New straw weaving product bleaching treatment method

A new method and straw weaving technology, applied in the field of straw weaving bleaching and dyeing processing, can solve the problems of affecting product sales and application fields, increasing the input cost of sewage treatment, and large water consumption in straw weaving and dyeing processing, etc. The effect of avoiding the contamination of the agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

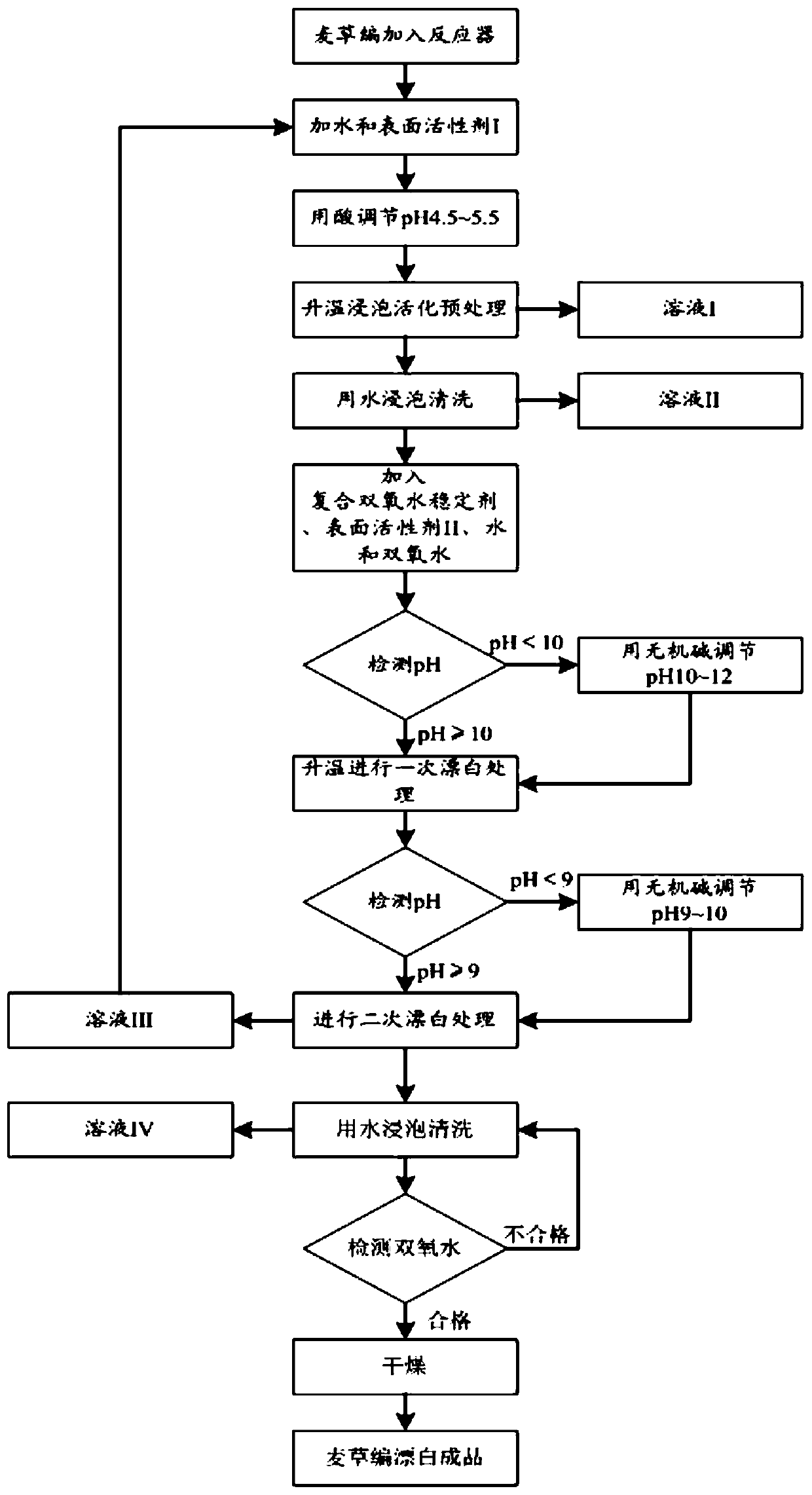

[0033] Embodiments of the present invention provide a new method for bleaching straw, comprising the following steps:

[0034] S1, activation pretreatment

[0035] Weigh 12.1g of wheat straw and put it into the reactor, add 300g of water and 0.12g of OP-10 to the reactor in turn, then adjust the pH of the solution to 5.0 with sulfuric acid, raise the temperature to 55°C, soak and activate for 60min, pretreatment Discharge solution I after finishing, at this moment, the pH of solution I is 7.1;

[0036] S2, cleaning

[0037] Add water to the reactor to cover the braided wheat straw, soak and wash for 20 minutes, then drain the water, that is, discharge solution II;

[0038] S3, bleaching treatment

[0039] S3.1, the preparation of composite hydrogen peroxide stabilizer: EDTA, sodium metasilicate, magnesium sulfate three kinds of agents are mixed evenly to obtain composite hydrogen peroxide stabilizer, composite stabilizer raw material weight ratio is: EDTA: sodium metasilica...

Embodiment 2

[0044] Embodiments of the present invention provide a new method for bleaching straw, comprising the following steps:

[0045] S1, activation pretreatment

[0046] Weigh 12.7g of wheat straw and put it into the reactor, add 300g of the solution III of Example 1 and 0.2g of OP-10 to the reactor in sequence, then adjust the pH of the solution to 4.5 with sulfuric acid, raise the temperature to 60°C, soak and activate the pre- Treat for 30min, discharge solution I after the pretreatment ends, at this moment, the pH of solution I is 6.0;

[0047] S2, cleaning

[0048] Add water to the reactor to cover the braided wheat straw, soak and wash for 10 minutes, then drain the water, that is, discharge solution II;

[0049]S3, bleaching treatment

[0050] S3.1, the preparation of composite hydrogen peroxide stabilizer: EDTA, sodium metasilicate, magnesium sulfate three kinds of agents are mixed evenly to obtain composite hydrogen peroxide stabilizer, composite stabilizer raw material ...

Embodiment 3

[0055] Embodiments of the present invention provide a new method for bleaching straw, comprising the following steps:

[0056] S1, activation pretreatment

[0057] Weigh 19.1kg of wheat straw and put it into the reactor, add 120kg of water and 20g of OP-10 into the reactor in turn, then adjust the pH of the solution to 4.6 with sulfuric acid, raise the temperature to 60°C, soak and activate the pretreatment for 120min, and the pretreatment is over After discharge solution I, at this moment, the pH of solution I is 7;

[0058] S2, cleaning

[0059] Add water to the reactor to cover the braided wheat straw, soak and wash for 30 minutes, then drain the water, that is, discharge solution II;

[0060] S3, bleaching treatment

[0061] S3.1, the preparation of composite hydrogen peroxide stabilizer: EDTA, sodium metasilicate, magnesium sulfate three kinds of agents are mixed evenly to obtain composite hydrogen peroxide stabilizer, composite stabilizer raw material weight ratio is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com