An electrical machine having a stator with rectangular and trapezoidal teeth

A stator and generator technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of increased motor manufacturing cost and complex motor structure, and achieve the goals of reducing the number of parts, improving heat transfer, and reducing copper loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

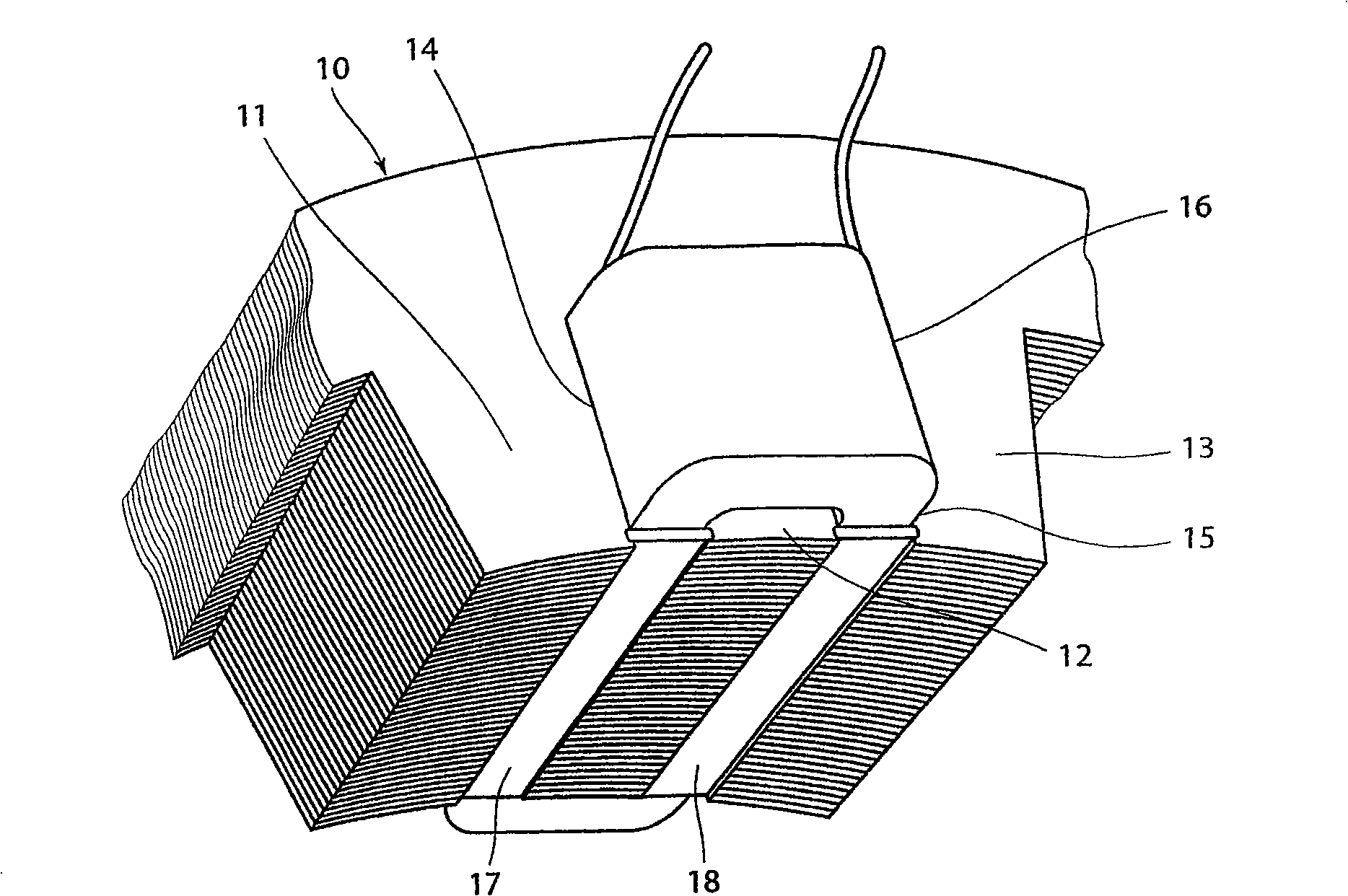

[0032] figure 1 A stack of stator laminations 1d is shown with teeth 11 , 12 , 13 forming slots 14 , 15 for receiving coils 16 . Each second tooth 12 is a parallel tooth and accommodates a coil 16 with the same opening and the same winding. as reference image 3 As stated, the grooves in this example are closed by wedges 17,18.

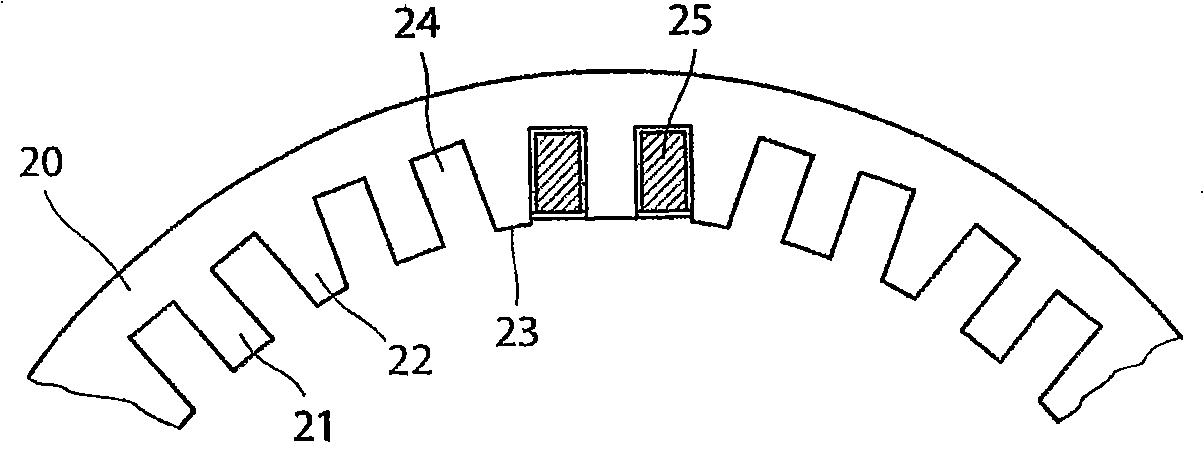

[0033] figure 2 Another embodiment of a stator lamination 20 for making an outer stator is shown. The rotor of the electric machine may be of prior art design and is not shown. The stator laminations 20 have alternately arranged parallel teeth 21 and trapezoidal teeth 22 that taper outwards towards the tooth tips 23 . Therefore, pairs of parallel slots 24 for insertion of prior art rectangular coils are provided. The width of adjacent teeth should be determined to optimize the voltage curve and detent torque. The teeth shown in this example have the same tip width. But the width can vary within a ratio of 0.9-1.1 to 1. The degree of constric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com