Application method of mixed permanent magnets in flux-switching permanent magnet motor

A permanent magnet motor and magnetic flux switching technology, which is applied to the magnetic circuit characterized by magnetic materials, the static parts of the magnetic circuit, and the shape/style/structure of the magnetic circuit, which can solve the high manufacturing cost of the magnetic flux switching permanent magnet motor. , The motor torque density is reduced, the cogging torque and the magnetic flux density are high, so as to reduce the risk of irreversible demagnetization, reduce the manufacturing cost, and alleviate the degree of magnetic saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

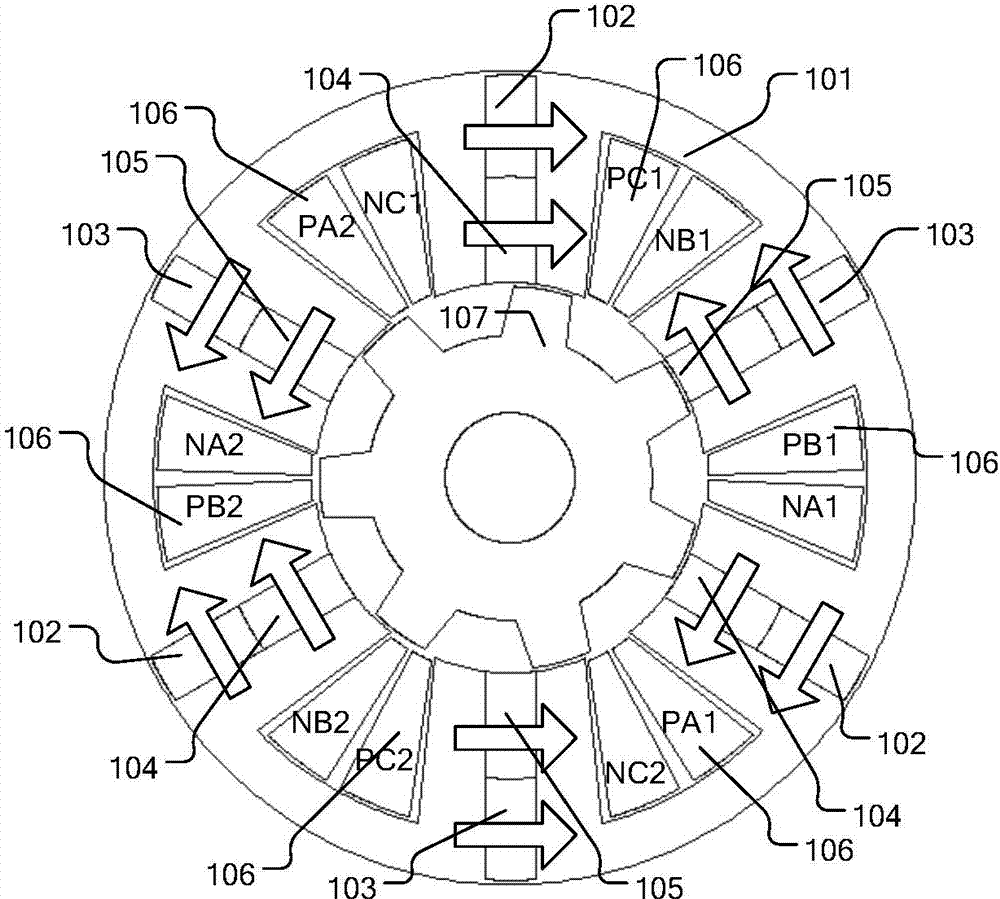

[0041]Install N35 NdFeB permanent magnets with high magnetic energy product at the position close to the yoke of the stator (Y) 101 module of the circular rotating electric machine, and install low The ferrite permanent magnet whose magnetic energy product grade is Y30, and the high magnetic energy product grade N35 NdFeB permanent magnet and the low magnetic energy product grade Y30 ferrite permanent magnet are bonded together by glue. Mixed permanent magnet module; a clockwise rare earth permanent magnet (Y) 102 with a clockwise magnetization direction and a clockwise ferrite permanent magnet (Y) with a clockwise magnetization direction are installed on one side of each circular rotary motor stator (Y) 101 module 104 is bonded and connected with glue to form an integrated hybrid permanent magnet module. On the other side of the circular rotary motor stator (Y) 101 module, a rare earth permanent magnet (Y) 103 with a magnetization direction counterclockwise and a magnetization...

Embodiment 2

[0043] In addition to forming a six-phase winding structure with a reasonable phase sequence arrangement, the rare earth permanent magnet (Y) 102 with a clockwise magnetization direction and the ferrite permanent magnet (Y) 104 with a clockwise magnetization direction are sandwiched by non-magnetic material aluminum The hybrid permanent magnet module composed of one-piece assembly is connected in the way of installation, the rare earth permanent magnet (Y) 103 with the magnetization direction counterclockwise and the ferrite permanent magnet (Y) 105 with the magnetization direction counterclockwise are clamped by non-magnetic material aluminum The other methods are the same as those in Embodiment 1, except that the hybrid permanent magnet module composed of one body is connected in the way of installation.

Embodiment 3

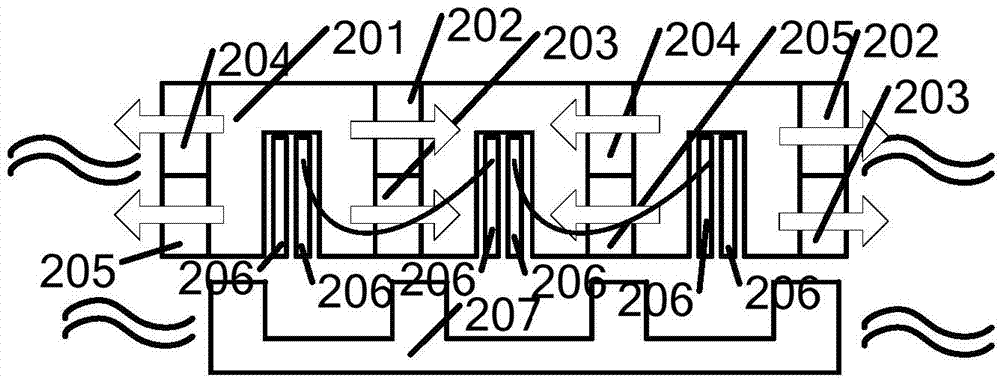

[0045] Install N35 N35 NdFeB permanent magnets with high magnetic energy product near the yoke of the U-shaped module of the linear motor stator (Z) 201, and close to the teeth of the U-shaped module of the linear motor stator (Z) 201 Install ferrite permanent magnets with low energy product grade Y30, and NdFeB permanent magnets with high magnetic energy product grades N35 and ferrite permanent magnets with low magnetic energy product grades Y30. Adhesive connection is A hybrid permanent magnet module is formed in one piece; a rare earth permanent magnet (Z) 202 with a clockwise magnetization direction and a clockwise ferrite permanent magnet with a clockwise magnetization direction are installed on one side of the U-shaped module of each linear motor stator (Z) 201 (Z) 203 is a hybrid permanent magnet module that is bonded and connected with glue, and on the other side of the U-shaped module of the linear motor stator (Z) 201, there is a rare earth permanent magnet (Z) 204 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com