High-speed fuel gas injection electromagnetic valve for vehicles

A solenoid valve, high-speed technology, applied to valve details, valve devices, combustion engines, etc., can solve problems such as complex structure and optimized design, and achieve the effect of simple mechanical equipment, small motion friction coefficient, and increased working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

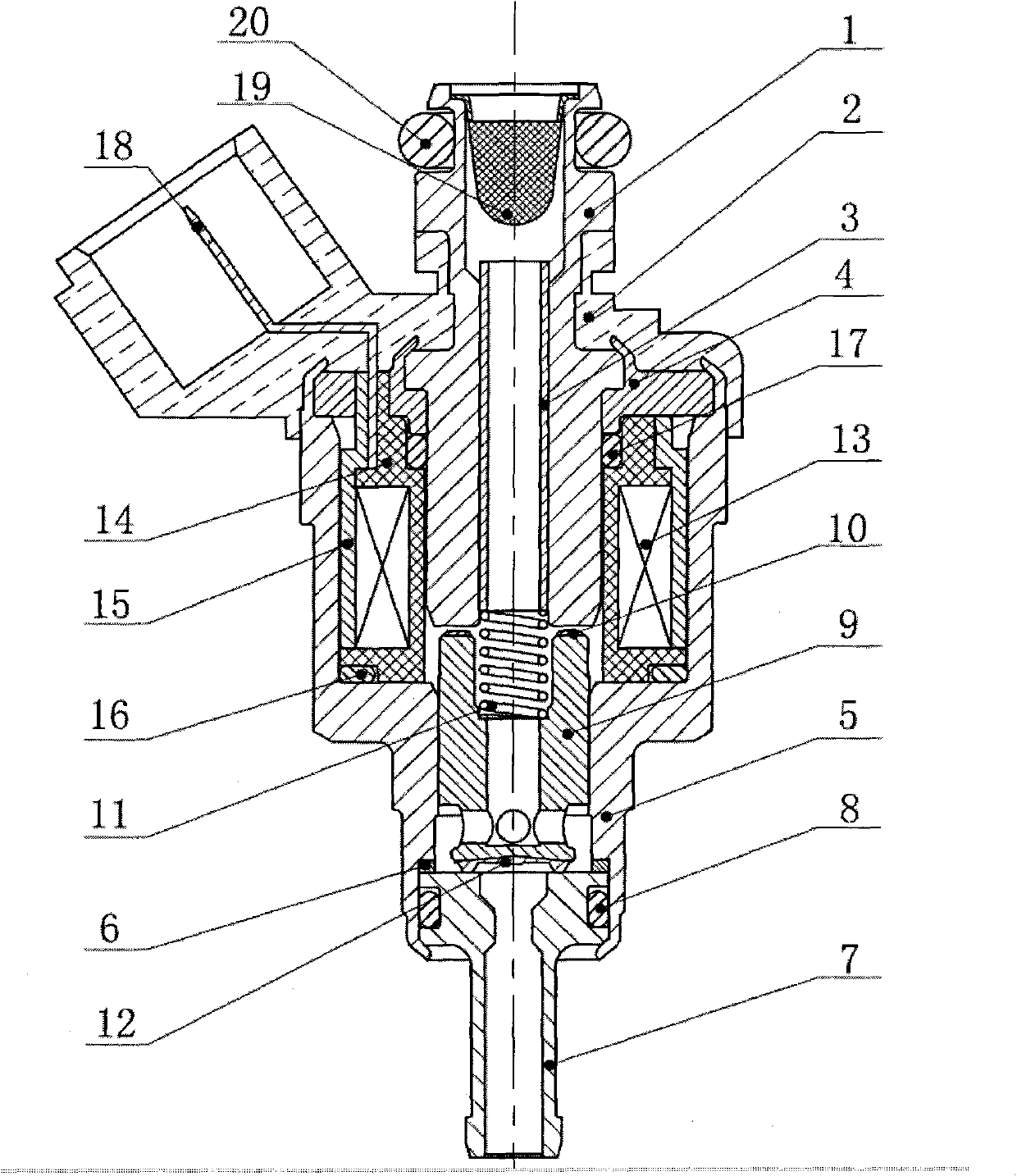

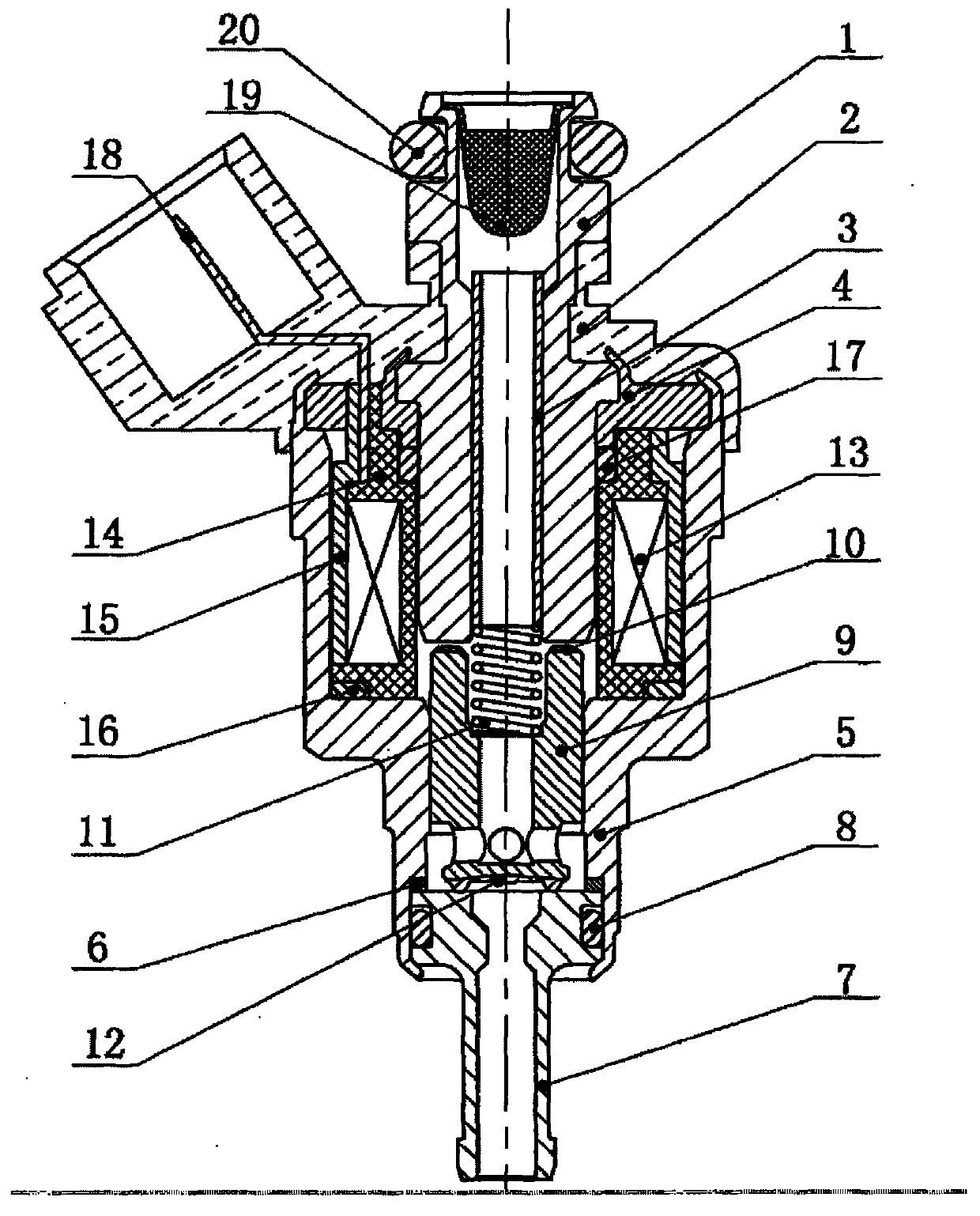

[0027] As shown in the figure, 1 is the fixed iron core, 2 is the shell, 3 is the copper pipe, 4. is the magnetic end cover, 5 is the valve seat, 6 is the gasket, 7 is the nozzle, 8 is the sealing ring, 9 is the dynamic Iron core, 10 is a shockproof gasket, 11 is a spring, 12 is a sealing gasket, 13 is an electromagnetic coil, 14 is a coil skeleton, 15 is a coil shell, 16 is a sealing ring, 17 is a sealing ring, 18 is a plug-in terminal, 19 is a gas filter screen, and 20 is a sealing ring.

[0028] A high-speed gas injection solenoid valve for vehicles, comprising a fixed iron core 1, a moving iron core 9, an electromagnetic coil 13, a nozzle 7, a casing 2 and a valve seat 5, and the fixed iron core 1, the moving iron core 9 and the nozzle 7 are along the gas flow direction Installed in the shell 2 and the valve seat 5 in turn; the outer middle of the fixed iron core 1 is provided with a shaft shoulder and is fixedly provided with a magnetically conductive end cover 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com