A high tensile signal transmission reel cable

A signal transmission, high tensile technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of cable damage, lifting and heavy handling machinery hoisting, frequent dragging, affecting the use of lifting equipment, etc. , to achieve enhanced life, enhanced anti-interference effect, enhanced electrical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

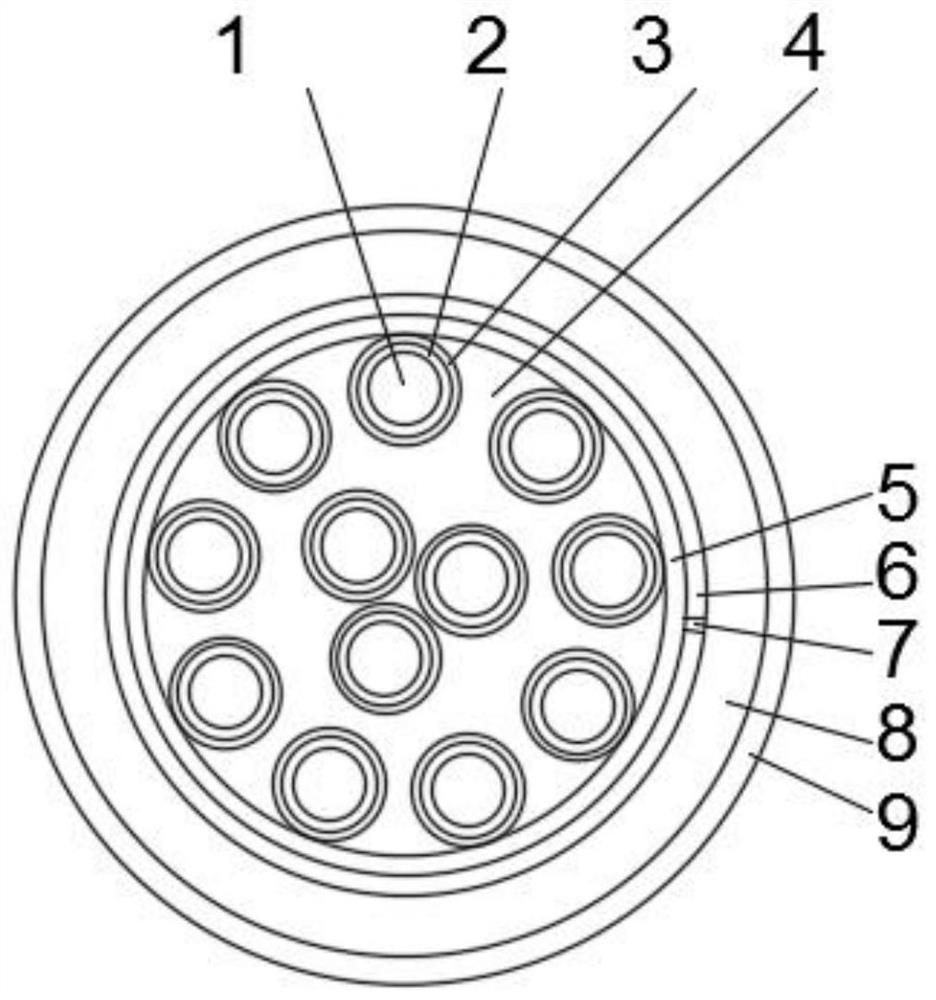

[0037] The preparation method of the cable is as follows: wrap the inner lining layer 5 on the outer side of the cable body, fill the hemp rope 4 between the cable body and the inner lining layer 5, and wrap the shielding layer 6 and the outer protective sheath 8 on the outer side of the inner lining layer 5 in turn. and a steel wire braid 9, and a drain wire 7 is arranged inside the shielding layer 6 to obtain a cable, and the cable is rewound by a rewinding device 11 to obtain a product;

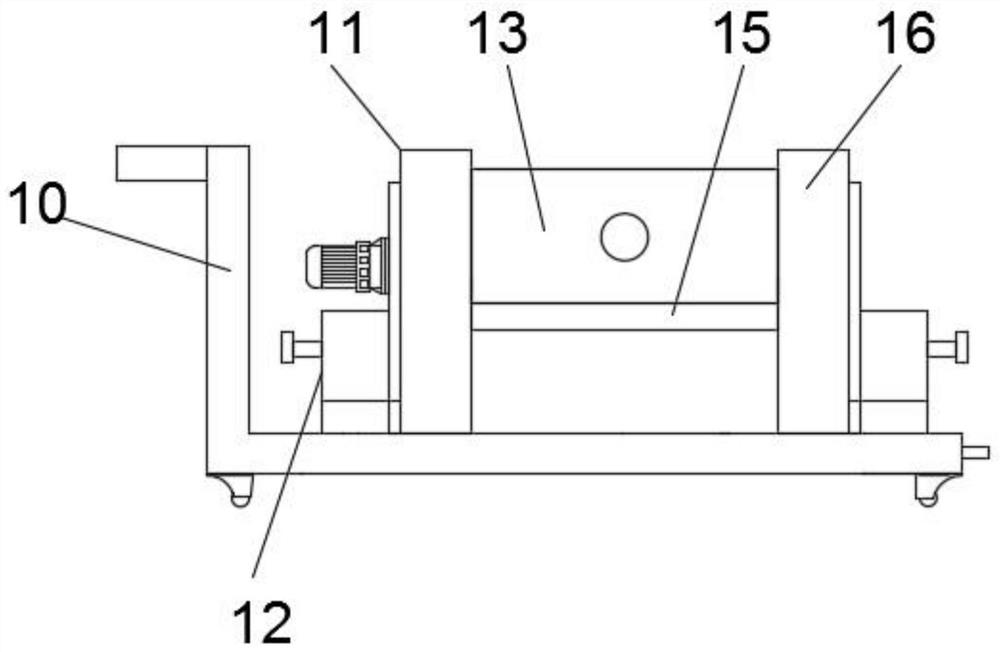

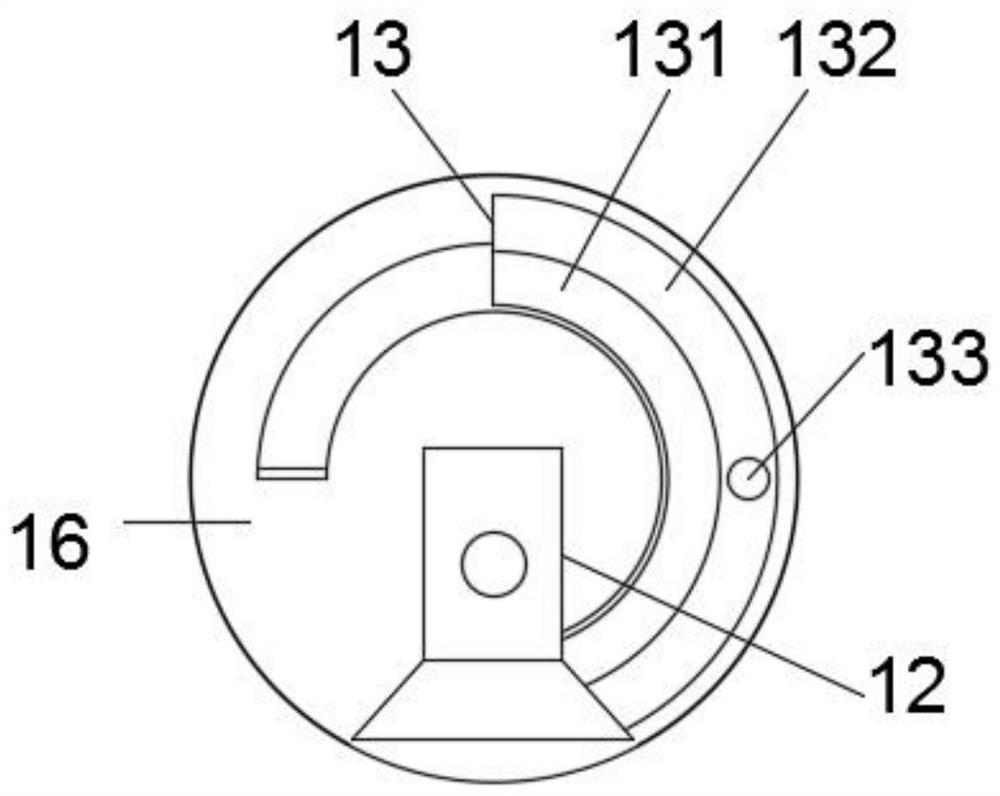

[0038] The winding device 11 includes a drum 15 and a disk 16, and the two ends of the drum 15 are equipped with a disk 16, and the two sides of the winding device 11 are symmetrically provided with a fixing mechanism 12 near the lower end. Winding device 11 is positioned at the upper surface of go-cart 10, and rain-shielding mechanism 13 is installed between two described discs 16, and described rain-shielding mechanism 13 is positioned at the front of cylinder 15, and described rain-shiel...

Embodiment 1

[0045] When performing cable rewinding, slide the rain-shielding mechanism 13 to the front of the drum 15, turn the fixing tube 133, and insert and fix it with the disc 16 through the fixing hole, so as to ensure that the rain-shielding mechanism 13 does not slide when working, and the cable Pass through the inside of the anti-winding mechanism 14, wind on the outer surface of the drum 15, start the motor one 17, drive the rotating shaft 18 to rotate, and then drive the arc plate 19 to rotate, so as to achieve the effect of adjusting the position of the cable winding, and start the motor two at the same time , to drive gear one 20 to rotate, and when gear one 20 and gear three 152 are engaged and connected, drive drum 15 to rotate to wind up the cable;

[0046] Rotate the shaft 126 to drive the second gear 125 to rotate. When the tooth surface of the tooth plate 123 meshes with the second gear 125, the tooth plate 123 is driven to move up and down. The lower housing 124 is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com