Plastic film winding mechanism

A technology of plastic film and winding mechanism, which is applied in the direction of thin material processing, winding strip, transportation and packaging, etc. It can solve the problems of complex structure, removal, inconvenient winding shaft, etc., and achieve winding and keeping tight The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

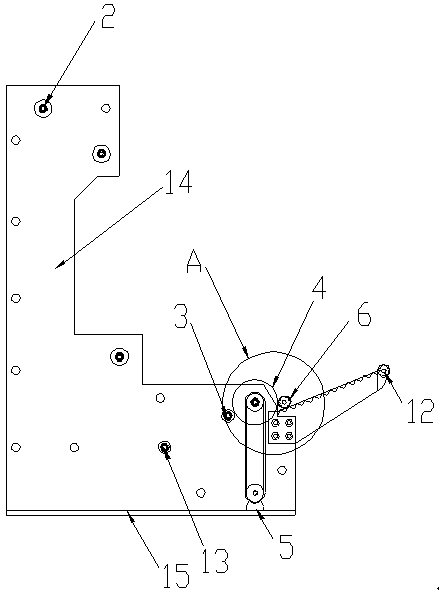

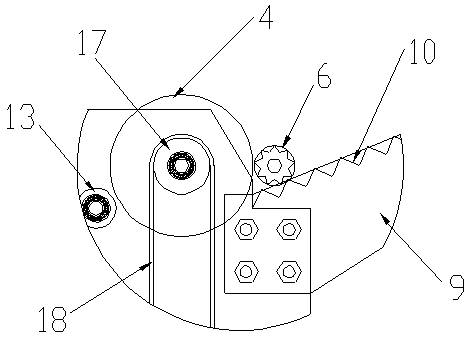

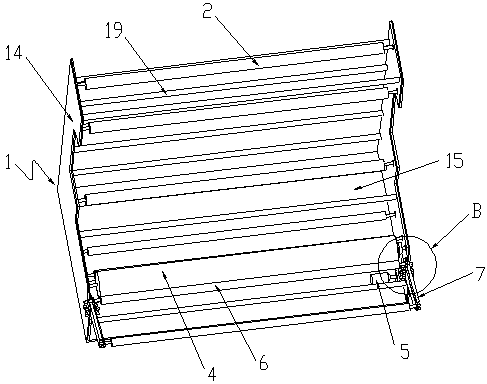

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 The plastic film winding mechanism shown includes a support 1, both ends of which are rotatably arranged on the upper part of the support 1 through bearings (not shown in the figure), and a horizontally arranged first conveying roller 2, both ends of which are rotatably arranged on the support through bearings. 1 The lower part and the second conveying roller 3 arranged horizontally, the driving roller 4 arranged horizontally at the lower part of the support 1 through bearing rotation at both ends, the driving motor 5 used to drive the rotation of the driving roller 4 and the winding roller The winding roller 6 of plastic film, described second conveying roller 3 and winding roller 6 are respectively positioned at the front and back sides of driving roller 4, and the height of second conveying roller 3 is less than the height of driving roller 4, when plastic film winds When the second conveying roller 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com