Stator for electric rotary machine

A technology for rotating electrical machines and stators, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of lengthening transition parts, etc., and achieve the effects of reducing occupied area, improving efficiency, and realizing common use of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Hereinafter, embodiments of the present invention will be described based on the drawings. It should be noted that the drawings are viewed along the direction of the symbols.

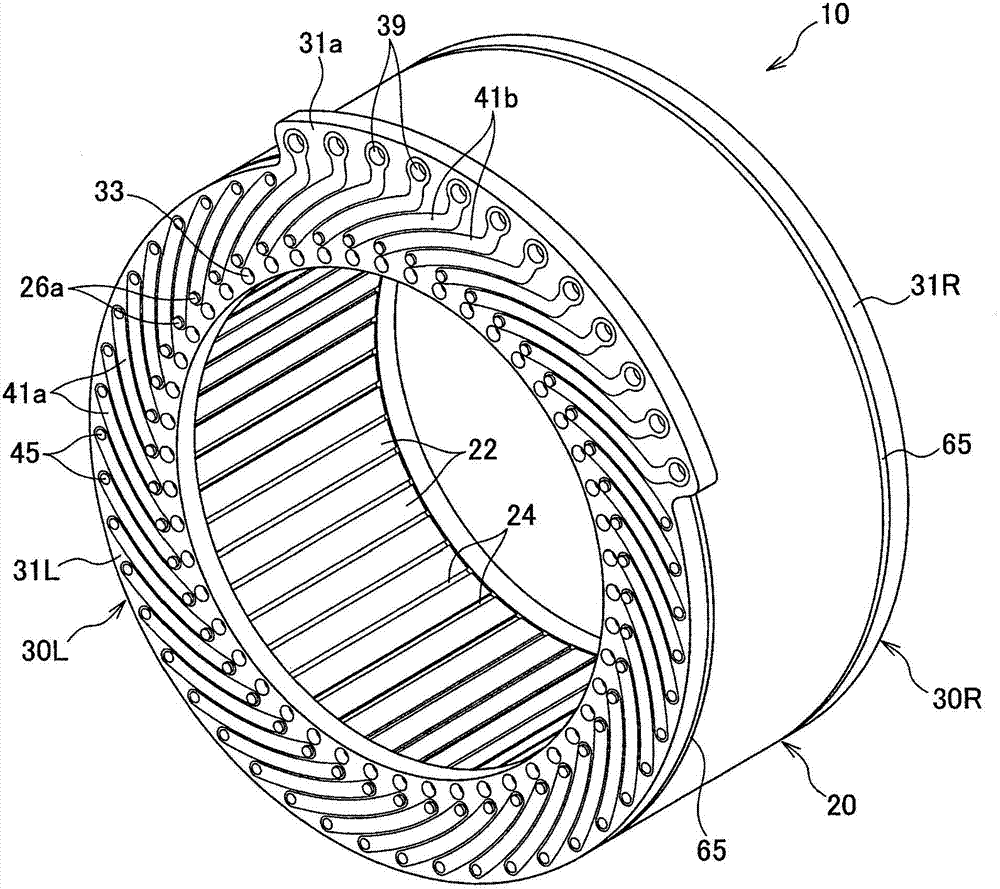

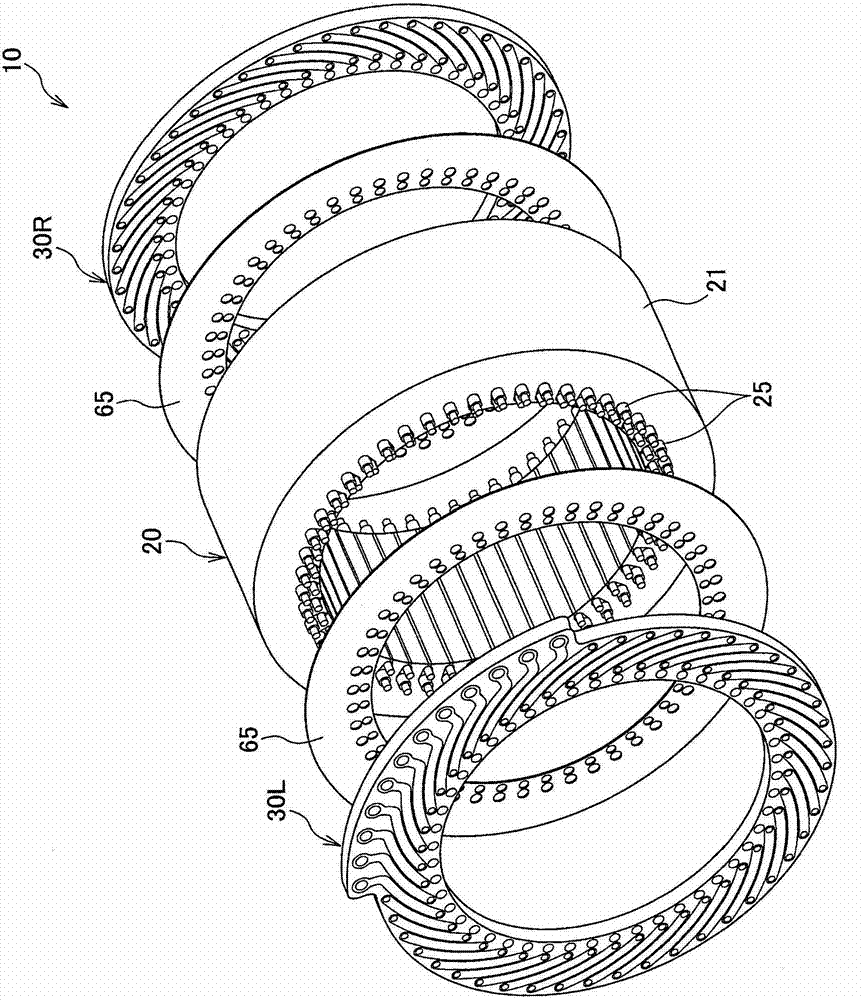

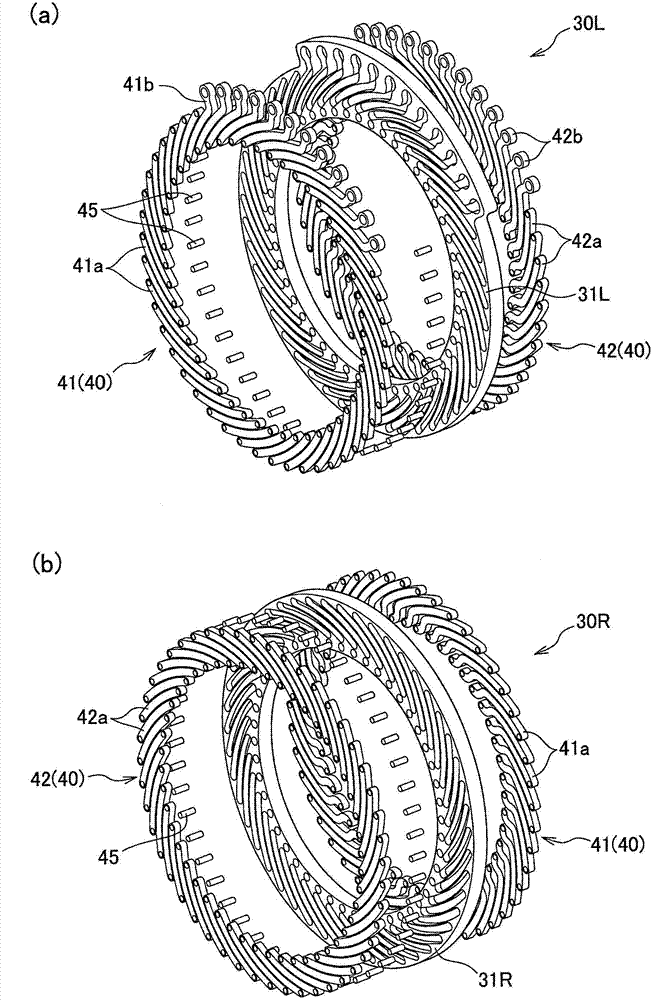

[0084] Such as figure 1 , figure 2 and Figure 5 As shown, the stator 10 of the rotating electrical machine according to this embodiment includes a stator core assembly 20 and a pair of base plate assemblies 30L, 30R. The base plate assemblies 30L, 30R are arranged and assembled on both sides of the stator core assembly 20 . An insulating sheet 65 such as a silicon wafer is arranged between the stator core assembly 20 and the base plate assemblies 30L, 30R to insulate the stator core assembly 20 from the base plate assemblies 30L, 30R.

[0085] The stator core assembly 20 includes a stator core 21 and a plurality (48 in the embodiment shown in the figure) of coil bars 25 .

[0086] The stator core 21 is formed by laminating, for example, a plurality of punched silicon steel sheets, and inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com