Patents

Literature

232results about How to "Reduce copper loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

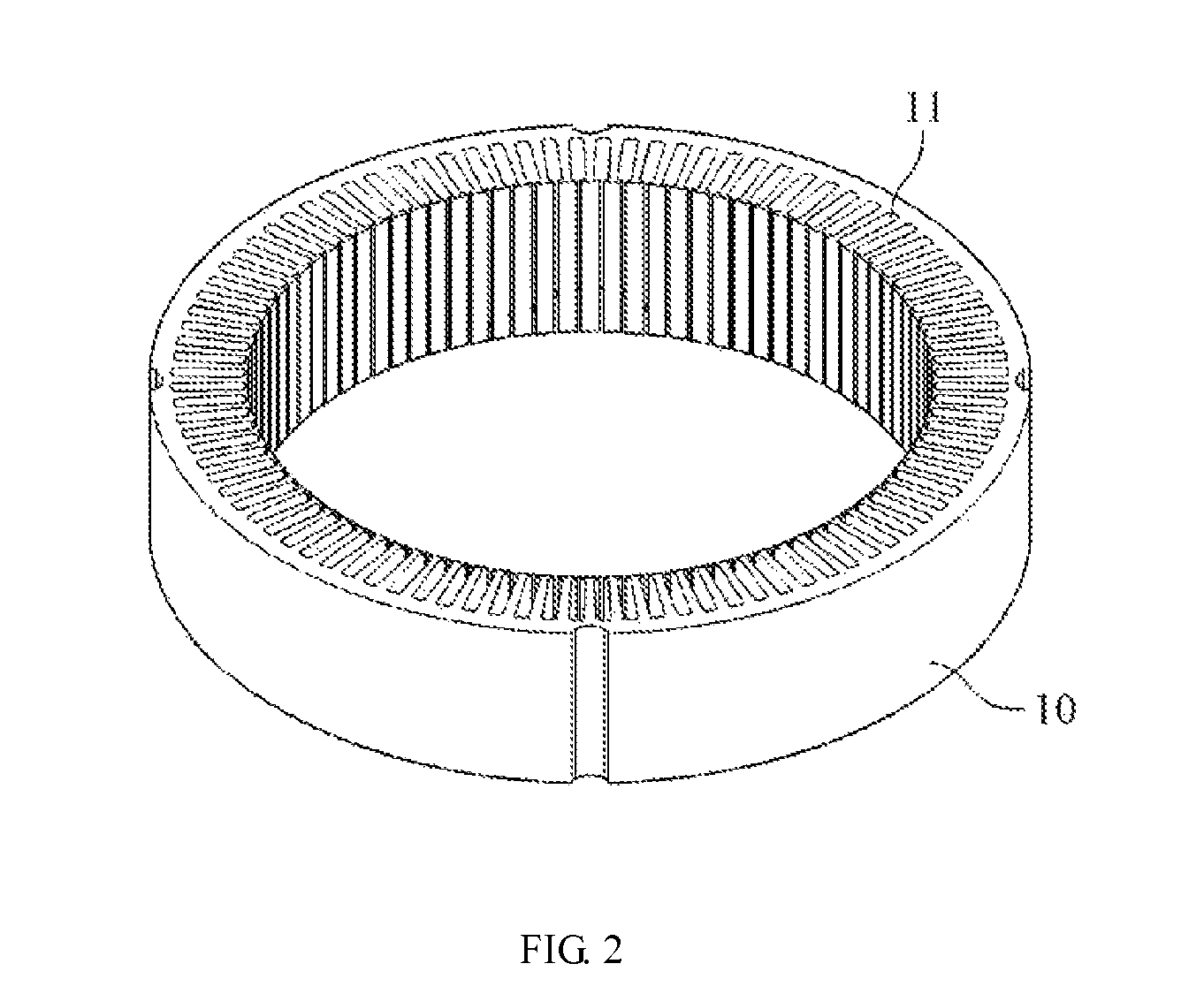

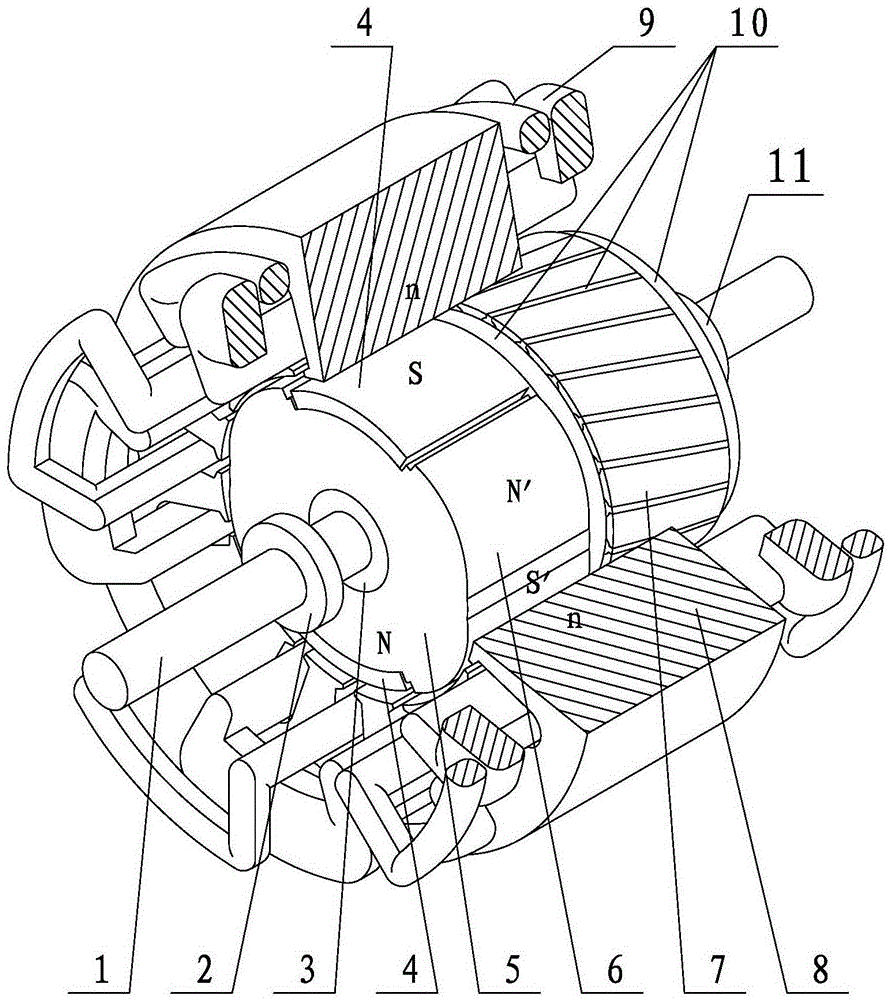

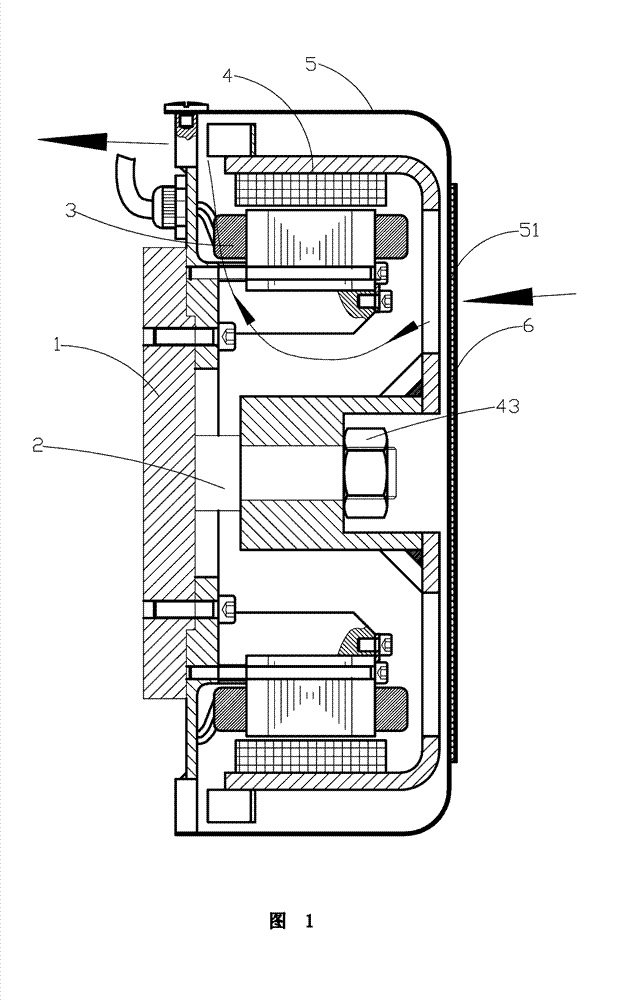

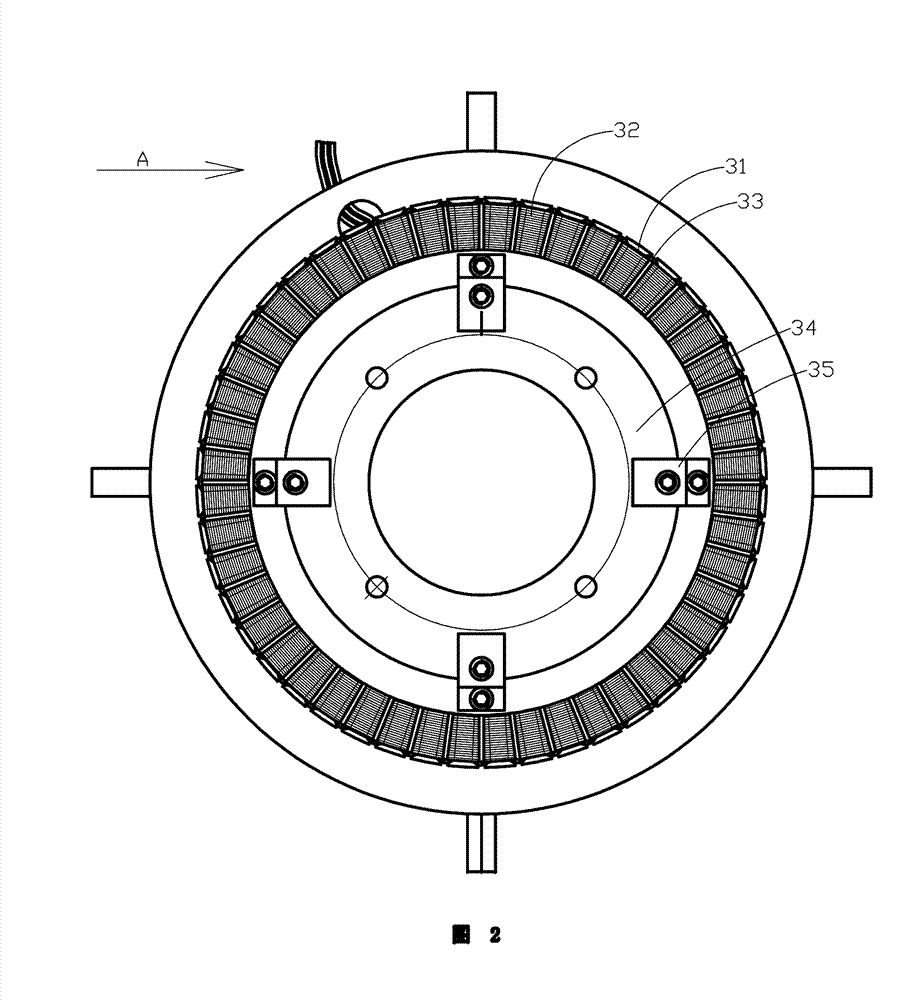

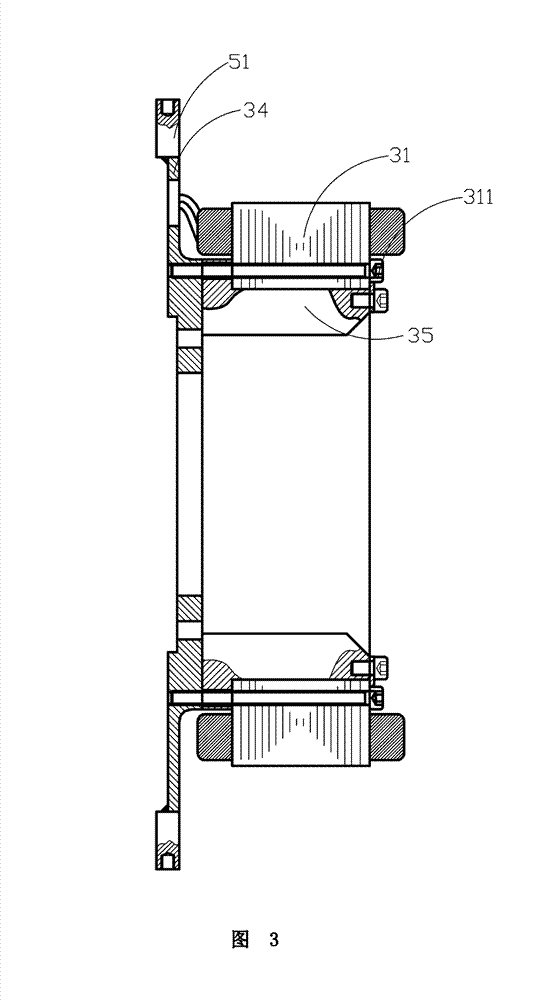

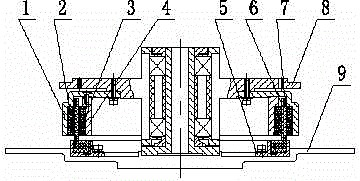

Ultrathin high-power direct current magnetoelectric motor

InactiveCN101951106ACompact structureImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsDrive shaftDirect current

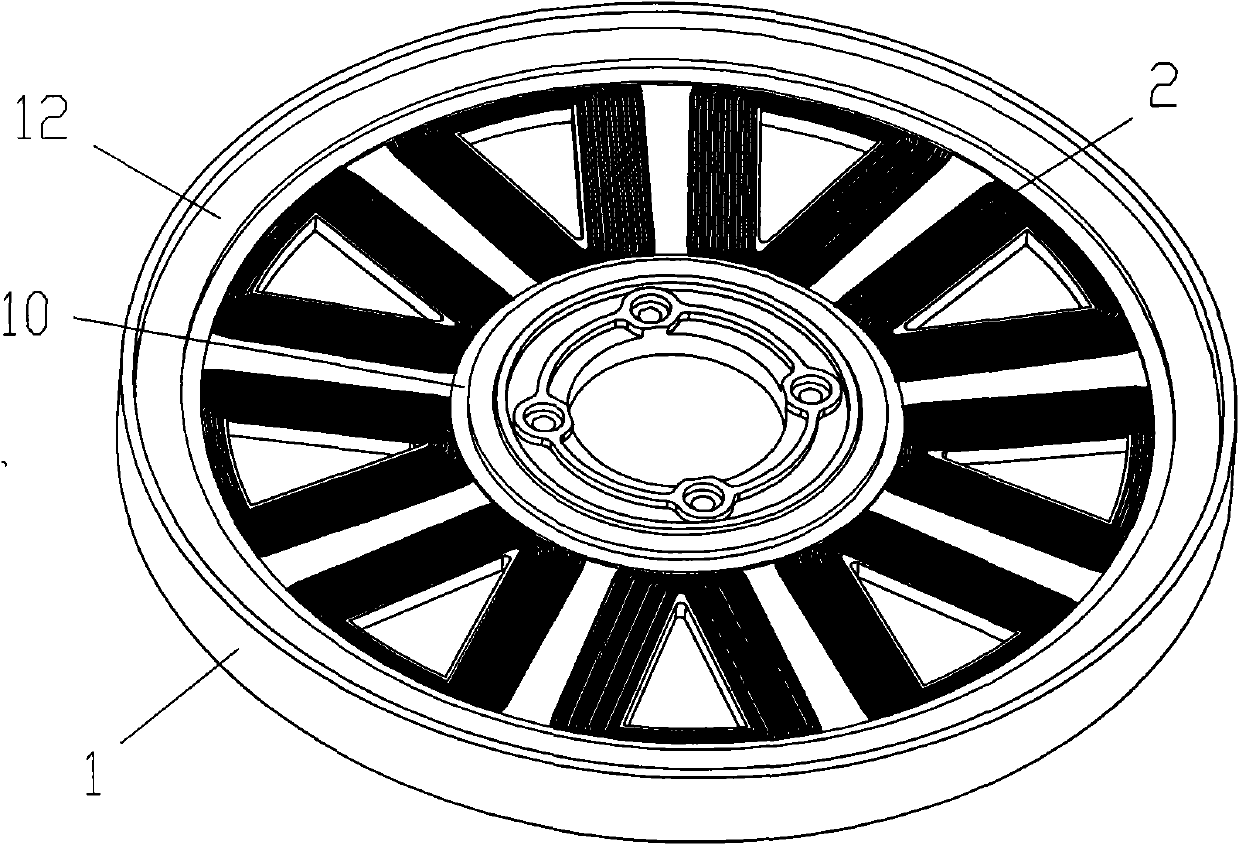

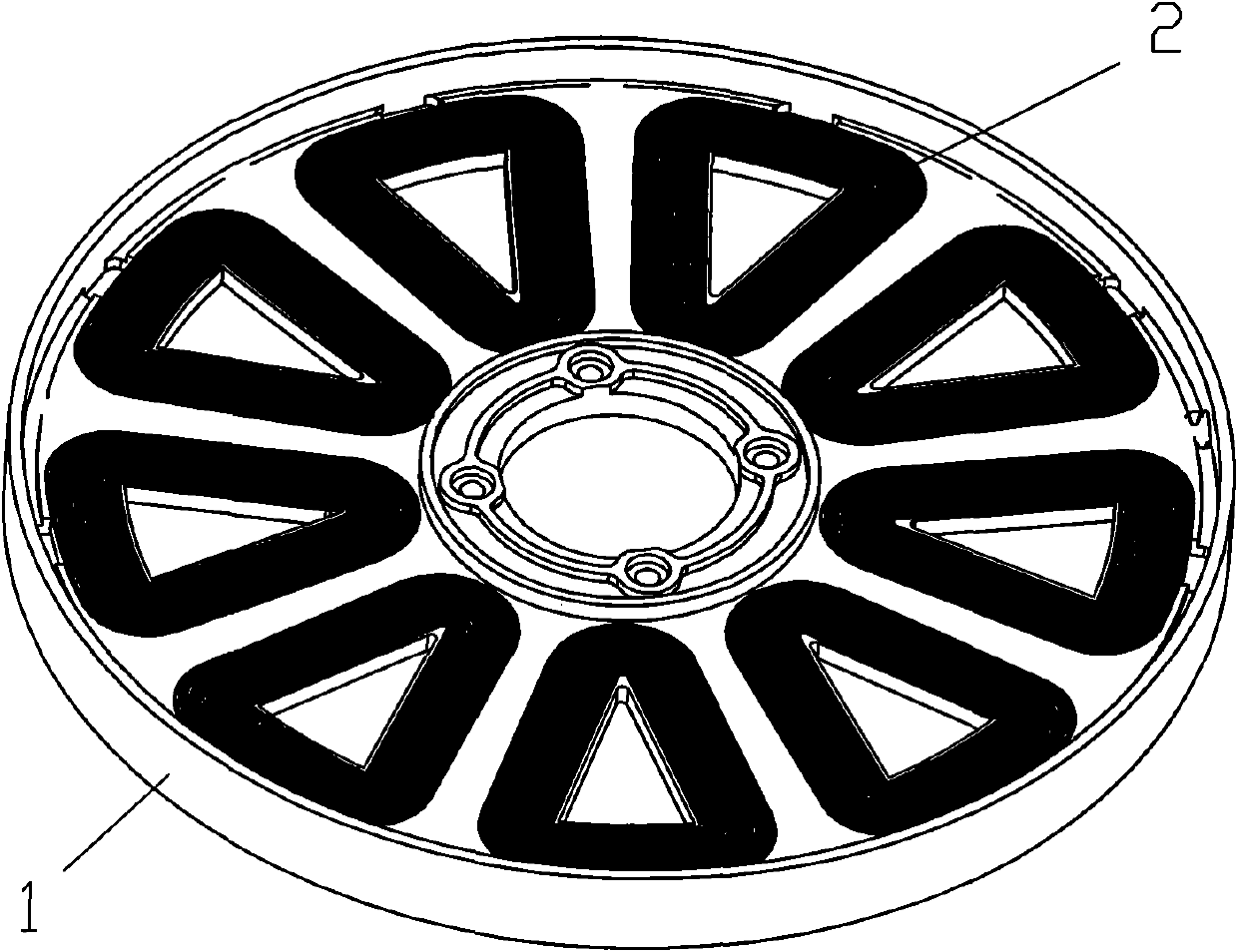

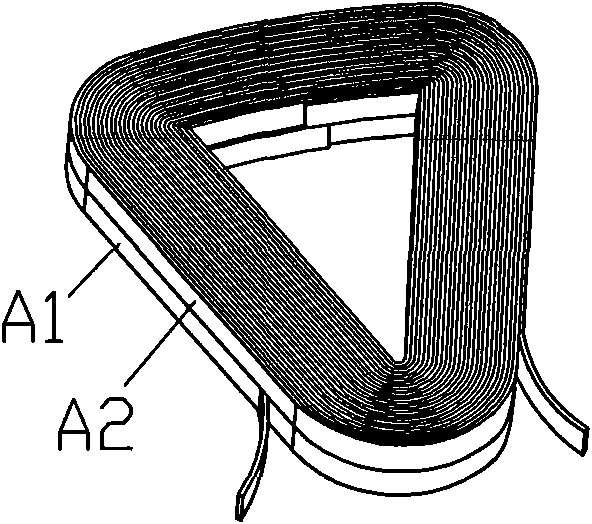

The invention discloses an ultrathin high-power direct current magnetoelectric motor, comprising a transmission shaft, a discal stator component sleeved at the middle section of the transmission shaft, discal rotor components which are respectively arranged at the two sides of the stator component and rotate with the transmission shaft, and an upper end cap and a lower end cap which are respectively arranged at the two sides of the rotor components. The stator component comprises a discal stator frame, a plurality of fan-shaped grooves which are arranged on the stator frame in a ring form, fan-shaped windings arranged in the fan-shaped grooves, and inner clamping rings and outer clamping ring for fixing the fan-shaped windings. The rotor component comprises a rotor plate fixedly connectedwith the transmission shaft, fan-shaped grooves which are arranged on the rotor plate in a ring form, and permanent magnets fixed in the grooves. The surface of the rotor plate, which provided with the permanent magnets, faces the fan-shaped windings. The motor of the invention has the advantages of higher efficiency and energy saving, and the manufacturing, the assembling and the maintenance of the stator winding are more simple, convenient and reliable.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

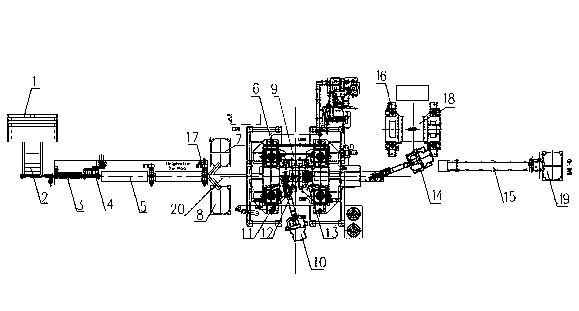

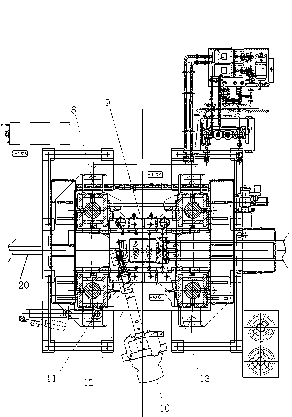

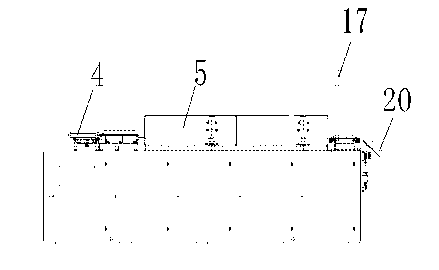

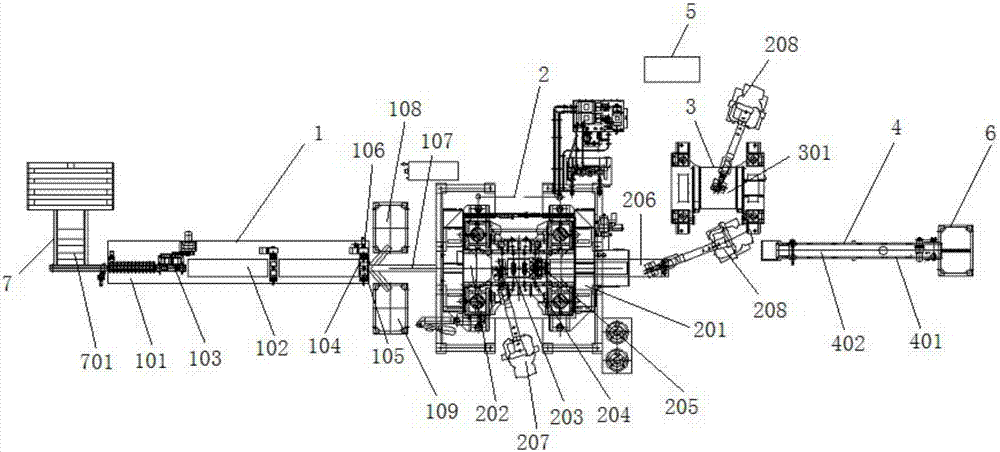

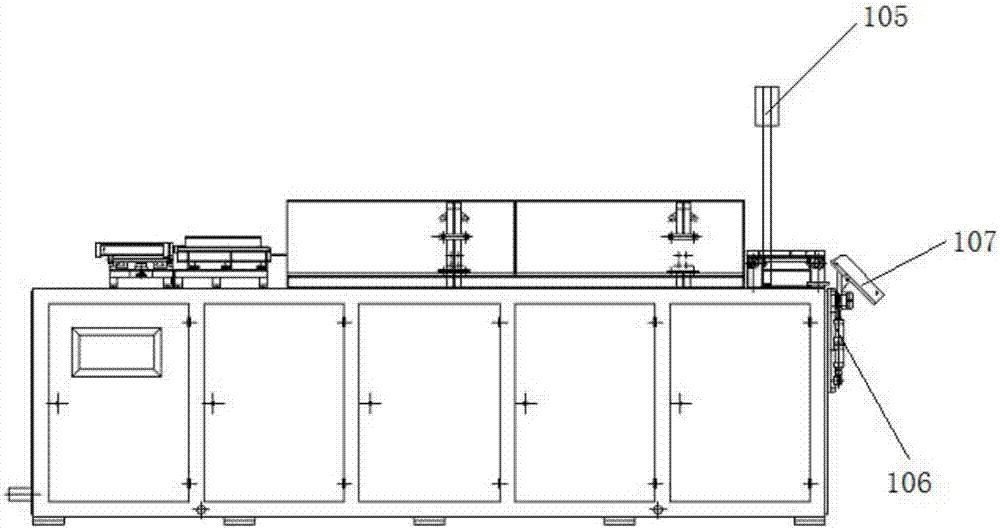

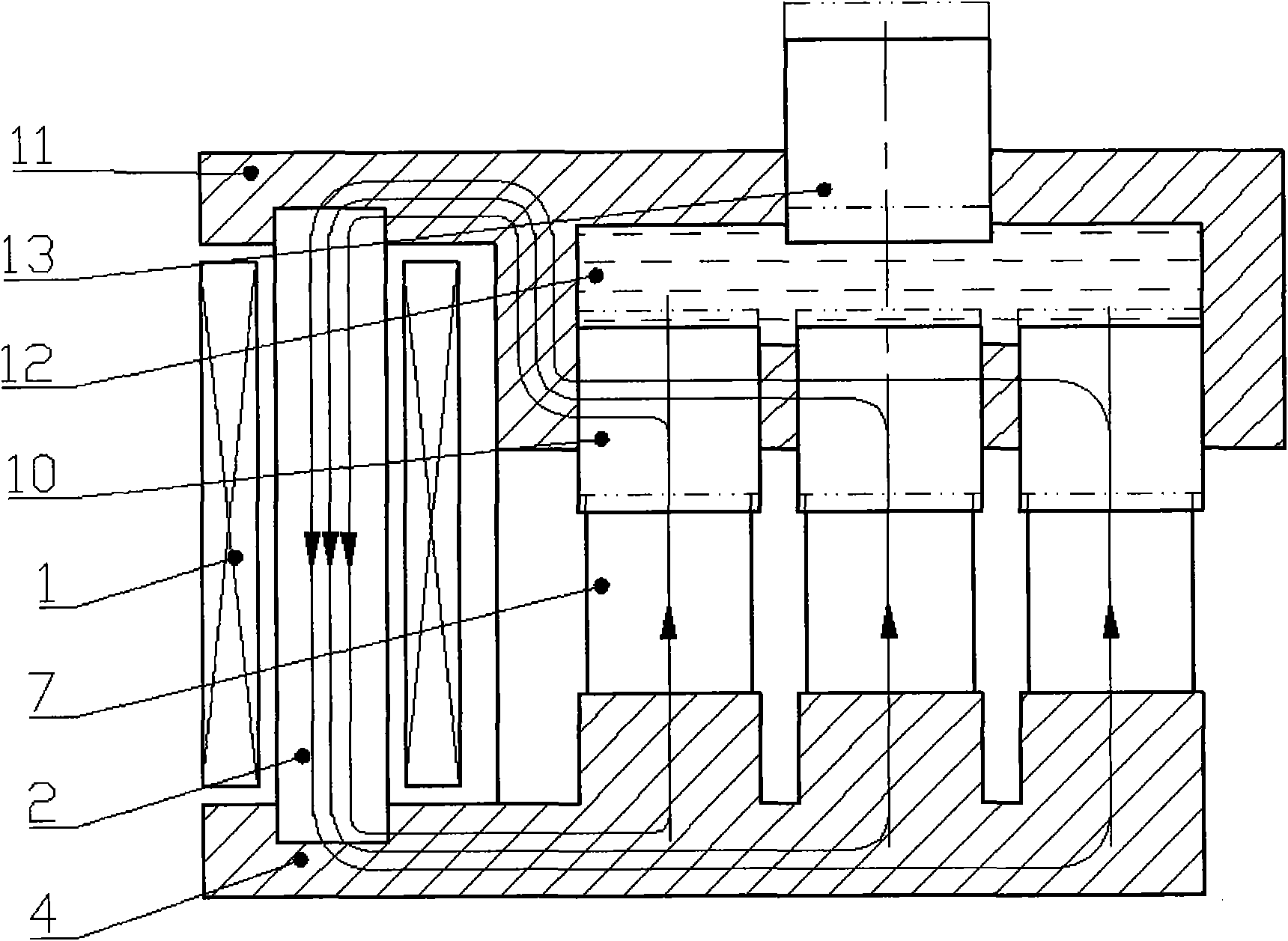

Production device and production technology for non-quenched and tempered steel forge piece automatic forging

InactiveCN103230997AEmission reductionImprove electricity efficiencyHandling devicesEngineeringUltimate tensile strength

The invention relates to the technical field of metal hot processing, in particular to the technical field of production device and production technology for non-quenched and tempered steel forge piece automatic forging. The device comprises a forging system, a feeding system and a discharging system, wherein the feeding system is arranged at the front end of the forging system, the discharging system is arranged at the rear end of the forging system, the forging system comprises an electric heating furnace connected with rear part of the feeding system, a forging pressing machine is connected with the rear part of the electric heating furnace, an edge trimmer is connected with the rear part of the discharging system, and the discharging system is connected with the rear part of the edge trimmer. According to the device provided by the invention, defects in the prior art is overcame, the full automatic line technology that the forge piece is heated once and is controlled by one worker is realized, is energy-saving and cost-reducing, labor saving, the outer surface and the inner quality of the forge piece is improved, and the service life is prolonged; as the mechanical property of each part of the forage is close to one anther, the forge piece quality and safety performance are improved, and the non quenched and tempered steel forging piece is high in tensile strength, fatigue strength and machinability.

Owner:ANHUI ANHUANG MACHINERY

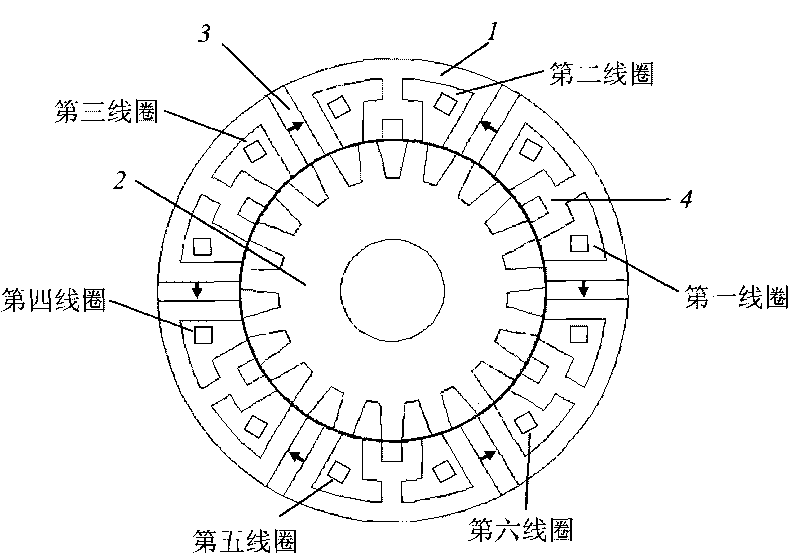

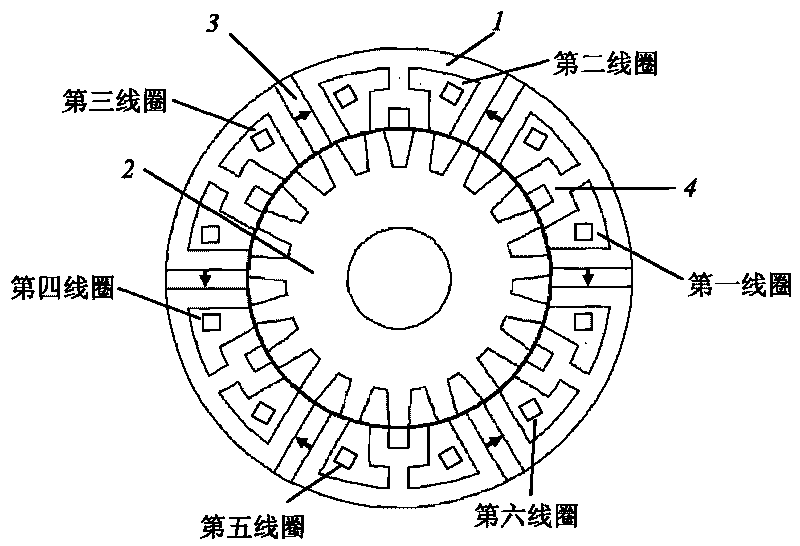

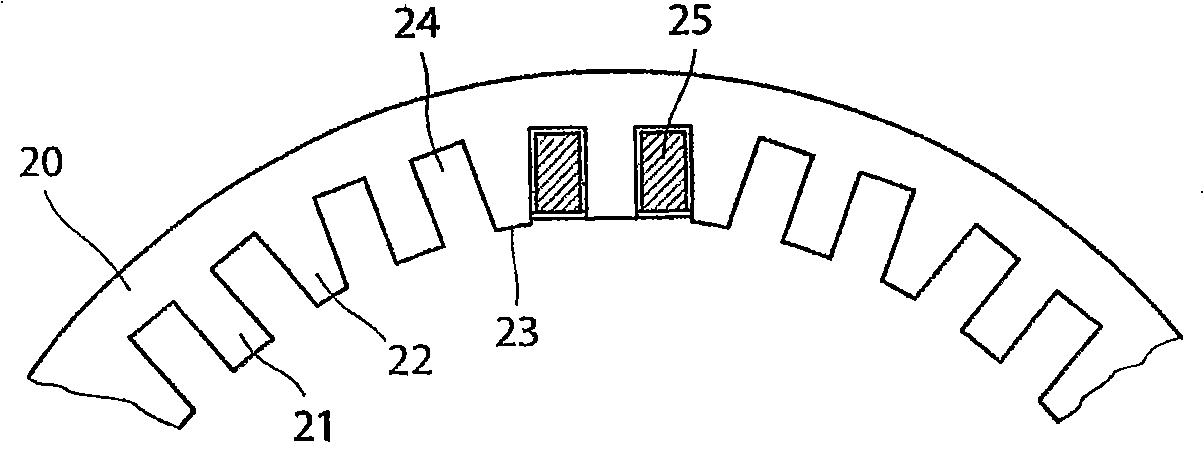

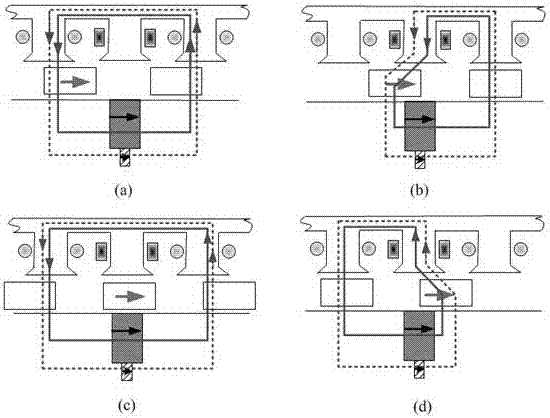

Multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine and fault-tolerance method thereof

InactiveCN101697431AIncrease magnetic circuit permeabilityReduce mutual inductanceMagnetic circuit stationary partsPhysicsMagnetic flux

The invention discloses a multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine and a fault-tolerance method thereof, belonging to a permanent magnetism fault-tolerance electric machine and a method. The electric machine comprises a salient pole stator, an armature winding and a salient pole rotor. Stator salient poles are E-shaped stator iron blocks; bar-shaped permanent magnets are embedded into a gap between every two E-shaped stator iron blocks in sequence; and stator windings which are coils from a first coil to a sixth coil are wounded on two E-shaped arms connected with the bar-shaped permanent magnets. Since the method employs the multitooth fault-tolerance permanent magnetism magnetic flux switching electric machine, the self inductance of the armature winding is increased; when the multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine uses high-coercive force permanent magnets, the short circuit current if can be restrained within the rated current iL without considerably increasing the number of turns of the armature winding. The invention has high reliability; the armature magnetic field makes small impact on the permanent magnets; the multi-gear structures of the stator and the rotor of the electric machine enable the electric machine to have small mutual inductance, strong magnetism isolating capability, big electrical inductance, strong capability of restraining the short circuit current and reduced location torque.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

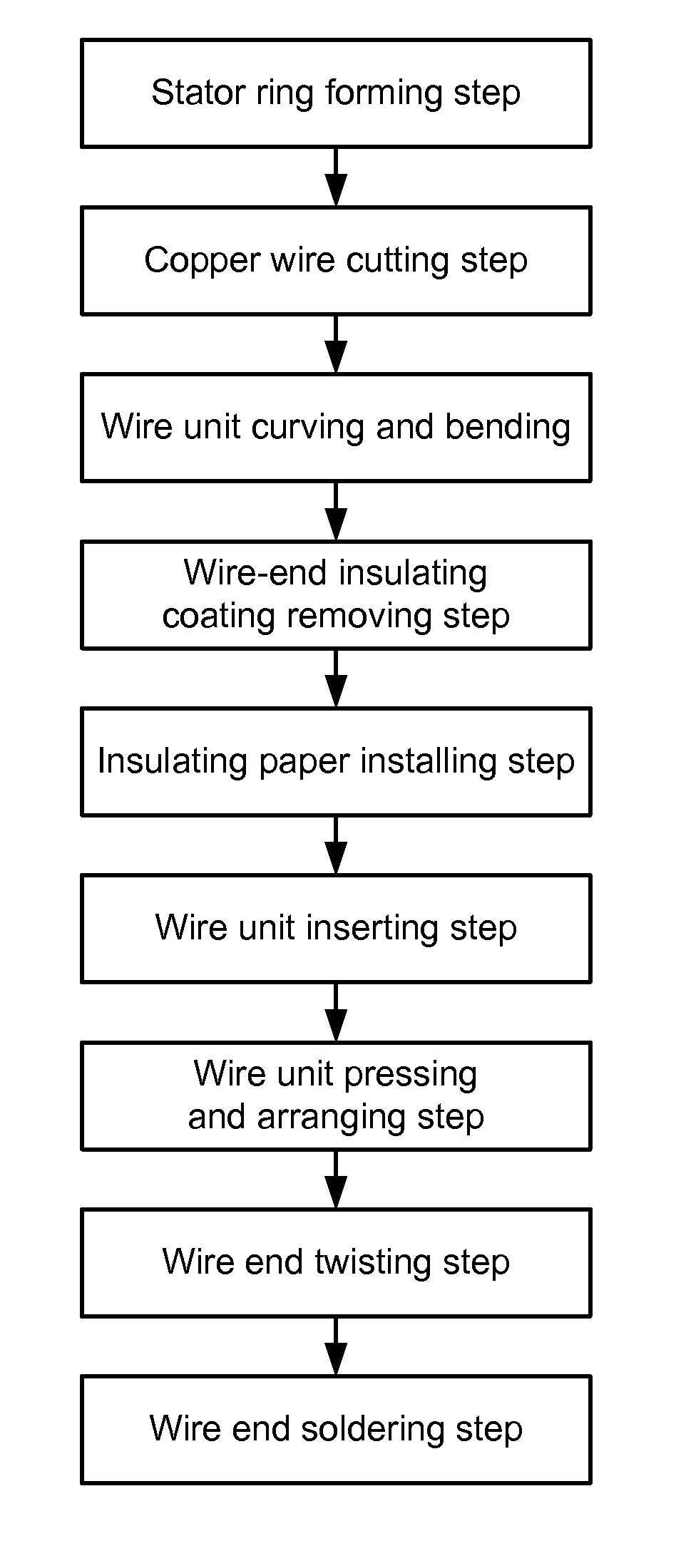

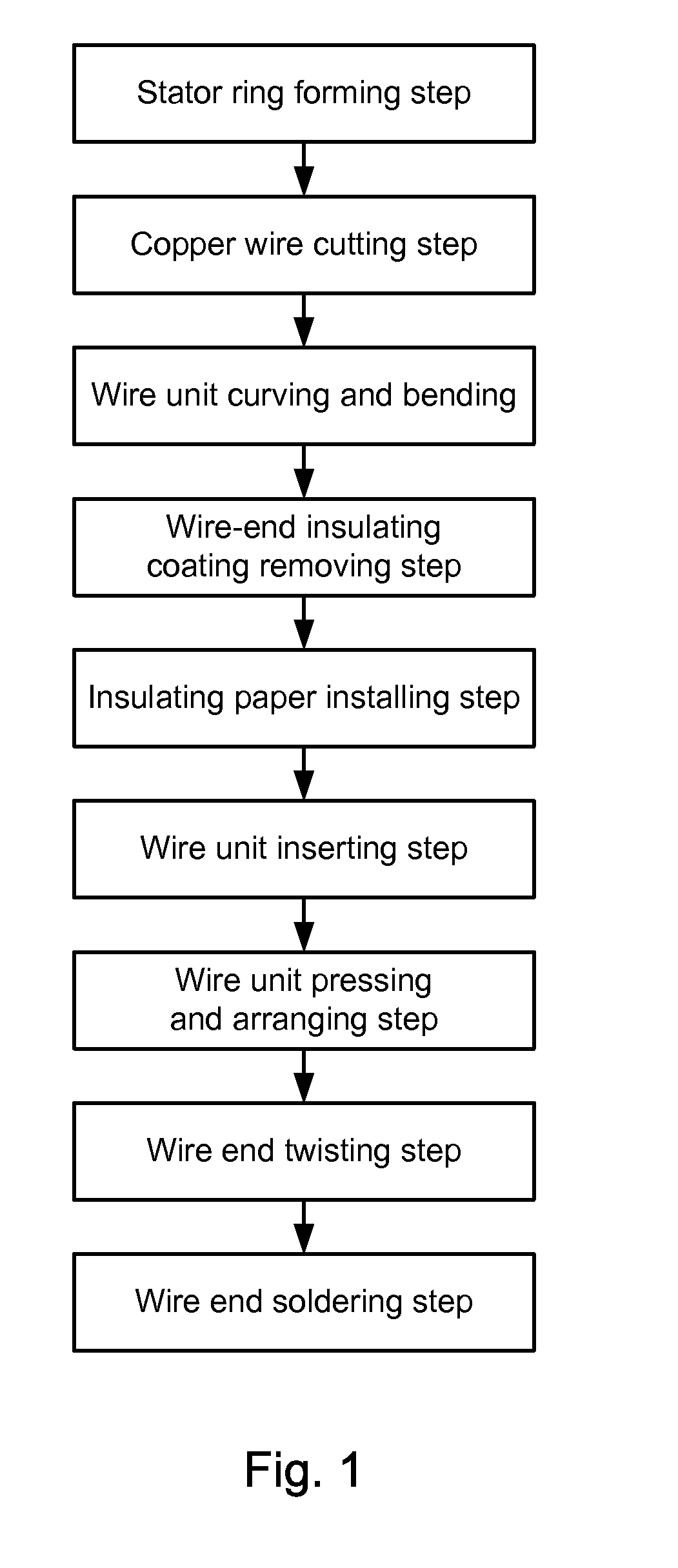

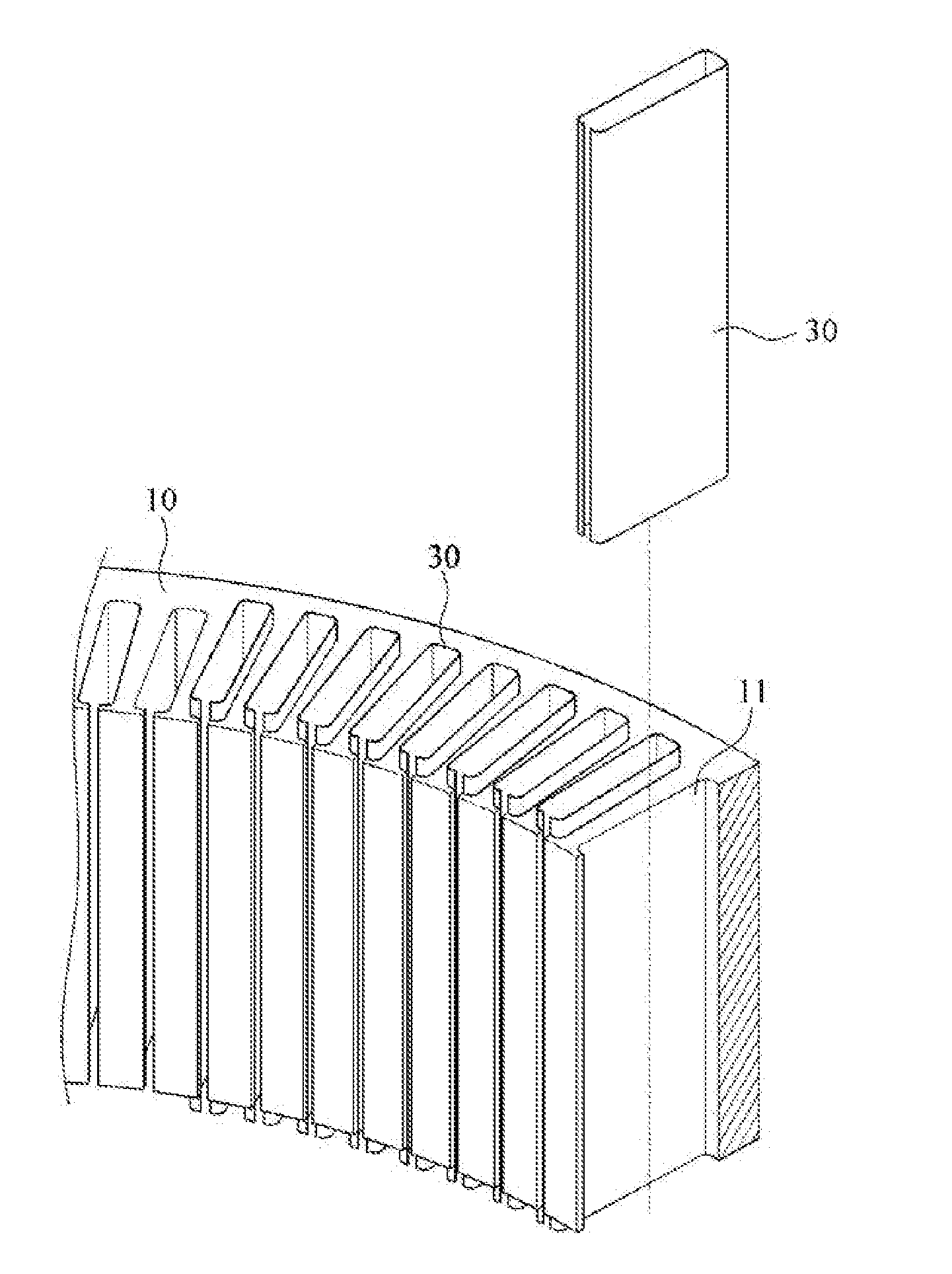

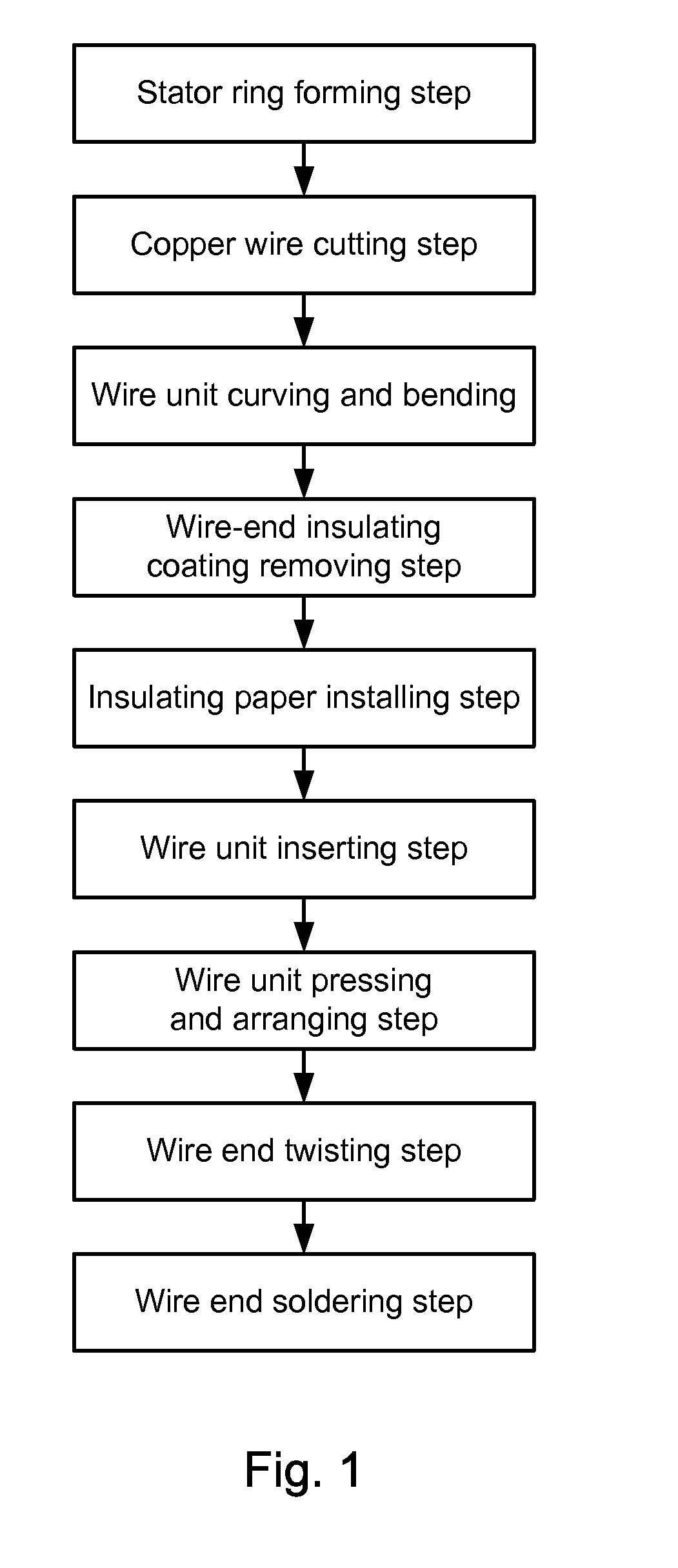

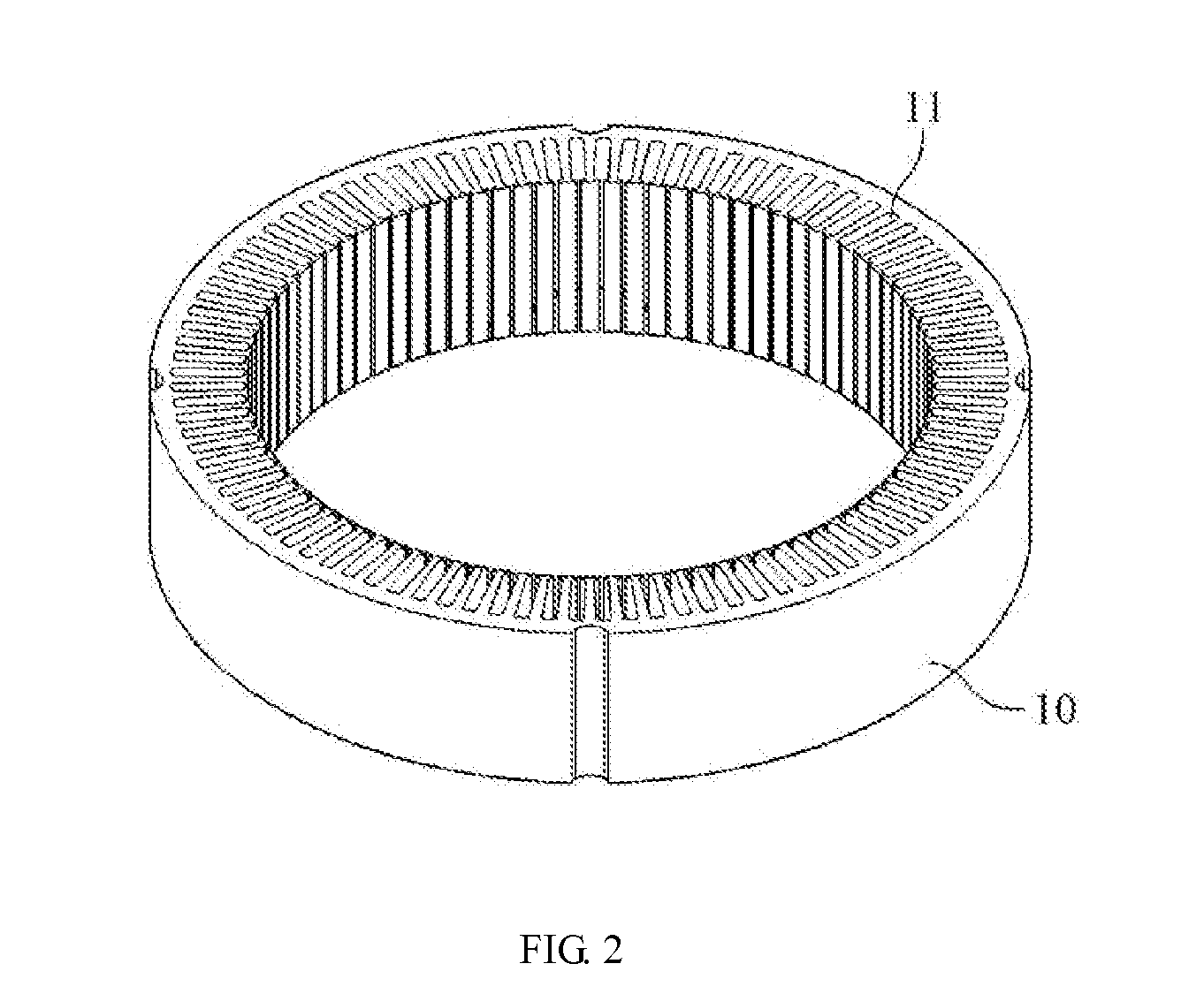

Method for making wound stator of automotive generator

InactiveUS8296926B2Efficiency problemEffective controlManufacturing dynamo-electric machinesMetal working apparatusCopper wireEngineering

A method for making a wound stator of an automotive generator is provided for replacing the conventional winding technique. The method includes: forming a stator ring provided with a plurality of annularly arranged radial through slots; cutting a copper wire into a plurality of wire units each having a rectangular cross section; inserting the wire units into the through slots in an interlacing manner; and soldering wire ends of the wire units sequentially so as to form a connected loop.

Owner:VICTORY IND CORP

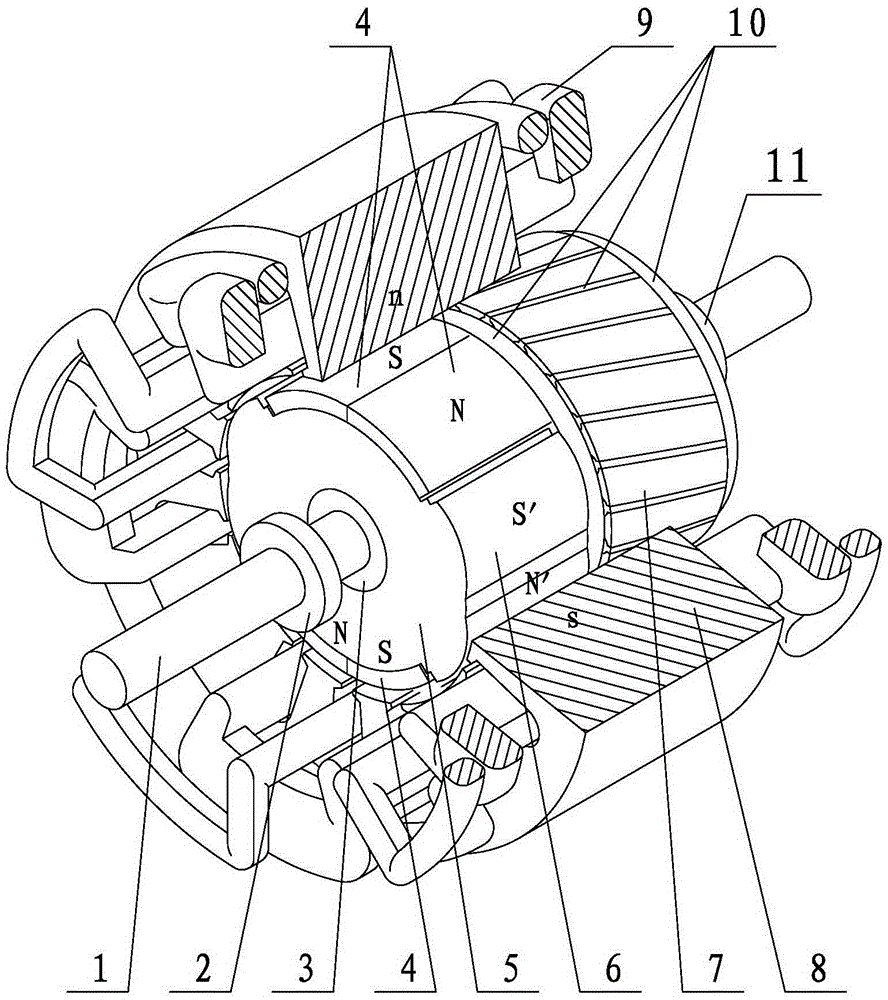

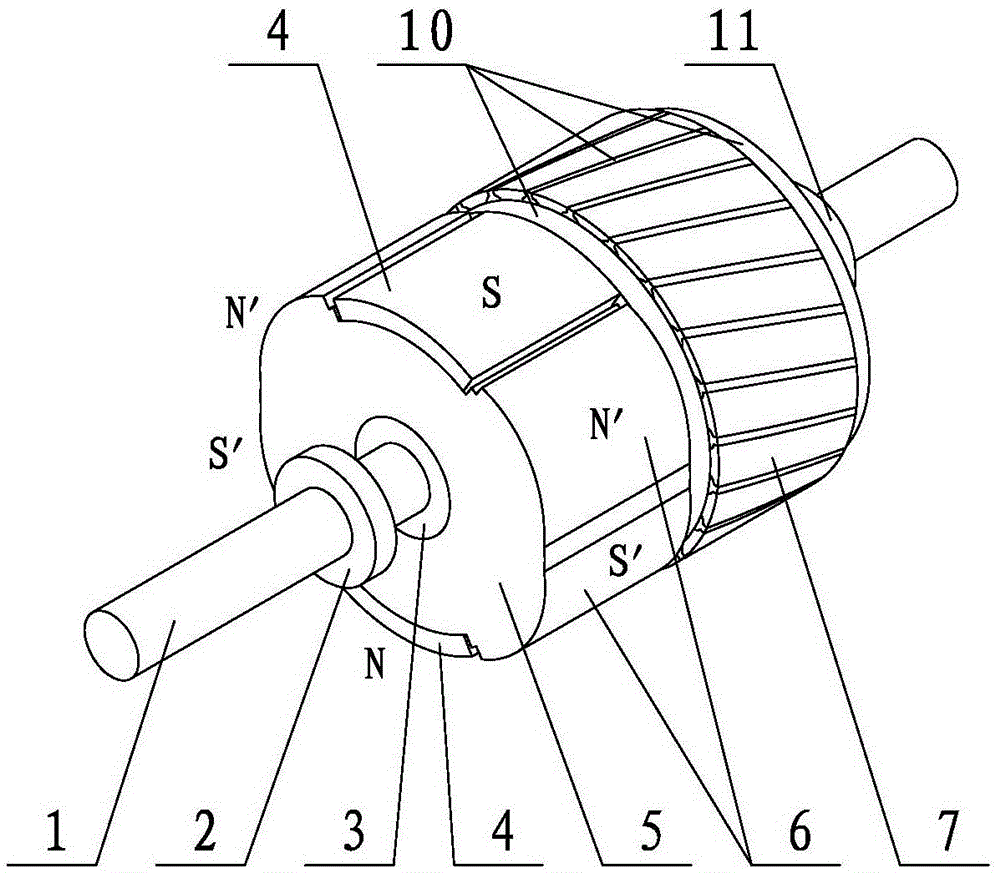

Transition asynchronous start permanent magnet synchronous motor and pole changing and speed changing method

ActiveCN105656271AReduce copper lossGuaranteed uptimeMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBrake torquePermanent magnet synchronous motor

The invention provides a transition asynchronous start permanent magnet synchronous motor and a pole changing and speed changing method and relates to a method applied to a permanent magnet synchronous motor. When the transition asynchronous start permanent magnet synchronous motor adopts a transition starting manner, a synchronous rotor iron core and one part of the radial outer surface of a permanent magnet leave away from the inner side of the inner surface of the iron core of the stator in a starting process, and the intensity of a rotor magnetic field established in a motor air gap of the permanent magnet is alleviated, so that a power generation braking torque generated by the permanent magnet is reduced, and the starting performance of the motor is easily improved. In a pole changing and speed changing synchronous operation process, a flux path of the rotor is changed, so that a rotor part of the transition asynchronous start permanent magnet synchronous motor can be automatically adaptive to change of the quantity of magnetic poles of the motor, so that the pole changing and speed changing of the permanent magnet synchronous motor can be realized.

Owner:江苏中工高端装备研究院有限公司

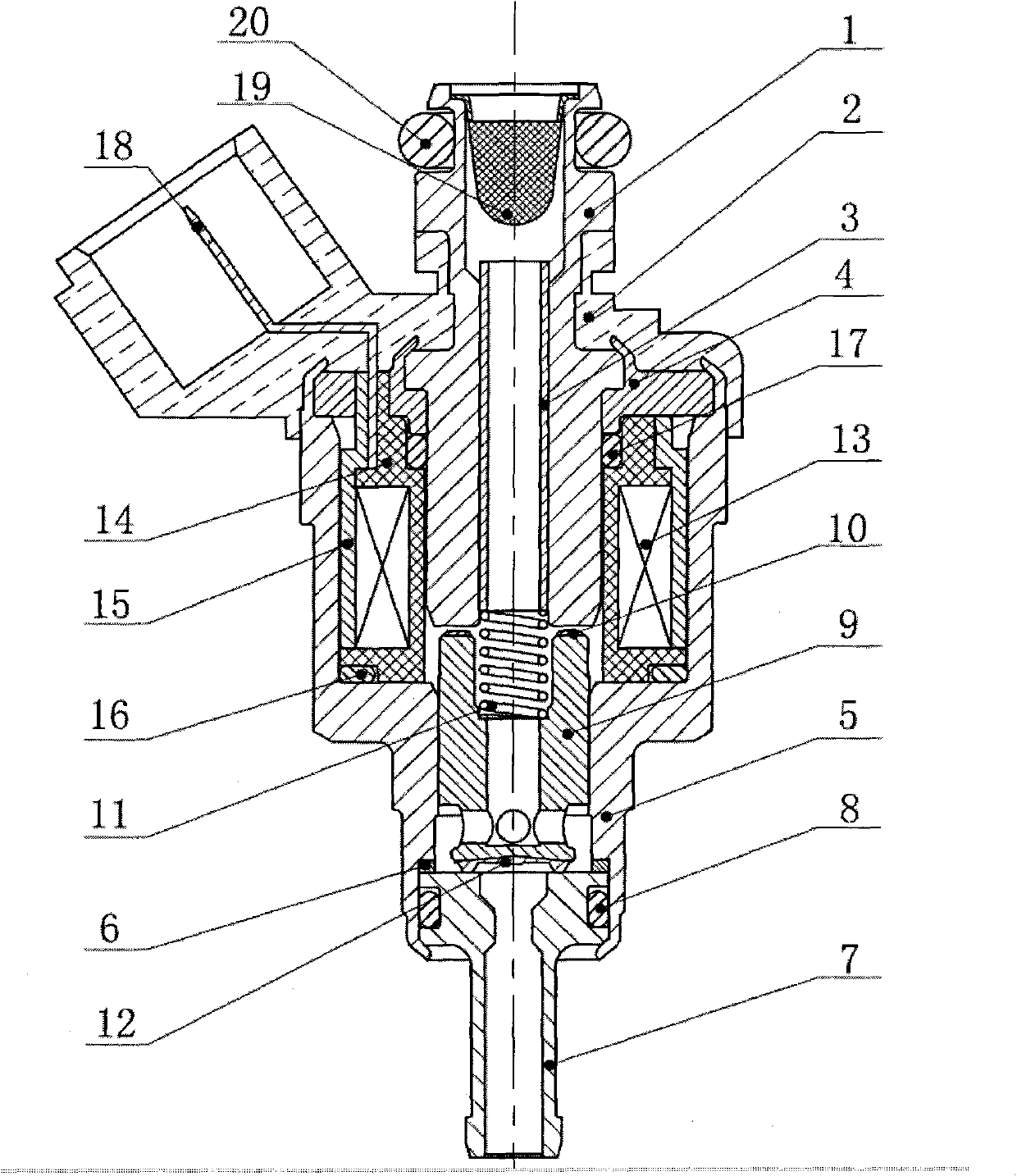

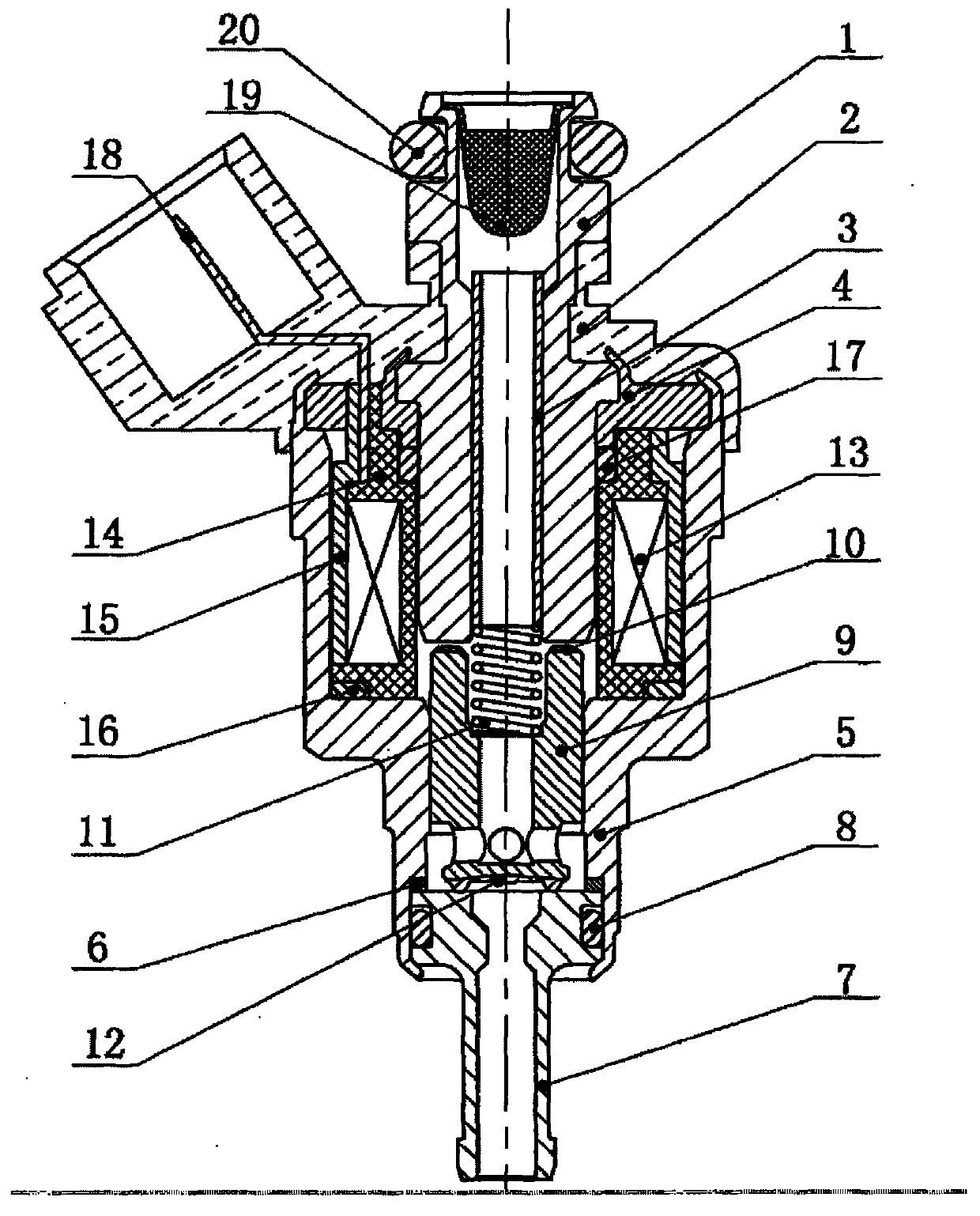

High-speed fuel gas injection electromagnetic valve for vehicles

InactiveCN101907044AReduce Flux LeakageStable Magnetic Operating PointOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringCopper

The invention discloses a high-speed fuel gas injection electromagnetic valve for vehicles. In the invention, a part of the electromagnetic valve is sleeved in a fixed core of a magnetism conducting end cover, and one end of the outer end of the fixed core is fixedly provided with a shell of a connecting terminal, while the other end is provided with a valve seat; one end of the fixed core is connected with a gas inlet, while the other end is connected with a movable core; the interior of the fixed core is hollow, and two sides of the inner wall of the fixed core are adhered with copper pipes; an electromagnetic coil wrapped by a coil shell is wound on a coil framework fixed on the fixed core; a spring is arranged between an inner hole of the fixed core and a concave port of the movable core, and a sealing piece is fixed at the other end of the movable core; and the outer end of the movable core is provided with a valve seat, and the tail end of the valve seat is provided with a nozzle. The invention optimizes magnetic circuits, reduces the temperature raise, improves the response speed, prolongs the service life of the valve body and is easy to mass production.

Owner:陆国祥

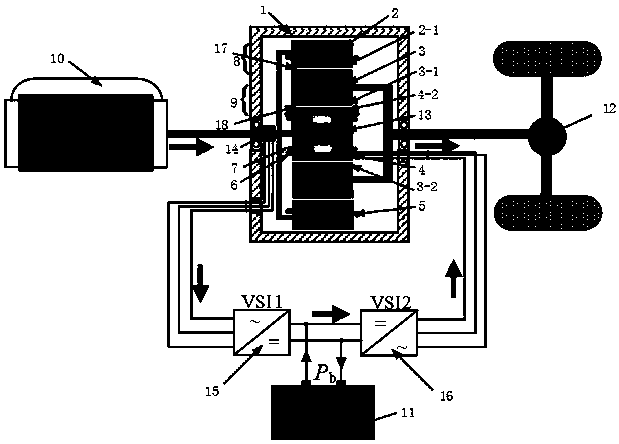

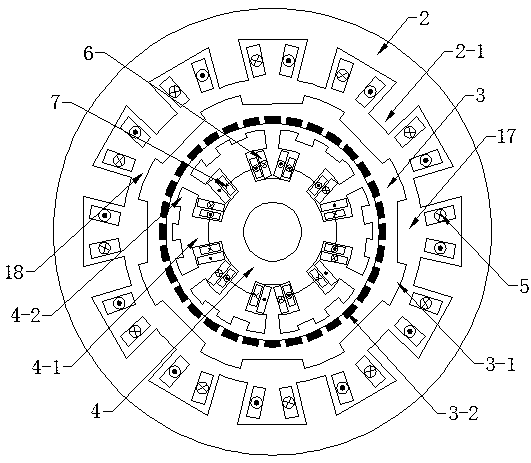

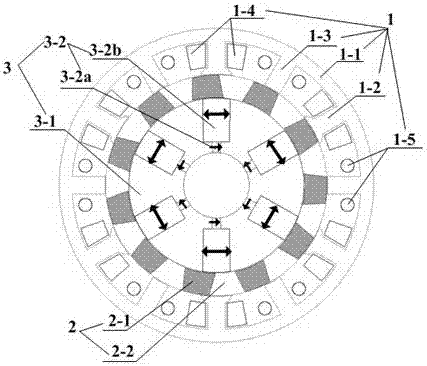

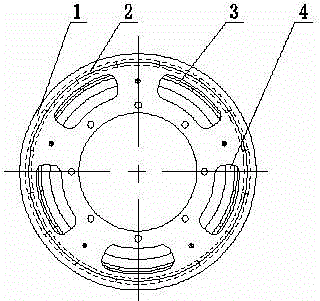

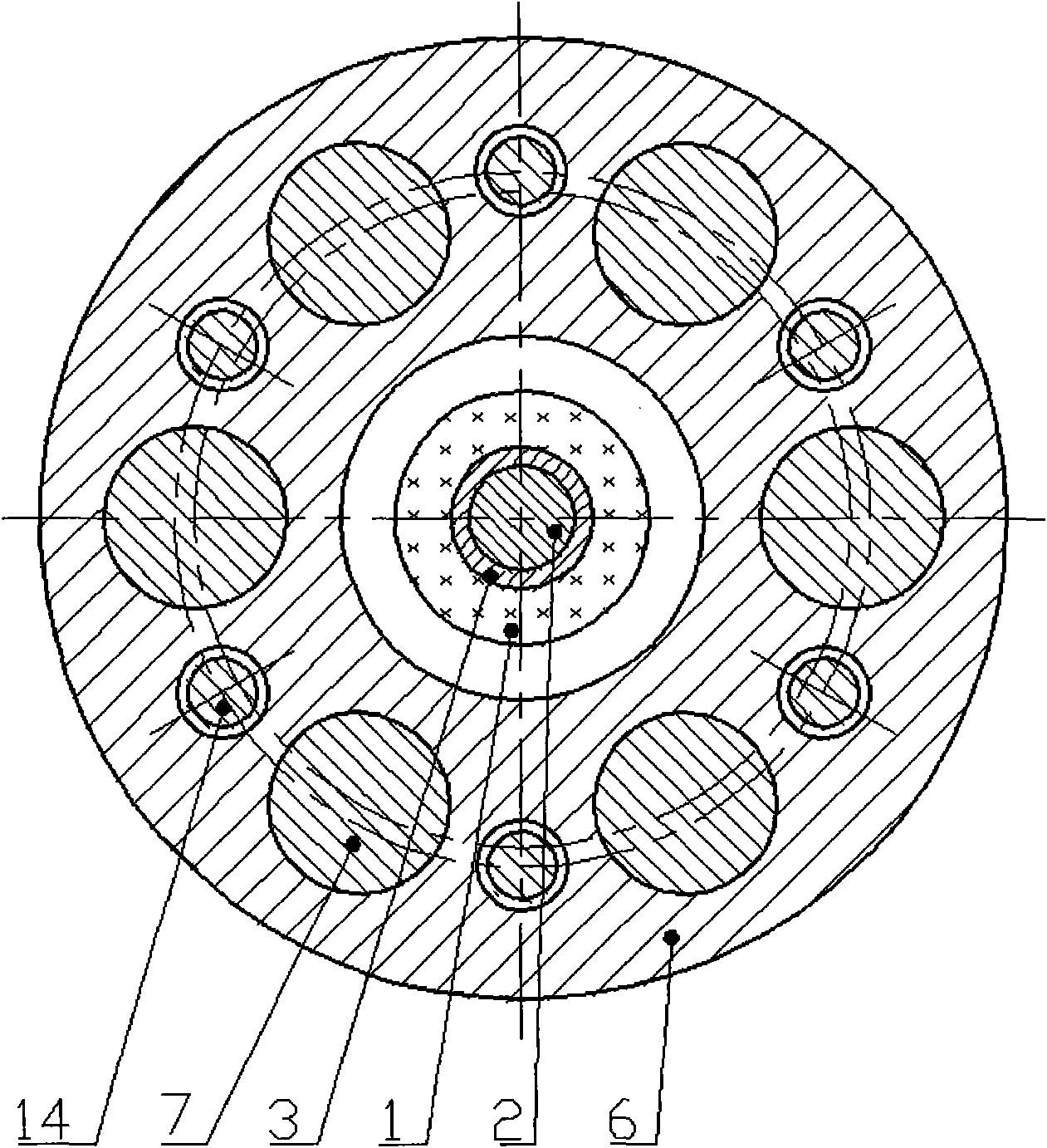

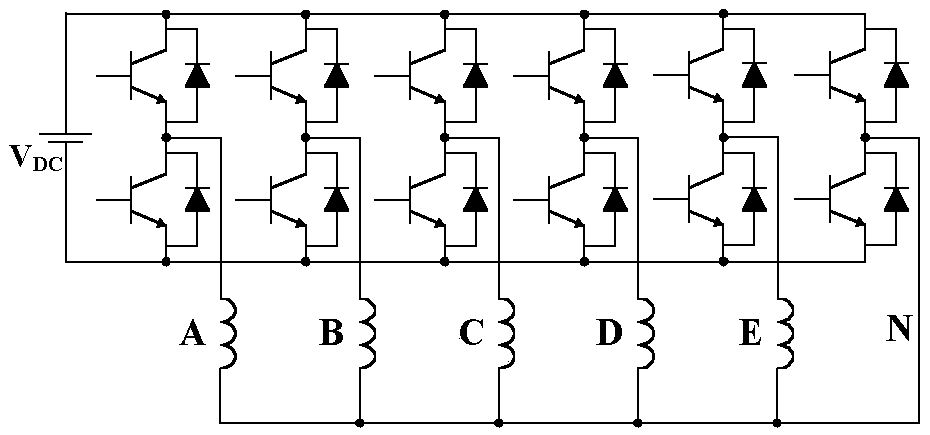

A magnetic flux modulate permanent magnet vernier motor with built-in stator

InactiveCN108988598AStrong fault toleranceStrong starting torqueMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

The invention provides a magnetic flux modulate permanent magnet vernier motor with stator compose of an outer rotor, an inner rotor and a stator arranged in a motor housing in sequence from outside in, There are twelve outer rotor salient poles (2-1) on the inner surface of the outer rotor 2, and eight inner rotor salient poles (3-1) on the outer surface of the inner rotor (3) near the outer rotor side, close to the inner side of the stator. The surface has a round surface structure and is embedded with sixteen pairs of permanent magnets (3-2). The stator (4) is connected to the casing (1) byiron blocks (13). The stator core has six stator teeth on the circumference (4-1). ), and three magnetic flux modulation poles (4-2) are placed on each stator tooth, Armature winding (6) and direct current excitation winding (7) of three-phase centralized type with two pairs of pole pairs are simultaneously arranged in the stator slot. The invention has the advantages of increasing torque outputcapacity, torque density, speed regulating range and mechanical strength, and simple processing and assembly.

Owner:CHONGQING UNIV

Method for Making Wound Stator of Automotive Generator

InactiveUS20100325874A1Efficiency problemEffective controlManufacturing dynamo-electric machinesMetal working apparatusCopper wireEngineering

A method for making a wound stator of an automotive generator is provided for replacing the conventional winding technique. The method includes: forming a stator ring provided with a plurality of annularly arranged radial through slots; cutting a copper wire into a plurality of wire units each having a rectangular cross section; inserting the wire units into the through slots in an interlacing manner; and soldering wire ends of the wire units sequentially so as to form a connected loop.

Owner:VICTORY INDAL

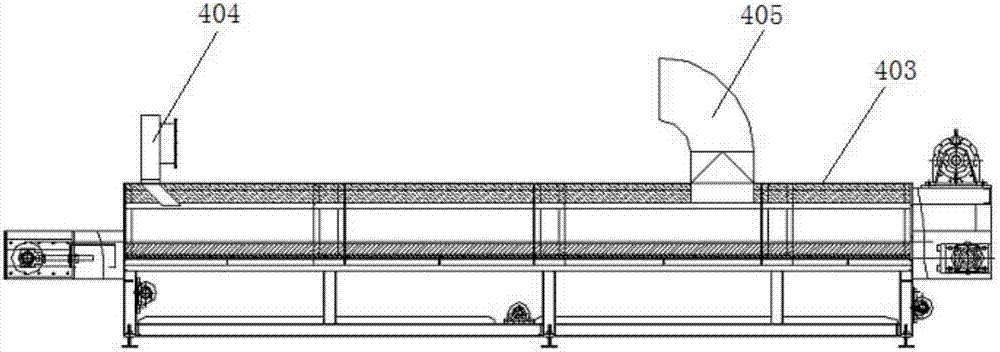

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

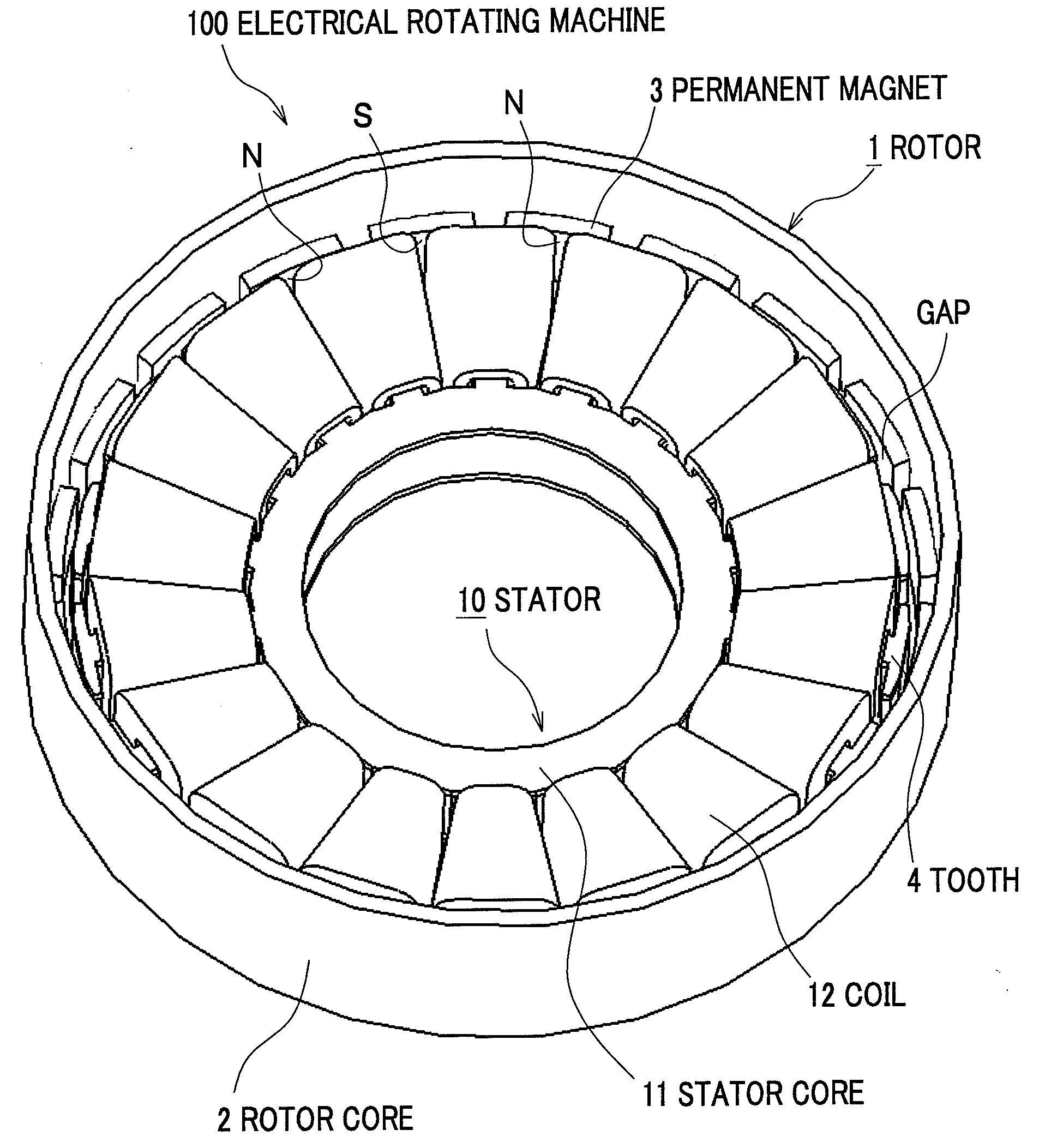

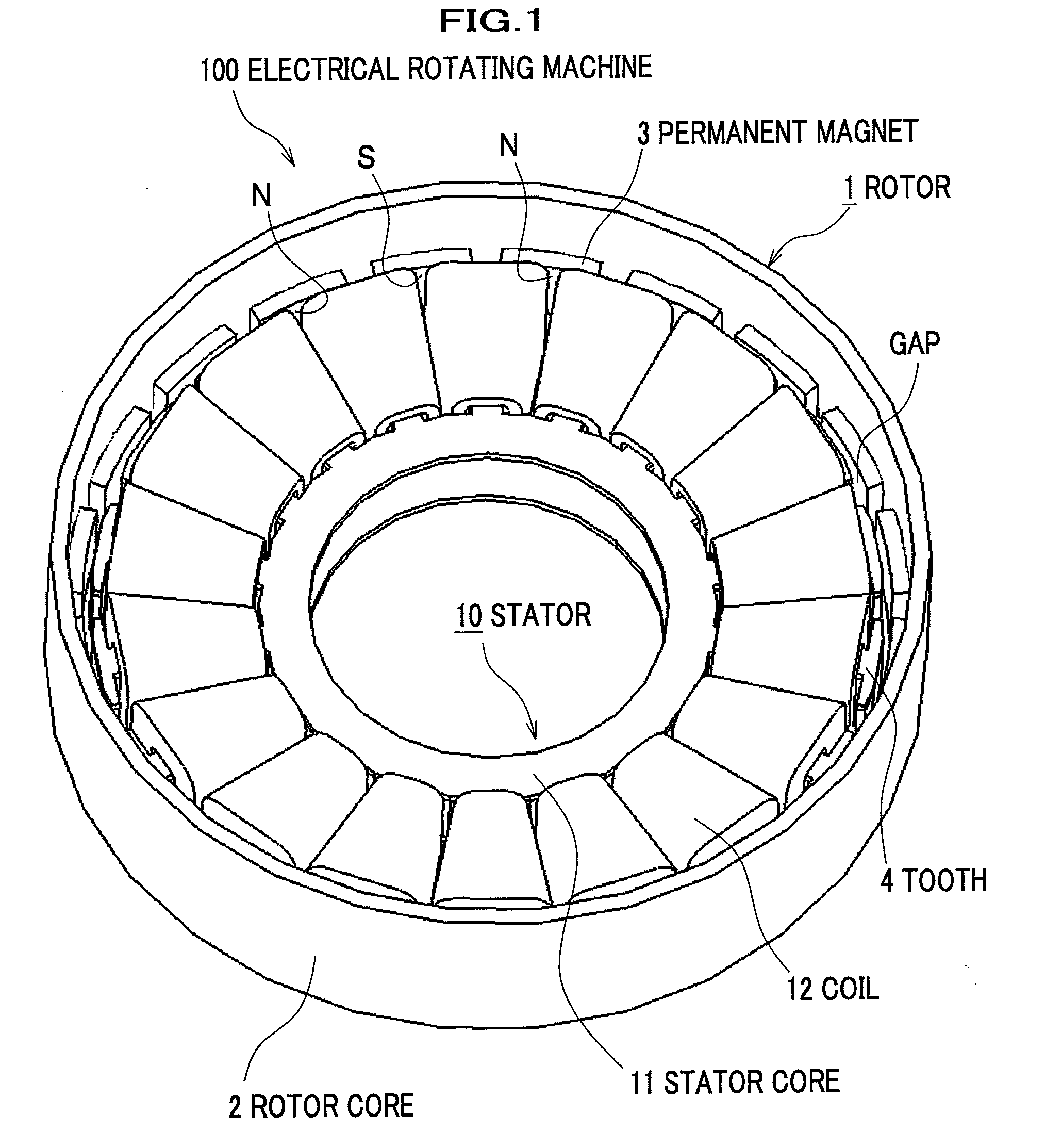

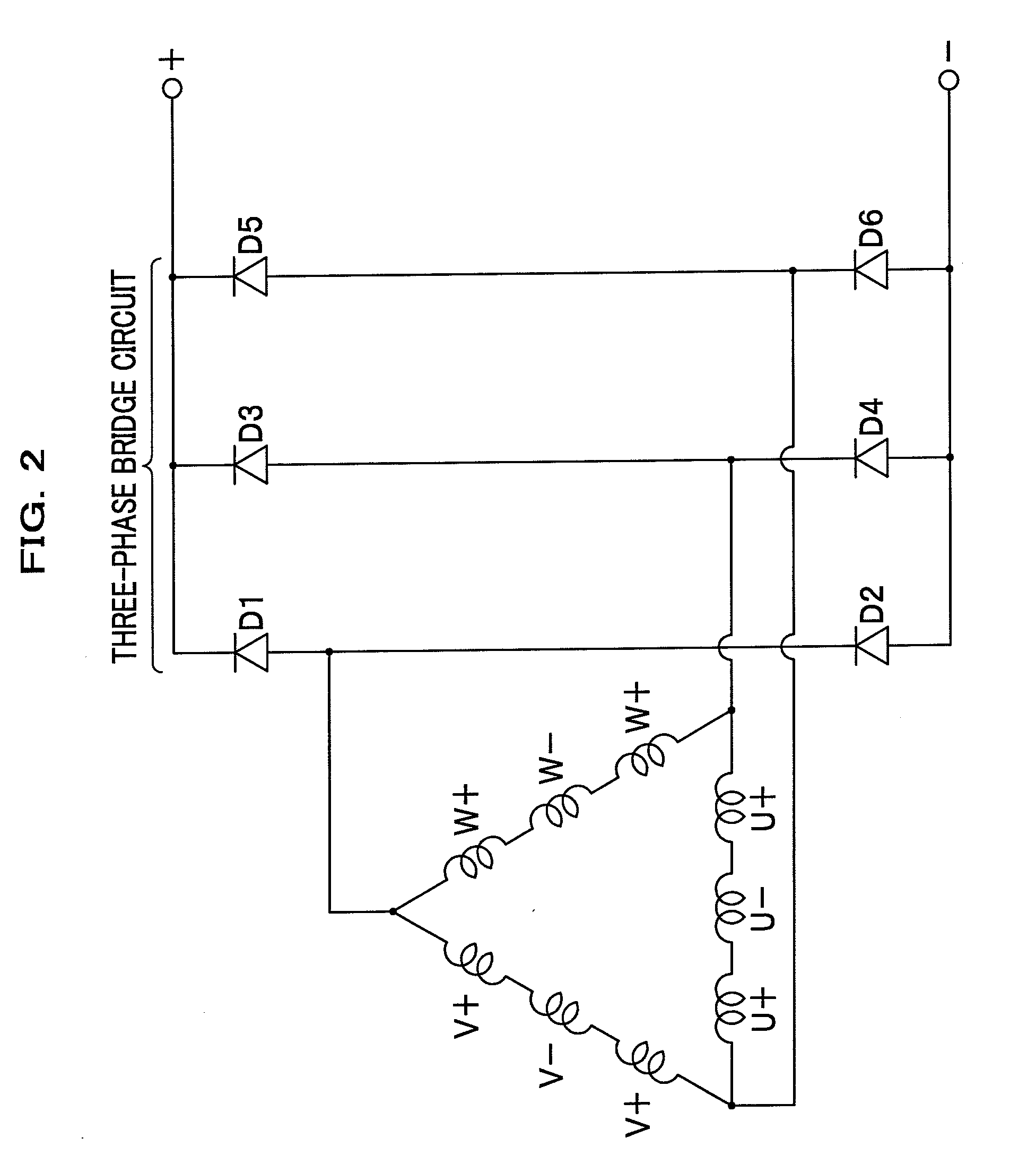

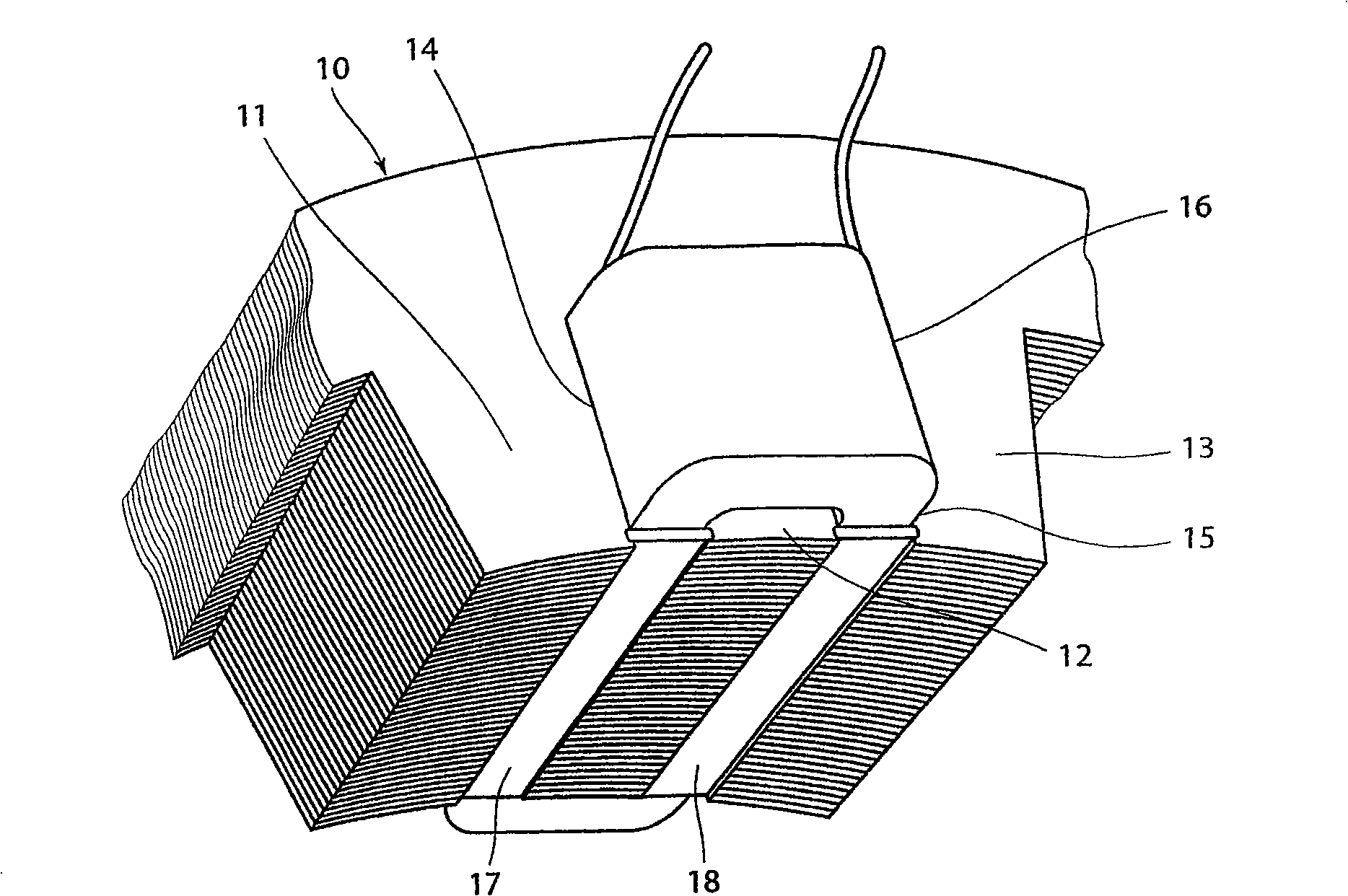

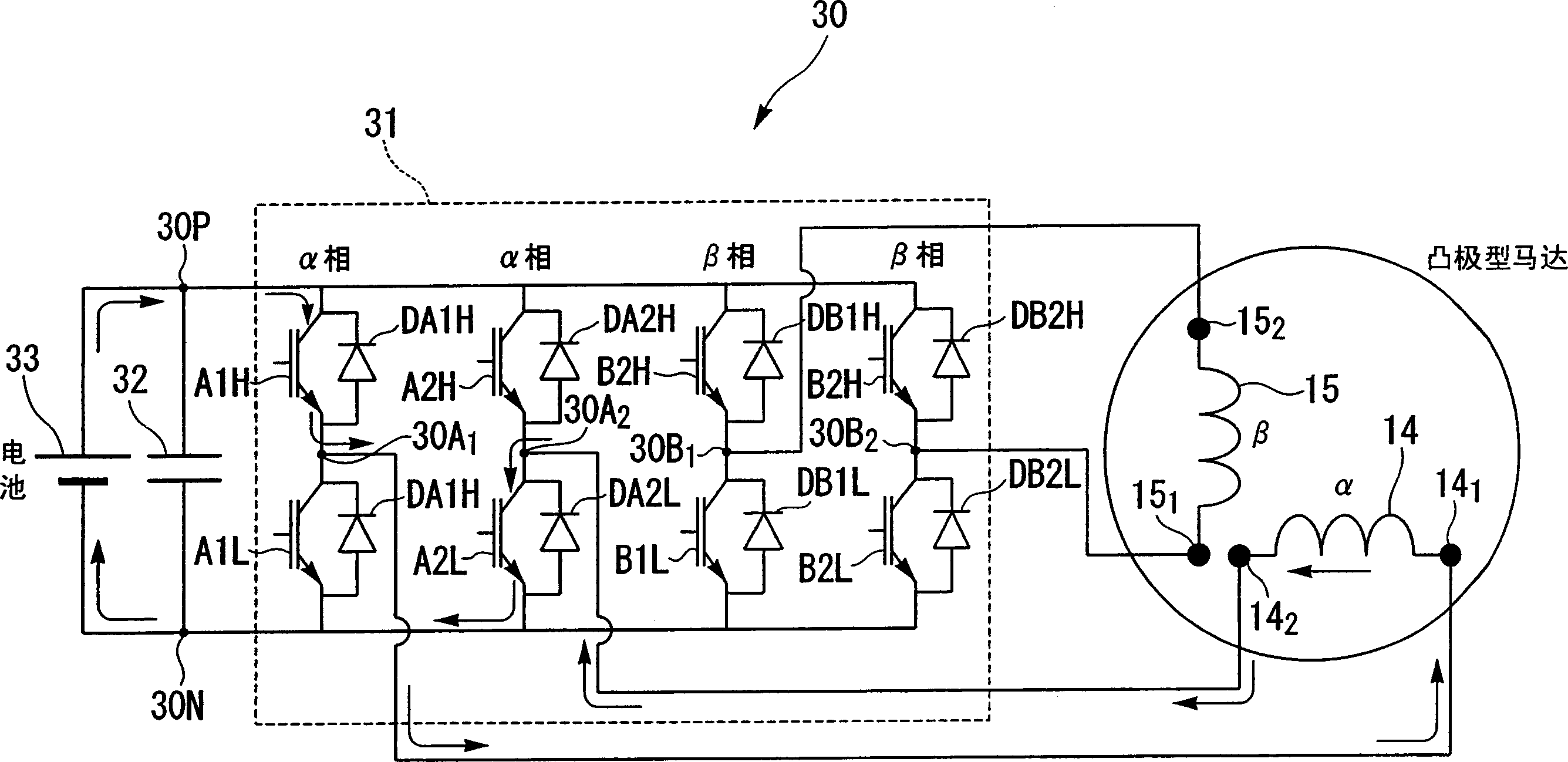

Electrical rotating machine

InactiveUS20080211338A1Reduce maintenanceReduce copper lossMagnetic circuit rotating partsAsynchronous induction motorsMagnetic polesPhysics

An electrical rotating machine with permanent magnets which is configured such that the ratio of the number of magnetic poles of permanent magnets 3 to the number of magnetic poles of coils 12 is at 10:9 or 8:9. The coils 12 are configured such that a middle coil U− and two adjacent coils U+, U+ on both sides thereof are in-phase connected to be in-phase coils for each phase, and there is satisfied the relationship that T2>T1 and T2>T3, where T2 is the turn number of the middle coil U−, and T1 and T3 are the turn numbers of the adjacent coils U+, U+.

Owner:KOKUSAN DENKI CO LTD

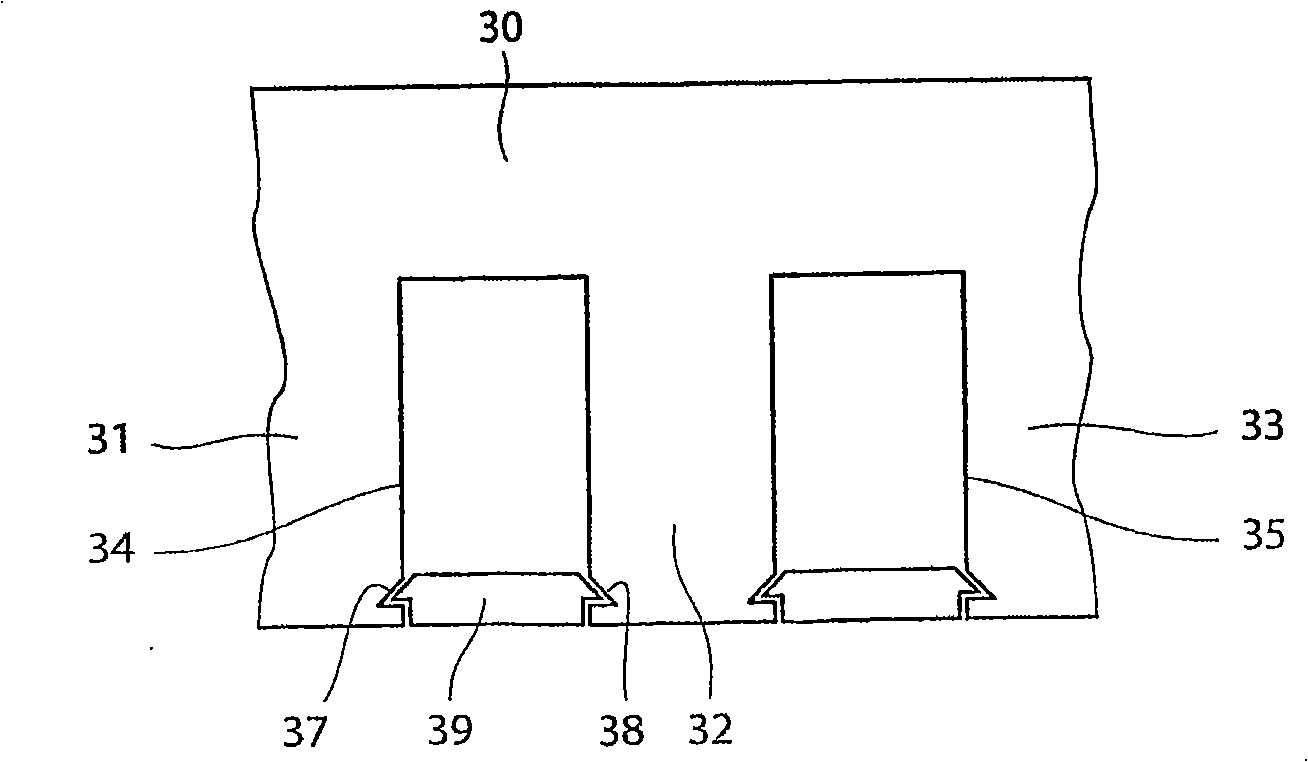

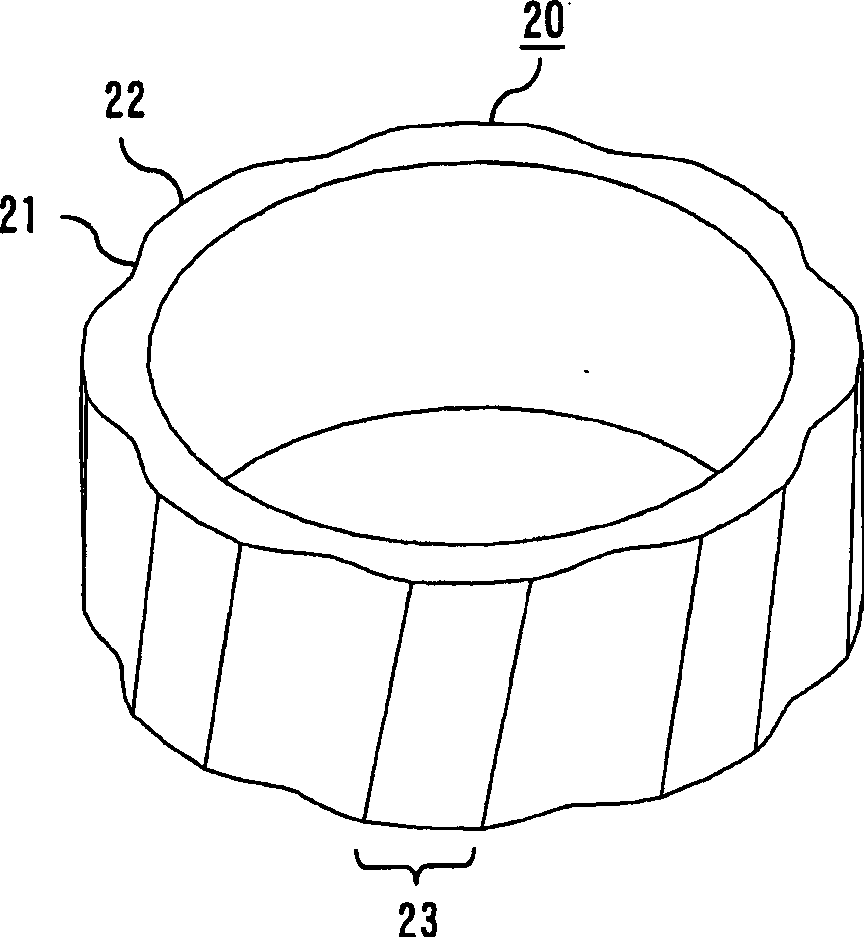

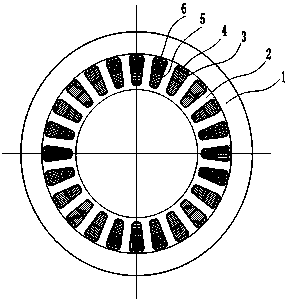

An electrical machine having a stator with rectangular and trapezoidal teeth

InactiveCN101411036AEasy to installLarge conductor cross sectionWindingsMagnetic circuit stationary partsElectric machineActuator

Arrangement at an electric machine, particularly motor, generator, or actuator, with a stator with teeth (11, 12) carrying coils (15), particularly one layer, for concentrated windings. A permanent magnetic rotor is movable relatively to the stator (11, 12). The teeth of the stator are arranged for receiving coils (15) with generally rectangular opening. Advantages are achieved if the stator teeth (11, 12) are provided to receive generally identical coils (15) closing the grooves (14, 16). The teeth (11, 12) may be alternating rectangular and converging / diverging toward the top, to provide grooves (14, 16), with parallel sides to enter the coils (15). The converging teeth (22) have preferably a shortened top (23). The grooves are preferably provided to make room for a semi magnetic groove wedge (17, 18) between adjacent teeth.

Owner:SMART MOTOR AS

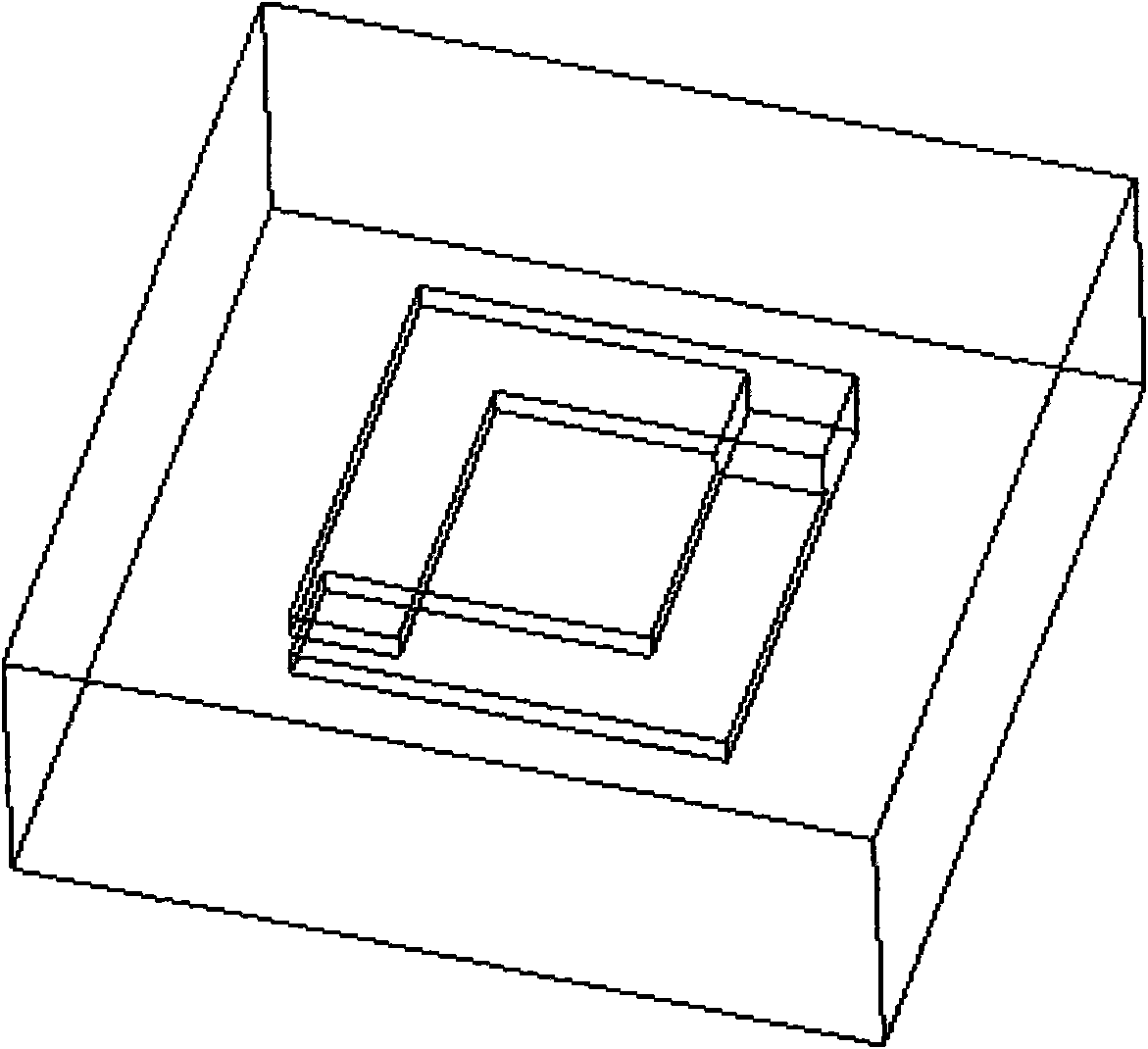

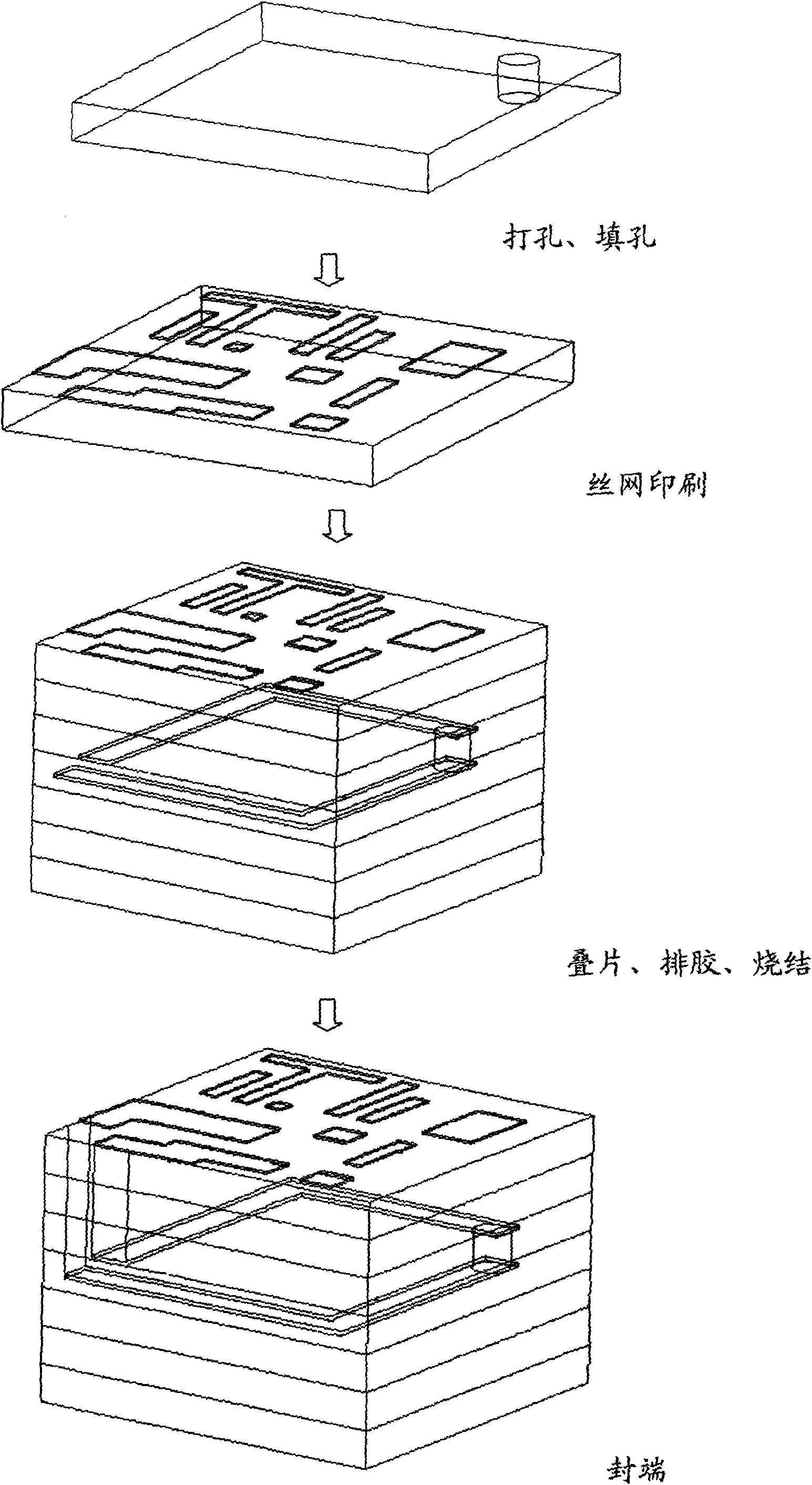

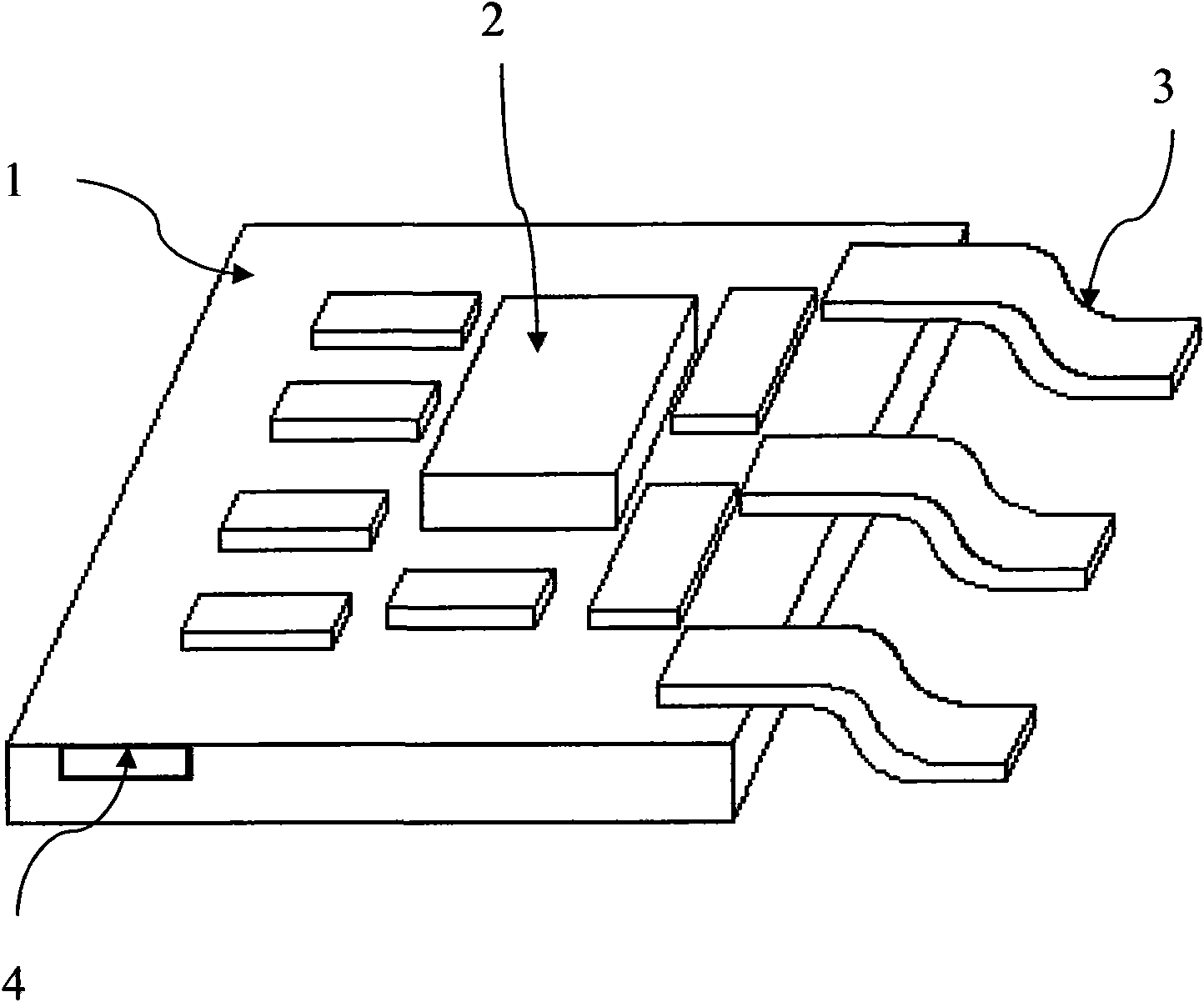

Substrate and magnetic device integrated DC-DC converter and preparation process thereof

InactiveCN101651404AAvoid errorsReduce volumePrinted circuit assemblingPrinted electric component incorporationFerrite substrateElectrical conductor

The invention discloses a substrate and a magnetic device integrated DC-DC converter. A magnetic device is integrated in a circuit substrate of the converter, and a surface electronic circuit is arranged on the surface of the substrate, wherein the substrate is a ferrite substrate, and the magnetic device is a conductor coil in a shape like the Chinese character of 'hui' and forms a closed inductor with ferrites around the magnetic device; both ends of the conductor coil extend to the side of the substrate, and the conductor coil and the surface electronic circuit are connected through a sealing end at the side face. The conductor coil of the converter is embedded in the substrate, and the substrate is a carrier of the magnetic device and the surface electronic circuit, thereby realizing the passive integration of the magnetic device and the circuit substrate and ensuring that the substrate also has the functions of the magnetic device. A separated inductor or transformer is not neededto be arranged in an assembly process, thereby greatly reducing the overall volume of a power module.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

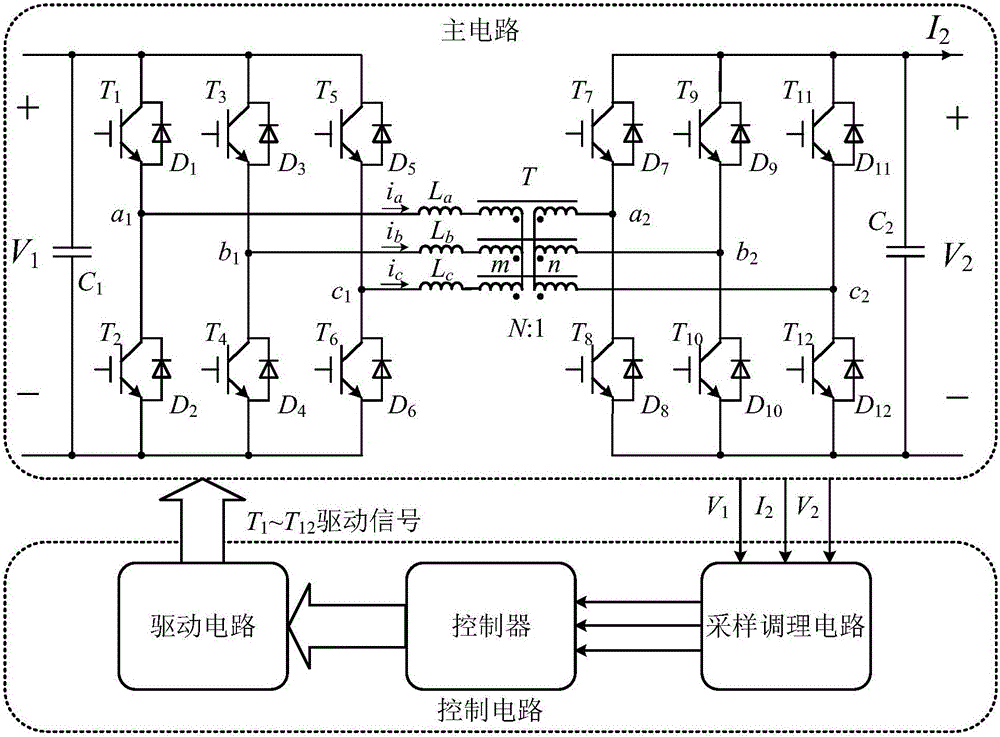

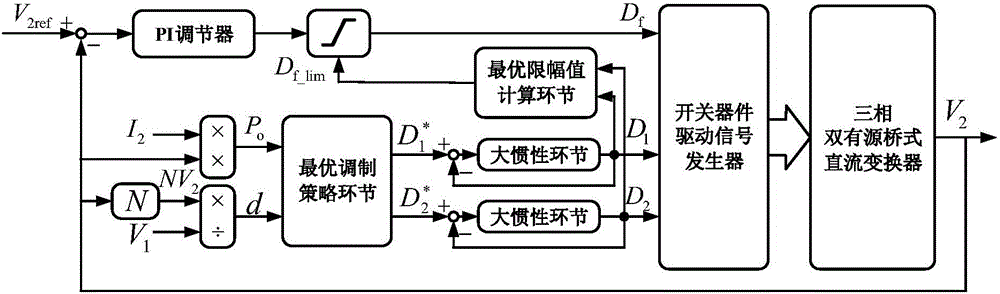

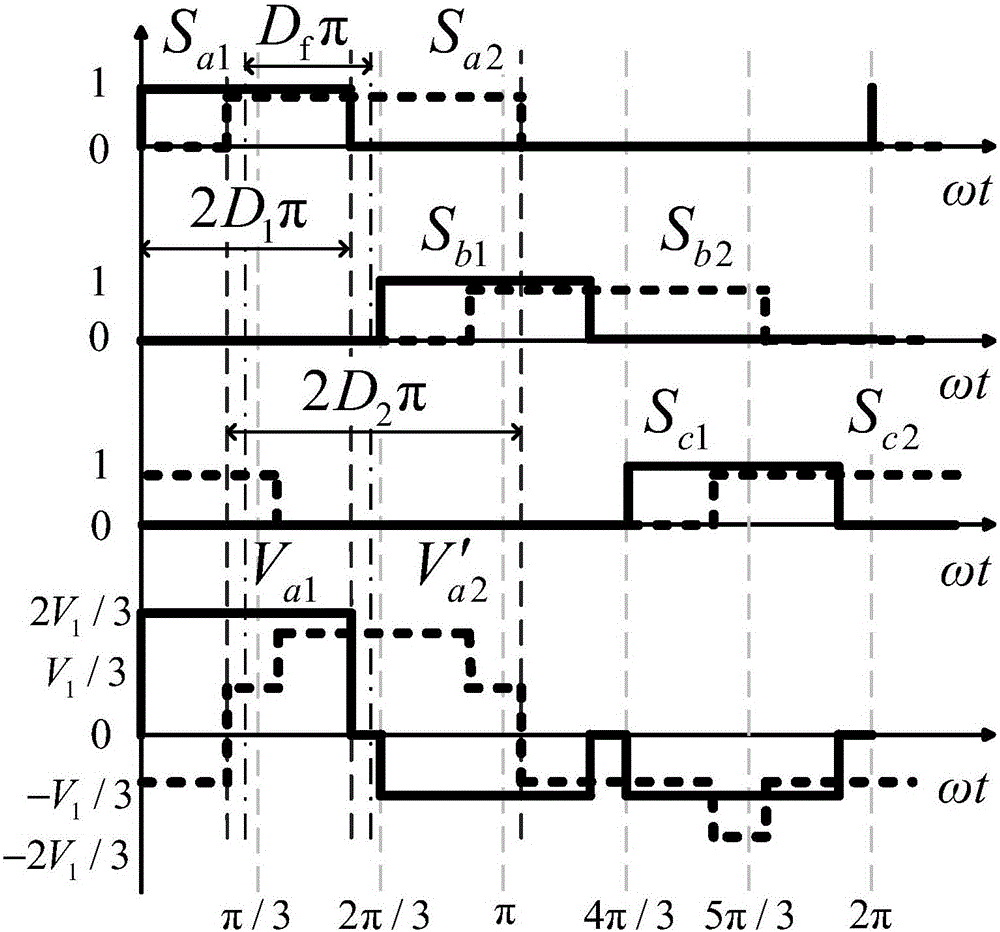

Control method of three-phase dual-active-bridge DC converter under current optimal modulation

InactiveCN105958830AImprove efficiencyReduce conduction lossEfficient power electronics conversionDc-dc conversionIntegratorPhase shifted

The invention provides a control method of a three-phase dual-active-bridge DC converter under a current optimal modulation. The method comprises a step of collecting DC side output voltage V2, DC side output current I2 and DC side input voltage V1 in each switch cycle, a step of multiplying the collected V2 by I2 to obtain a transmission power Po, at the same time multiplying V2 by a transformer transformation ratio N, dividing the above product by V1, and obtain a voltage transformation ratio d, a step of allowing Po and d to go through an optimal modulation strategy link to obtain the reference value D1* and D2* of duty ratios D1 and D2, and then obtaining the duty ratios D1 and D2 through two large inertia links or pure integrator links, a step of allowing the duty ratios D1 and D2 to go through an optimal amplitude limit value calculation link, and obtaining the optimal amplitude limit value Df_lim of a phase shift ratio, a step of carrying out difference comparison on a DC side output reference value V2ref and V2, allowing a difference to go through a PI regulator and an amplitude limit link with an amplitude limit value, and obtaining a phase shift ratio Df, and a step of obtaining the driving signal of each switch device according to the duty ratios D1 and D2 and the phase shift ratio Df, and driving a corresponding switch device.

Owner:XI AN JIAOTONG UNIV

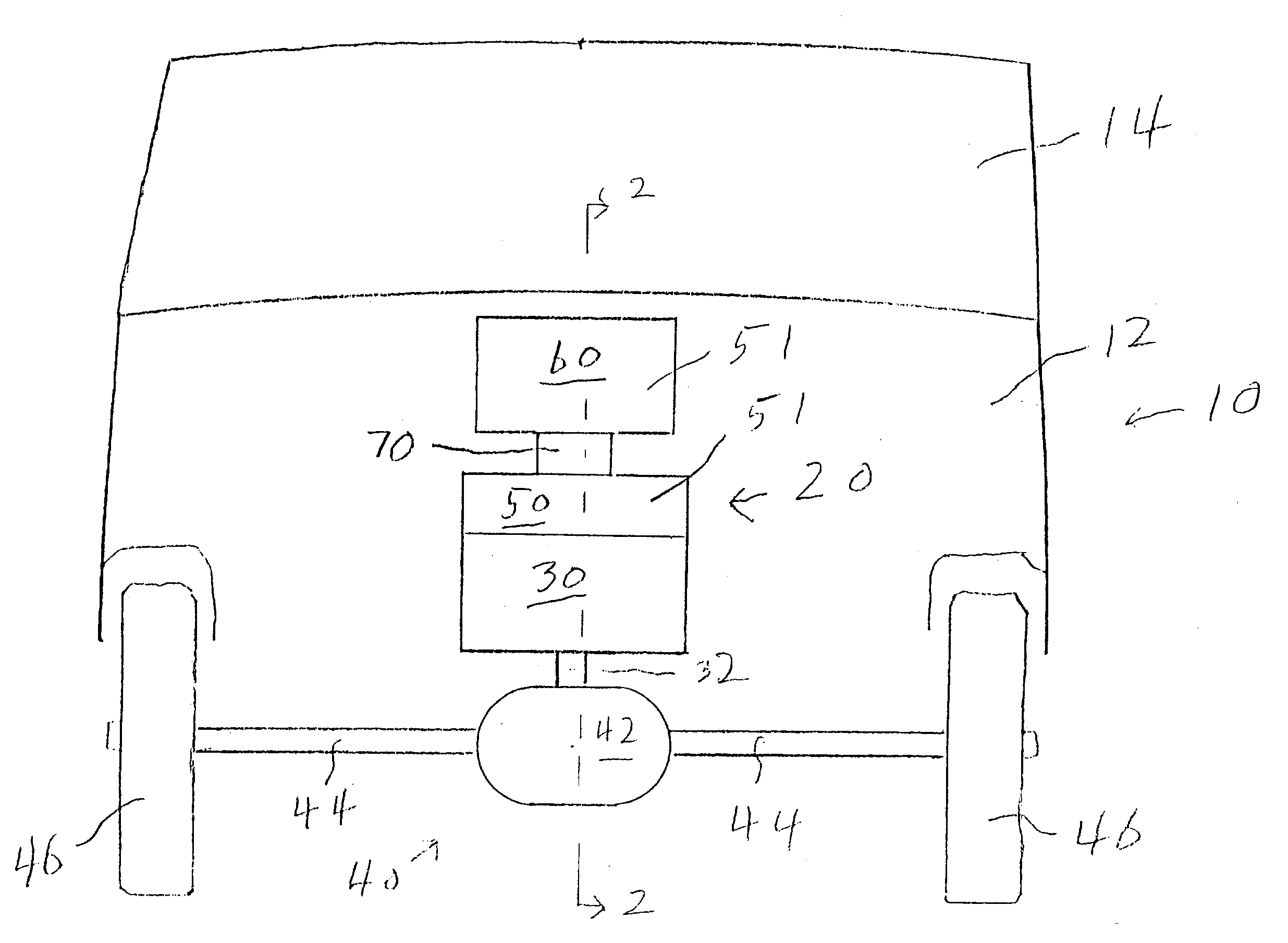

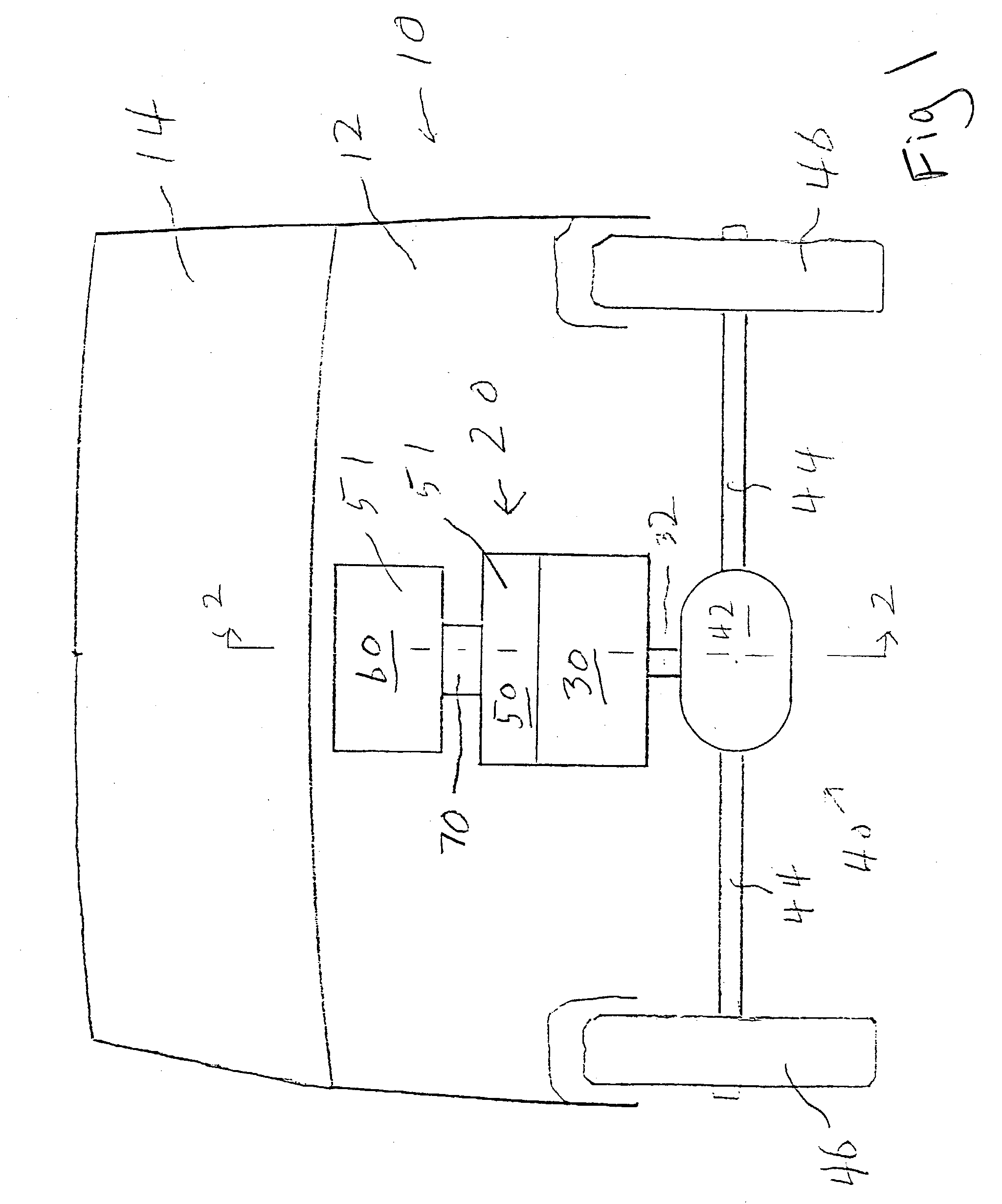

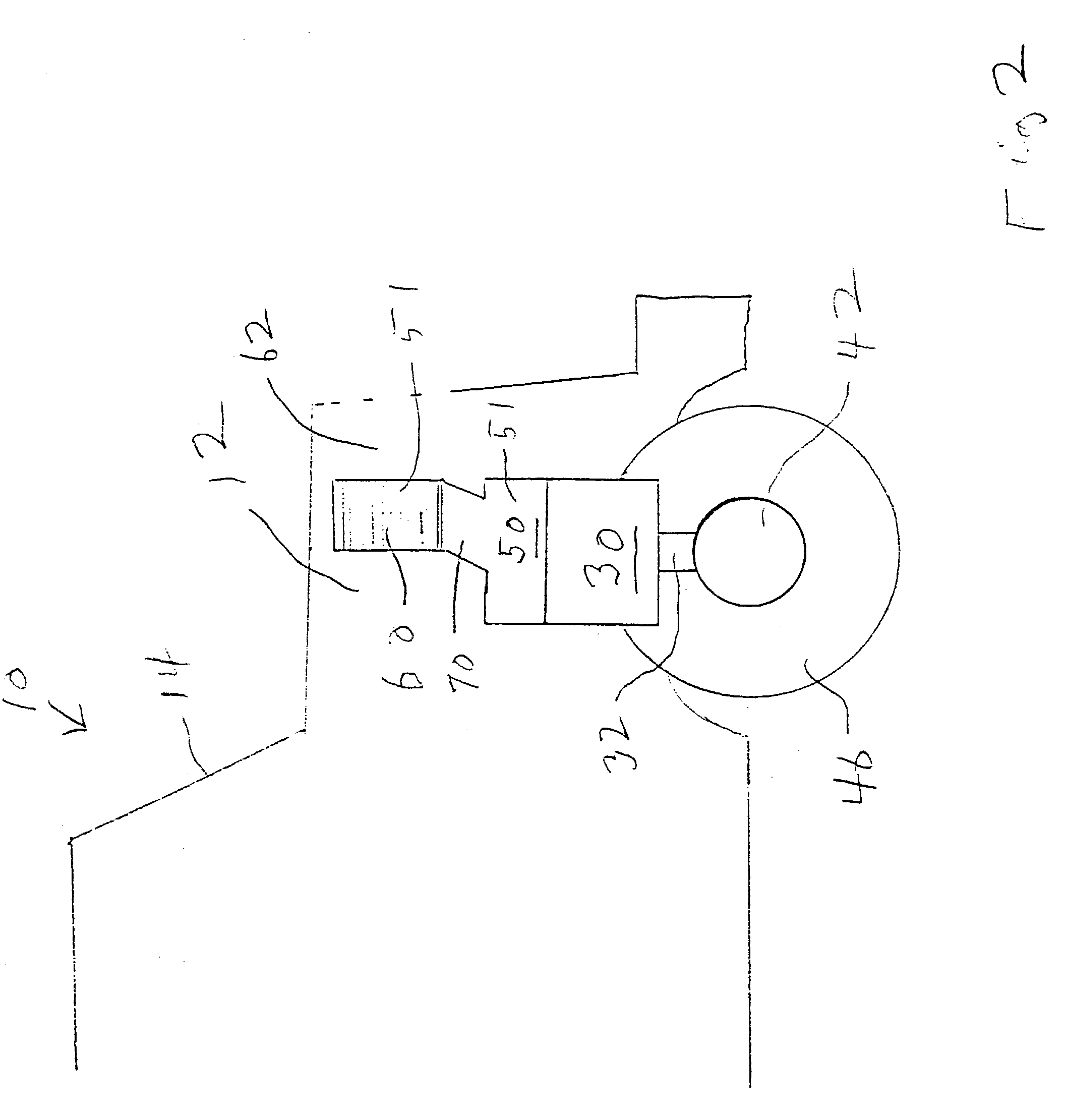

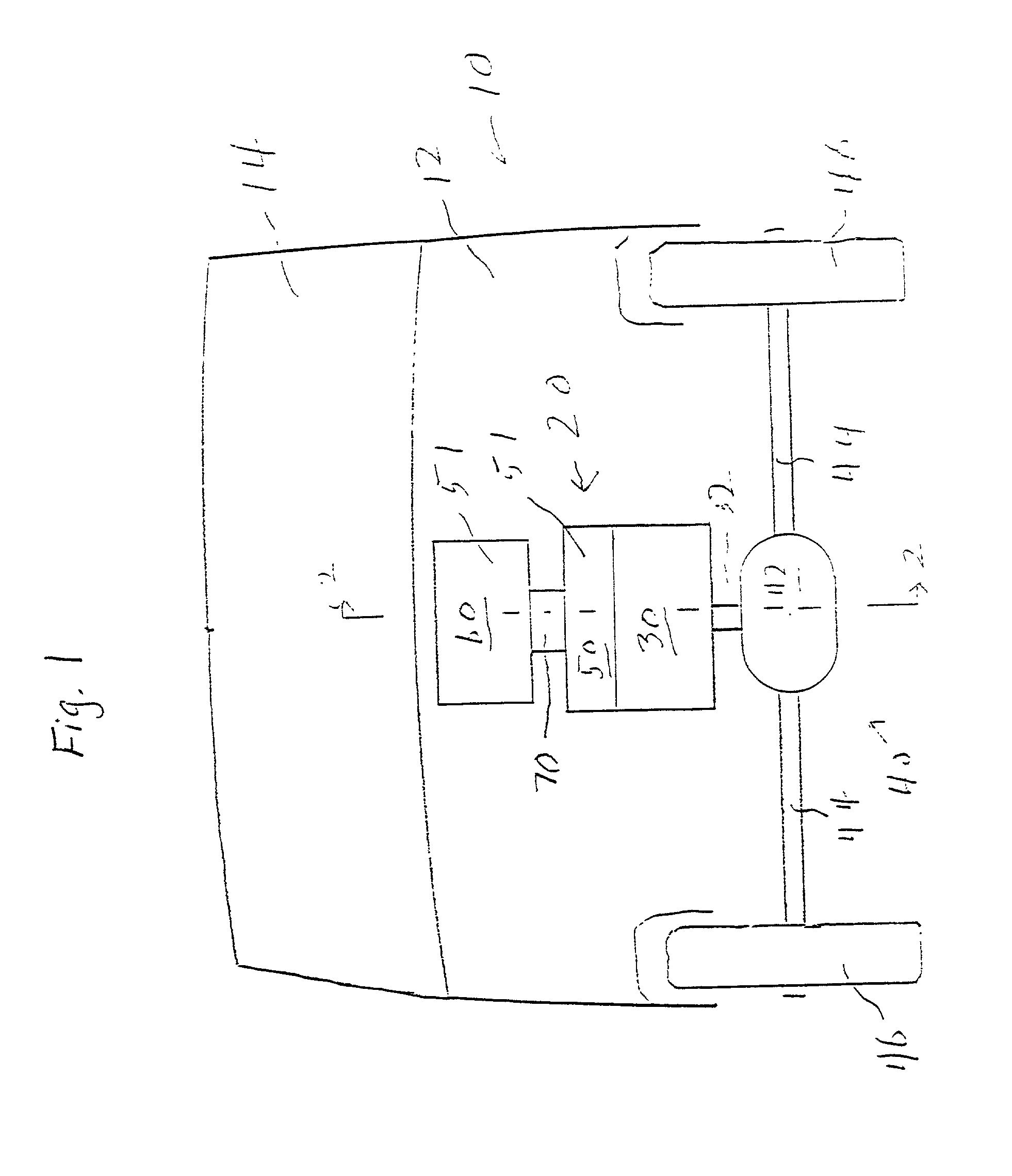

Cooling system for electric vehicle

InactiveUS20030116313A1Reduce copper lossImprove efficiencyAir-treating devicesMagnetic circuit rotating partsDrive wheelElectric vehicle

A motive power system for an electric vehicle has a drive train connected to one or more drive wheels of the vehicle. The motive power system has an electrical motor having a motive power output connection for attachment to the drive train. A first heat exchanger has thermal connection to the electrical motor to remove heat from the electrical motor, the first heat exchanger employing a coolant fluid. A second heat exchanger is in thermal contact with the coolant fluid and with an ambient atmosphere for removing heat from the coolant fluid.

Owner:ODONNELL DENNIS W

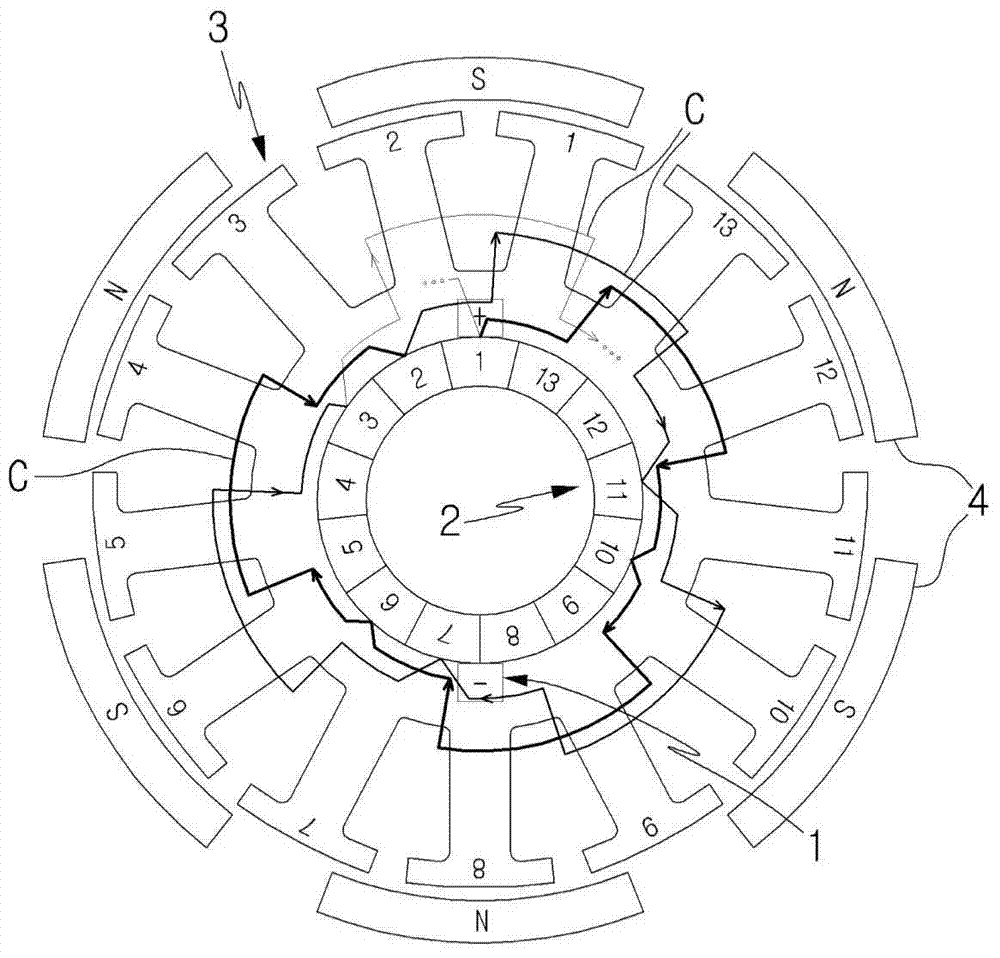

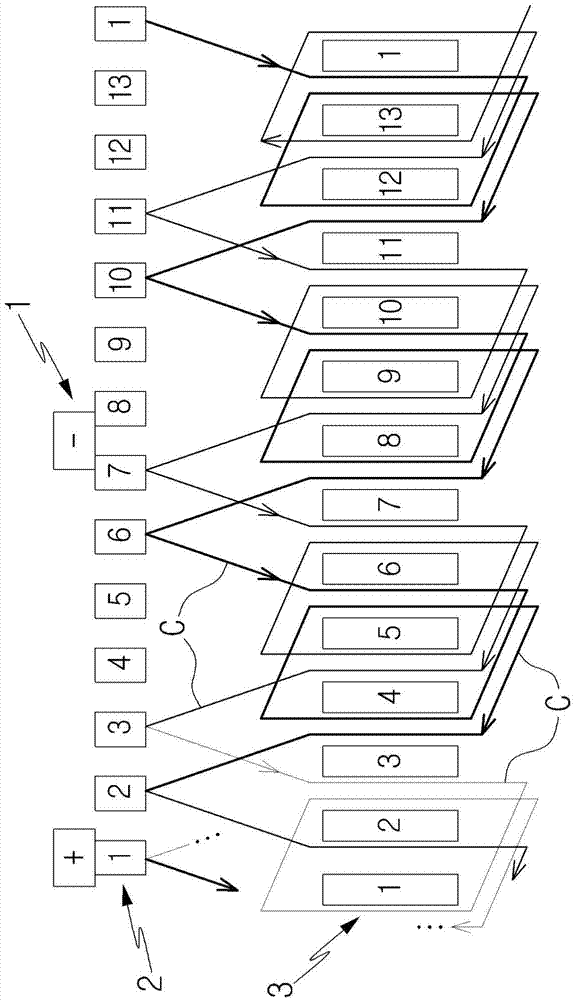

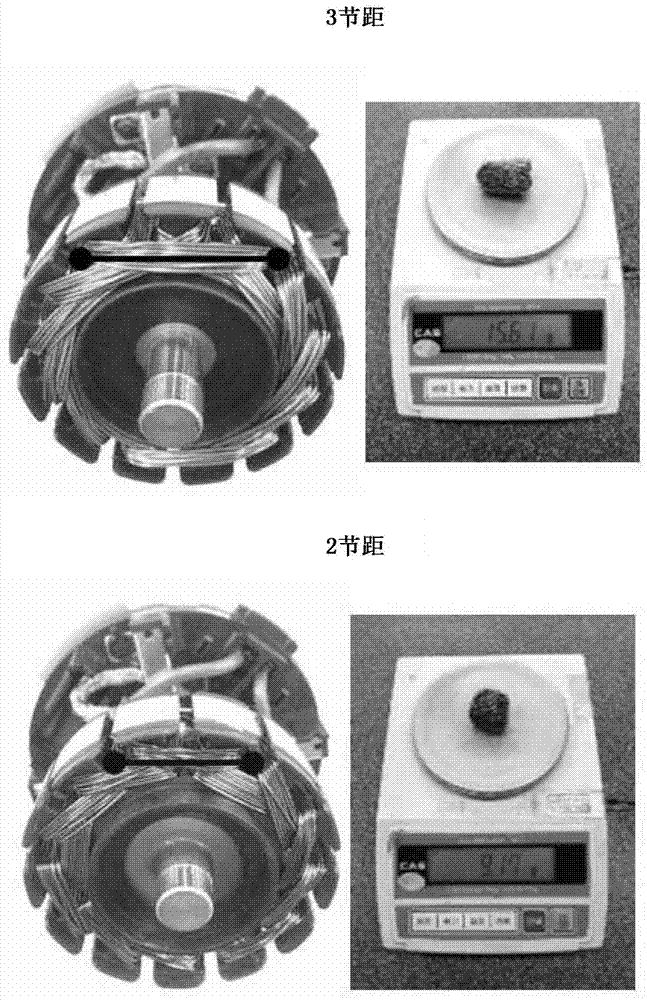

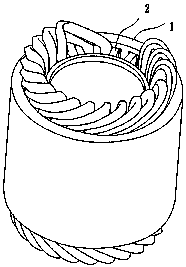

A motor coil winding structure

ActiveCN104518595AMaximize efficiencyReduce copper lossWindings conductor shape/form/constructionPower flowEngineering

The invention aims to provide a motor coil winding structure. After being led in a slot, a coil (C) from each segment of a commutator (2) to an iron core (3) side is led out to a slot with a 2-pitch interval from the slot and is wound on two teeth; in a motor, the coil is wound on the segments of the commutator (2) and the teeth and the slots of the iron core (3), the number of the segments of the commutator (2) of the motor is 13, the number of the teeth and the number of the slots of the iron core are 13, and the number of poles of a magnet (4) which is counterpoised to the outside of the iron core (3) is six; and thus, compared with a winding structure in the prior art which is wound with an interval of more than 3 pitches, the overall winding length and winding amount can be reduced, copper loss generated when a current flows through the coil (C) can be remarkably reduced, even if a coil (C) is wound with the amount less than that of a coil (C) of a motor in the prior art which is wound with an interval of more than 3 pitches set in the iron core (3), efficiency or more than the identity can be achieved, manufacturing cost is remarkably saved while motor efficiency is improved, and the size and the weight of the motor can be miniaturized.

Owner:HYO SEONG ELECTRIC

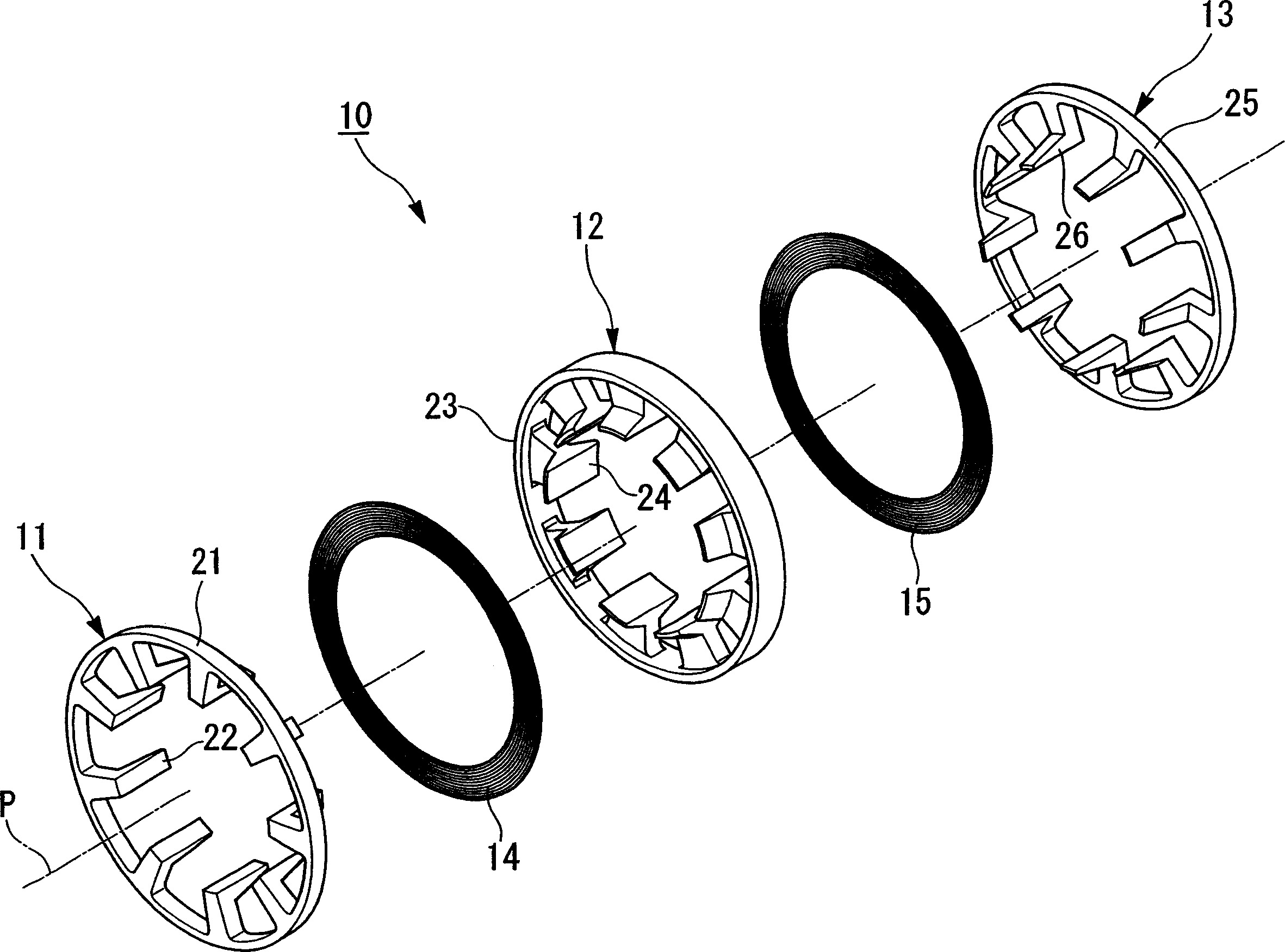

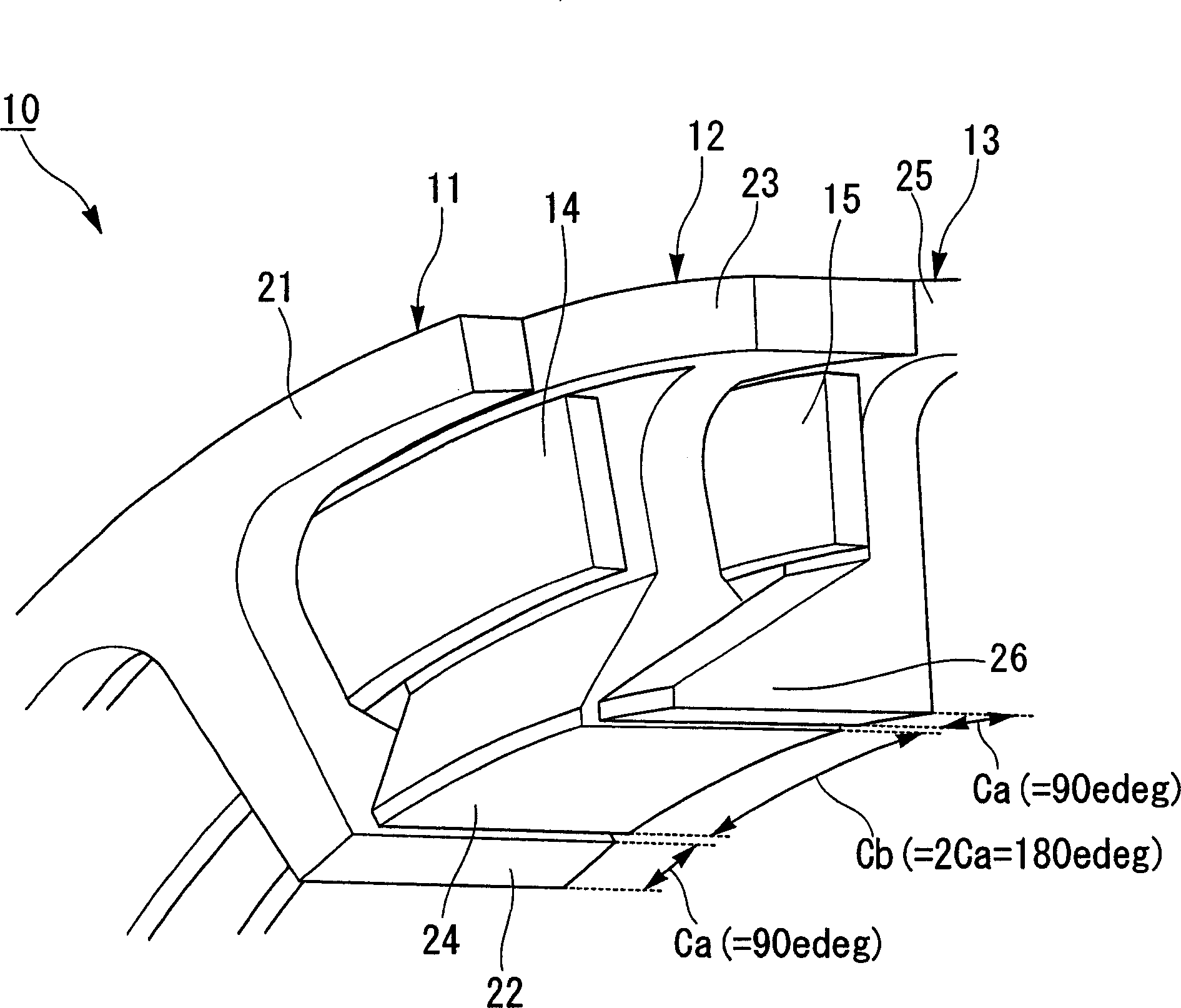

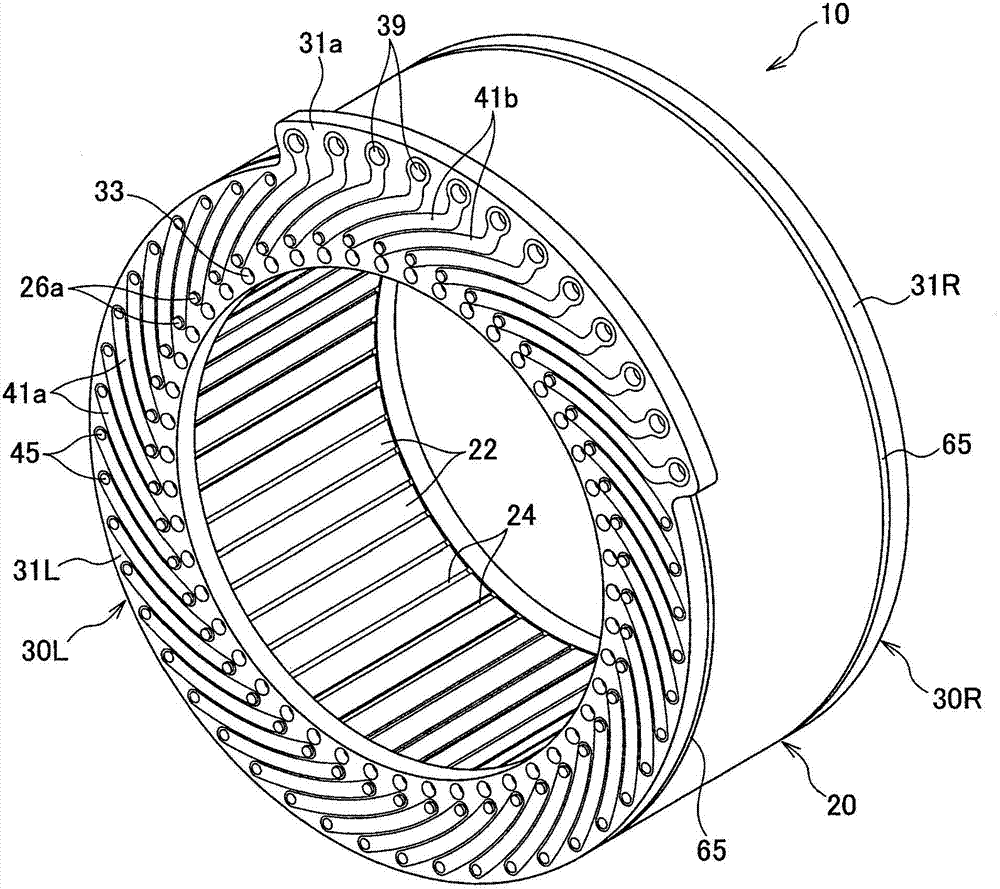

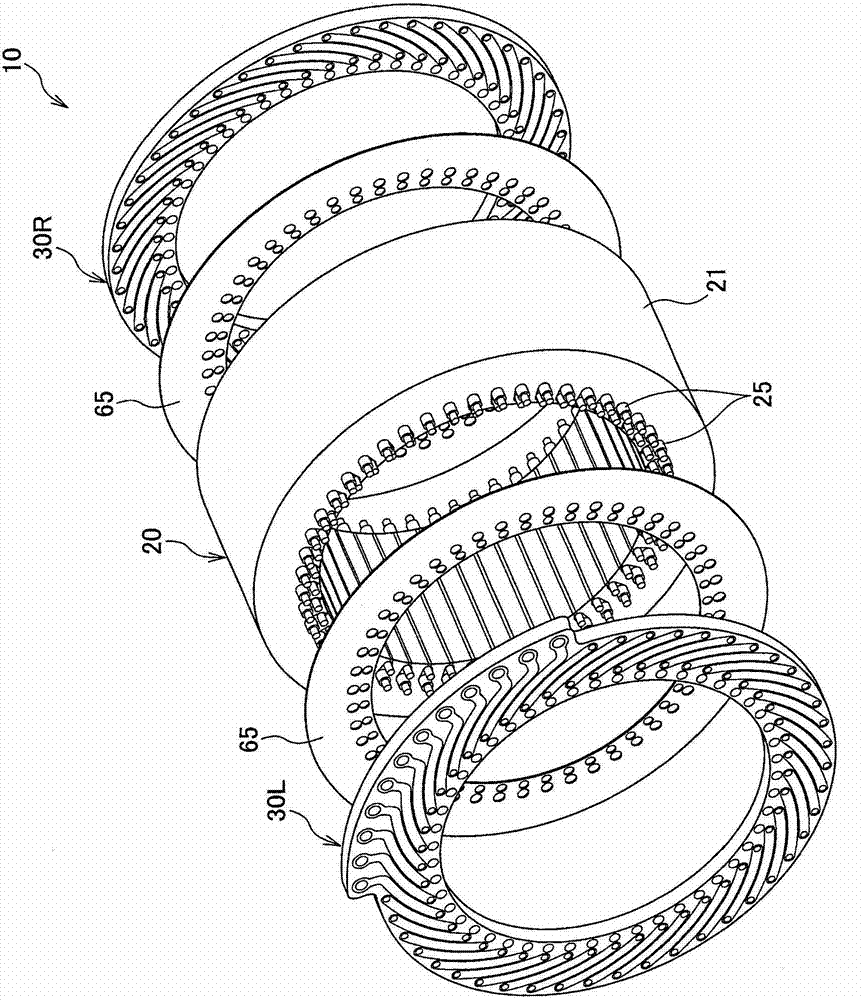

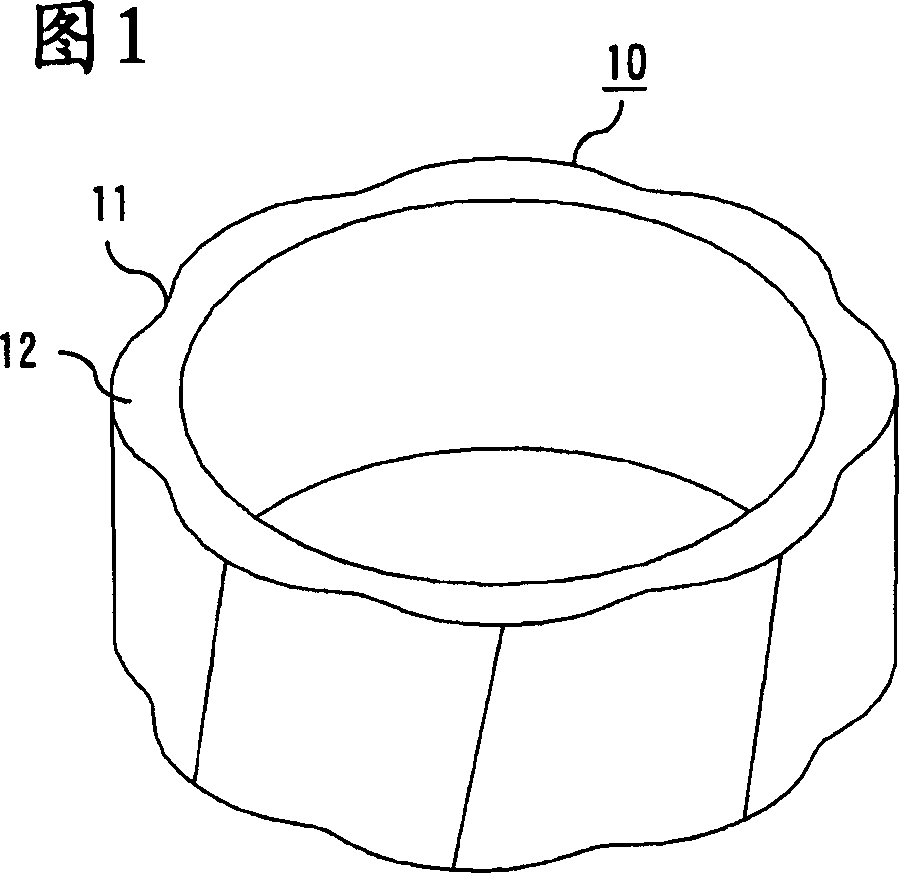

Stator, motor, and method of manufacturing such stator

InactiveCN1829044AAvoid elevationSmall sizeMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringConductor Coil

The invention provides a method, which overlay connects axially track rings (11), (12), (13) in order, to make the rings has the same axis with a shaft line (P). Arranging axially each claw-like induced poles (22), (24), (26). When the axial end-face of A phase rear yoke (21) contacts with the other axial end-face of B phase rear yoke (23), the base ends of claw-like induced poles (22), (24) arranged along the axis with proper interval, axially grip alpha phase ring winding (14) and fixed the winding. When the other axial end-face of B phase rear yoke (23) contacts with the axial end-face of D phase rear yoke (25), the base ends of claw-like induced poles (242), (26) arranged along the axis with proper interval, axially grip beta phase ring winding (15) and fixed the winding.

Owner:HONDA MOTOR CO LTD

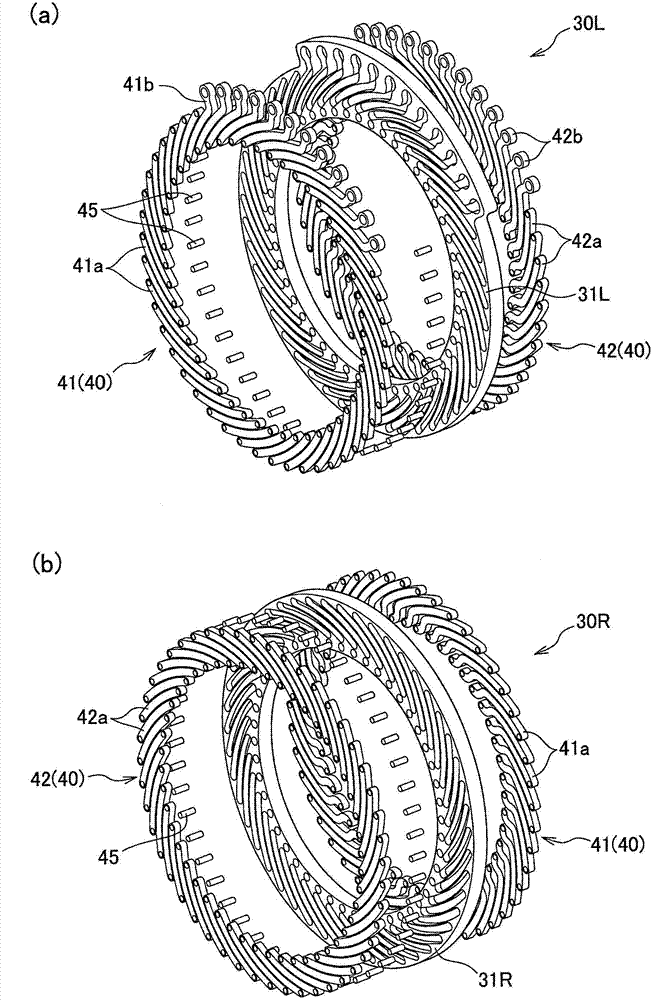

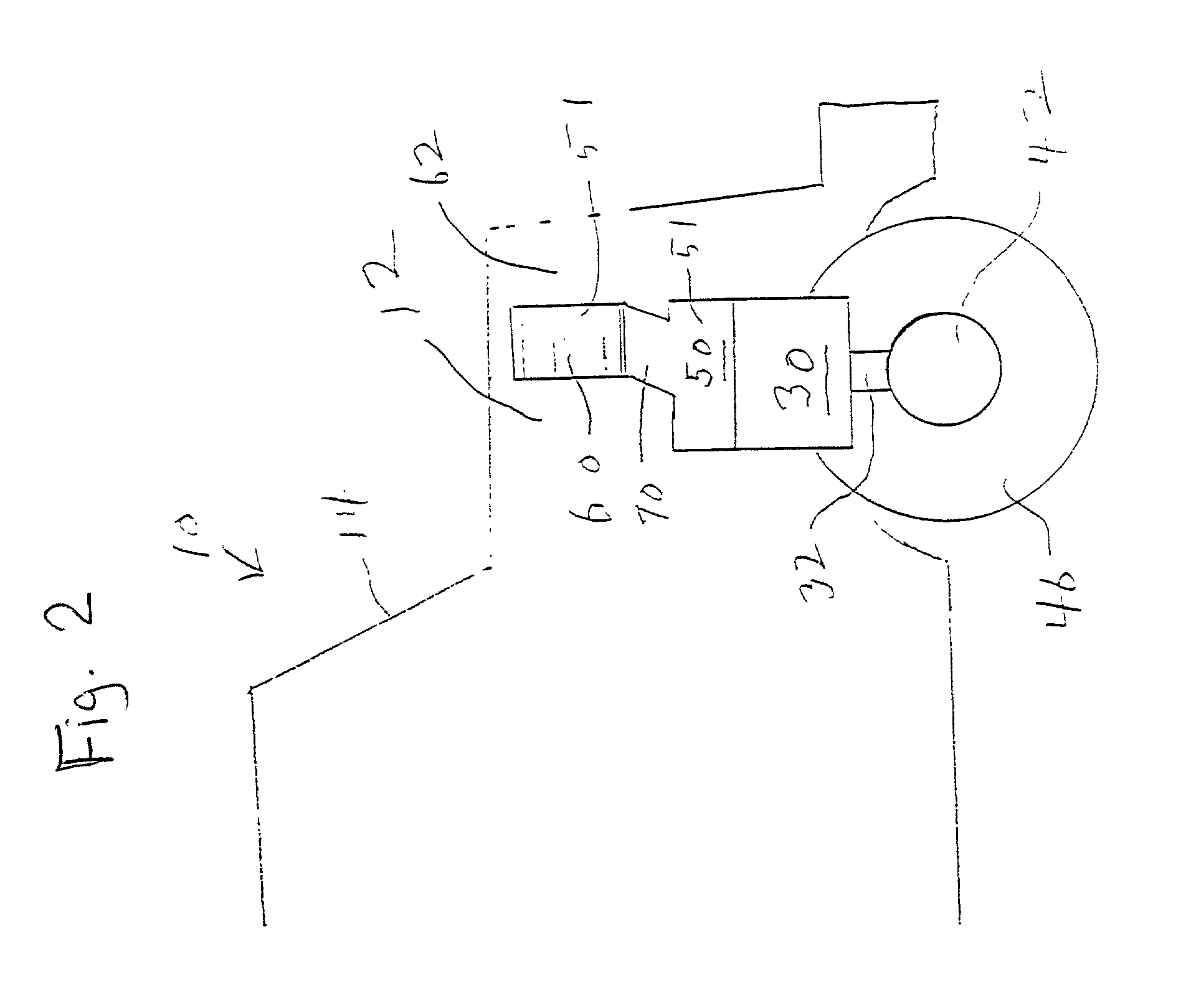

Stator for electric rotary machine

ActiveCN102891548ACurb sticking outMiniaturizationMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineEngineering

The invention provides a stator (10) for an electric rotary machine which can be reduced in size by suppressing the projection of extending portions in the axial direction and which can enhance the performance thereof by suppressing the copper loss as a result of the length of the extending portions being reduced. The stator (10) includes: a stator core (21); and segmented coils (50) of a plurality of phases, wherein: the segmented coils (50) of a plurality of phases have pluralities of coil bars (25) which are inserted individually in a plurality of slots (23) in the stator core (21) and which extend substantially in a straight line and pluralities of connection coils (40) which connect together the coil bars (25) of the same phase to thereby make up extending portions; the connection coils (40) each comprise an inner connection coil (42) and an outer connection coil (41) which are disposed in different axial positions; and the inner connection coil (42) faces an outer connection coil (41) of a different phase in an axial direction and the outer connection coil (41) faces the inner connection coil (42) of a different phase in the axial direction.

Owner:HONDA MOTOR CO LTD

Cooling system for electric vehicle

InactiveUS20020112851A1Reduce copper lossImprove efficiencyAir-treating devicesVehicle heating/cooling devicesDrive wheelElectric vehicle

A motive power system for an electric vehicle has a drive train connected to one or more drive wheels of the vehicle. The motive power system has an electrical motor having a motive power output connection for attachment to the drive train. A first heat exchanger has thermal connection to the electrical motor to remove heat from the electrical motor, the first heat exchanger employing a coolant fluid. A second heat exchanger is in thermal contact with the coolant fluid and with an ambient atmosphere for removing heat from the coolant fluid.

Owner:ODONNELL DENNIS W

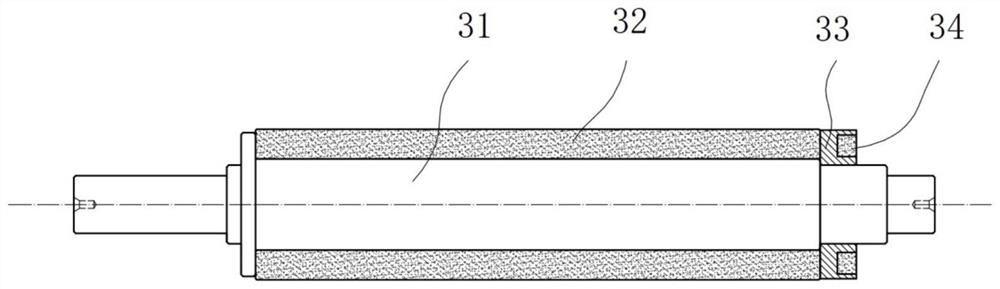

External-rotor intermediate-frequency permanent magnet generator device

InactiveCN102738934AImprove automationSave human effortMagnetic circuit rotating partsMagnetic circuit stationary partsIntermediate frequencyConductor Coil

An external-rotor intermediate-frequency permanent magnet generator device comprises a power interface fixing disc, a power shaft arranged on the power interface fixing disc, an internal stator connected with the power interface fixing disc, an annular external rotor connected with the power shaft and having a magnetic steel, and a protection cover connected with the internal stator and provided with an air inlet. The external rotor of the intermediate-frequency permanent magnet generator device is arranged outside the internal stator; an iron core lamination of the stator is designed to a coil slot shape and is distributed on the external circumference; the winding form is designed to a centralized winding form; and a stator winding coil is wound on the teeth individually in such a manner that one tooth corresponds to one independent coil and both sides of each coil have one pole respectively so as to form a fractional-slot winding. The stator iron core can be conveniently fixed on a stator reinforcement rib because the coil has a short and small end; the rotor is a multi-polar magnetic steel rotor; and the stator and the stator iron core are shorter in comparison with the generator of the same capacity, so that generator can be designed to a flat structure, which can have no rear bearing and of which the front end can be directly connected with an interface of a power oil machine.

Owner:FUJIAN YANAN ELECTRIC MACHINE

Less-rare-earth multi-excitation-source double-stator flux-switching memory motor

InactiveCN106911237AAchieve separationSolve mutual problemsMagnetic circuit rotating partsMagnetic circuit stationary partsRare earthEngineering

The invention discloses a less-rare-earth multi-excitation-source double-stator flux-switching memory motor, which belongs to the technical field of motor body design and operating principles. Coaxial outer stators, rotors and inner stators are sleeved together in turns from outside to inside to compose the memory motor, wherein a radial air gap exists between the outer stators and the rotors, the rotors and the inner stators, the outer stators are composed of armature core teeth, fault-tolerant teeth and stator yokes, and the rotors are composed of a rotor support, a magnetic silicon steel block and a magnetic insulation block, and meanwhile, the inner stators are composed of the inner stator core and a combined permanent-magnet cell block. The double-stator structure of the motor realizes the separation of armature winding and permanent magnet and solves the problem that multiple excitation sources inside the traditional flux-switching permanent magnet motors restrain each other, thereby easily increasing motor power density and torque density. The memory motor maintains high air-gap flux density and ensures of the motor power density and the torque density, meanwhile, the consumption of rare-earth permanent-magnetic materials is effectively lowered. On the other side, the memory motor can realize flexible adjustment of a motor air-gap field and expand the range of speed operation.

Owner:YANGZHOU UNIV

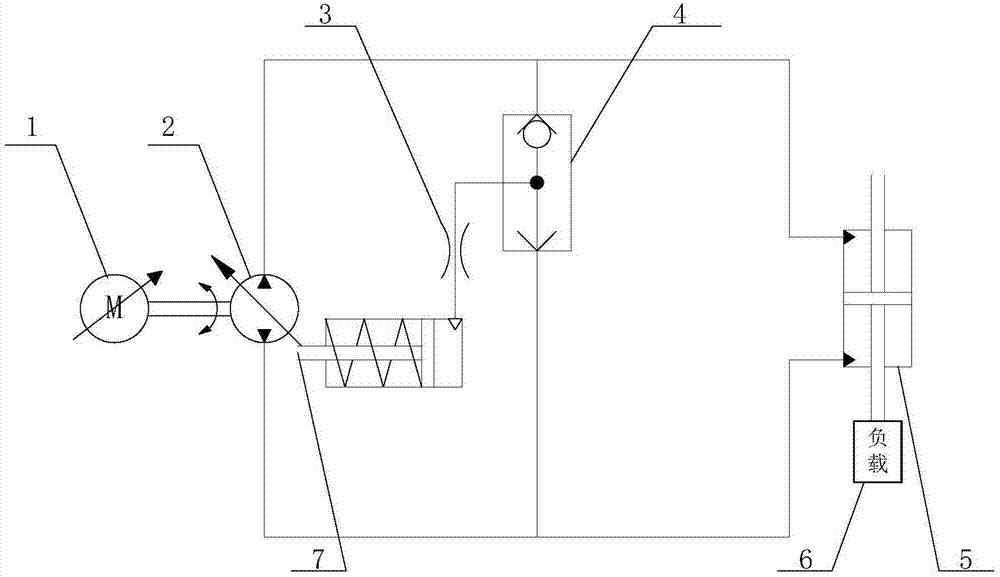

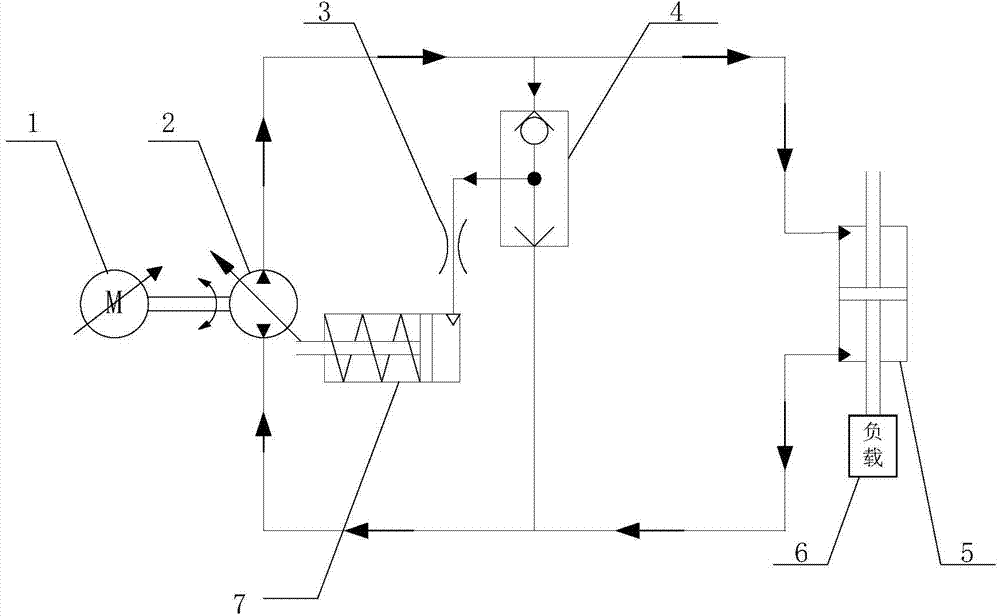

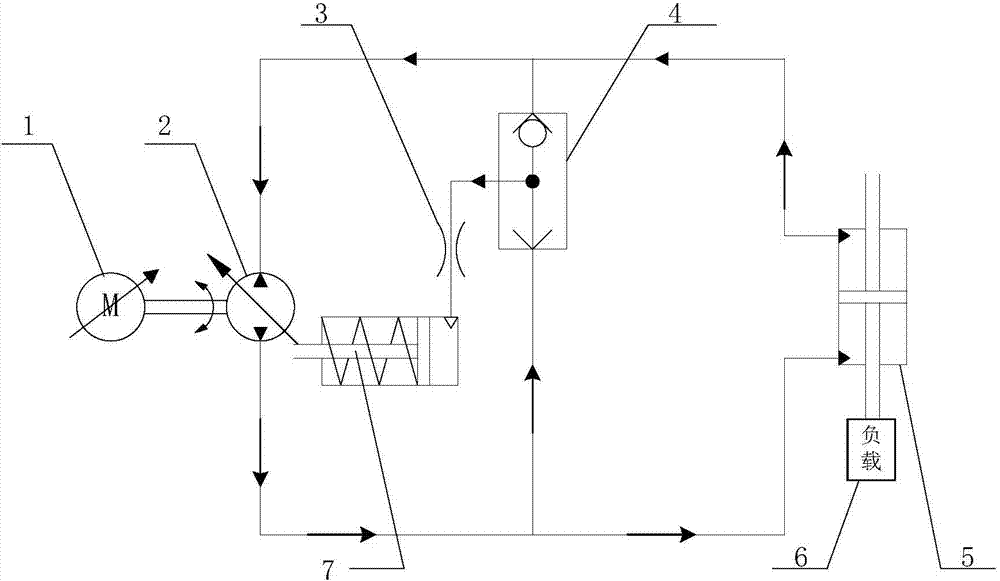

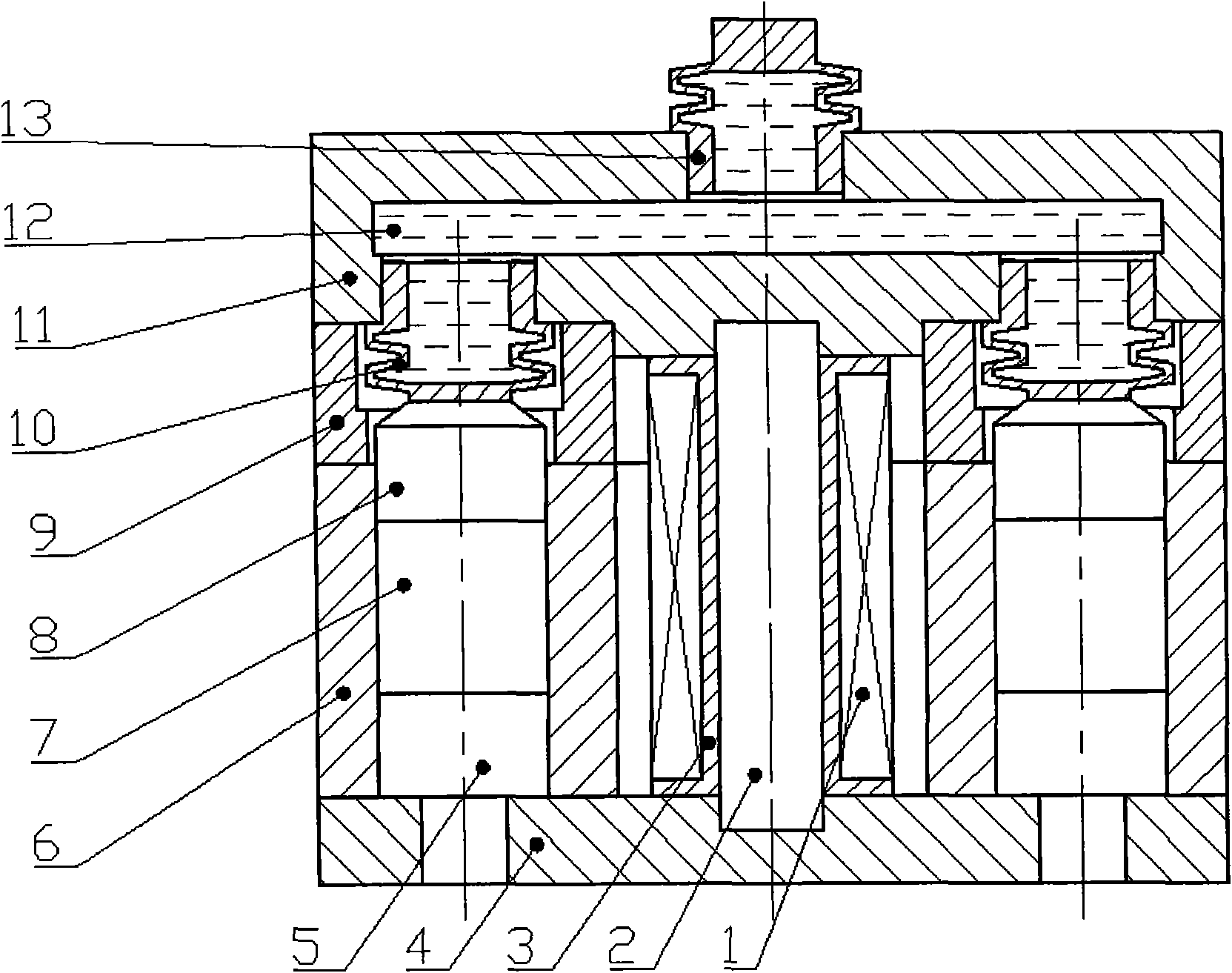

Electro-hydrostatic actuator sensitive to load

InactiveCN104747514AReduce copper lossReduce feverServomotor componentsServomotorsHydraulic cylinderHydraulic pump

The invention relates to an electro-hydrostatic actuator sensitive to load. The actuator comprises a variable displacement hydraulic pump, symmetrical hydraulic cylinders, a feedback module and an actuating mechanism. The electro-hydrostatic actuator sensitive to load can reduce heat dissipation of a whole system and further reduce power consumption of the whole system.

Owner:BEIHANG UNIV

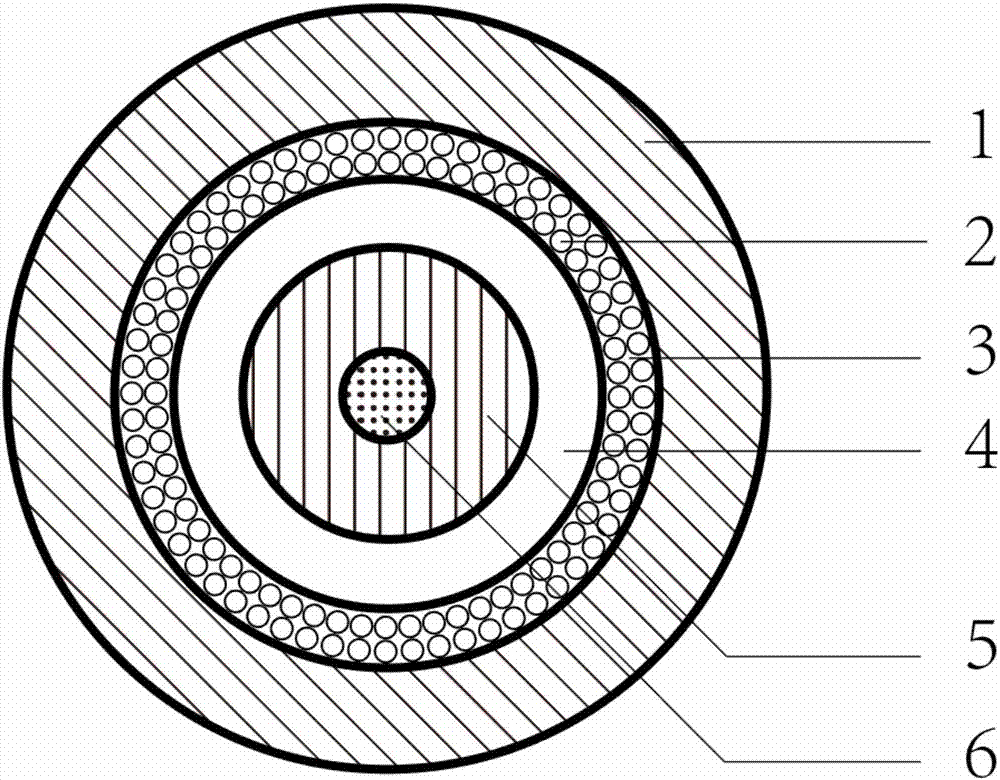

Double-magnet double-rotor permanent magnet motor for flywheel

InactiveCN105207431AShorten the axial lengthEnhanced air gap magnetic fieldDynamo-electric machinesStator coilPermanent magnet motor

The invention relates to a double-magnet double-rotor permanent magnet motor for a flywheel. The double-magnet double-rotor permanent magnet motor includes a rotor assembly and a stator assembly; the rotor assembly comprises an outer rotor, outer magnets, an inner rotor and inner magnets; the rotor assembly is fixedly and coaxially connected with the bearing seat of the flywheel through the outer rotor; the outer rotor is coaxially and fixedly connected with the inner rotor; the outer magnets uniformly distributed on and fixedly connected with the inner ring surface of the outer rotor; the inner magnets are uniformly distributed on and are attached to the outer ring surface of the inner rotor; in the same radial dimension, the polarity of the outer magnets is opposite to the polarity of the inner magnets; the stator assembly includes a stator coil, a stator frame and a stator bracket; the stator assembly is connected with the supporting frame of the flywheel through the stator bracket; the stator coil is fixed on the stator bracket through the stator frame and is installed between the inner magnets and the outer magnets, so that two air gaps can be generated respectively. With the double-magnet double-rotor permanent magnet motor adopted, an air gap magnetic field can be improved, effective cutting axial length of the stator coil can be reduced, and copper loss can be reduced; and the axial length of the rotor assembly can be reduced, so that the axial length of the whole flywheel can be reduced, and the weight of an overall structure is small.

Owner:SHANGHAI XINYUE METER FACTORY

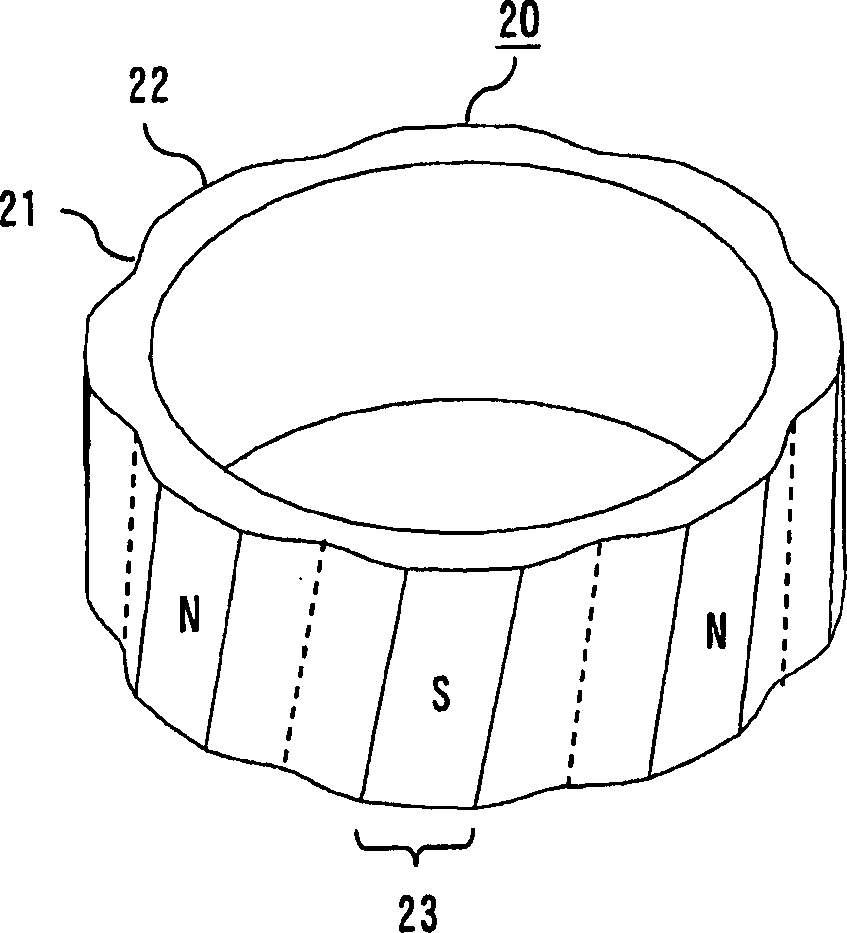

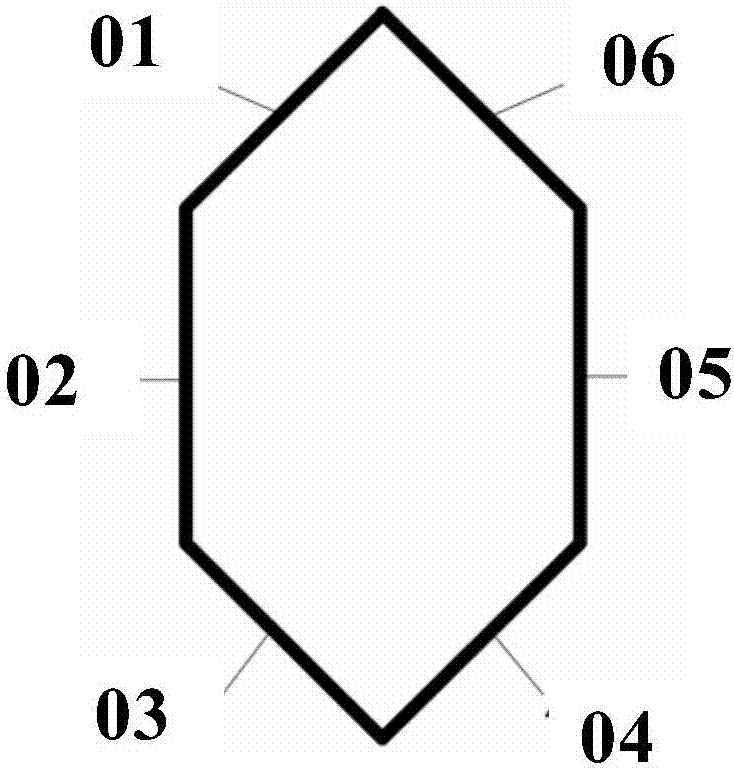

Ring type sintered magnet

InactiveCN1770595AControlling the MMF DistributionIncrease magnetic fluxMagnetic circuit rotating partsManufacturing dynamo-electric machinesCompression moldingWave shape

A ring-shaped sintered magnet made of rare earths with strong magnetic force, and a concave-convex part formed on the outer circumference of the ring. By twisting the concave-convex part in the axial direction, in addition to reducing the deformation of the magnetization distribution in the rotation direction, it can also reduce the cogging torque. the goal of. In the ring-shaped sintered magnet manufactured by orienting the magnetic powder through a magnetic field, compression molding, and sintering, periodic concave-convex shapes (21, 22) are formed on the outer circumference of the ring at least in a part of the axial direction of the ring. (21, 22) The magnetic poles of the magnet are periodically formed along the concave-convex shape (21, 22) while varying with the position in the axial direction, and the magnetic pole boundaries are provided in the concave portion (21). In particular, the concavo-convex shape (21, 22) is rotated in the axial direction and formed obliquely. In addition, the concavo-convex shape (21, 22) is formed in a waveform close to the absolute value of a sine wave.

Owner:MITSUBISHI ELECTRIC CORP

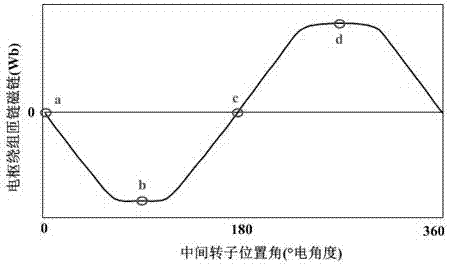

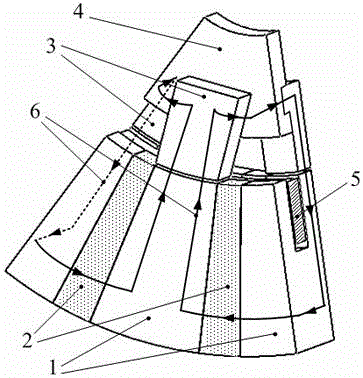

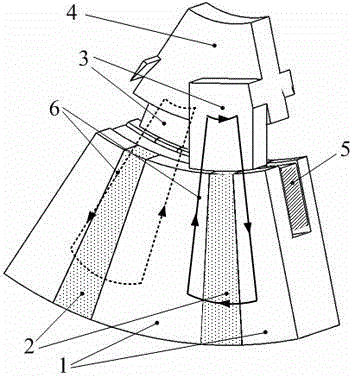

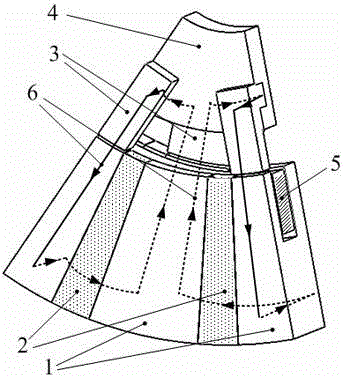

Magnetism gathering passive rotor transverse magnetic flux single-phase motor

ActiveCN104967270ASimplify core structureIncrease profitSynchronous machine detailsMagnetomotive forceMagnetization

The invention discloses a magnetism gathering passive rotor transverse magnetic flux single-phase motor, and belongs to the transverse magnetic flux motor technology field. The single-phase motor comprises a stator composed of C-shaped stator iron cores and C-shaped permanent magnets, a rotor composed of an L-shaped rotor iron core and a rotor annular magnetic conductive structure, an annular armature winding. The C-shaped stator iron cores and the C-shaped permanent magnets are arranged alternatively in the circumference, and the C-shaped permanent magnets magnetize in the circumferential direction and the magnetization directions of two adjacent C-shaped permanent magnets are opposite. The annular armature winding is wound in the recessed groove formed after the C-shaped stator iron cores and the C-shaped permanent magnets are arranged alternatively. Grooves for insertion of L-shaped rotor iron cores in uniform distribution are formed in the rotor annular magnetic conductive structure. The C-shaped permanent magnets provide an effective magnetomotive force when a main excitation path formed among the rotor, the air gap and the stator goes through the yoke section of the rotor, and the permanent magnet utilization rate is raised.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Giant magnetostriction parallel micrometric displacement actuator

InactiveCN101615862AReduce volumeReduce copper lossPiezoelectric/electrostriction/magnetostriction machinesEngineeringActuator

The invention relates to a giant magnetostriction parallel micrometric displacement actuator, which realizes parallel magnetic circuit by adopting a plurality of giant magnetostriction material (GMM) short rods, or arranging GMM short rings outside an excitation coil to reduce the magnetic resistance of GMM and reduce the ohm power consumption of coil; GMM and electromagnetic coil achieve separation structurally to reduce the influence of coil heating on the actuator; the magnetostriction displacement of GMM is output after being amplified by a micrometric displacement amplifier.

Owner:SHANGHAI UNIV

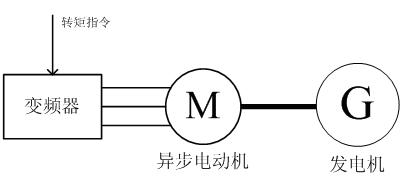

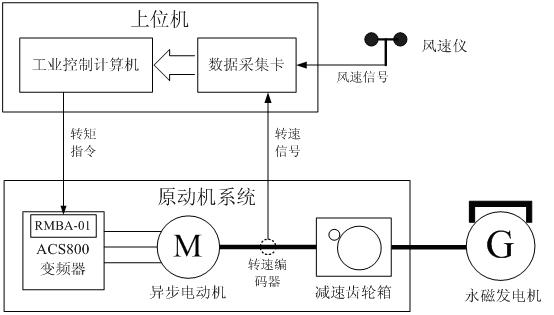

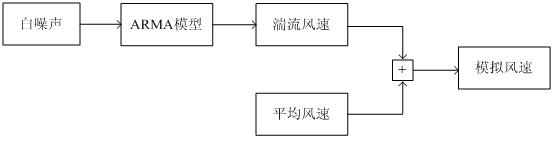

Wind turbine simulator applicable to testing of direct driving type wind generating set and model selection method thereof

InactiveCN102156044AReduced torque output requirementsReduce manufacturing costEngine testingFrequency changerModel selection

The invention discloses a wind turbine simulator which comprises a prime motor system and an upper computer, wherein the prime motor system comprises a frequency converter, a three-phase asynchronous motor and a reduction gearbox; and the upper computer comprises a data acquisition card, an industrial control computer, a rotating speed encoder, an anemometer and wind turbine simulation software. In each working cycle period of the wind turbine simulator, the upper computer acquires the rotating speed and wind speed signal, calculates the output reference torque of the prime motor system through the wind turbine simulation software and transmits the output reference torque to the frequency converter in the prime motor system; and the frequency converter controls and adjusts the output mechanical torque of the reduction gearbox through the torque. Aiming at the output characteristics that the conventional wind turbine simulator based on the three-phase asynchronous motor hardly realizes low rotating speed and high torque, the invention provides the wind turbine simulator applicable to testing of a direct driving type wind generating set.

Owner:NANJING UNIV OF SCI & TECH

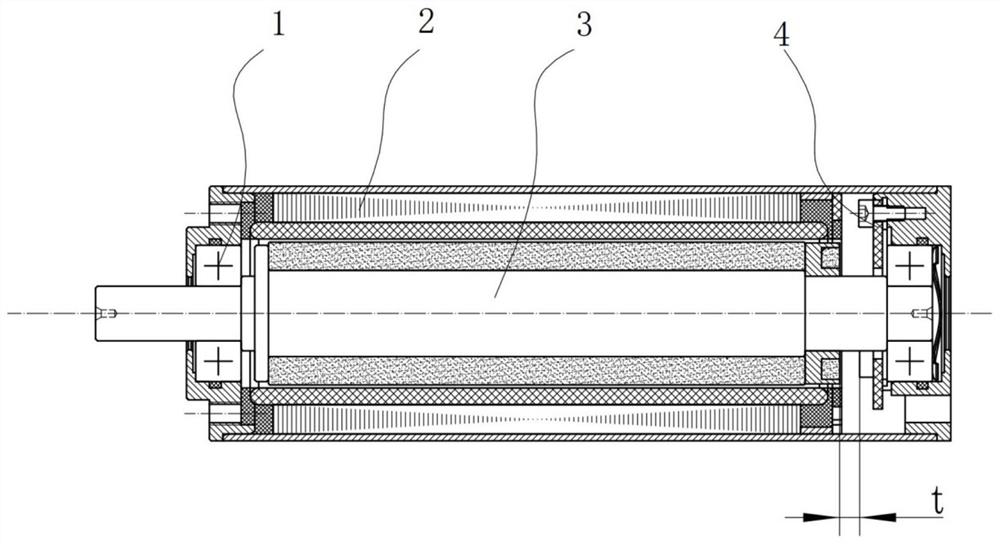

Coreless brushless direct current motor

PendingCN111884385ACompact structureSmall sizeMagnetic circuit rotating partsSupports/enclosures/casingsBrushless motorsElectric machine

The invention discloses a coreless brushless direct current motor, which comprises a bearing, a stator, a rotor and a rotor position sensor assembly, wherein the stator coreless winding is a concentric multilayer winding; a winding lead is welded by adopting an adapter plate assembly; the multi-pole annular magnetic pole is P, the HALBACH structure is adopted for overall multi-pole magnetization,and it is guaranteed that the air gap flux density wave of the winding coupling part is in a sine form; the motor end cover, the casing, the stator, the rotor, the bearing and the Hall positioning circle center are coaxially arranged. The product provided by the invention is simple in structure, convenient to assemble, compact in structure, small in size, small in size, light in weight, small in loss, high in efficiency, high in power and torque density, high in counter potential sine, low in waveform distortion rate, low in operation noise and vibration, small in torque ripple and high in reliability. The coreless brushless motor has the advantages of simple structure, high dynamic response speed, stable control operation, high control precision, high reliability and the like.

Owner:杭州精导智能科技有限公司

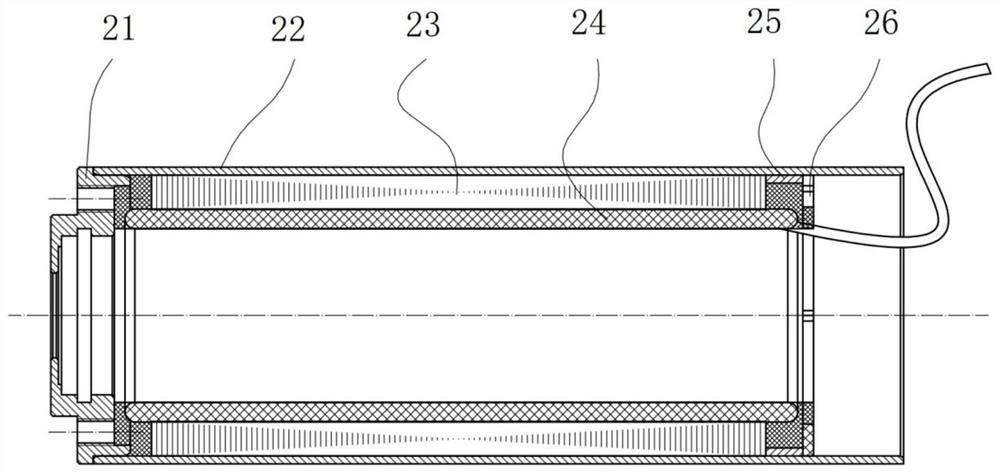

Slotless motor for implantable axial flow blood pump

PendingCN107104570AEliminate torqueReduce radial thicknessBlood pumpsMagnetic circuit stationary partsCopper wireBlood pump

The invention discloses a slotless motor for an implantable axial flow blood pump. The slotless motor comprises a stator iron core, a stator winding, a rotor rotating shaft and a rotor permanent magnet. The slotless motor is characterized in that the stator iron core is formed by axially punching a circular silicon steel sheet, the rotor permanent magnet is made of a permanent magnetic material and is supportive of radial magnetizing, a coil of the stator winding is positioned between the stator iron core and the rotor rotating shaft, the stator winding is pasted on the inner wall of the stator iron core which is cylindrical, and the stator iron core is of a tooth-slotless structure. A direct-current brushless slotless structure is adopted, so that tooth-slot torque is eliminated, and copper loss is lowered. A triphase winding is divided into two layers of structures, copper wires at the end are arranged regularly, and thickness is consistent with that of a central portion, so that radial thickness of the end of the motor is reduced. High-heat-conductivity epoxy resin is used to fix the stator winding, so that the problem that the coil generates heat is solved effectively, the motor winding is fixed, and electromagnetic vibration and noise are avoided.

Owner:FUWAI HOSPITAL CHINESE ACAD OF MEDICAL SCI & PEKING UNION MEDICAL COLLEGE

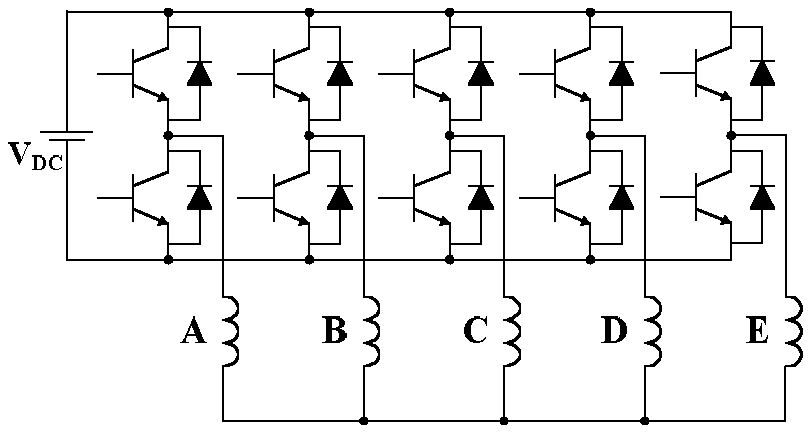

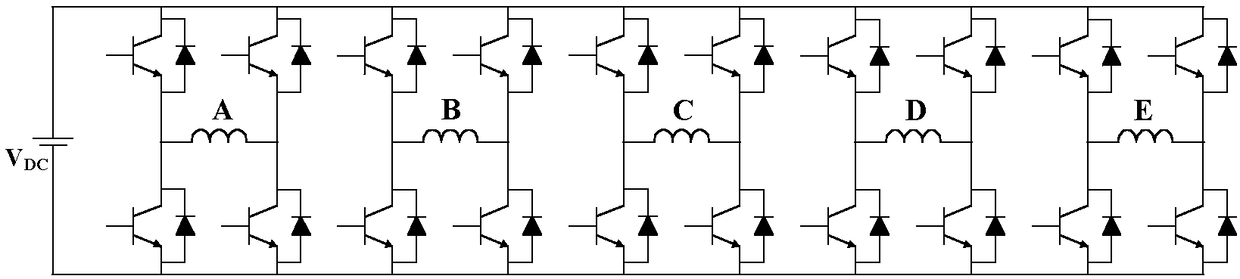

5-phase permanent magnetism motor short circuit fault tolerance control method based on power constant principle

ActiveCN108832869AGuarantee that the maximum output torque remains unchangedReduce torque fluctuationTorque ripple controlElectric motor controlFault tolerancePower inverter

A 5-phase permanent magnetism motor short circuit fault tolerance control method based on a power constant principle belongs to the multi-phase fault tolerance permanent magnetism motor field, and solves the problems that a common 5-phase PMSM motor is poor in a motor torque output capacity and large in torque fluctuations when one phase of the winding has short circuit failure; the method can adjust the current of other non-short circuit phase when the motor has end short circuit fault, thus keeping the output power of the motor unchanged; when the motor has switch tube short circuit faults,the switch tubes of same positions of opposite bridge arms are conducted, and the current of other non-short circuit phase is adjusted, thus keeping the output power of the motor unchanged; the methodcan weaken the influences on the motor by short circuit faults of inverter switch tubes, thus reducing the subsequent fault tolerance control difficulty.

Owner:HARBIN INST OF TECH

Combined permanent magnet brushless motor stator and manufacturing method thereof

PendingCN110011436AReduce NVHIncrease profitMagnetic circuit stationary partsManufacturing stator/rotor bodiesBrushless motorsCircular surface

The invention provides a combined permanent magnet brushless motor stator and a manufacturing method thereof. A stator core is formed by a tooth part iron core formed by winding and a yoke part iron core, the tooth part iron core is located inside, the yoke part iron core is located outside, an inner circular surface of the tooth part iron core has no notch, a winding is placed into a groove froman outer circular surface or is wounded tooth by tooth, a tooth part winding is sleeved in the yoke part iron core to form a stator assembly after being manufactured, the invention is suitable for a fractional slot winding is also suitable for a distributed winding, the iron core has no slot and almost has no cogging torque, the motor running performance is good, the material utilization rate is high, the design is optimized and flexible, the motor efficiency and specific power are easy to improve, and the automatic production is easy to achieve.

Owner:杨世国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com