Machining method for impeller of hydraulic retarder of heavy truck

A technology of hydraulic retarder and processing method, which is applied in the field of auto parts processing, can solve the problems of helical tooth 2 deviation, product scrapping, troubles, etc., achieves convenient installation and disassembly, ensures processing accuracy, and avoids product scrapping or two The effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

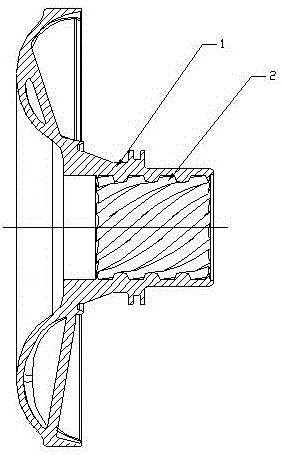

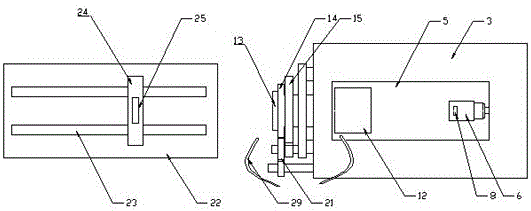

[0037] Such as Figure 2-Figure 7 Shown is a special processing mechanism for the processing of the impeller of the hydraulic retarder of the truck, including

[0038] A processing frame 3, processing components are installed on the processing frame 3, the processing components include

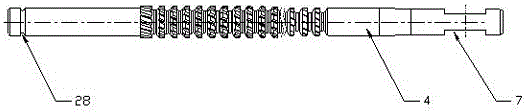

[0039] A broach assembly, the broach assembly includes a helical broach 4, on the upper end of the processing frame 3 there is a groove 5 for the helical broach 4 to reciprocate in the horizontal direction, and at one end of the processing frame 3 there is a The through hole through which the helical broach 4 passes and communicates with the groove 5 has a pull rod 6 extending into the groove and connected with the helical broach 4 through a quick loading and unloading structure at the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com