Polyurethane film winding equipment and using method

A technology of polyurethane film and equipment, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of poor winding effect and achieve the effect of increasing stability and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

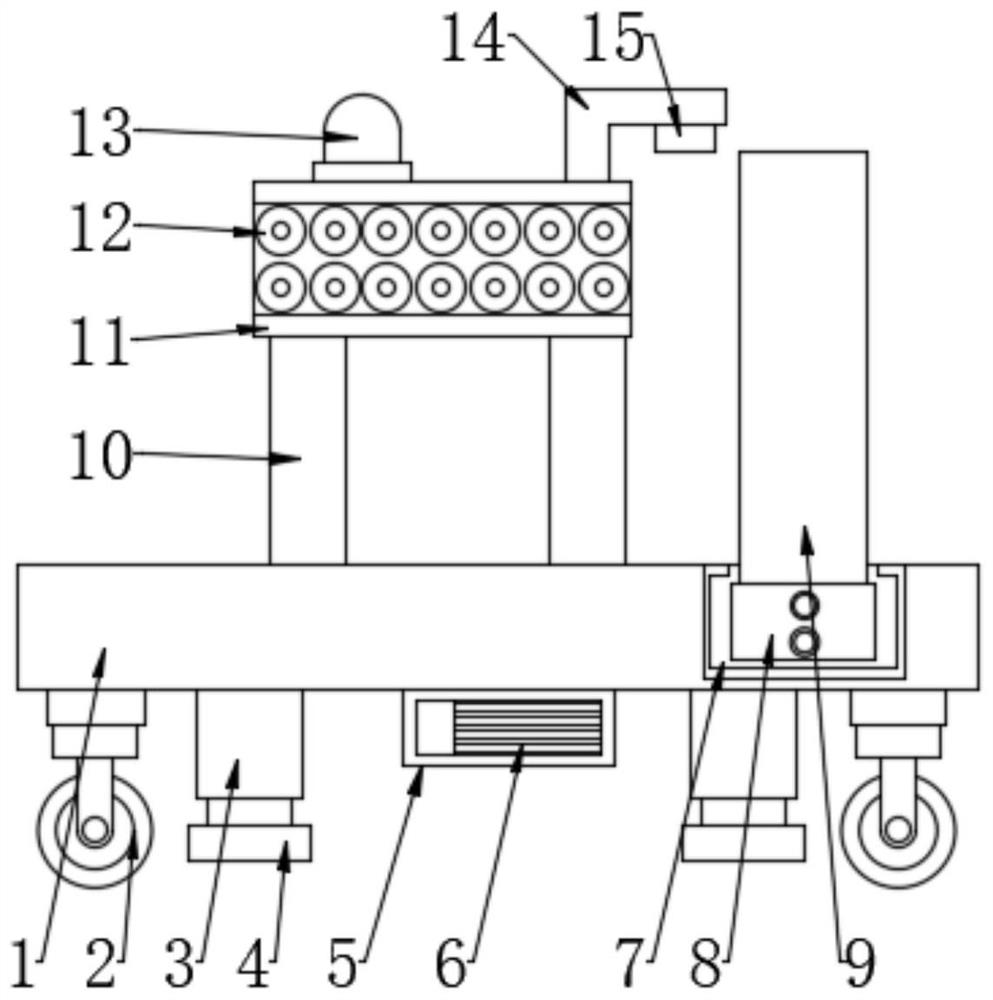

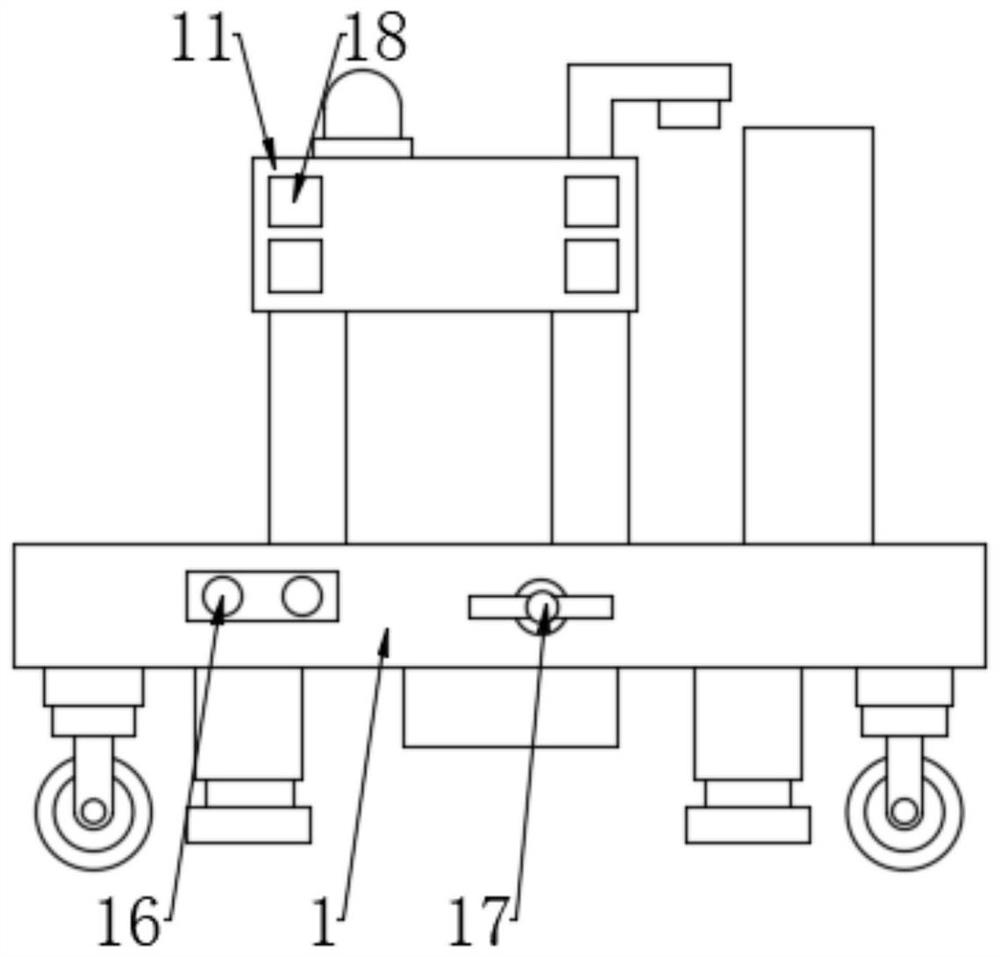

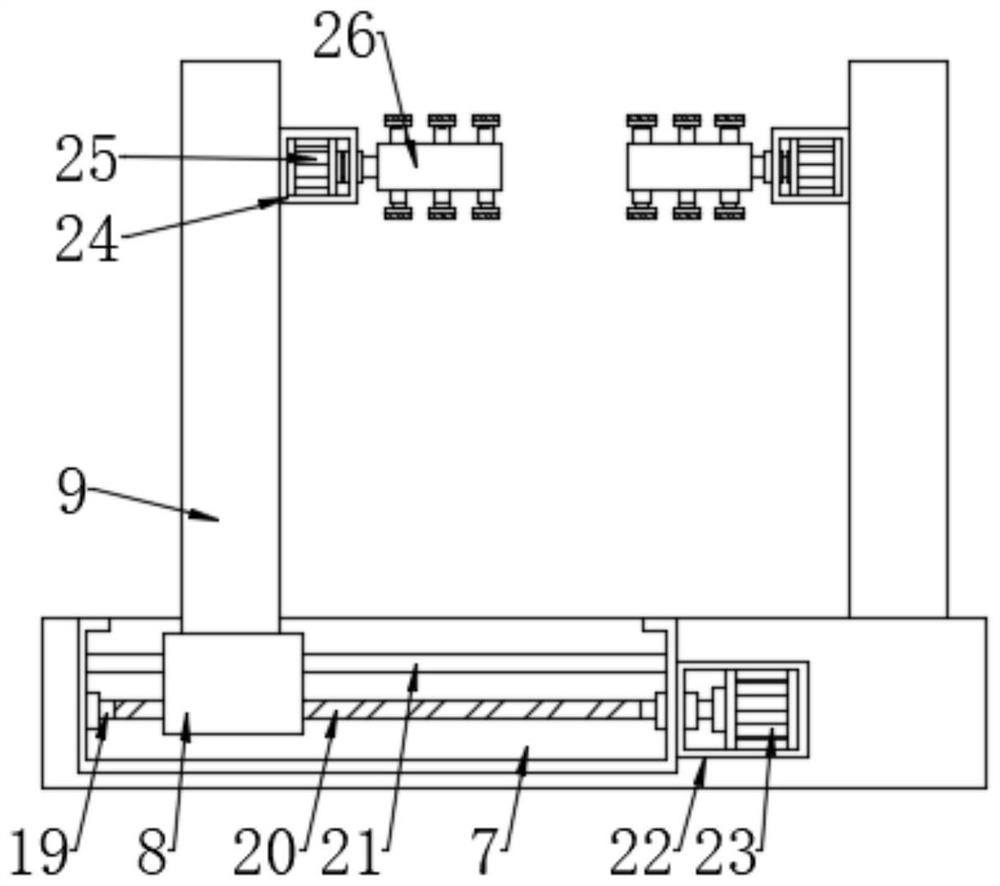

[0033] see Figure 1-6 , the present invention provides the following technical solutions: a polyurethane film winding equipment and use method, including a moving plate 1, the top of the moving plate 1 is fixedly connected with a transmission cabin 11 through a vertical plate 10, through the transmission cabin 11, the film can be rolled When the film is protected, the film can be prevented from breaking due to external factors. At the same time, the transmission angle of the film can be limited to prevent the film wound on the material roller from being very messy. The transmission cabin 11 is provided with a transmission wheel 12 through bearings and axles. The wheel shaft of the transmission wheel 12 is fixedly connected with a gear 28, and the gears 28 are meshed and connected by a tooth chain 29. The surface of the transmission cabin 11 is fixedly connected with a first motor box 18, and a third rotating motor is fixedly connected in the first motor box 18. 27. The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com