Automatic winding machine for steel cable production

A winding machine and automatic technology, applied in the field of steel cable production, can solve problems such as the influence of the service life of the steel cable and the surface corrosion of the steel cable, and achieve the effect of increasing the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

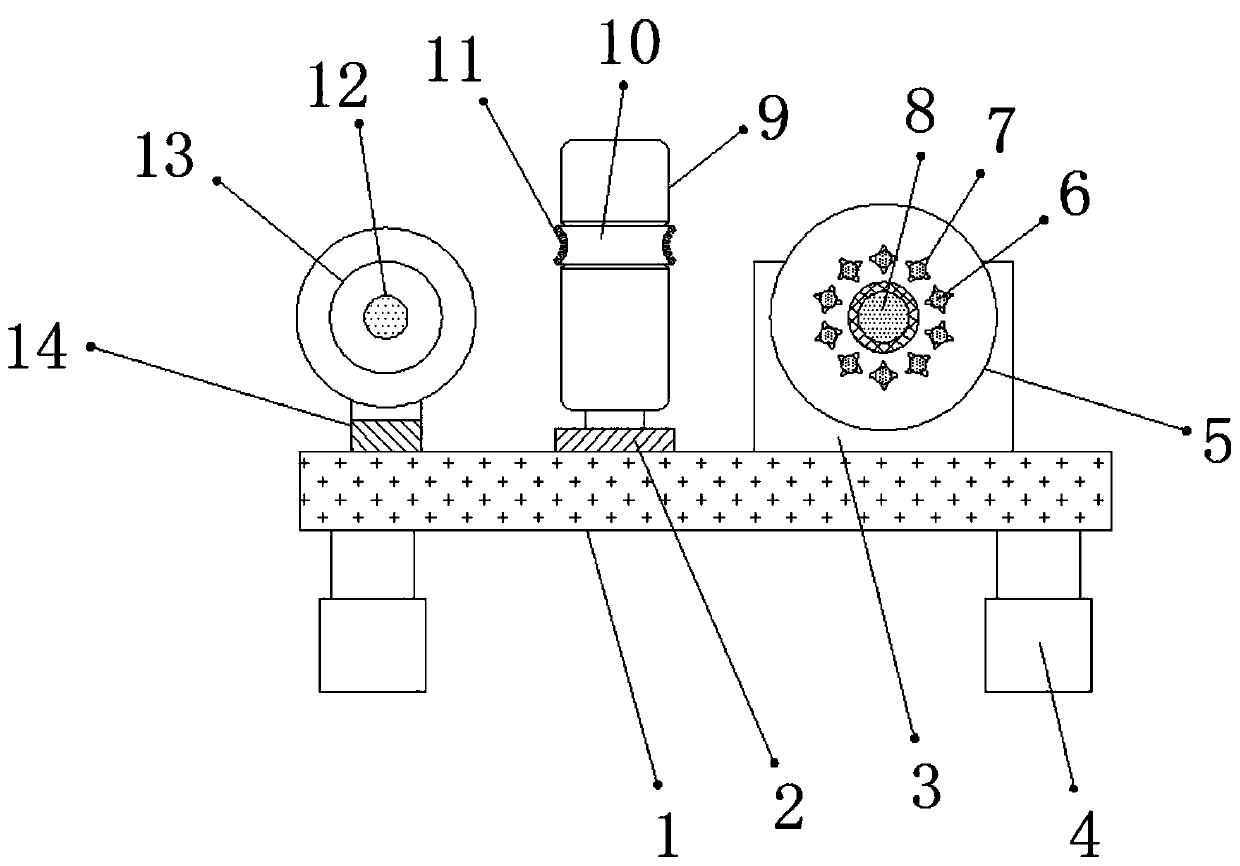

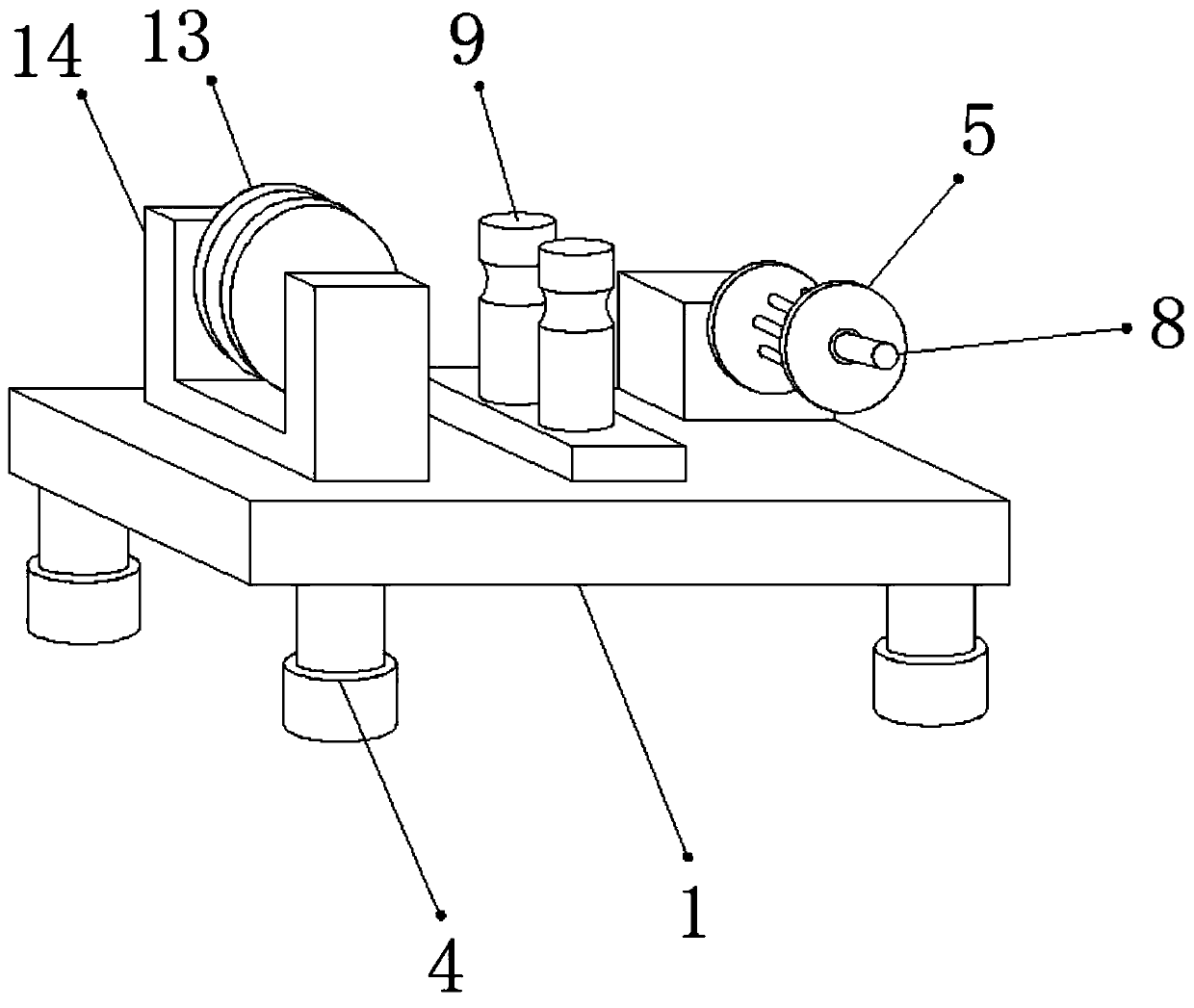

[0026] refer to Figure 1-3 , an automatic winding machine for steel cable production, comprising a fixed seat 1, one side of the outer wall of the top of the fixed seat 1 is connected with a support plate 3 by bolts, and one side of the outer wall of the support plate 3 is connected with a rotating rod 8 through a bearing rotation, and the rotation The outer wall of the rod 8 is sleeved with a winding disk 5, and the outer walls on both sides of the winding disk 5 and the outer walls on both sides of the rotating rod 8 are provided with threaded holes, and the inner walls of the threaded holes are threaded with a fixed bolt 17, and the opposite side of the winding disk 5 The side outer walls are connected with winding rods 6 by bolts, and the outer walls of the winding rods 6 are provided with convex ribs 7 distributed equidistantly. 2 Both sides of the top outer wall are rotationally connected with constraining rollers 9, and the outer walls of the two constraining rollers 9...

Embodiment 2

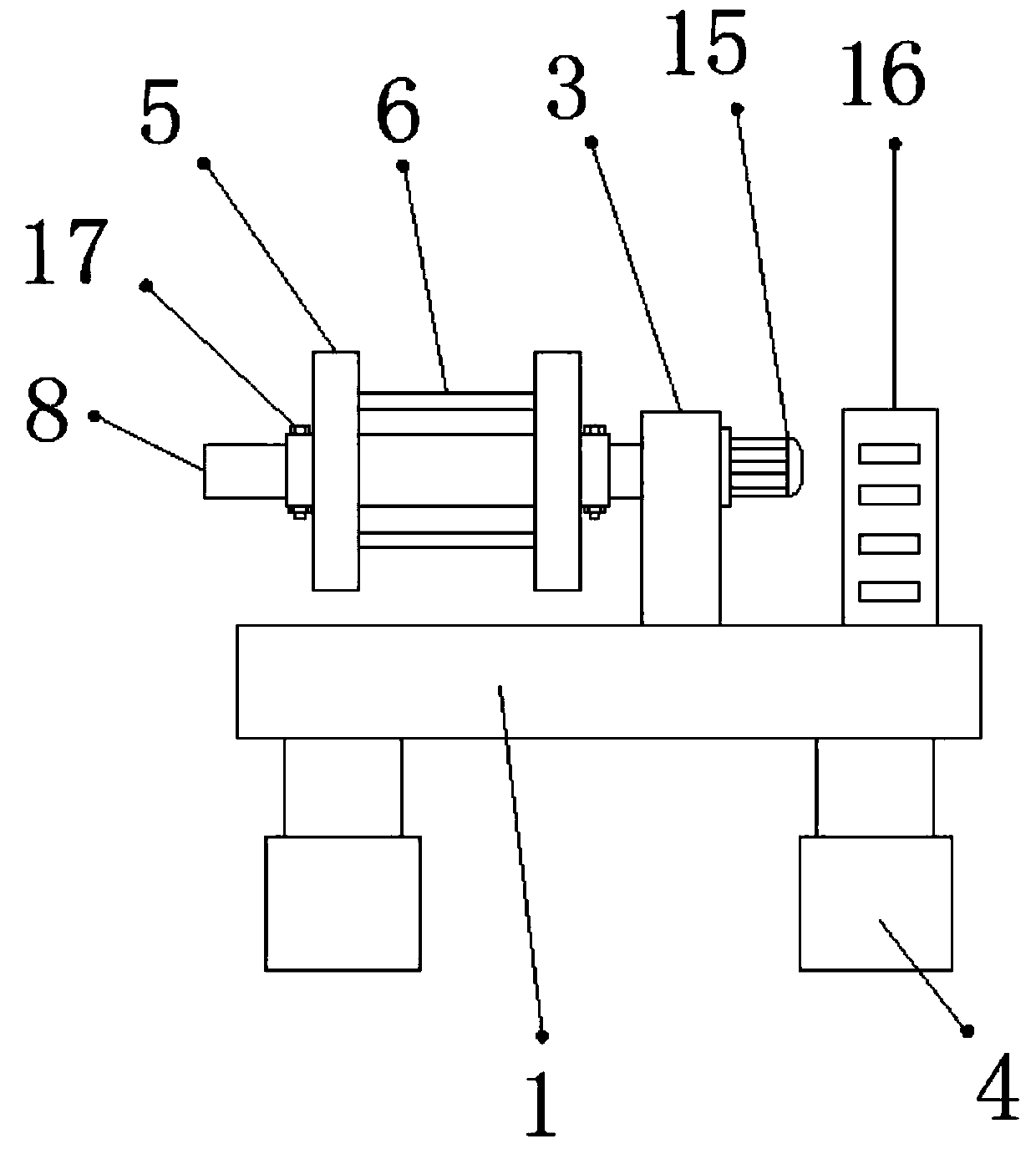

[0030] refer to Figure 4 , an automatic winding machine for steel cable production. Compared with Embodiment 1, the present embodiment has thread grooves on both sides of the top outer wall of the winding disc 5, and the inner walls of the two thread grooves are threaded with fixed pins 19. The outer walls of the two fixing pins 19 are threadedly connected with a constraining plate 18 .

[0031] Working principle: When in use, pass the steel cable through the restraining disc 13 and the restraining roller 9 and wind it on the winding disc 5, turn on the switch, and make the motor 15 drive the rotating rod 8 to rotate through the control box 16, so that the winding disc 5 is on the steel The cable is wound and rolled, and the friction force between the steel cable and the winding rod 6 is increased through the rib 7, so that the steel cable is wound, and the winding disc 5 is prevented from idling due to the relatively smooth surface of the steel cable. , the steel cable will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com