Device for quickly fixing mooring rope for ship docking

A fast and ship-like technology, applied to ships and other directions, can solve the problems of laborious winding, easily damaged hull, hull buffering, etc., and achieve the effect of improving winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

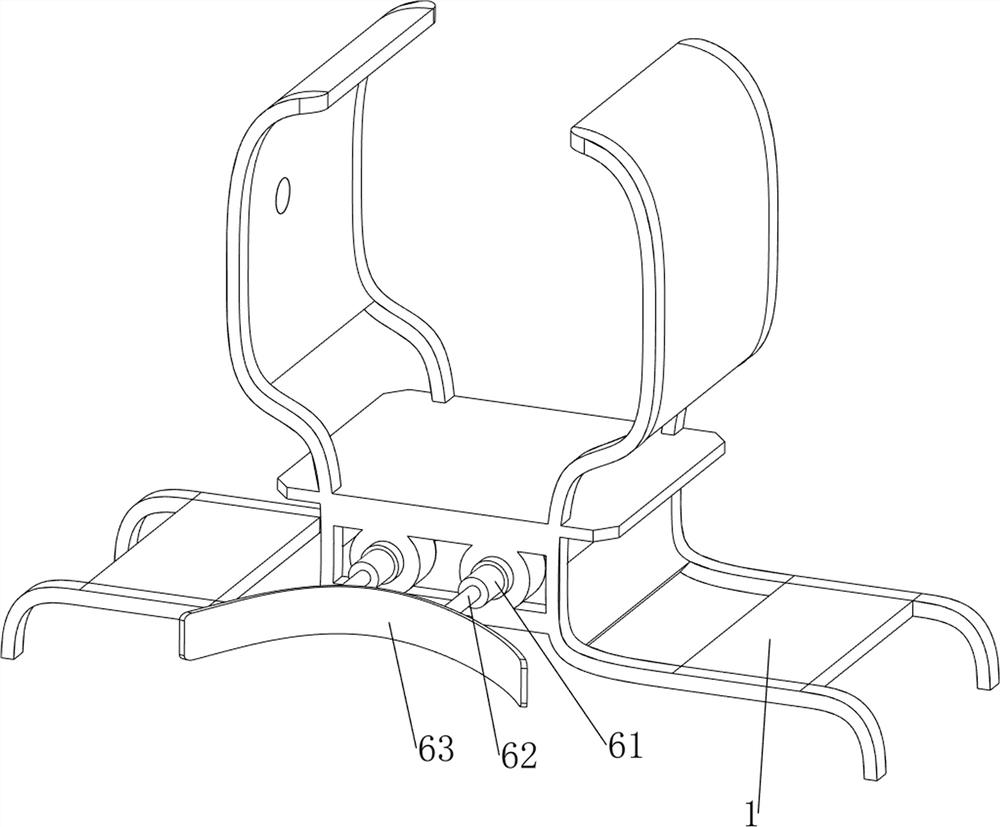

[0070] A device for quickly fixing mooring ropes for berthing ships, such as figure 1 and figure 2As shown, it includes a main frame 1, an expansion bolt 2, a first shaft sleeve 3, a reel 4, a rotating mechanism 5 and a buffer mechanism 6. The lower part of the main frame 1 is provided with an expansion bolt 2 symmetrically sliding on the left and right sides, and the expansion bolt The number of 2 is four, and the middle of the main frame 1 is provided with two first bushings 3, and the upper part of the two first bushings 3 is rotatably provided with a winding wheel 4, and the middle of the main frame 1 is provided with a rotating mechanism 5 , the rotating mechanism 5 cooperates with the reel 4, and the front side of the middle part of the main frame 1 is provided with a buffer mechanism 6.

[0071] When people need to dock the ship, people can place the device in a suitable position, and then people can press the expansion bolt 2 downwards, and the expansion bolt 2 can f...

Embodiment 2

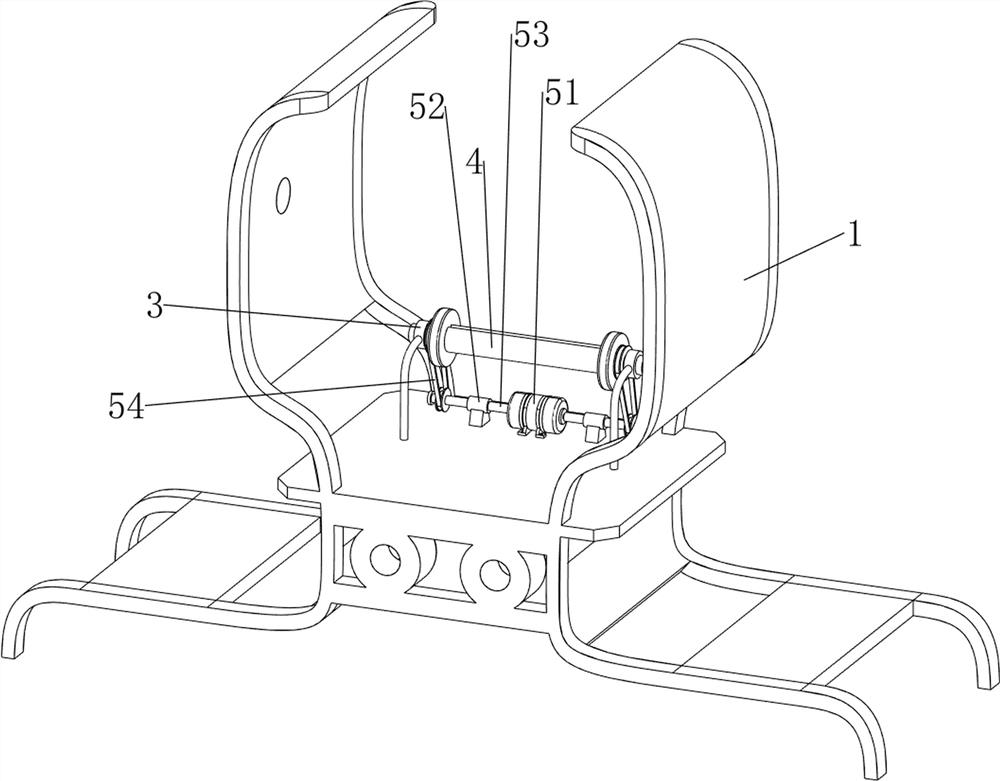

[0073] In a preferred embodiment of the present invention, as Figure 3-Figure 6 As shown, the rotating mechanism 5 includes a double-head motor 51, a second axle sleeve 52, a transmission shaft 53 and a belt assembly 54. Two second shaft sleeves 52, the two second shaft sleeves 52 are equipped with transmission shaft 53 for rotation, the transmission shaft 53 is connected with the output shaft of the double-head motor 51, and the outer sides of the two transmission shafts 53 are connected with the reel 4. Belt assembly 54 is installed, and belt assembly 54 is made up of two pulleys and belt, and a pulley is located on the power transmission shaft 53, and another pulley is located on the reel 4, and belt is wound between two adjacent pulleys.

[0074] When people need to wind up the mooring cable, people can start the double-head motor 51, which can drive the transmission shaft 53 to rotate, thereby driving the belt assembly 54 to rotate, and then can drive the reel 4 to rotat...

Embodiment 3

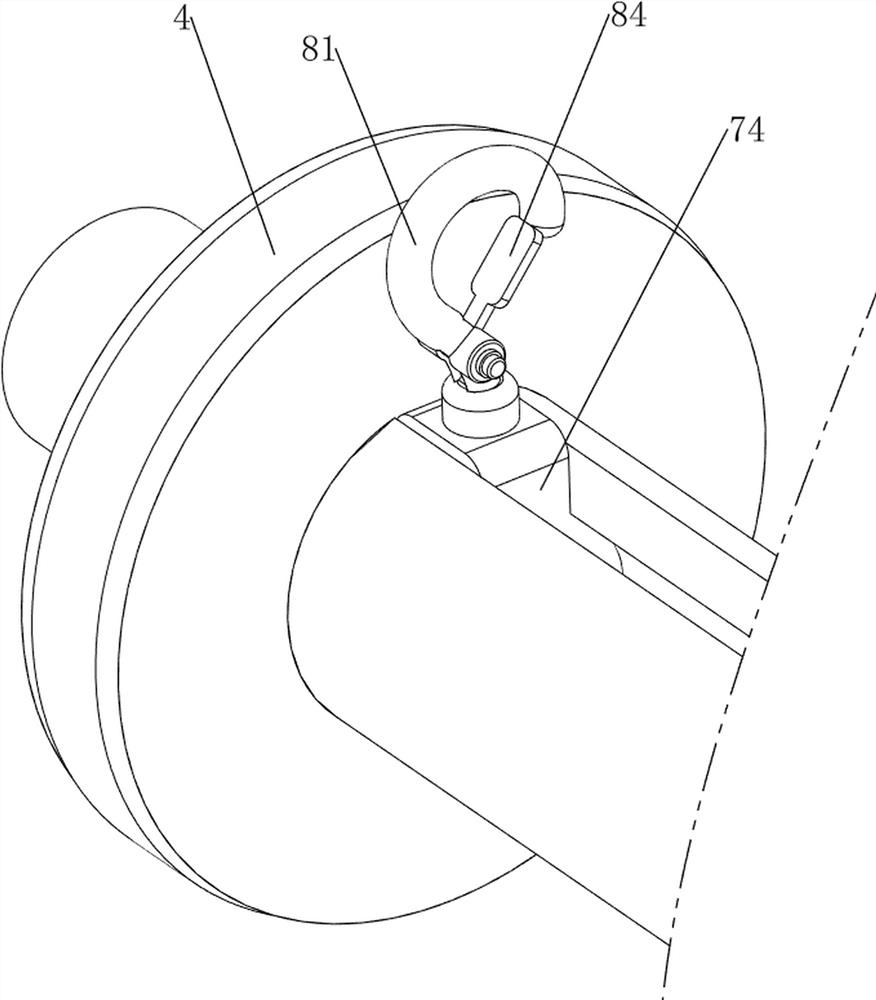

[0078] In a preferred embodiment of the present invention, as Figure 7-Figure 15 As shown, a push mechanism 7 is also included. The push mechanism 7 includes a support frame 71, a screw mandrel 72, a nut 73 and a connecting block 74. The left and right sides of the rear part of the main frame 1 are symmetrically provided with a support frame 71. Two support frames 71 is provided with screw mandrel 72, and screw mandrel 72 is connected with reel 4 penetratingly, and screw mandrel 72 is threaded and is provided with nut 73, and nut 73 is provided with connecting block 74, and connecting block 74 and reel 4 slide formula fit.

[0079] During the winding process of the mooring cable, people can wind the mooring cable around the connecting block 74. When the reel 4 rotates, the reel 4 can drive the connecting block 74 to rotate, and then the nut 73 can be driven to rotate. Motion on screw mandrel 72, and then can drive connecting block 74 to move, thereby just can cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com