A winding device for plastic pipe extrusion molding

A winding device and plastic tube technology, applied in the direction of thin material processing, transportation and packaging, and delivery of filamentous materials, etc., can solve problems such as loose tubes, external packaging, and relative position of guide rollers that cannot be adjusted. Avoid the effect of accumulation and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

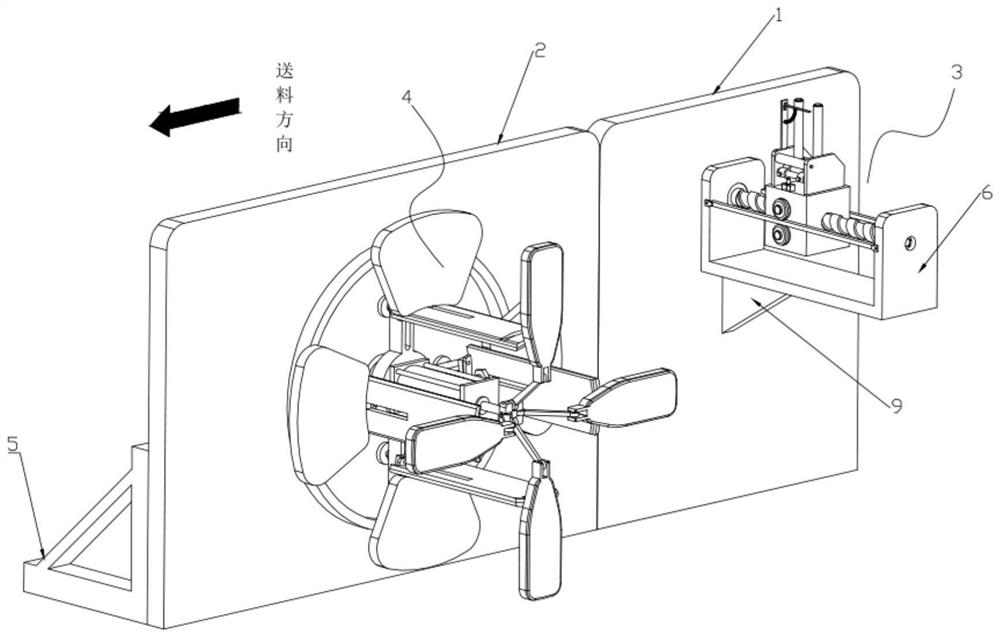

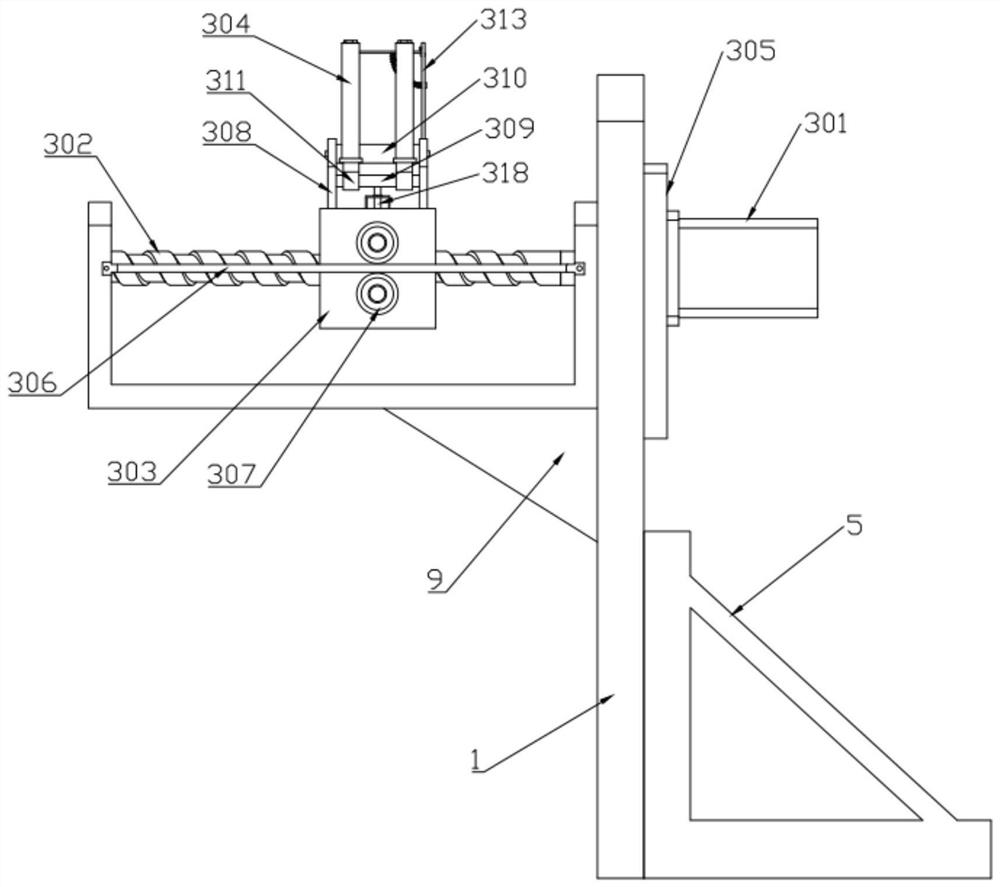

[0023] like Figures 1 to 7 As shown, a plastic tube extruded molded winding device includes a substrate 1, a substrate 2, a conveying mechanism 3, and a winding mechanism 4, the substrate one 1 and the substrate 2 2 fixedly connected in the feed direction, the substrate A fixing frame 5 is fixed to the substrate 1 1 by inverted the "匚" shaped mount 6, and is used to guide the extruded molded plastic tube by an inverted "匚" shaped mounting frame 6. The other end of the substrate 2 2 is provided with a hosted 7, and a bearing 8 is disposed in the housing 8, and the winding mechanism 4 is mounted inside the hosted 7, and is used to wind a extruded plastic tube.

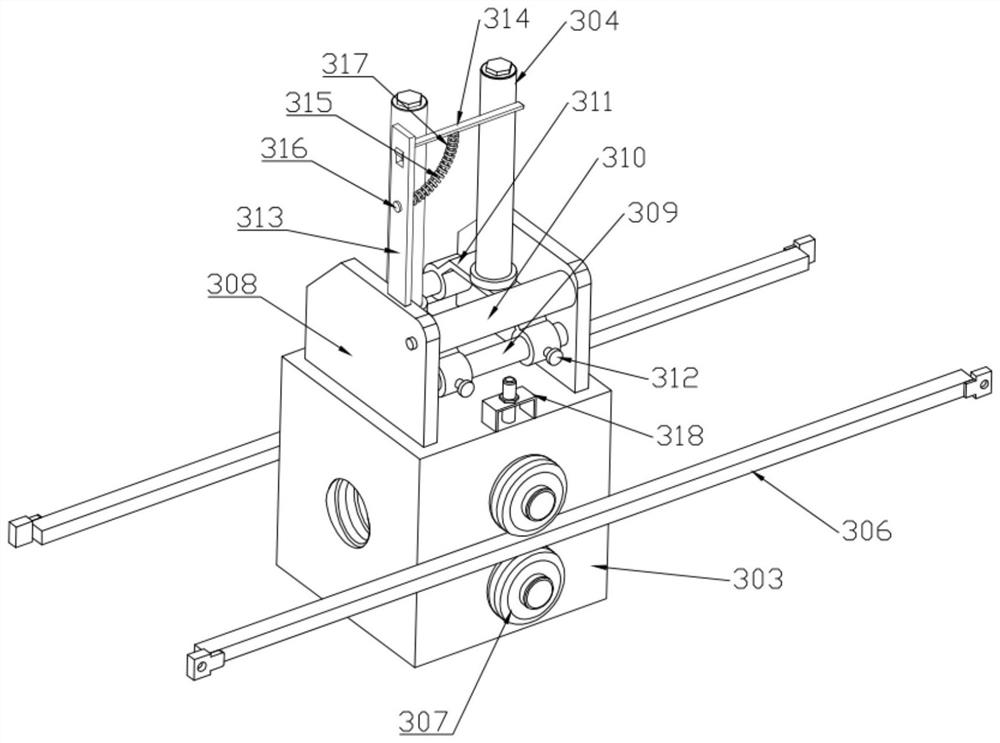

[0024] In the present embodiment, the conveying mechanism 3 includes a driving motor one 301, a lead screw 302, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com