Ultrathin high-power direct current magnetoelectric motor

A permanent magnet motor, high-power technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit static parts, magnetic circuit rotating parts, etc., can solve the problem that the power of ironless motors cannot be increased, Solve problems such as unreasonable stator winding forming process, achieve reasonable utilization of winding space, solve unreasonable forming process, and reasonable forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

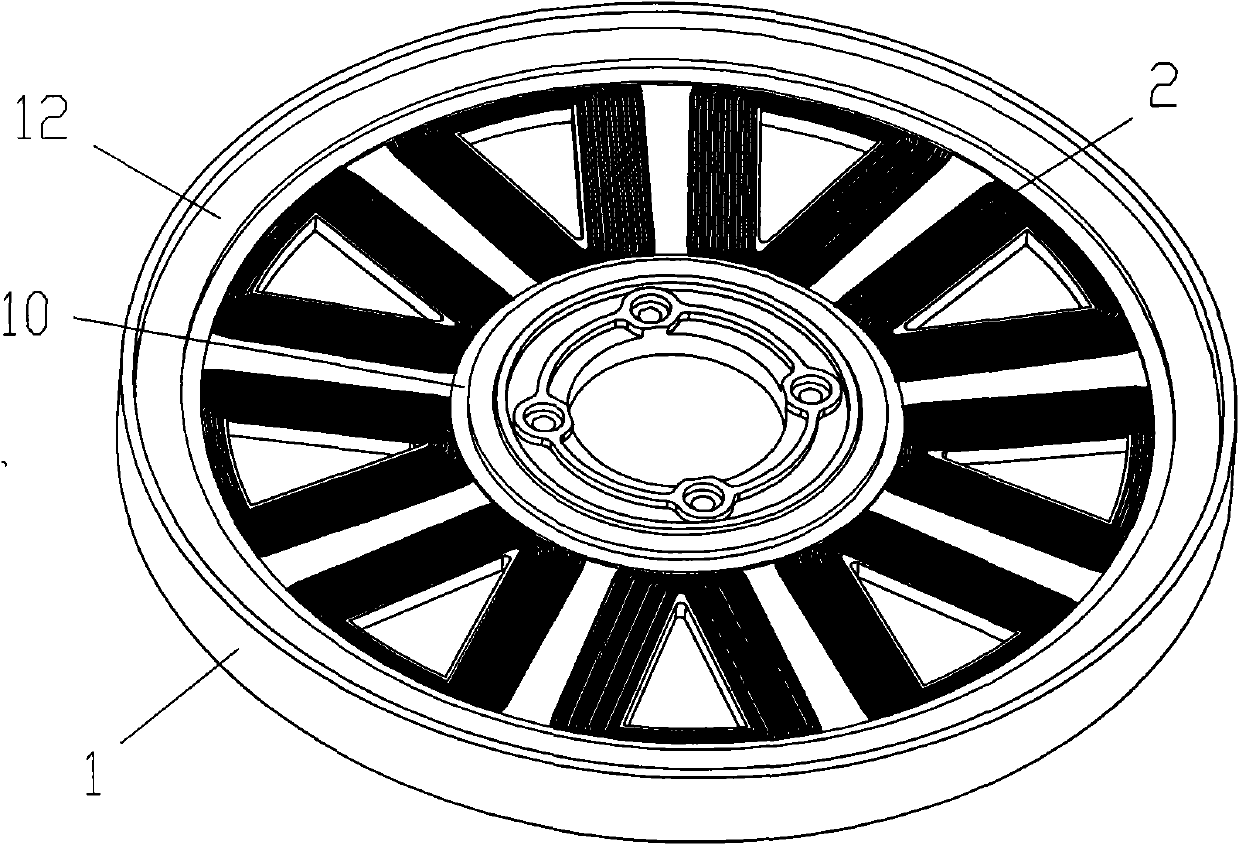

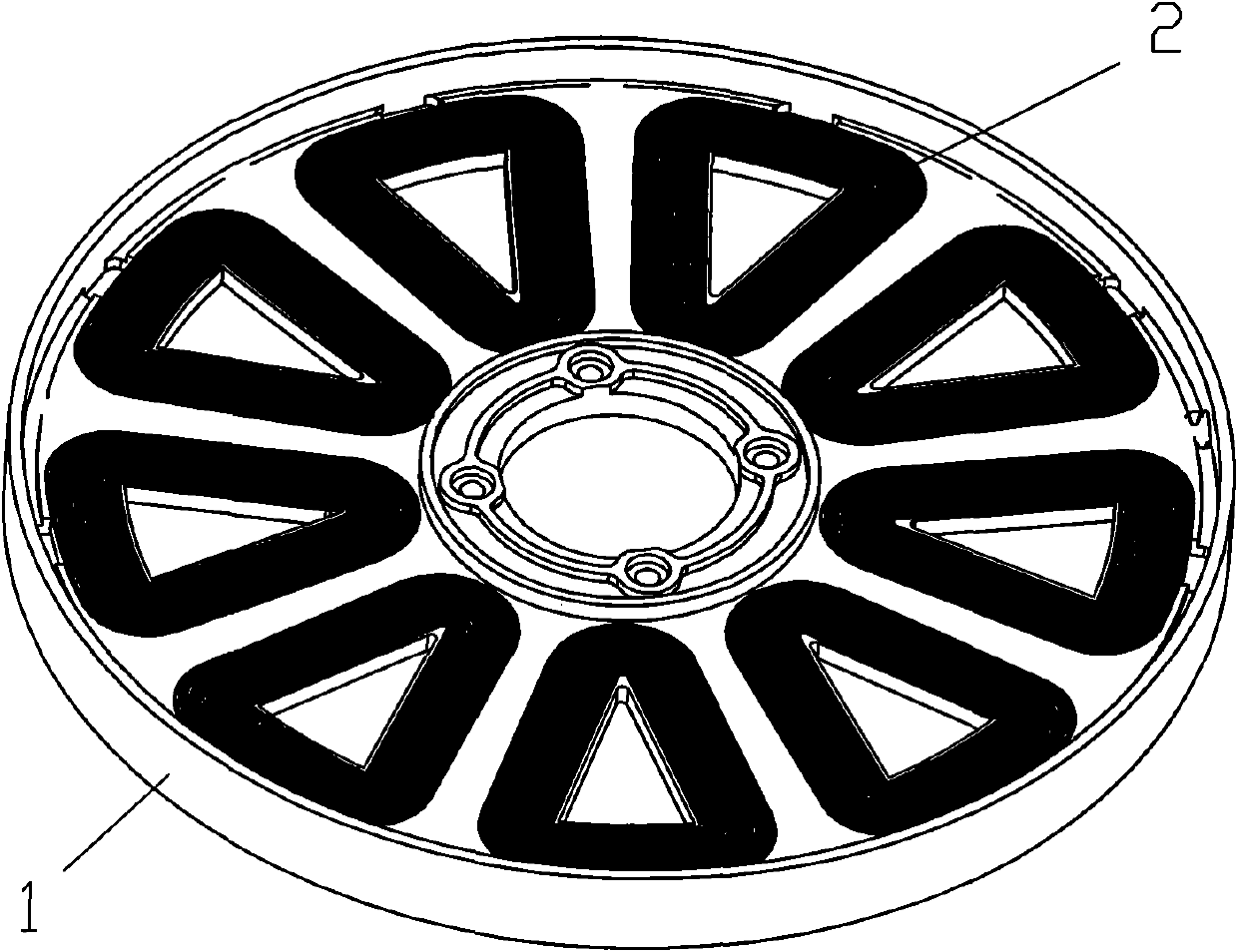

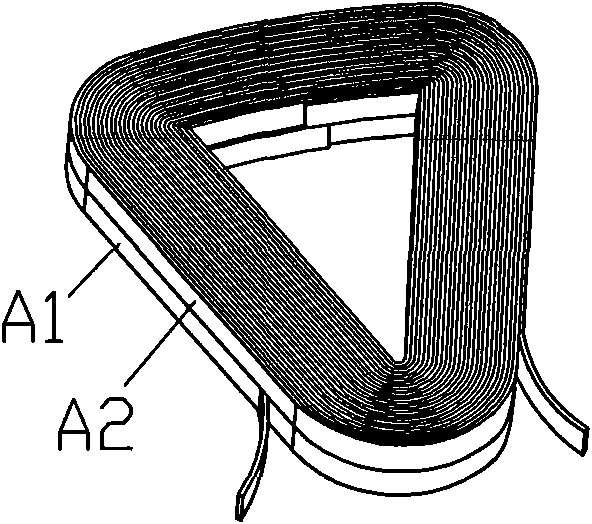

[0019] like figure 1 , figure 2 As shown, it is the basic structure of a preferred embodiment of the present invention. The ultra-thin high-power DC permanent magnet motor includes a transmission shaft 8, a disc-shaped stator part sleeved in the middle section of the transmission shaft 8, and respectively arranged on the stator parts. , the disk-shaped rotor parts on the lower two sides that can rotate together with the transmission shaft 8, the upper end cover 11 and the lower end cover 5 that respectively encapsulate the stator part and the rotor part, and the upper end cover 11 and the lower end cover 5 respectively pass a rolling bearing 7 and Drive shaft 8 is connected. Wherein, the stator parts include: a disk-shaped stator frame 1, nine fan-shaped slots 16 (the number of fan-shaped slots can also be selected according to needs, as long as they are evenly arranged), and are arranged on the stator frame 1. The sector winding 2 in the sector slot 16 , the inner pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com