Substrate and magnetic device integrated DC-DC converter and preparation process thereof

A magnetic device, DC-DC technology, applied in the direction of converting DC power input to DC power output, instruments, electrical components, etc., can solve problems such as large volume, increase contact area, realize ultra-thin, and avoid device errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] The invention has universality for the manufacture of substrates and magnetic device integrated DC-DC converters.

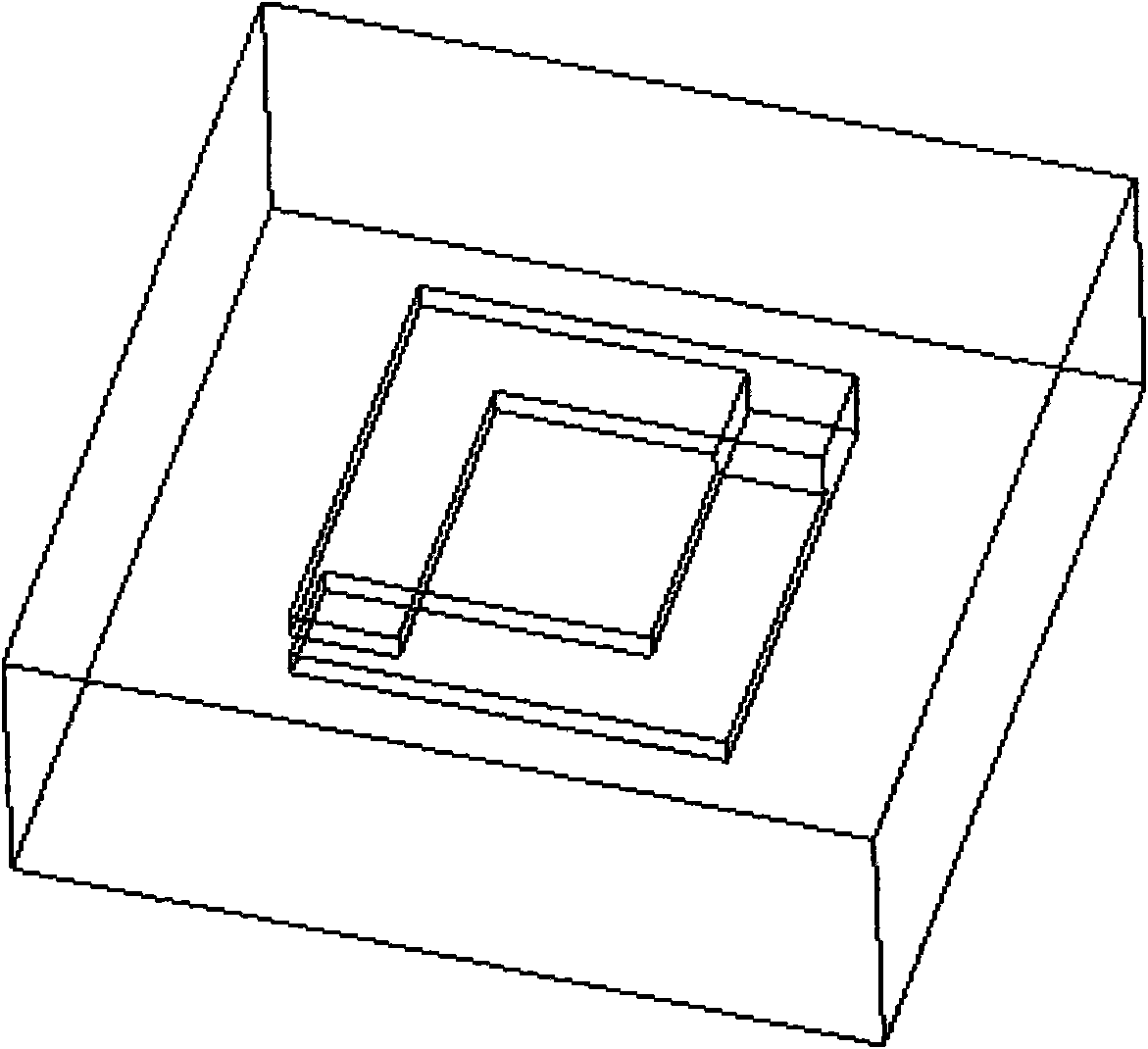

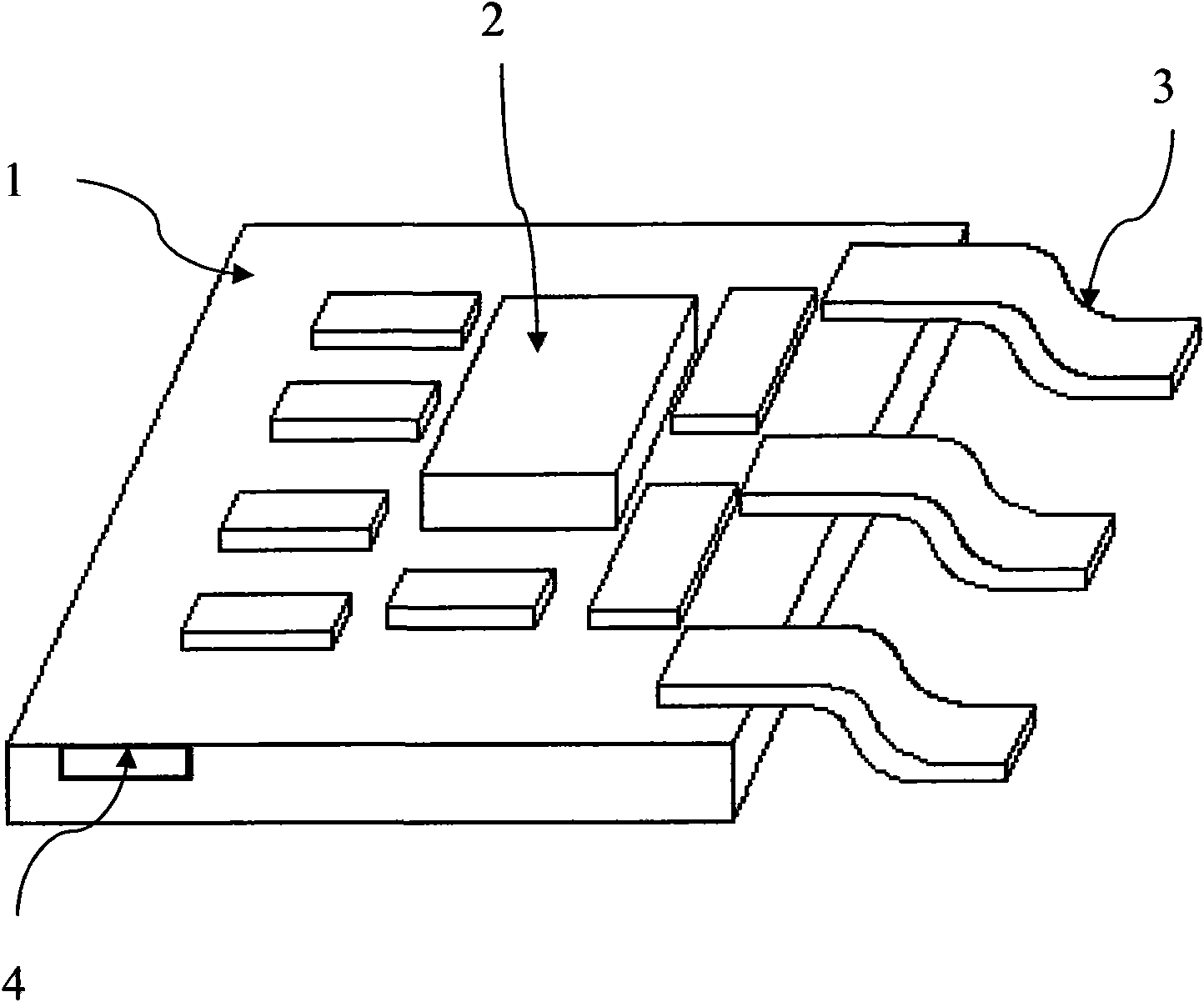

[0029] 1. Structural design: among the present invention, the coil is a zigzag coil, and the ferrite around the coil forms a closed inductance such as figure 1 As shown, the coil at both ends is extended to the side of the substrate, and the coil is connected to the electronic circuit on the substrate through side sealing.

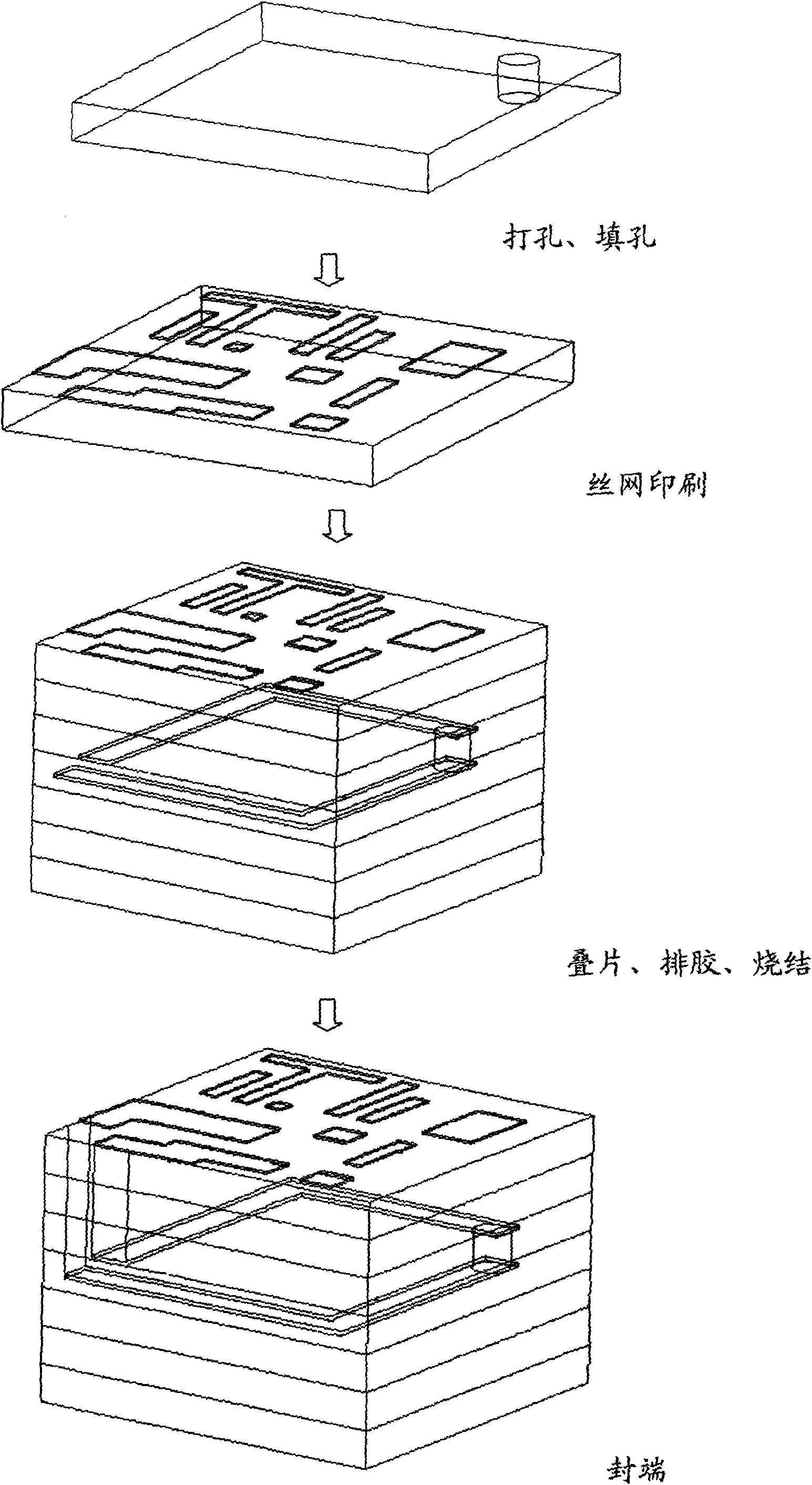

[0030] 2. technology realizes: what the present invention adopted is LTCC (low temperature co-fired ceramics) technology, as figure 2 , the specific process is as follows. Add dispersants, plasticizers and binders to the low-temperature sintered ferrite powder, the models are: M1135, M1125 and B75702, ball milled evenly, cast into a 30um thick film by wet process, and then cut into A single diaphragm of specified size; a blind b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com