Textile fabric winder

A technology for textile fabrics and winders, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of slow winding speed, loose fabrics, time-consuming and labor-intensive, etc., to reduce the number of winding turns, The effect of speeding up the winding speed and improving the winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

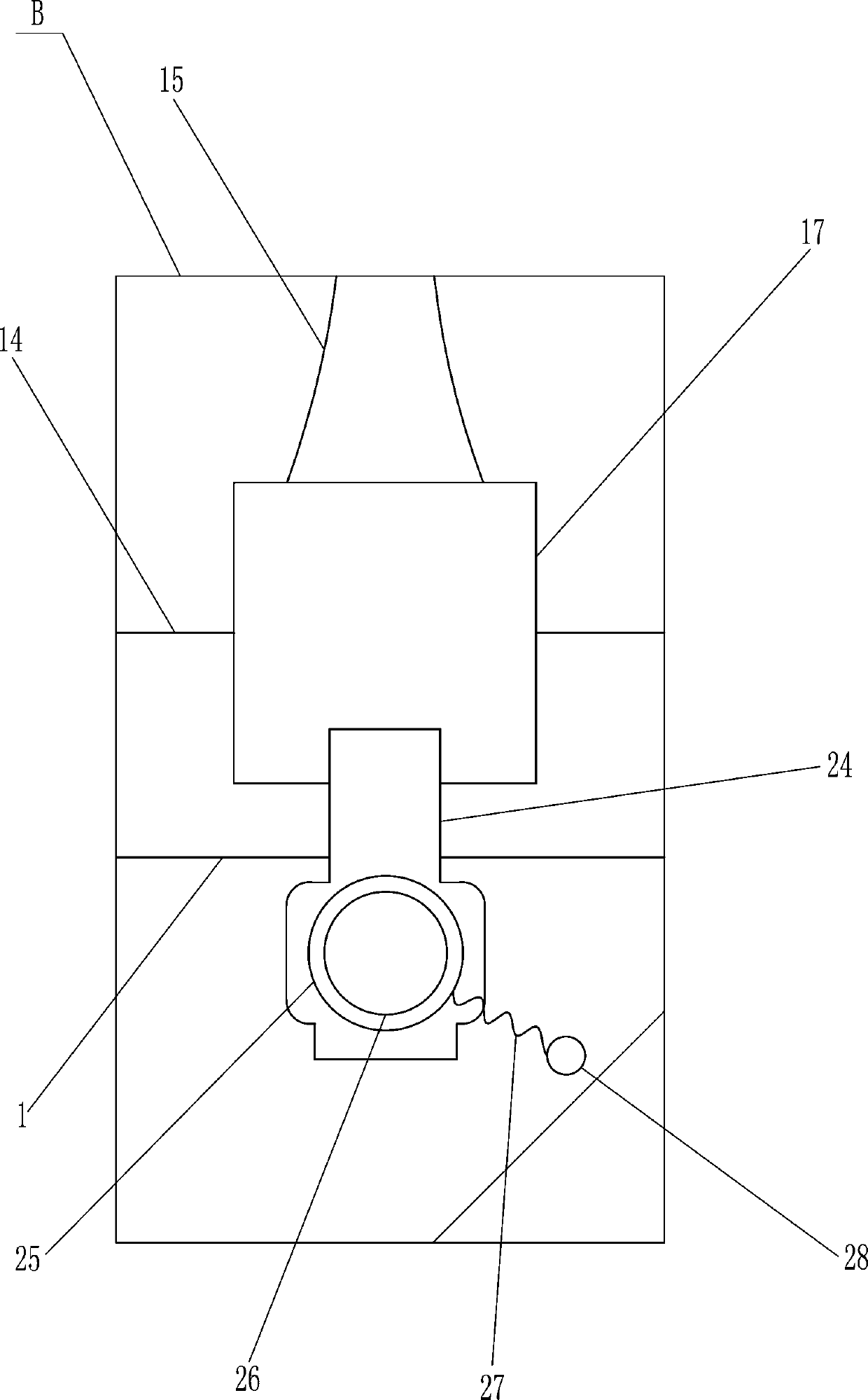

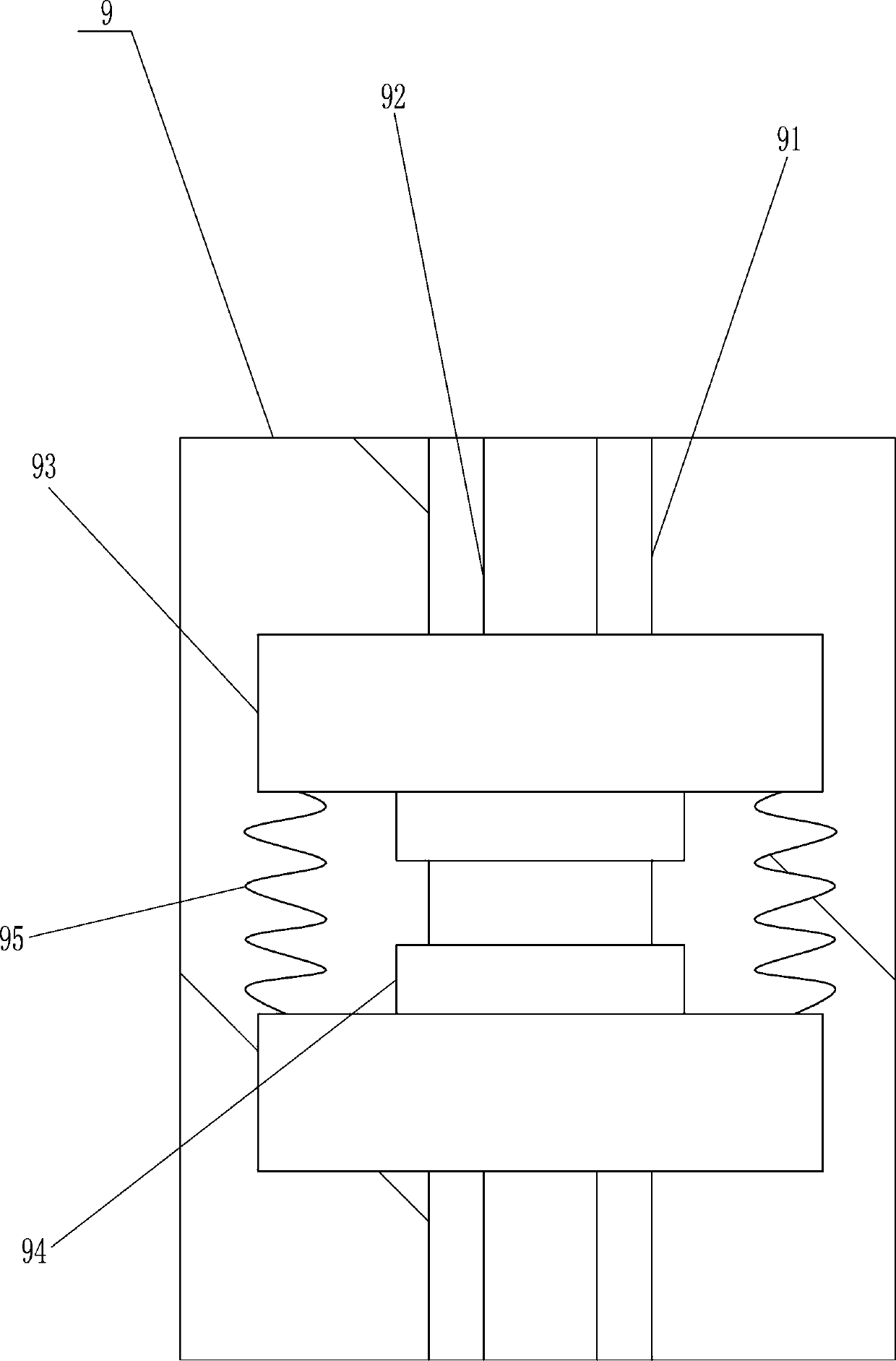

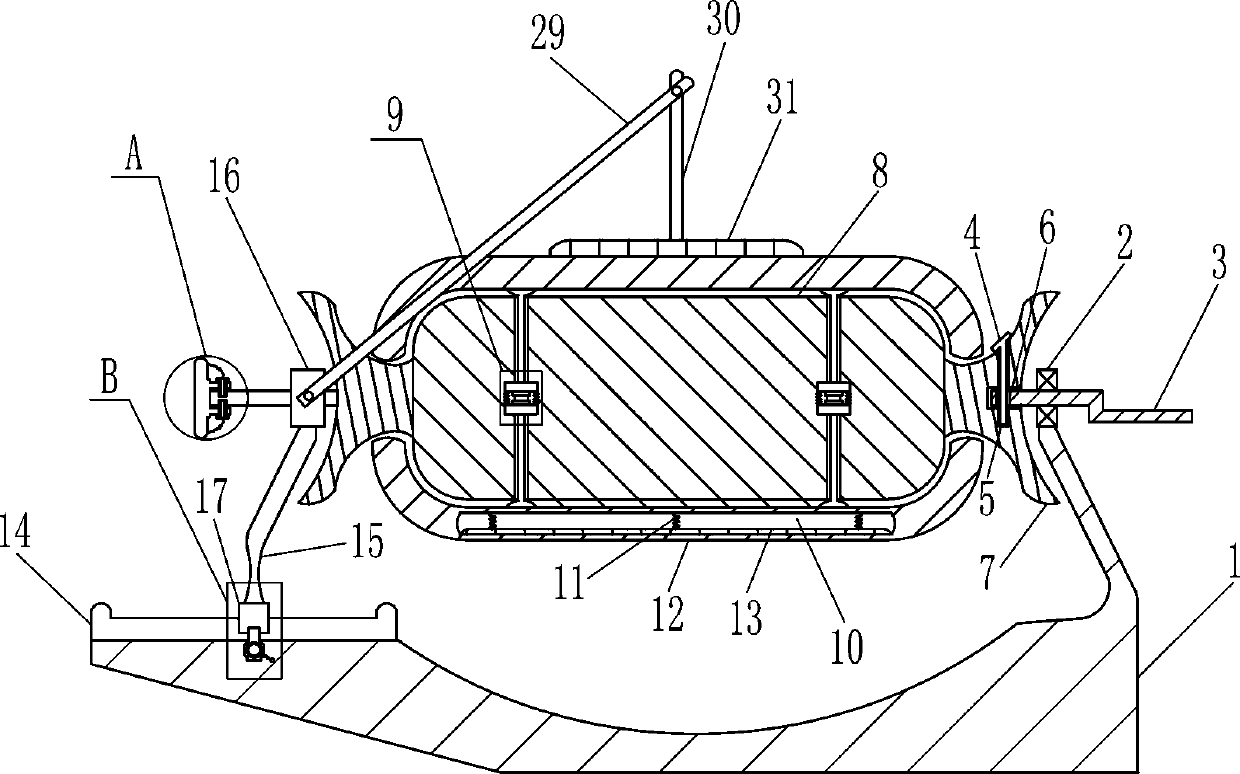

[0022] A textile cloth winder such as Figure 1-4 As shown, it includes base 1, bearing seat 2, rotating rod 3, first bolt 4, connecting column 7, rotating column 8, adjusting device 9, second spring 11, lifting plate 12, first pressing block 13, straight slide Rail 14, pole 15, fixed cover 16, slide block 17 and fixed rod 18, bearing seat 2 is installed on the right side of base 1 top, and rotating rod 3 is connected with interference in bearing seat 2, and rotating rod 3 left part has the second A threaded hole 6, the right part of the connecting column 7 has a cross hole 5, the left part of the rotating rod 3 is located in the cross hole 5, the first threaded hole 6 is internally screwed with the first bolt 4, and the first bolt 4 is passed through the cross hole 5 , the middle part of the connecting column 7 is connected with a rotating column 8, and the left and right parts of the front side of the rotating column 8 are provided with an adjusting device 9, and the parts o...

Embodiment 2

[0024] A textile cloth winder such as Figure 1-4 As shown, it includes base 1, bearing seat 2, rotating rod 3, first bolt 4, connecting column 7, rotating column 8, adjusting device 9, second spring 11, lifting plate 12, first pressing block 13, straight slide Rail 14, pole 15, fixed cover 16, slide block 17 and fixed rod 18, bearing seat 2 is installed on the right side of base 1 top, and rotating rod 3 is connected with interference in bearing seat 2, and rotating rod 3 left part has the second A threaded hole 6, the right part of the connecting column 7 has a cross hole 5, the left part of the rotating rod 3 is located in the cross hole 5, the first threaded hole 6 is internally screwed with the first bolt 4, and the first bolt 4 is passed through the cross hole 5 , the middle part of the connecting column 7 is connected with a rotating column 8, and the left and right parts of the front side of the rotating column 8 are provided with an adjusting device 9, and the parts o...

Embodiment 3

[0027] A textile cloth winder such as Figure 1-4As shown, it includes base 1, bearing seat 2, rotating rod 3, first bolt 4, connecting column 7, rotating column 8, adjusting device 9, second spring 11, lifting plate 12, first pressing block 13, straight slide Rail 14, pole 15, fixed cover 16, slide block 17 and fixed rod 18, bearing seat 2 is installed on the right side of base 1 top, and rotating rod 3 is connected with interference in bearing seat 2, and rotating rod 3 left part has the second A threaded hole 6, the right part of the connecting column 7 has a cross hole 5, the left part of the rotating rod 3 is located in the cross hole 5, the first threaded hole 6 is internally screwed with the first bolt 4, and the first bolt 4 is passed through the cross hole 5 , the middle part of the connecting column 7 is connected with a rotating column 8, and the left and right parts of the front side of the rotating column 8 are provided with an adjusting device 9, and the parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com