A magnetic flux modulate permanent magnet vernier motor with built-in stator

A magnetic flux modulation and vernier motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electromechanical device, etc., can solve the problems of complex magnetic field distribution, magnetic field mutual coupling, and motor analysis difficulties, so as to reduce the difficulty of processing and production , wide range of speed regulation, easy production and assembly wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

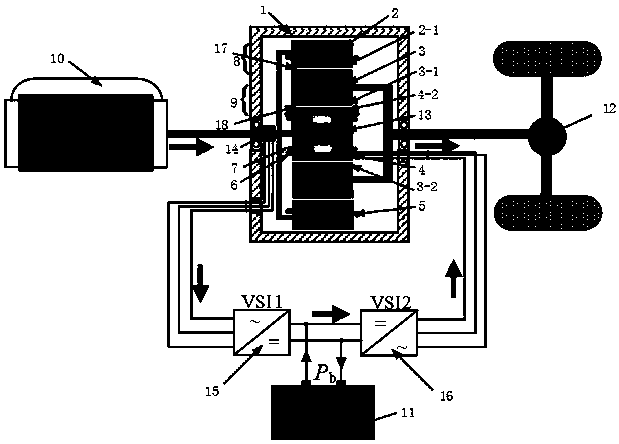

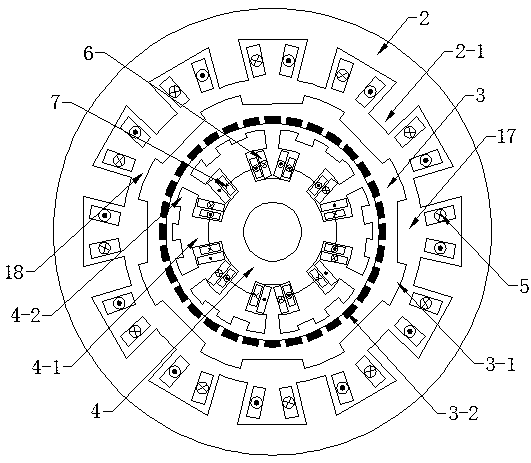

[0015] Such as figure 1 and figure 2 As shown, the present invention includes a motor casing 1, inside the motor casing, an outer rotor 2, an inner rotor 3 and a stator 4 are sequentially arranged from the outside to the inside, and the inner surface of the outer rotor 2 has twelve outer rotor salient poles 2-1 , the three-phase centralized outer rotor armature winding 5 is placed in the outer rotor slot; the inner rotor 3 includes an iron core and a permanent magnet 3-2, and the outer surface of the inner rotor 3 near the outer rotor side has eight inner rotor salient poles 3-1, The inner surface near the stator side has a circular surface structure and is embedded with sixteen pairs of permanent magnets 3-2. The permanent magnets 3-2 are magnetized in the radial direction and the adjacent permanent magnets are magnetized in the opposite direction; the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com