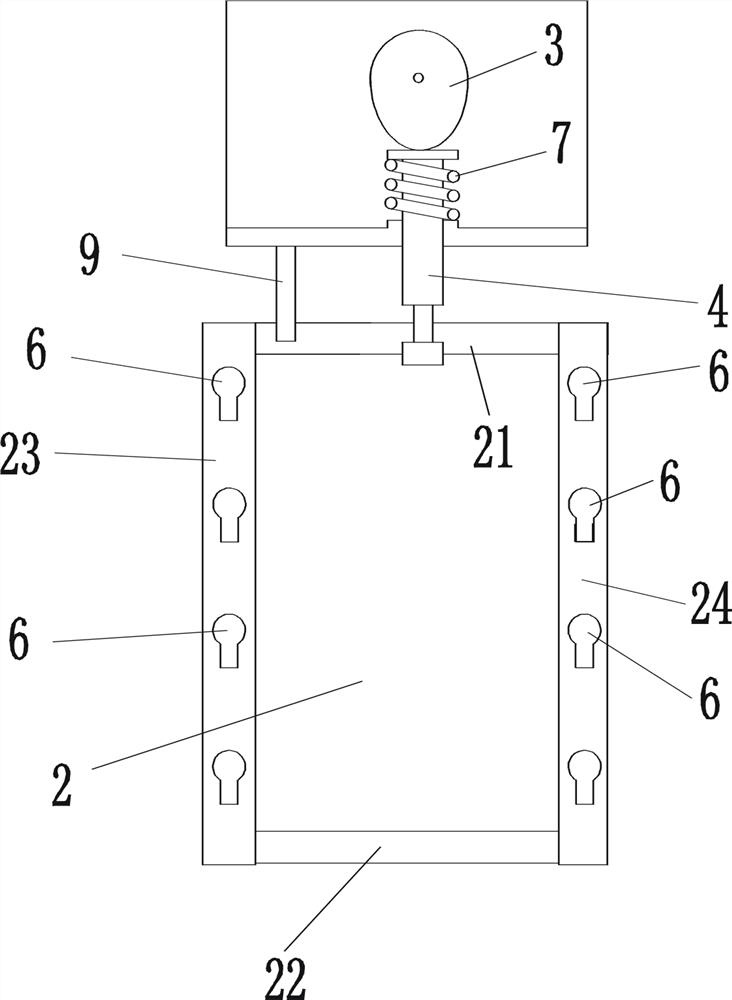

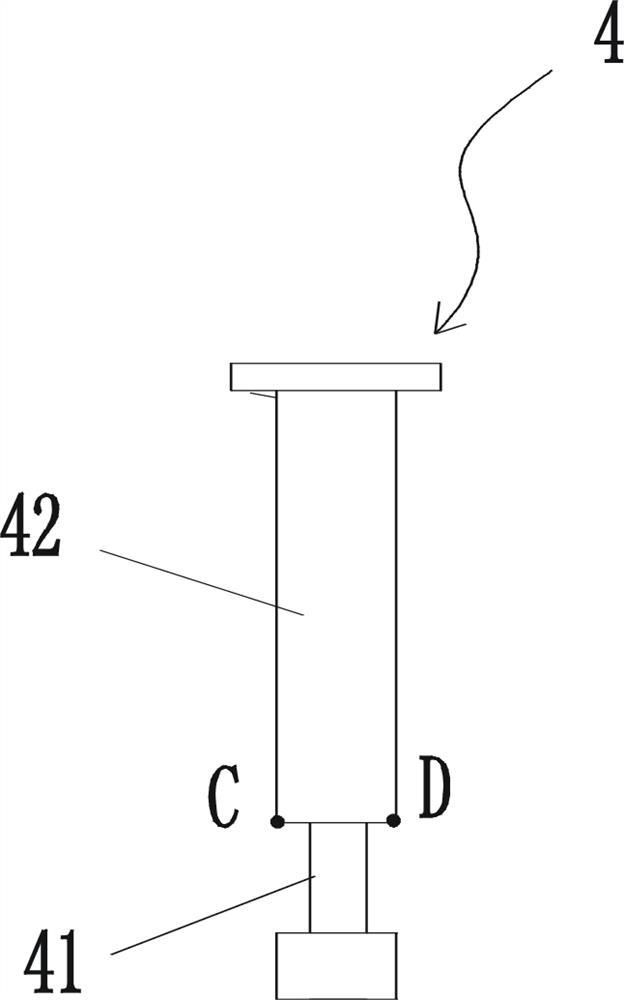

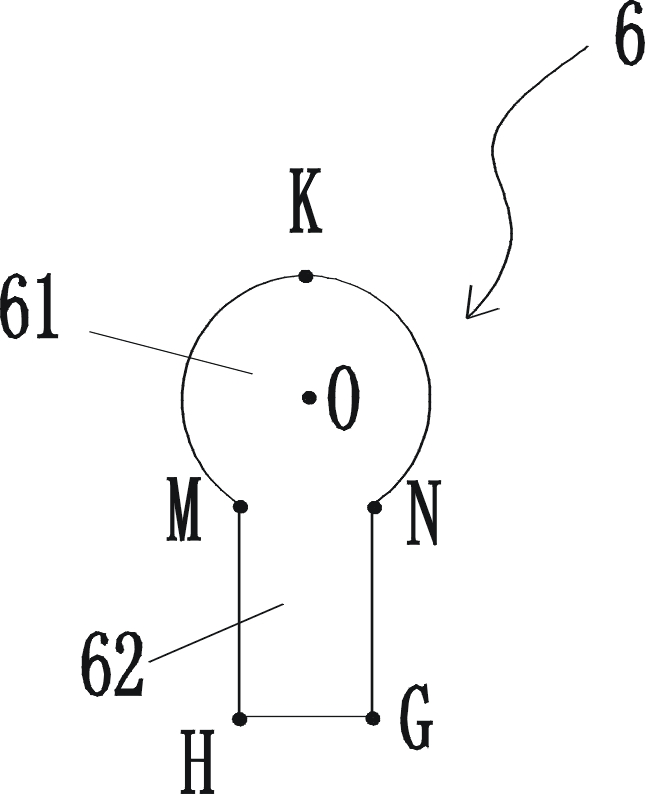

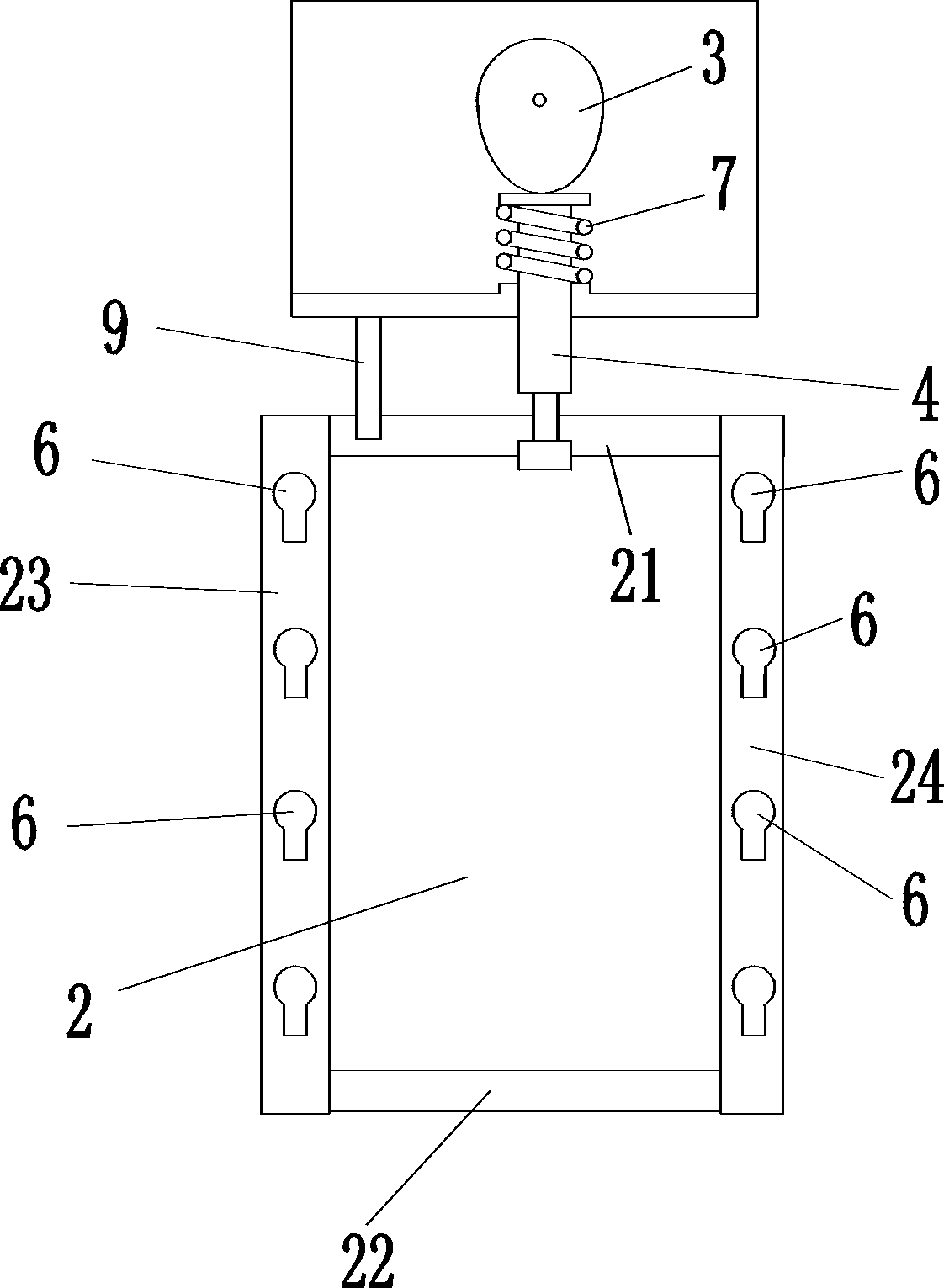

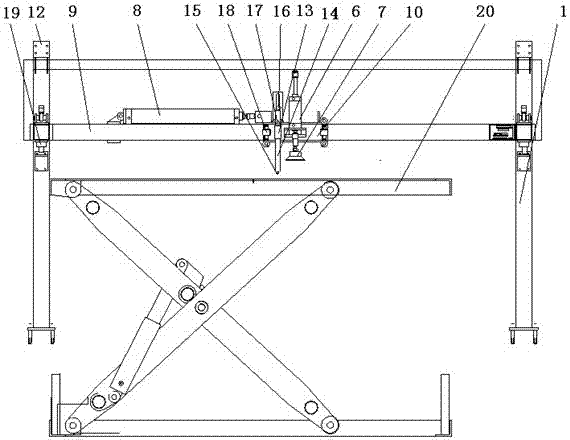

A height adjustment device for a press test platform

InactiveCN106427043BGuaranteed horizontal positionGuaranteed machining accuracyWork benchesPressesDrive shaftTest platform

The invention discloses a height adjustment device for a pressure machine test platform. The height adjustment device comprises the test platform and further comprises a driving mechanism and a height adjustment mechanism. The driving mechanism comprises a servo motor and a worm gear transmission unit. The height adjustment mechanism comprises adjusting sliding blocks and a base which are sequentially located on the lower side of the test platform, the test platform is in horizontal contact with the adjusting sliding blocks, the two adjusting sliding blocks are arranged on the two sides of the base, and the adjusting sliding blocks on the two sides of the base form inclined plane matching with the base. A support is fixed to the base, a transmission shaft matched with the worm gear transmission unit to rotate is arranged in a space defined by the base, the support, the adjusting sliding blocks and the test platform, the transmission shaft is in contact with the adjusting sliding blocks on the two sides of the base, and in the rotating process, the distance between the adjusting sliding blocks on the two sides of the base is adjusted.

Owner:NANJING AGRICULTURAL UNIVERSITY

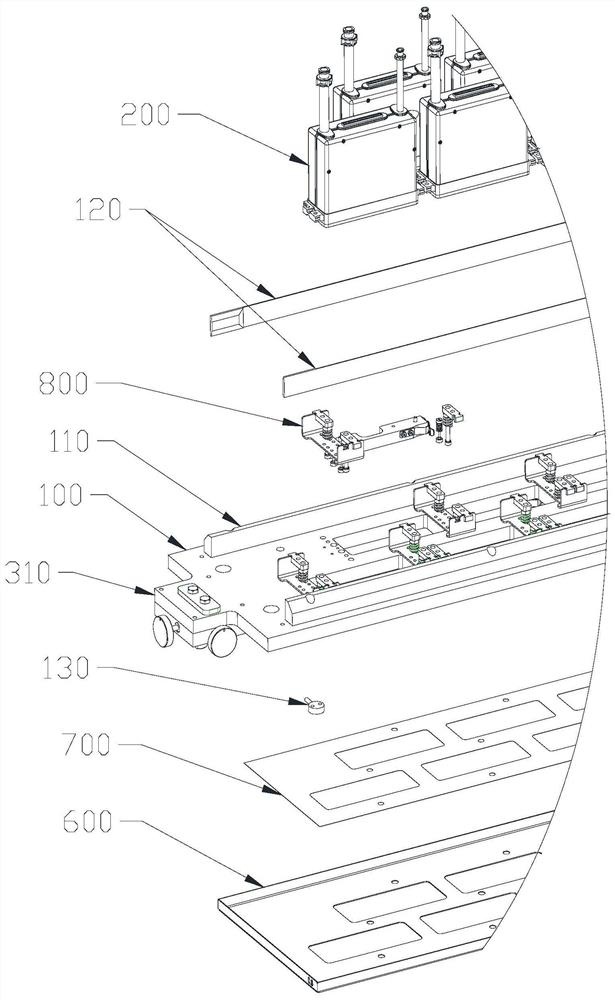

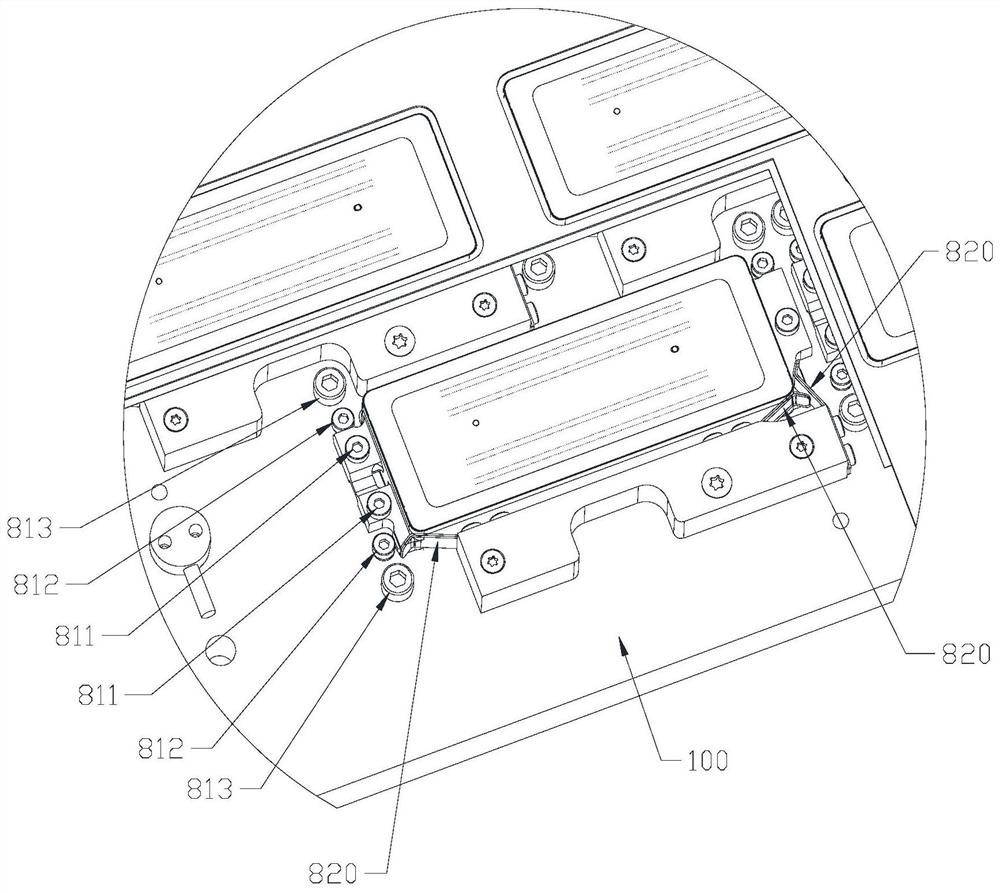

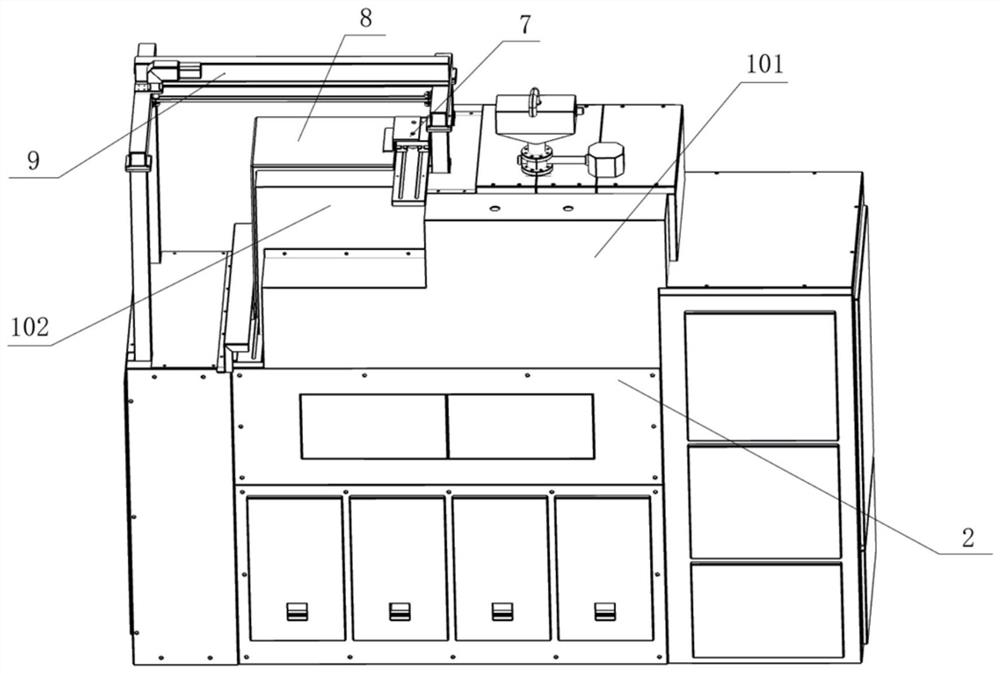

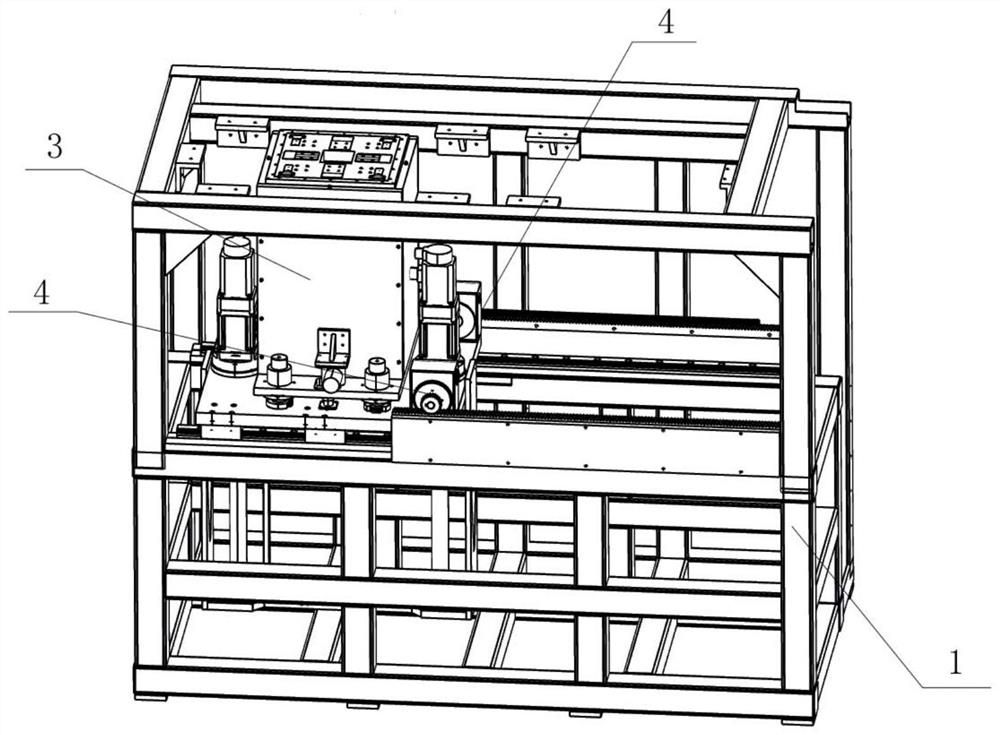

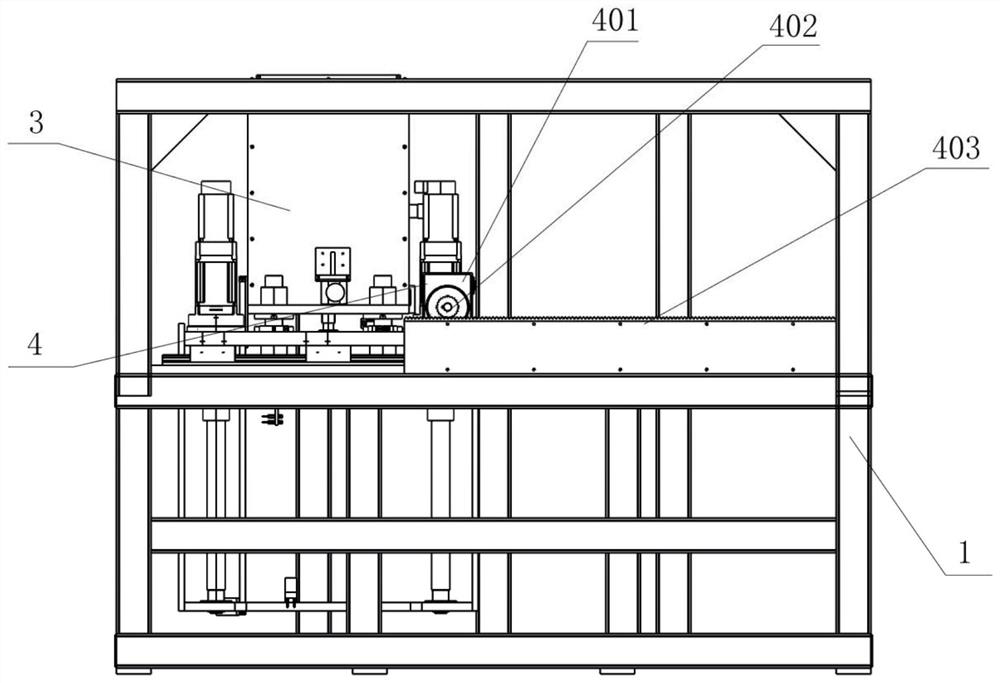

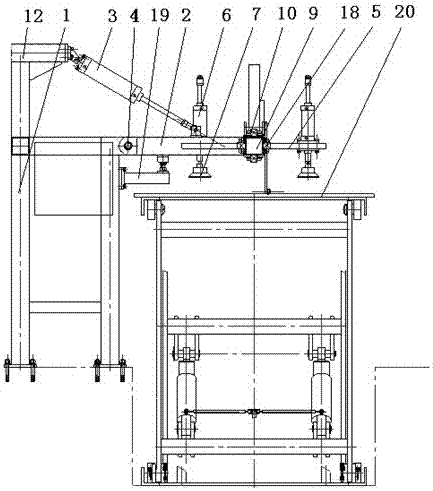

A table transfer transportation system for large slm equipment

ActiveCN111268411BSolve the problem of horizontal accuracyImprove manufacturing precisionControl devices for conveyorsTransit systemWorkspace

The invention relates to a worktable transfer transportation system for large-scale SLM equipment, which is used to transfer worktables. The power supply for power supply of the system, the frame body includes a work area and a pick-up area, and the workbench driving device is connected to the frame body and the workbench respectively, and is used to drive the workbench between the work area and the pick-up area The housing is connected to the frame body, and the workbench leveling device is connected to the workbench. Compared with the prior art, the invention satisfies the airtightness requirements for the operation of the SLM equipment, and has the advantages of easy pick-up, stable and reliable structure, and high work efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

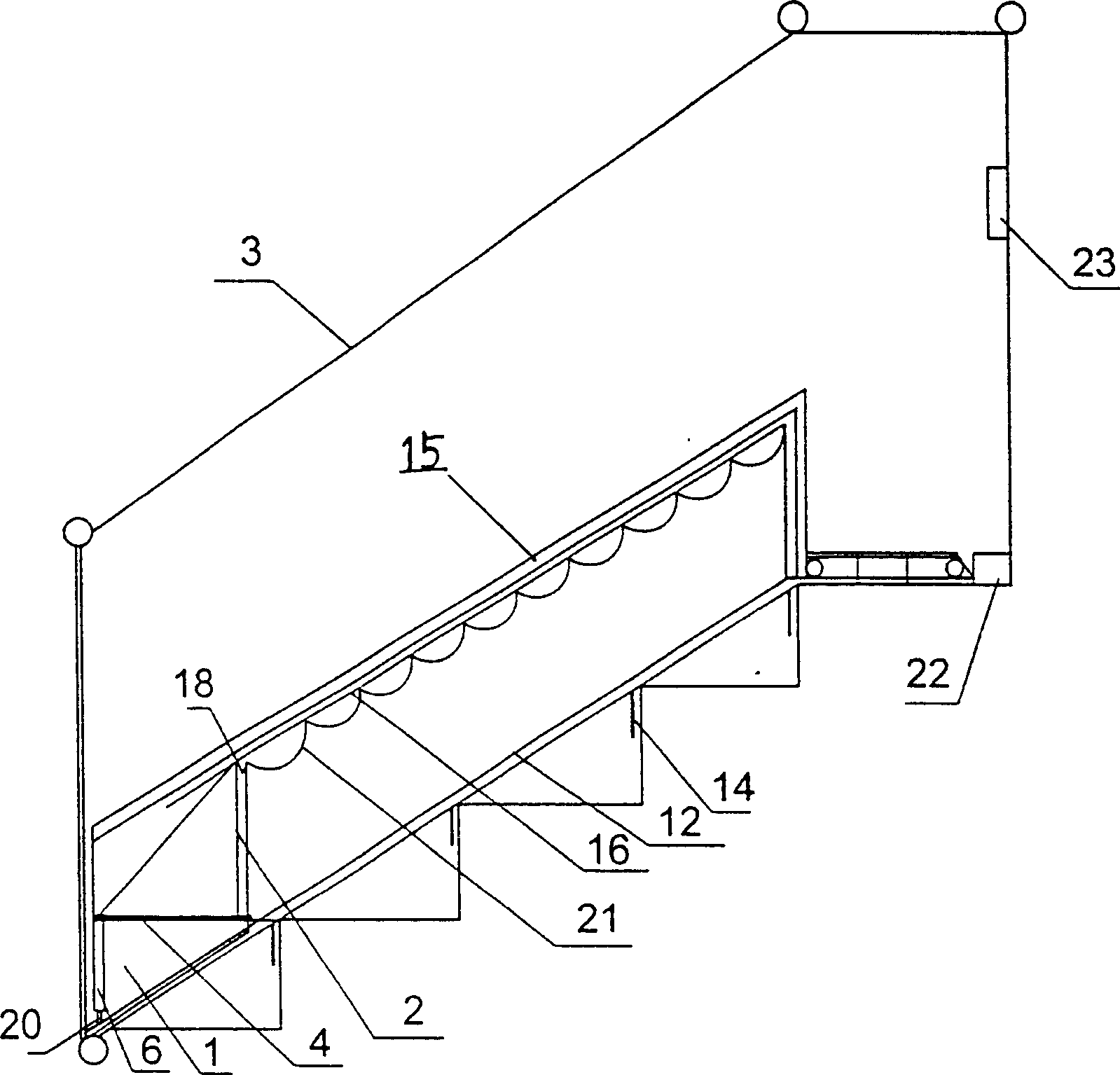

Domestic escalator

A domestic escalator used by laying it on existinig stairs is composed of carriage, handrail, track, steel cable, electric motor and control cabinet. The front end of treadle on the carriage is pivoted with the lower bottom plate. Its rear end has supporting sleeve tubes on the bottom to sleeve around the vertical columns on the bottom plate and move up and down. The track bearing and anti-skew bearing are arranged on the bottom plate. Said carriage moves along the stairs under the drive of motor and steel cable.

Owner:姚家庚

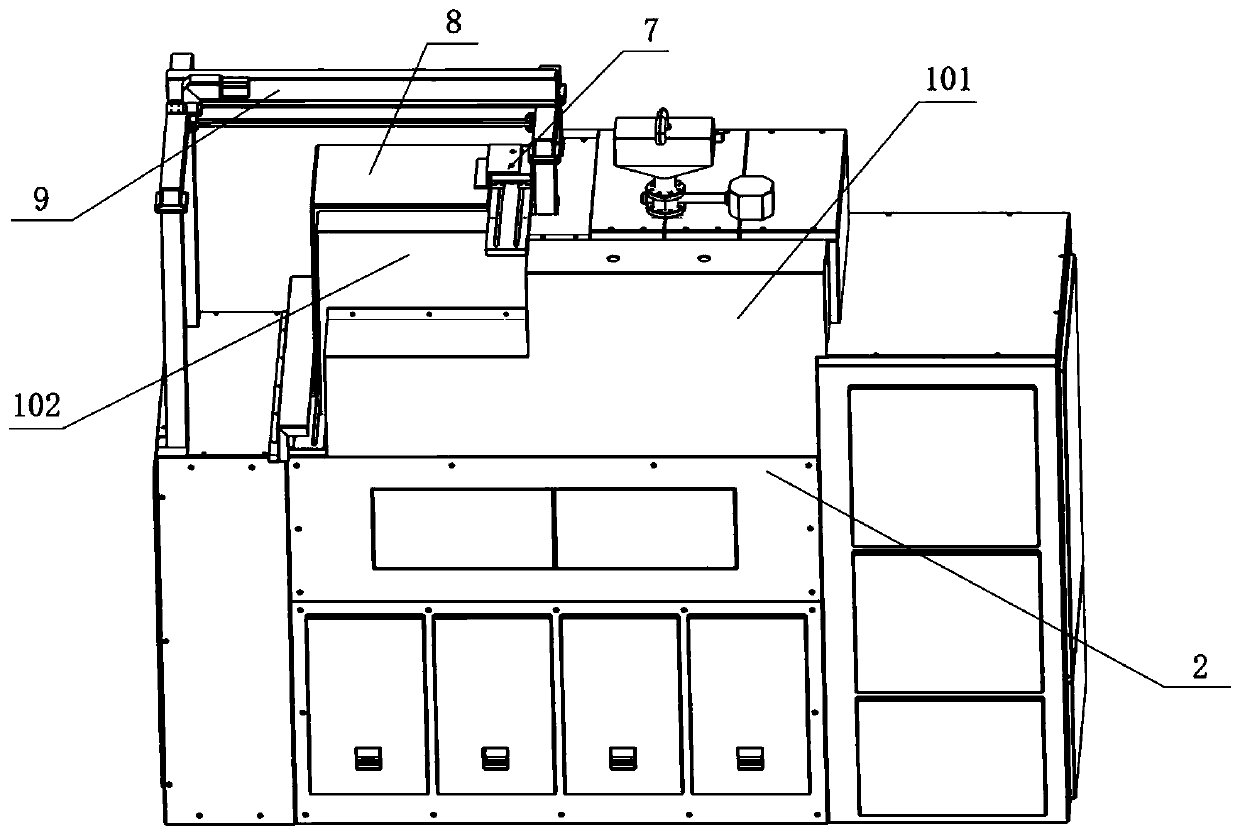

Workbench transferring and conveying system used for large-sized SLM equipment

ActiveCN111268411AEasy PickupImprove manufacturing precisionControl devices for conveyorsWorkspaceWorkbench

The invention relates to a workbench transferring and conveying system used for large-sized SLM equipment. The workbench transferring and conveying system is used for conveying a workbench and comprises a frame, a shell, a workbench driving device, a workbench leveling device and a power source for supplying power to the whole system, wherein the frame body comprises a working area and a part collecting area, the workbench driving device is connected with the frame and the workbench separately and is used for driving the workbench to move between the working area and the part collecting area,the shell is connected with the frame body, and the workbench leveling device is connected with the workbench. Compared with the prior art, the workbench transferring and conveying system meets the requirement of the SLM equipment for airtightness during operation, and has the advantages that part collecting is facilitated, the structure is stable and reliable, and the working efficiency is high.

Owner:EAST CHINA UNIV OF SCI & TECH

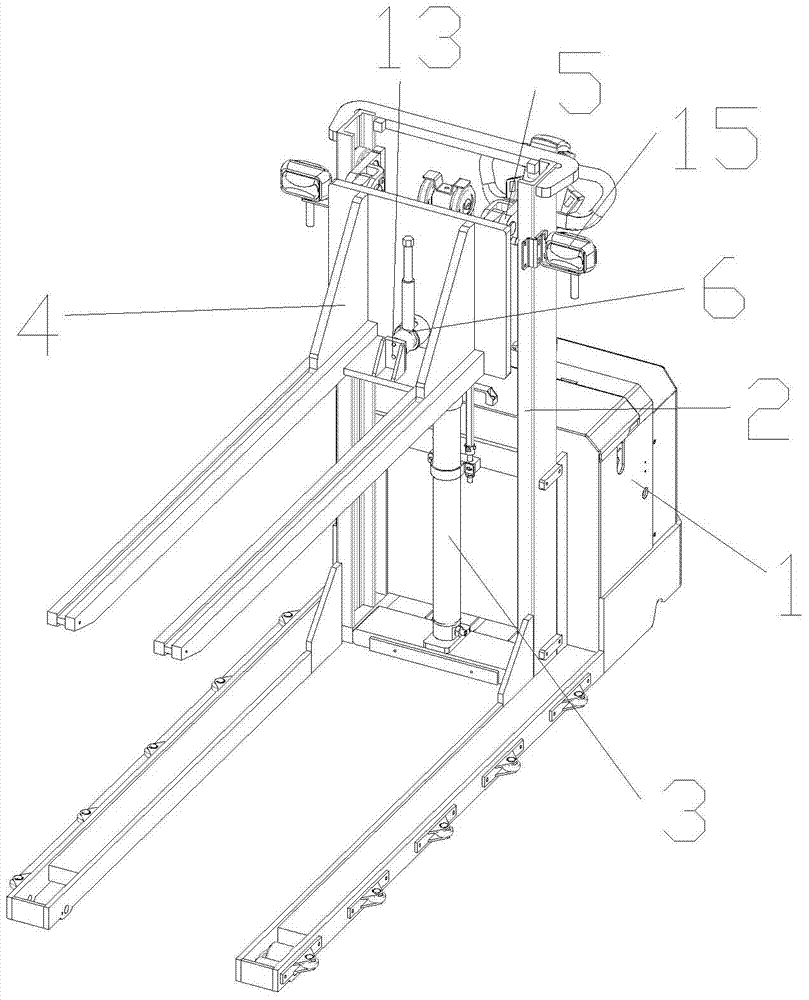

A quartz tube stacker

The invention discloses a quartz tube stacking truck, which comprises a vehicle frame. The front frame of the vehicle frame is connected with a fork front frame through a middle cylinder assembly, and the top of the fork front frame is connected with the door by a hinge. The quartz tube stacker is also equipped with a jack on the front frame of the fork, and the jack can reversely push the door frame during work, so that the front frame of the fork can rotate around the hinge connected to the door frame. Rotate, and then achieve the effect of adjusting the angle of the front frame of the fork. During the use of the present invention, the fork front frame provided on the door frame is suitable for transfer during the firing process of quartz tubes, and the fork front frame can be lifted by the jack provided on it. The fine adjustment of the angle can ensure the horizontal position of the quartz tube to be transferred and the quartz furnace, so as to avoid the occurrence of the quartz tube being damaged during the process of transferring the quartz tube.

Owner:SUZHOU PIONEER MATERIAL HANDLING EQUIP & TECH

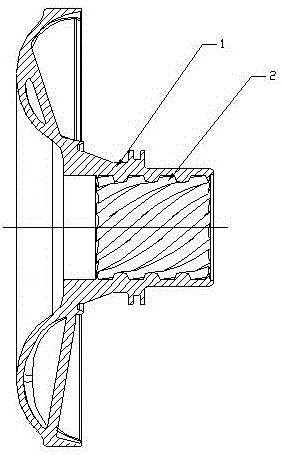

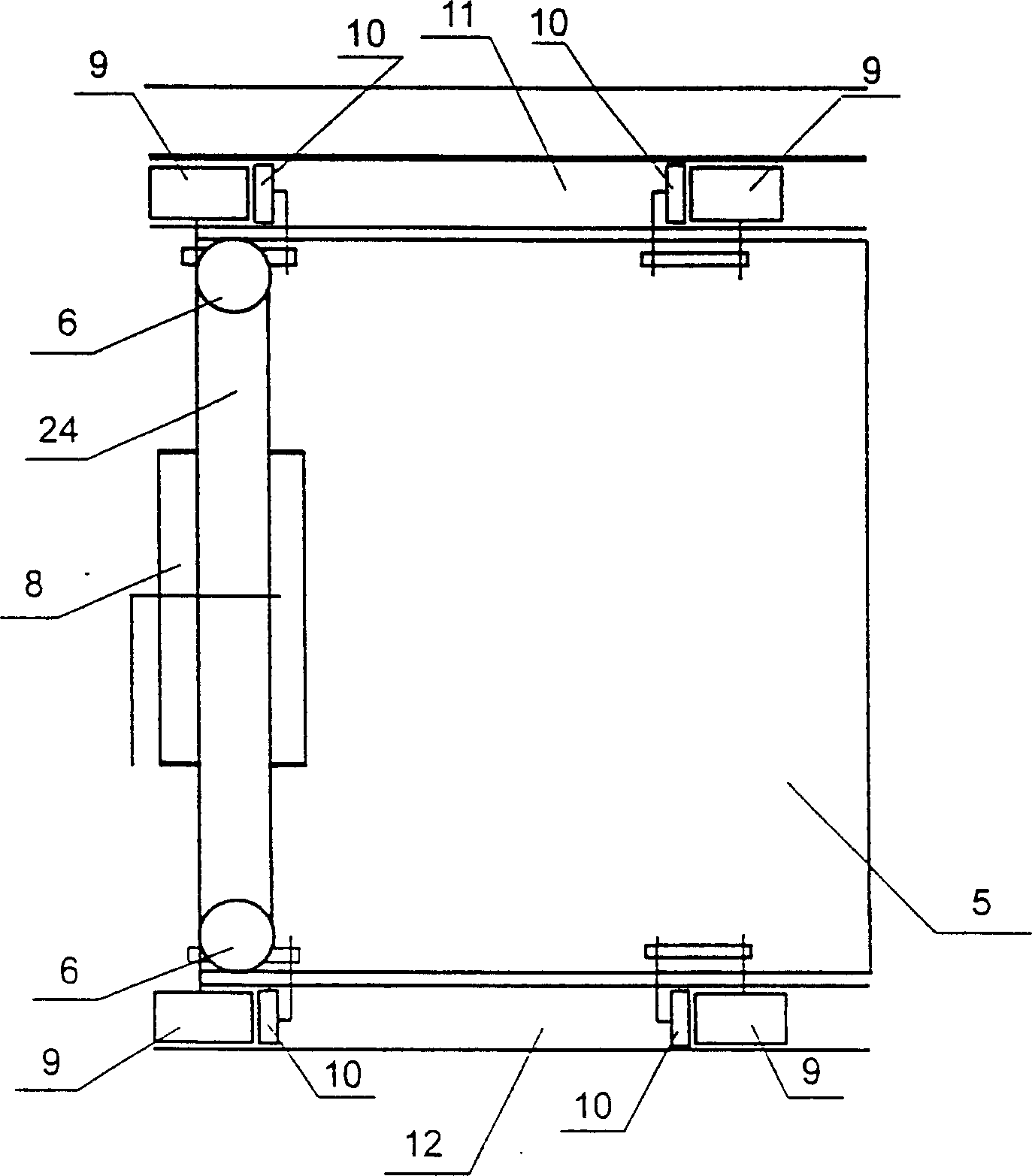

Single board automatic feeding machine

ActiveCN104891225BGuaranteed horizontal positionNovel structureArticle feedersFixed frameControl system

The invention discloses an automatic veneer feeding machine, which is characterized in that it comprises a fixed frame, a turning lever, a control system, a turning cylinder, a rotating shaft, a suction cup support, a lifting cylinder, a vacuum suction cup, a moving cylinder, an induction support, a contact roller, a contact Switch, fixed guide rail frame and sliding sleeve, the fixed frame is composed of outrigger frame and connecting rod, one side of the outrigger frame is connected by connecting rod, the two ends of the other side are respectively hinged with the flipping rod, one end of the flipping cylinder is connected with the connecting rod, and the other One end is connected with the turning rod, and the other end of the turning rod is connected with the fixed guide rail frame. One end is connected with the sliding sleeve, and the two sides of the sliding sleeve are respectively provided with suction cup brackets. The lifting cylinder is fixed on the suction cup bracket, and the lower end of the lifting cylinder is connected with the vacuum suction cup. It has novel structure, high work efficiency, low labor intensity, high degree of automation and easy operation. advantages of stability.

Owner:SHANDONG BAISHENGYUAN GRP

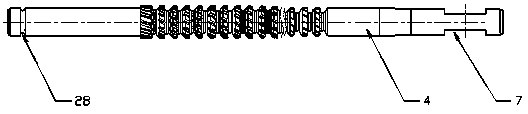

Hoisting, positioning and lubricating structure of reciprocating pump high-precision rack hole machining boring rod

PendingCN114054793AGuaranteed horizontal positionBoring barsMaintainance and safety accessoriesStructural engineeringMechanics

The invention discloses a hoisting, positioning and lubricating structure of a reciprocating pump high-precision rack hole machining boring rod, and relates to the field of petroleum engineering equipment. The hoisting, positioning and lubricating structure specifically comprises a lifting appliance, a boring rod, a copper sleeve part, a rack, a rack hole machining clamp, a cavity between an end cover and a copper sleeve, a lifting hole, an outer circle, a positioning outer circle, an oil inlet channel, an oil return channel, a friction inner hole, various copper sleeve part positioning and mounting holes and a copper sleeve part positioning and mounting hole gland. By adopting the hoisting, positioning and lubricating structure of the reciprocating pump high-precision rack hole machining boring rod, when the high-precision rack hole is machined, the boring rod and a copper bush part on the boring rod can be horizontally hoisted, so that the hoisting time for replacing the position of a machining hole is shortened easily through a compact hole space of a rack structure; the copper sleeve part is convenient to position and high in positioning precision, and the accurate position of the boring rod is guaranteed; and the outer circle of the boring rod and the friction inner hole of the copper sleeve part as a friction pair are fully lubricated, so that the service life of the friction pair can be prolonged.

Owner:黄秀芳

Hub ventilation and heat dissipation device

PendingCN113187654AGuaranteed horizontal positionGuaranteed to workShaftsMachines/enginesRotational axisThermodynamics

The invention provides a hub ventilation and heat dissipation device. The hub ventilation and heat dissipation device comprises a hub, wherein a wind wheel shaft is fixedly installed at the back side of the hub; an air inlet groove is formed in the windward side of the hub; a gravity offset ring is movably installed in the air inlet groove through an offset bearing; an air inlet hole passing through an S-shaped air inlet channel is formed in the side edge of the rotating axis of the gravity offset ring; an annular air inlet groove is formed in the hub; the air inlet hole communicates with the annular air inlet groove; the annular air inlet groove communicates with a plurality of induced draft ducts arranged in a hub interlayer; an annular air outlet groove matched with the air outlet hole is formed in an air outlet ring; and an air return pipe is fixedly installed at the bottom of the air outlet ring. Through the arrangement of the gravity offset ring and the interlayer ducts in the hub, atmospheric precipitation is effectively prevented from entering the hub, and the interior of the hub is actively cooled through wind energy, so that the energy consumption of equipment is reduced, normal work of connecting parts in the hub is guaranteed, and the heat dissipation effect is improved.

Owner:中广核新能源蚌埠有限公司

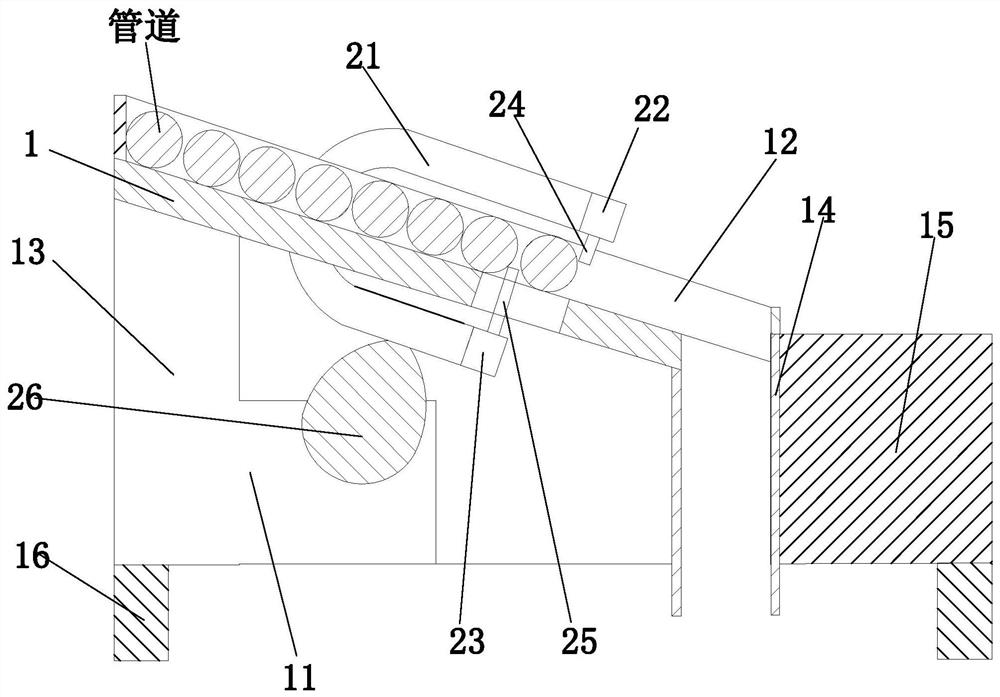

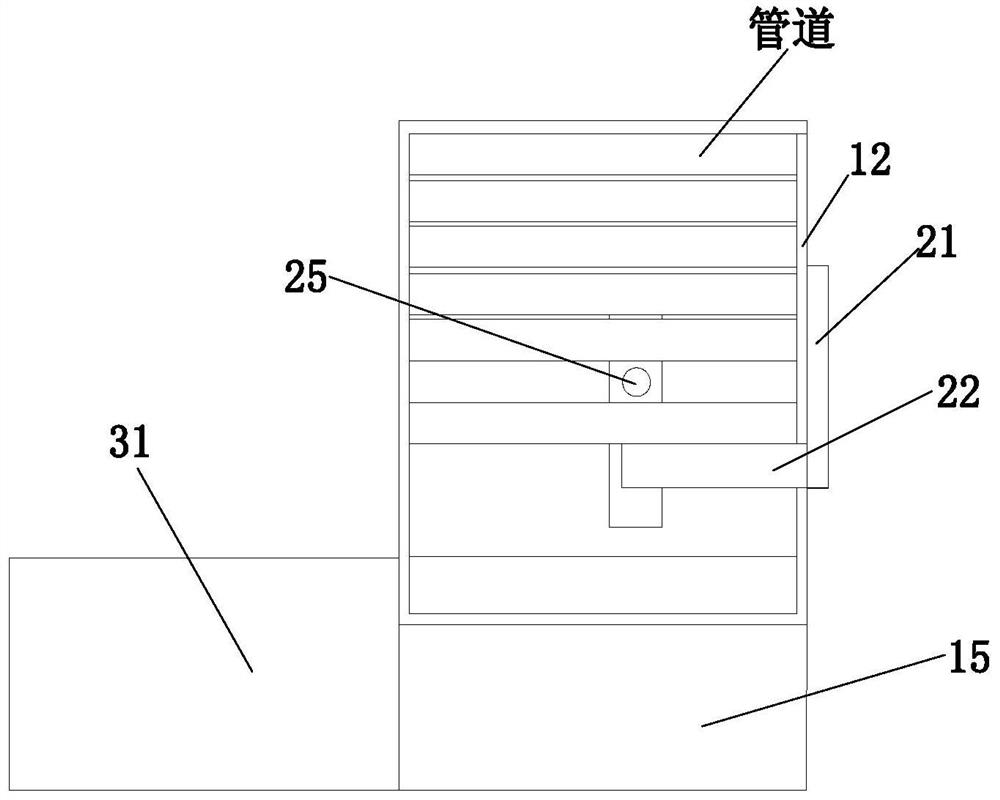

Intelligent construction equipment for long-distance energy pipelines

ActiveCN111810716ASame distanceConvenient docking workPipe laying and repairButt jointCivil engineering

The invention relates to intelligent construction equipment for long-distance energy pipelines. The intelligent construction equipment comprises a mounting frame, a falling device and a butt joint device, the falling device is installed on the rear end face of the mounting frame through a pin shaft, and the butt joint device is installed on the front end face of the right side of the mounting frame. The intelligent construction equipment realizes the function of rolling-down of the pipelines one by one through the falling device, so that it is ensured that the distance between the pipelines isconsistent; and an adjusting mechanism of the butt joint device can adjust the up-down moving distance of a clamping mechanism according to the different heights of the two pipelines, so that it is ensured that the horizontal positions of the two pipelines correspond with each other when the two pipelines are clamped, butt joint work of the two pipelines is facilitated, and thus the working efficiency is greatly improved.

Owner:江苏优霸五金工具有限公司

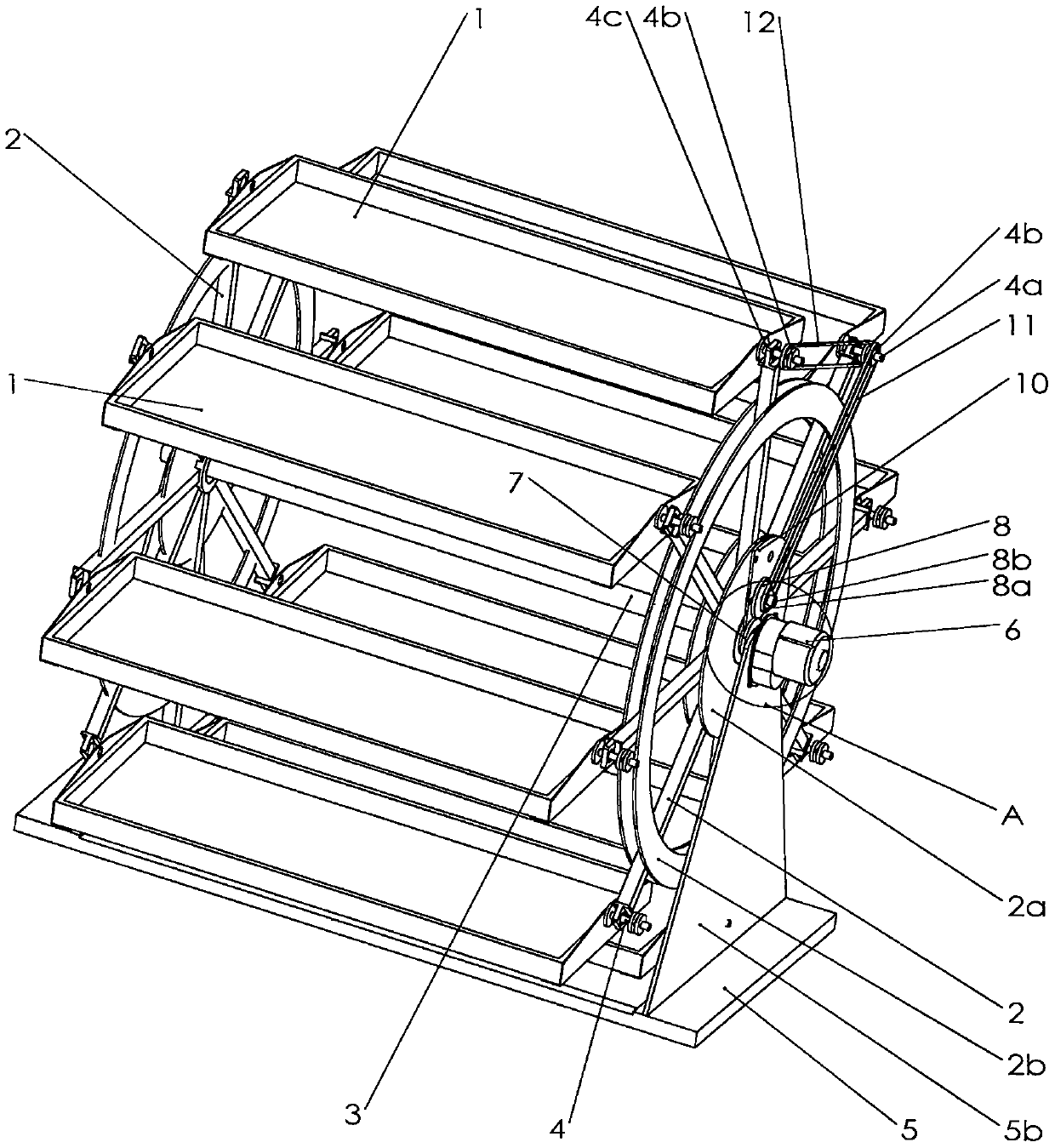

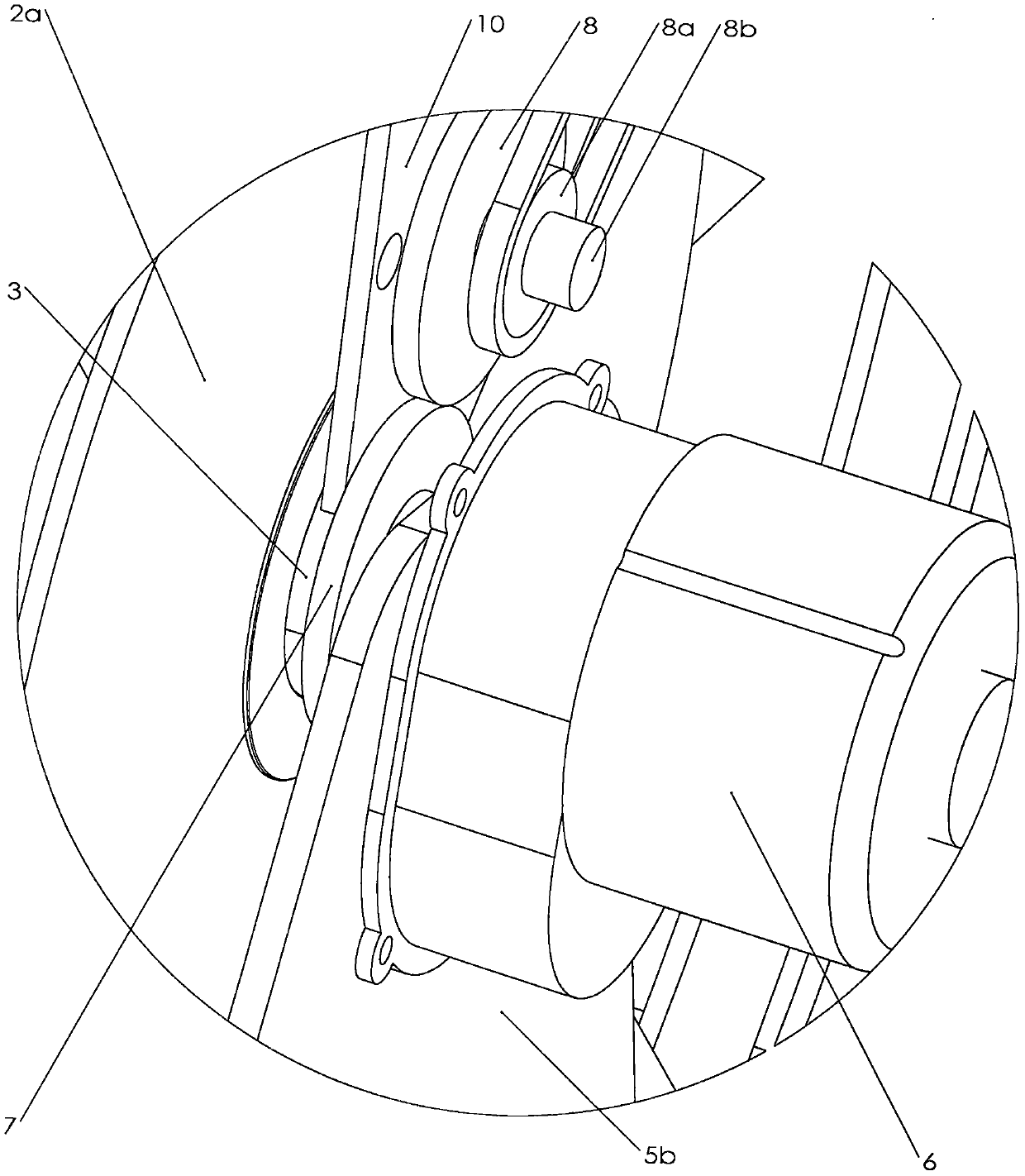

Cage rotating aerial planting method and device thereof

InactiveCN107683726AGuaranteed level statusMake up for the deflection angle problemRoof improvementClimate change adaptationCouplingEngineering

The invention discloses a cage rotating aerial planting method and device thereof. The cage rotating aerial planting method and device distribute and unfold more artificial planters to the air and rotate them. The cage rotating aerial planting method and device have the following advantages: 1. it is possible to obtain much larger planting area than the actual surface area occupied by the device designed according to the method; 2, since the planters can be rotated in the air, all the planters can receive uniform sunshine; 3, the cage rotating aerial planting method and device are extremely easy to manage. The main components of the cage rotating aerial planting device designed according to the method include a base, a base center support, a bracket, a drive system, a coupling head, and platform-type or cylindrical planters. The cage rotating aerial planting equipment is characterized in that the bracket is connected with each platform-type or cylindrical planters through the couplinghead to form a cage form. Cage form integral elements are in a revolution relationship with the base center support element. The planter element is in a revolution relationship relative to the cage form elements through the coupling head. The aerial planting method is of great benefit not only for the settlement of planting in tall buildings, roofs and community and ecological landscape planting in parks, but also for improving the living environment of human beings and providing a new ecological space for human survival and sustainable development.

Owner:徐爱华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com