Rapid winding and bundling integrated device for fire hose production

A fire hose and fast technology, applied in the parts, packaging, transportation and packaging of strapping machinery, can solve the problems affecting the production efficiency of fire hoses and the low efficiency of winding and bundling of fire hoses, so as to improve the winding efficiency. Efficiency, improve the effect of winding, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

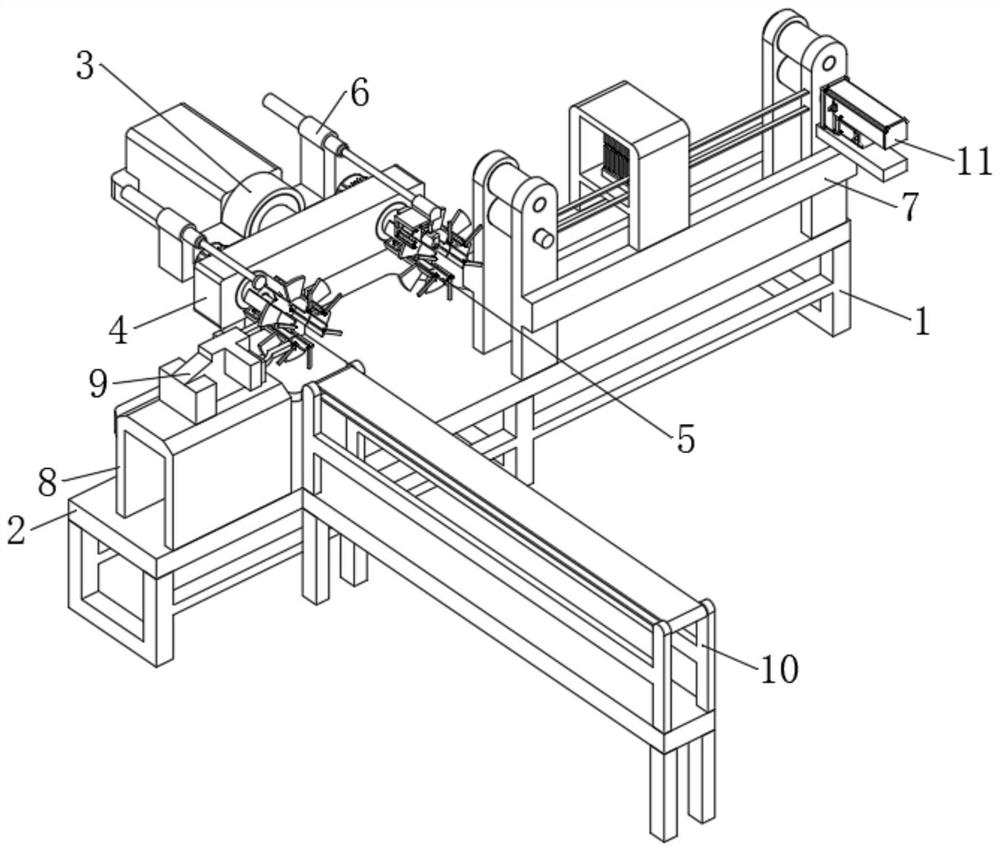

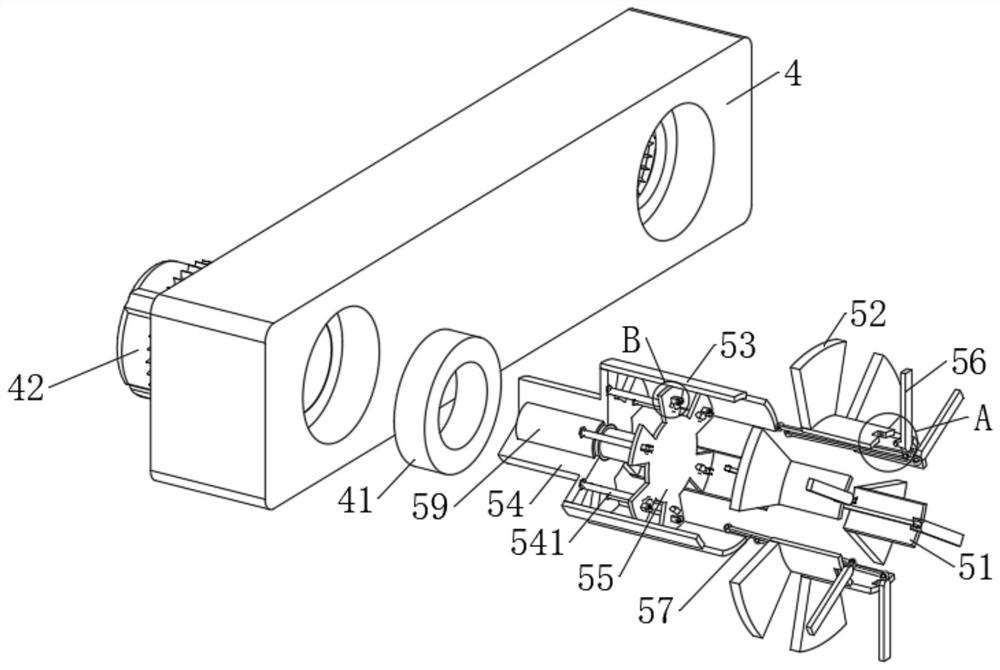

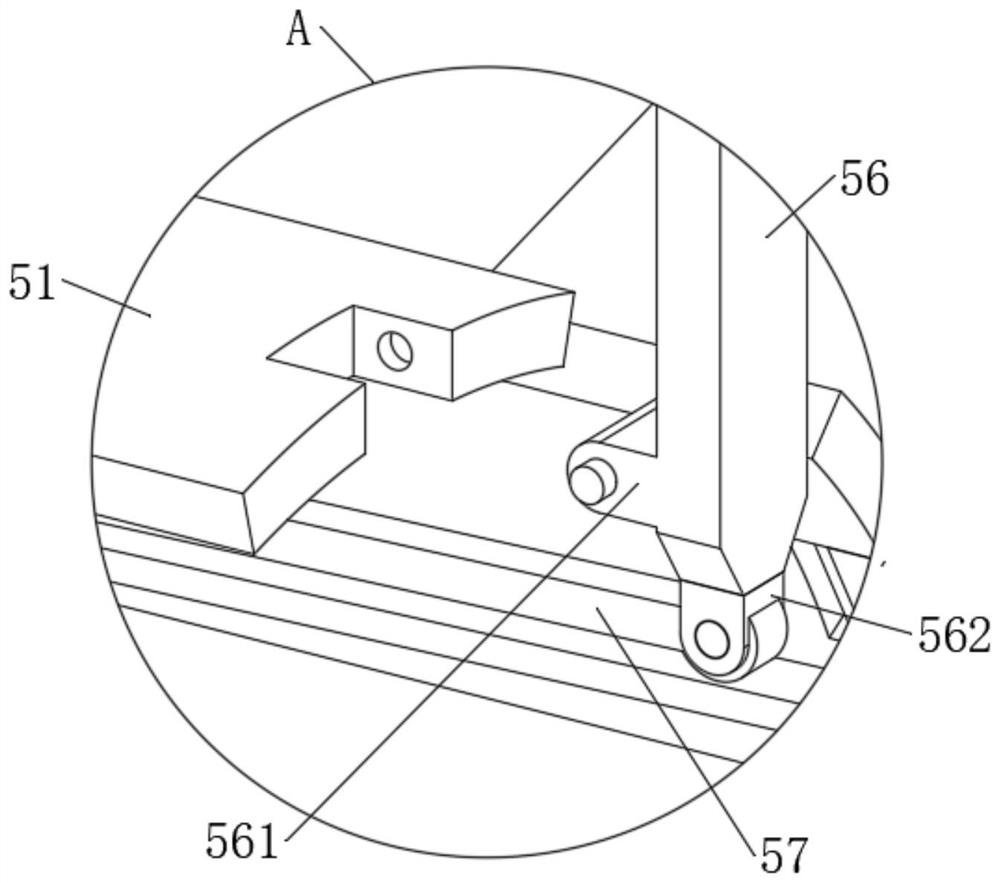

[0029] Example: such as Figure 1-8 As shown, the present invention provides a fast winding and binding integrated device for the production of fire hoses, including a base frame 1, a base plate 2 is fixedly installed on the top of the base frame 1, and a support frame 3 is fixedly installed in the middle of the top end of the base plate 2 to support The top of the frame 3 is provided with a rotating frame 4, and the side of the rotating frame 4 away from the supporting frame 3 is provided with a winding assembly 5, and the winding assembly 5 is provided with two symmetrically distributed ones, and the top of the supporting frame 3 is fixedly installed with a winding assembly 5. The auxiliary assembly 6 used in conjunction with the volume assembly 5, the top side of the bottom frame 1 is fixedly installed with a dredging assembly 7, the side of the top of the bottom frame 1 away from the dredging assembly 7 is fixedly installed with a translation mechanism 8, and the driving en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com