Production device and production technology for non-quenched and tempered steel forge piece automatic forging

A production equipment, non-quenched and tempered steel technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of broken grain connection, poor working environment, large fluctuations in forging quality, etc., to achieve quality The effect of stable indicators, clean production environment, and reduced heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

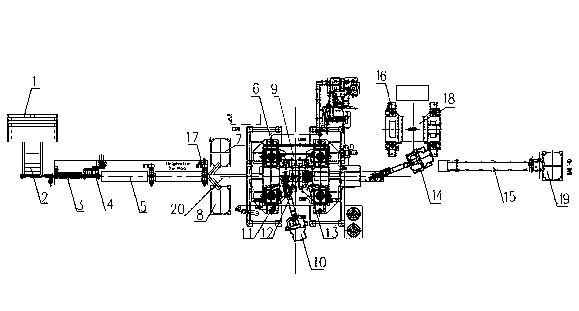

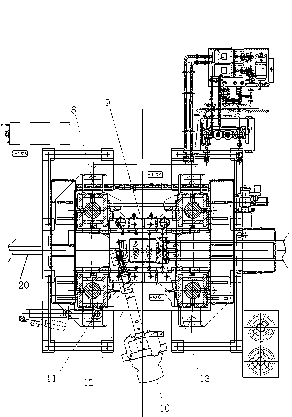

[0027] The technical scheme and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

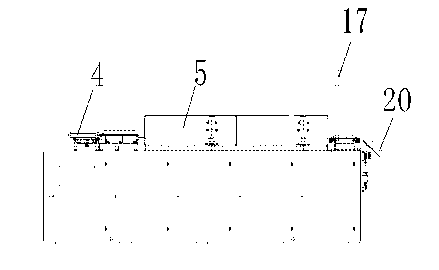

[0028] Such as figure 1 As shown, a fully automatic forging production equipment for non-quenched and tempered steel forgings, including a forging system, a feeding system is provided at the front end of the forging system, and a discharging system is provided at the rear end of the forging system. The forging system includes a forging system connected to the feeding system The electric heating furnace 5 is connected with a forging press 6, the forging press 6 is connected with a trimming machine 16, and the trimming machine 16 is connected with a discharge system, and the furnace mouth of the electric heating furnace 5 is provided with a conveyor Roller table, a temperature measuring and sorting device 17 is installed above the conveying roller table, and the tail of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com