Crown reinforcement for airplane tire

A technology for aircraft tires and reinforcements, applied in aircraft tires, reinforcement layers of pneumatic tires, tire parts, etc., can solve problems such as selection limitations of mechanical stiffness optimization, and achieve the effect of reducing time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

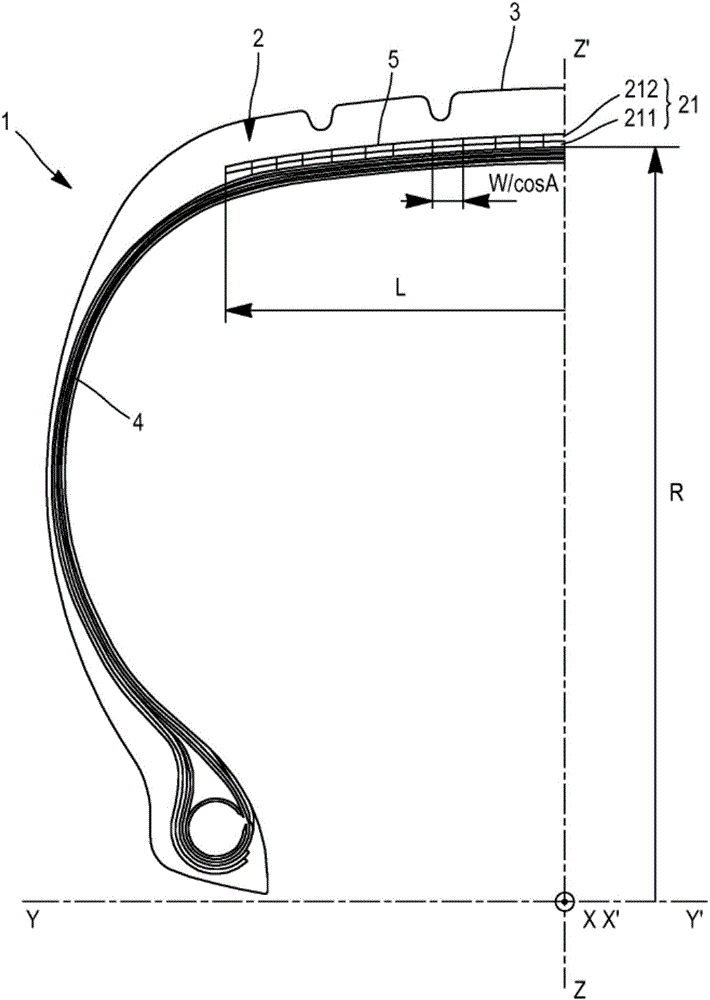

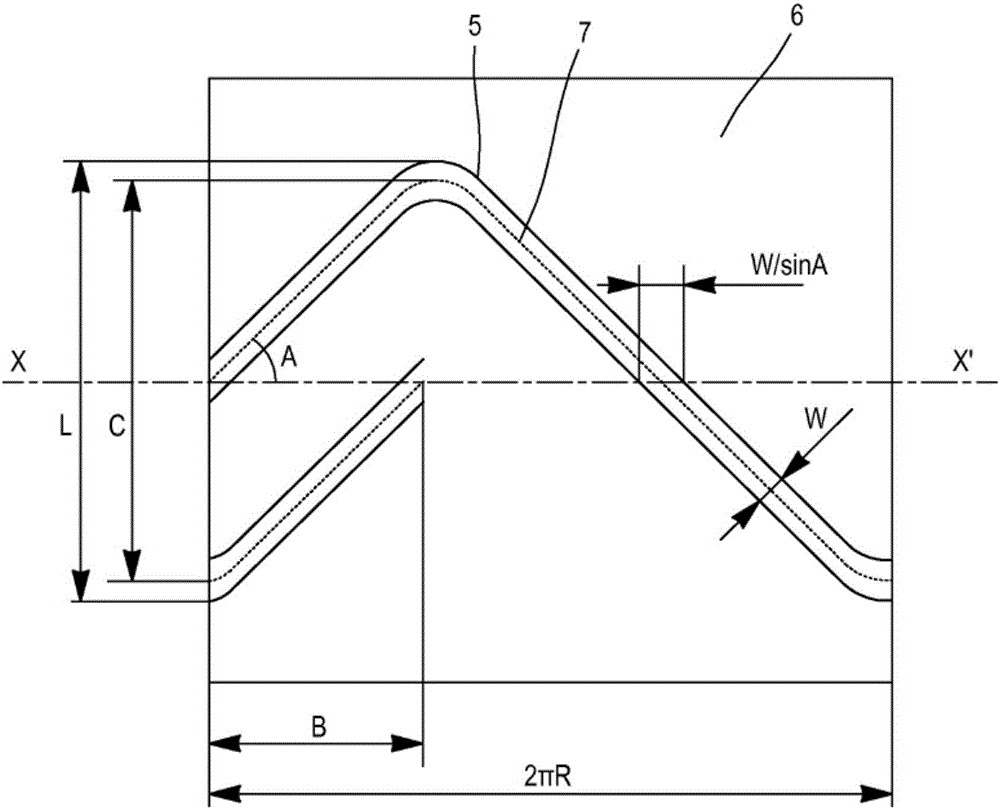

[0045] figure 1 Shows a half view in cross-section of an aircraft tire 1 comprising radially inside the tread 3 and radially on the The working reinforcement 2 on the outside of the body reinforcement 4. Said working reinforcement 2 comprises a working double ply 21 consisting of at least two radially superimposed working layers (211, 212), wound by zigzag circumferentially on a cylindrical laying surface of radius R A strip of width W is obtained, the axis of rotation of the cylindrical paving surface being the axis of rotation (YY') of the tyre. In a radial plane (YZ), each working layer (211, 212) consists of axially juxtaposed sections of the strip 5 having a width W / cosA, where W is the width of the strip 5 (not shown), It is measured perpendicular to the bisector of the strip 5 and A is the angle (not shown) formed by the bisector of the strip 5 with respect to the circumferential direction (XX') in the equatorial plane (XZ).

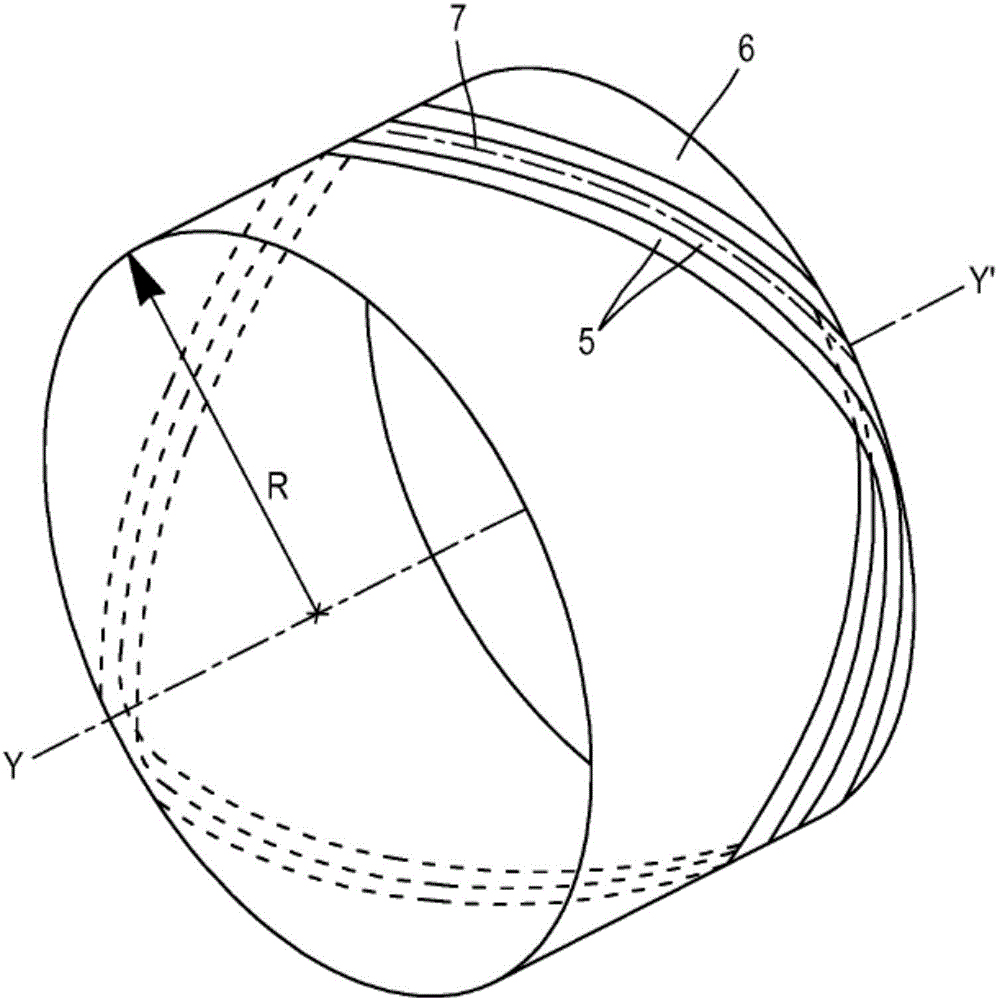

[0046] figure 2 is a perspective view ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com