Giant magnetostriction parallel micrometric displacement actuator

A giant magnetostrictive and micro-displacement technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of increasing actuator volume and coil power consumption, etc. problem, to achieve the effect of small copper loss, easy multi-point floating output, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

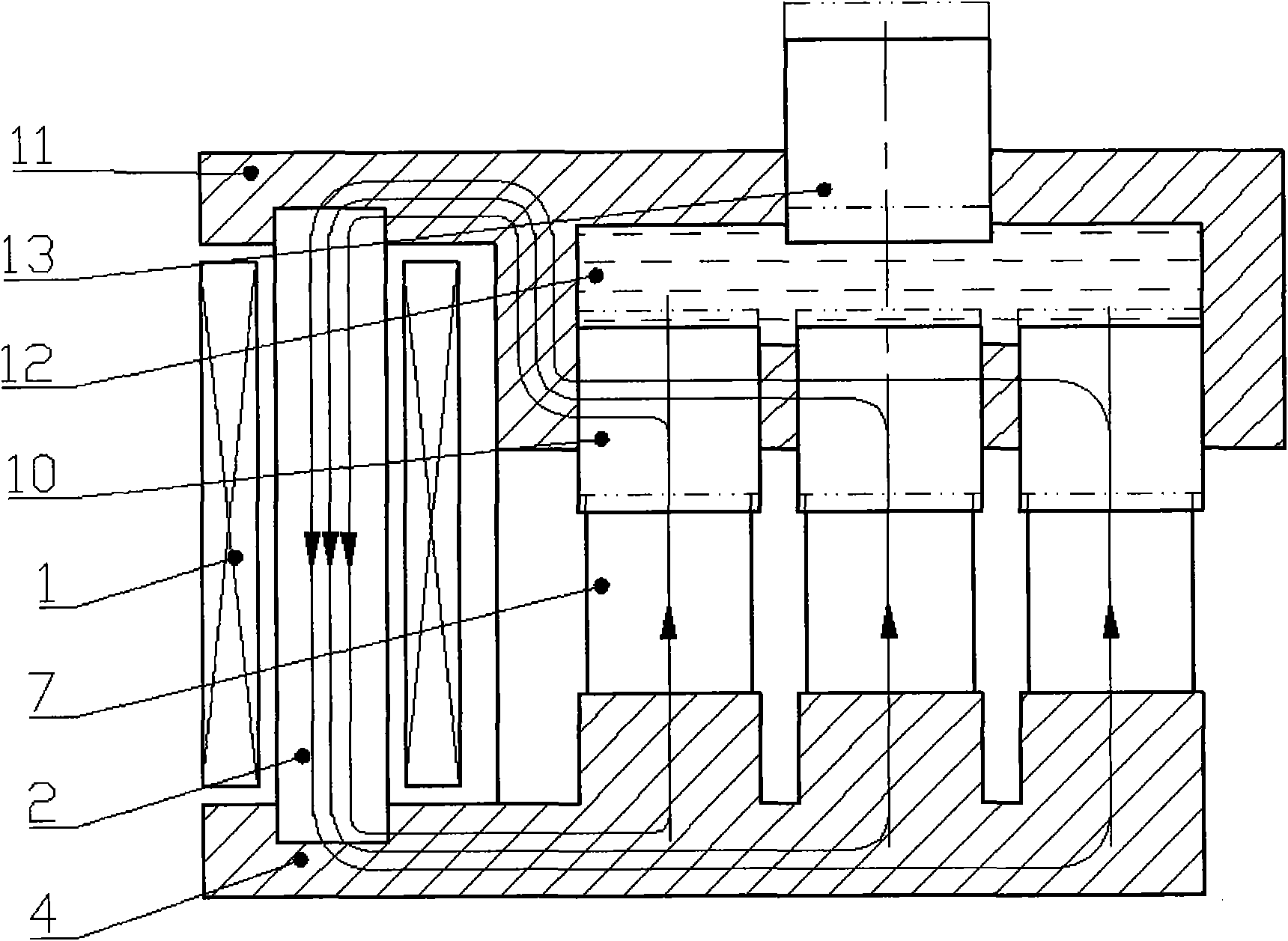

[0024] Preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing: See figure 1 , The giant magnetostrictive parallel micro-displacement actuator includes GMM7 and excitation coil 1, and a GMM ring or multiple GMM rods 7 are arranged in parallel on a closed magnetic circuit jointly generated by one or several parallel excitation coils 1. The micro-displacement generated by the GMM ring or GMM rod 7 is amplified by a displacement amplifier 12 and then output.

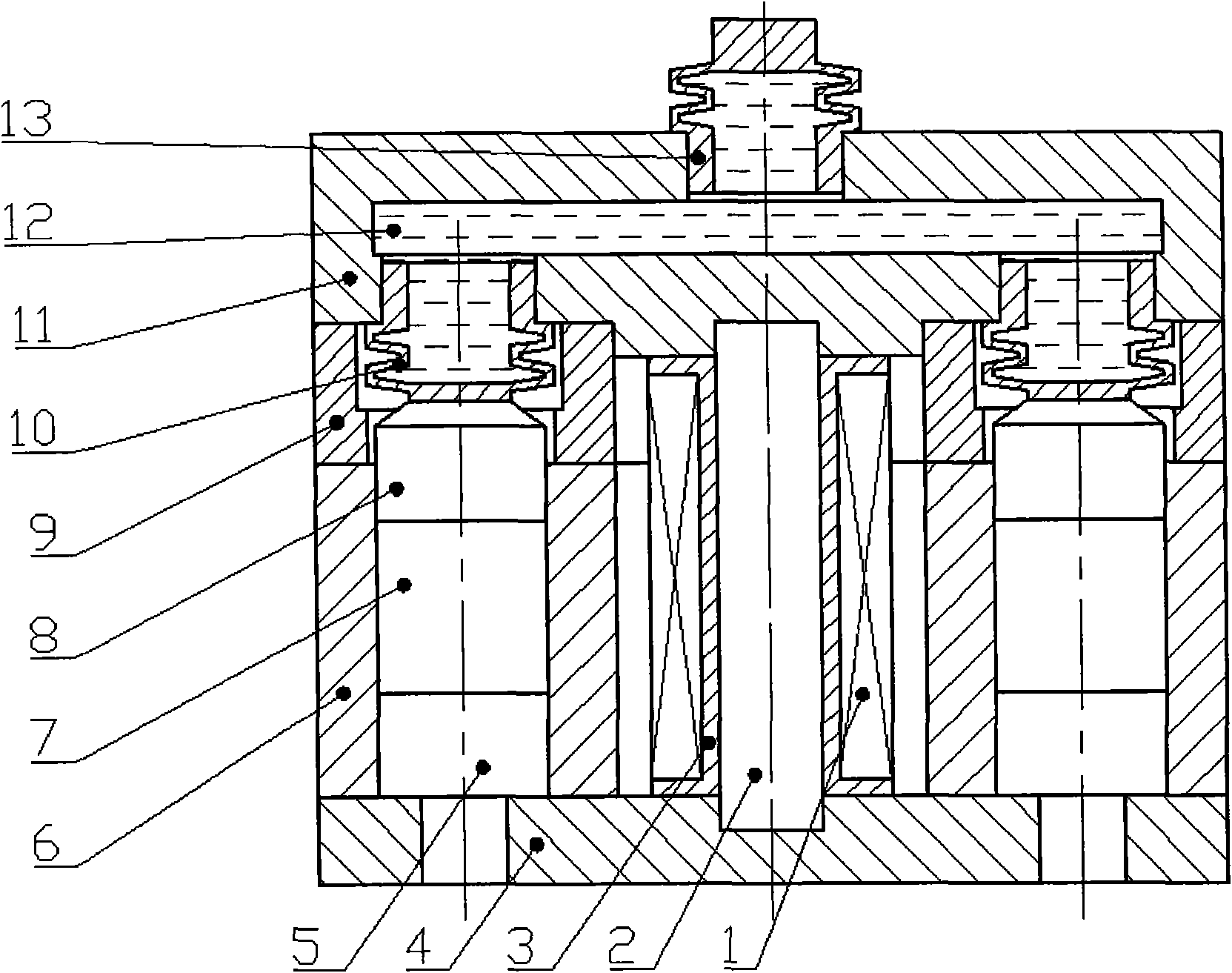

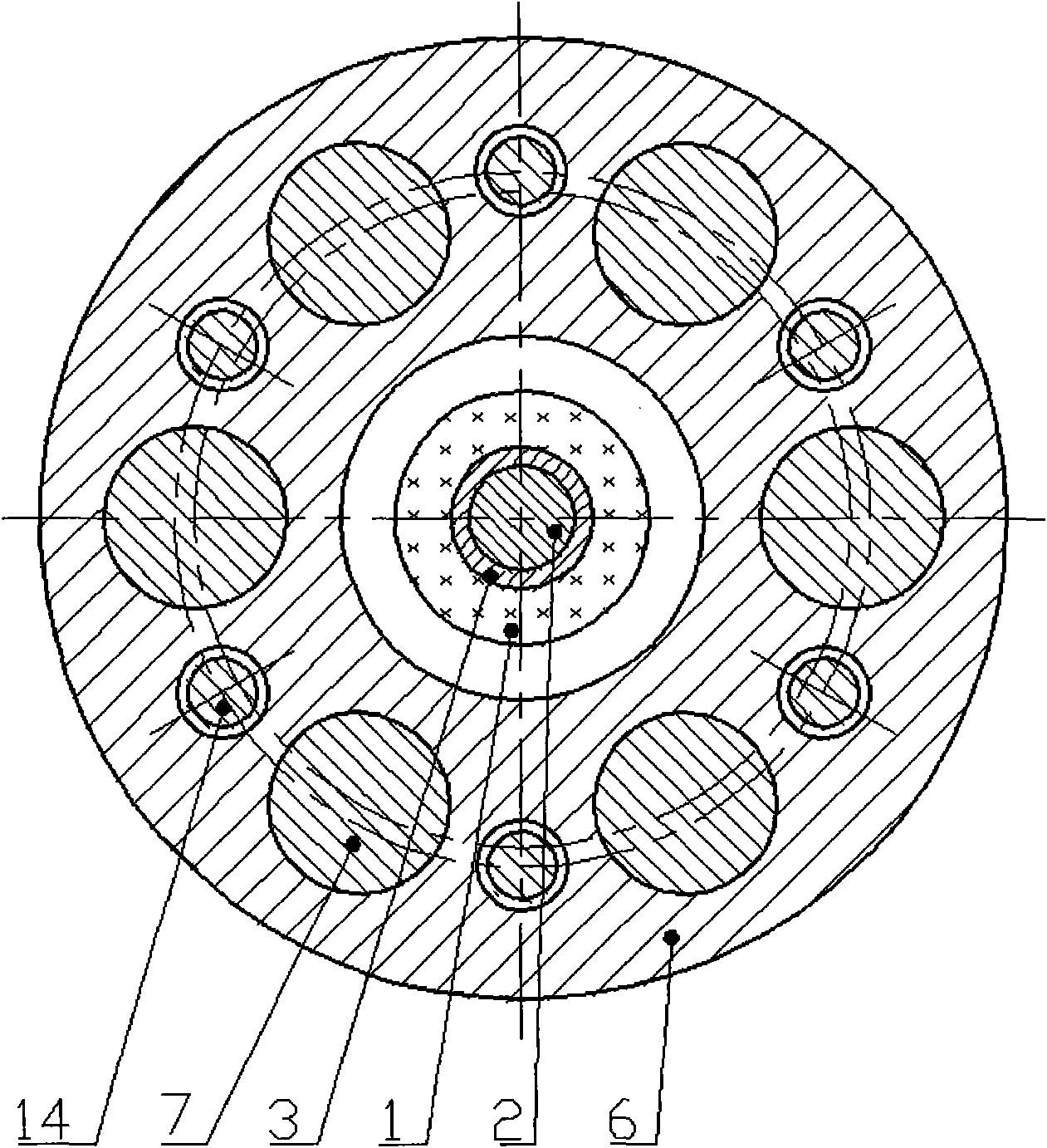

[0025] figure 2 and image 3 A first embodiment of the invention is shown. This example mainly consists of an electromagnetic coil with an iron core, 6 short GMM rods and a hydraulic micro-displacement amplifier. It should be pointed out that the number of GMM rods here can be other numbers, not limited to 6. The GMM rods 7 are evenly distributed along the circumferential direction around the axis of the coil 1, such as image 3 shown. A closed magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com