Slotless motor for implantable axial flow blood pump

A slotless motor and implantable technology, which is applied in the field of medical equipment, can solve the problems of inability to effectively use the end of the winding, increase the magnetic flux leakage and copper loss of the motor, and reduce the rotational torque of the motor, so as to achieve stable operation, Effects of eliminating cogging torque and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

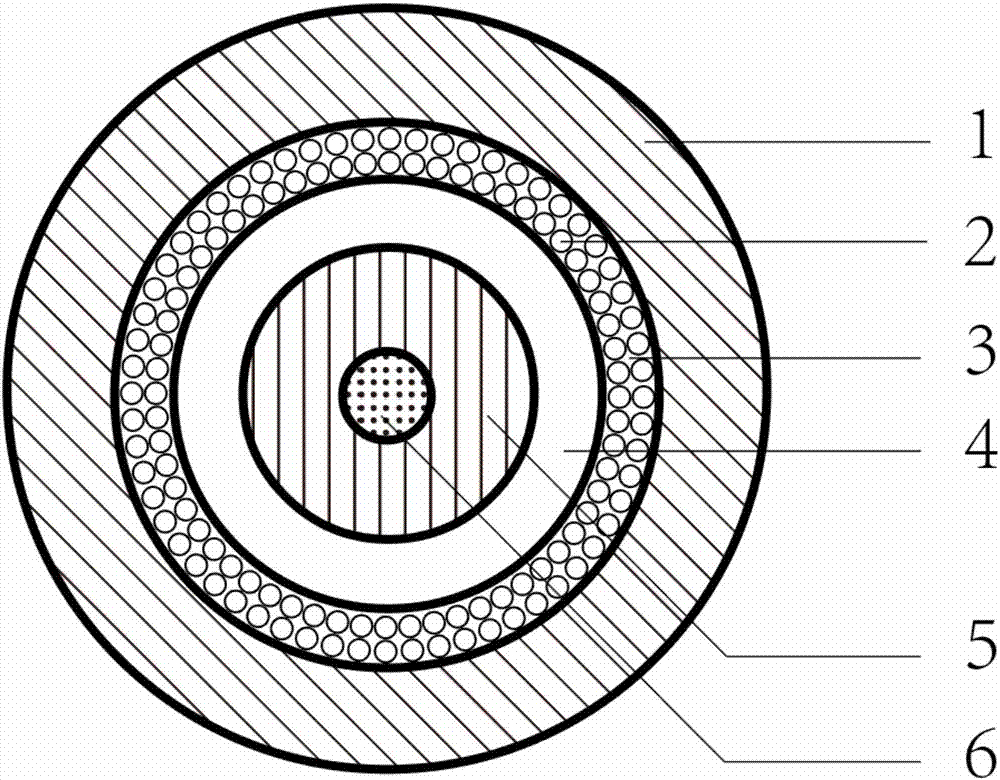

[0022] see figure 1 , figure 2 Shown: a slotless motor for an implantable axial blood pump, which includes a stator core 1, a stator winding 2, a rotor shaft 6, and a rotor permanent magnet 5. The stator core 1 is formed by a circular silicon steel sheet axially Stamping, the rotor permanent magnet 5 is a permanent magnet material, radially magnetized, the coil of the stator winding 2 is between the stator core 1 and the rotor shaft 6, and the stator winding 2 is pasted on the inner wall of the barrel-shaped stator core. The stator core 1 is a structure without cogging.

[0023] The stator core is composed of silicon steel sheets, and the silicon steel sheets are cold-rolled silicon steel sheets. Compared with hot-rolled silicon steel sheets, the advantage is that the hysteresis loss of the motor is small, and the efficiency of the motor is improved. A plurality of silicon steel sheets are stamped in the axial direction to form the stator core 1 .

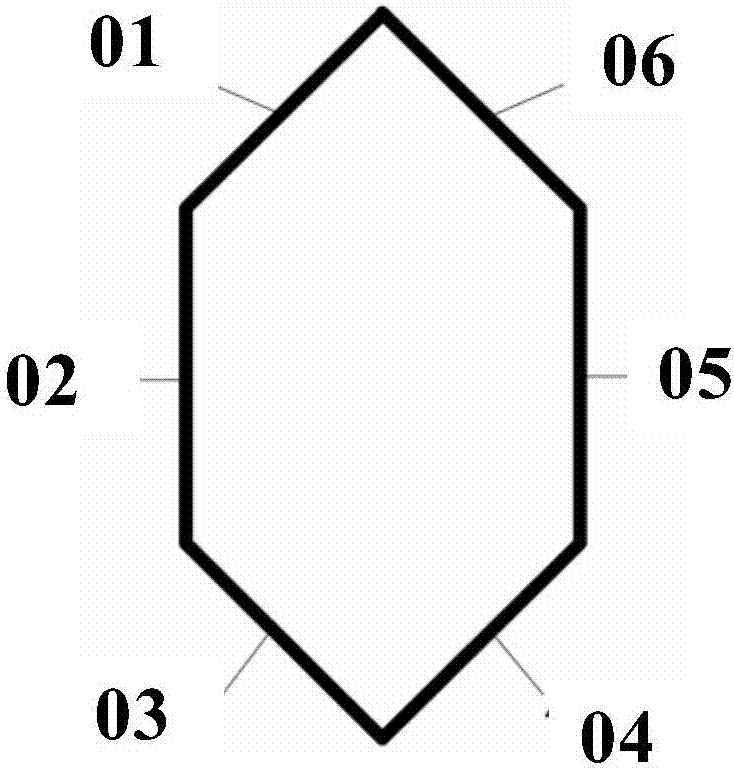

[0024] Among them, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com