Method for preparing naphthalene series water reducing agent

The technology of naphthalene-based water-reducing agent and naphthalene sulfonic acid is applied in the field of preparation of concrete admixtures, which can solve the problems of labor, waste of energy-consuming raw materials, pollution of the environment by calcium sulfate waste residue, and quality of sodium sulfate affecting the quality, so as to reduce the cost of raw materials, The effect of factors that improve production and social benefits and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

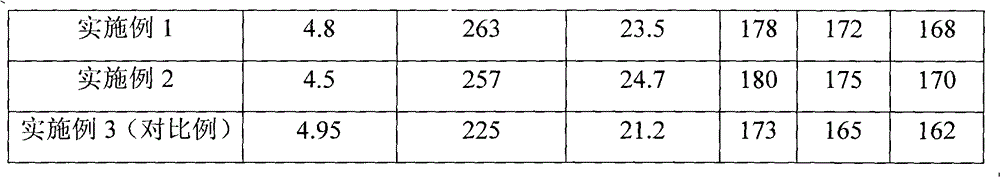

Embodiment 1

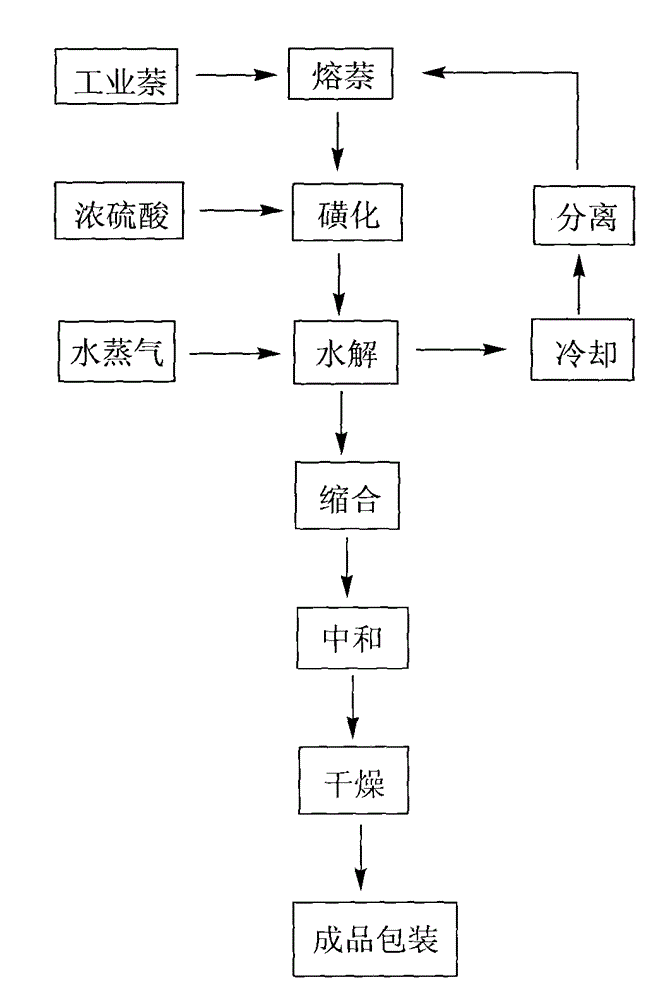

[0026] like figure 1 As shown in the process flow, the production process of high-concentration naphthalene-based water reducer mainly includes steps such as melting naphthalene, sulfonation reaction, steam hydrolysis to remove naphthalene, recovery and application of naphthalene, condensation reaction, and neutralization reaction.

[0027] The specific method is as follows:

[0028] (1) Melting naphthalene. Put 3000kg (23.4kmol) of industrial naphthalene in a melting tank and melt it to obtain molten industrial naphthalene at 100°C.

[0029] (2) Sulfonation reaction. The liquid industrial naphthalene of above-mentioned step (1) gained molten state is squeezed in the sulfonation kettle by metering pump, simultaneously 2000Kg 98% concentrated sulfuric acid (20.4kmol) is squeezed into sulfuric acid head tank (industrial naphthalene: sulfuric acid mol ratio=1.15: 1 ), the temperature in the kettle was raised to 140°C, and the metered concentrated sulfuric acid was evenly added...

Embodiment 2

[0037] With the 460Kg industrial naphthalene recovered in 2560Kg industrial naphthalene and embodiment 1, the 37% formaldehyde consumption in the step (5) is changed into 1550Kg, and the liquid high-concentration type naphthalene series high-efficiency water reducing agent of step (6) will neutralize the reaction to finish gained The finished product is directly sent to the spray tower for spray drying to obtain the finished solid high-concentration naphthalene-based high-efficiency superplasticizer, and other steps remain unchanged.

[0038] (1) Melted naphthalene

[0039] Industrial naphthalene 2560kg and naphthalene 460kg reclaimed according to the method described in example 1 are concentrated in melting tank and melted, and liquid industrial naphthalene (23.6kmol) of molten state is obtained at 100 ℃;

[0040] (2) Sulfonation reaction:

[0041]The liquid industrial naphthalene of the molten state obtained in the above step (1) is squeezed into the sulfonation kettle by a...

Embodiment 3

[0050] Embodiment 3 (comparative example):

[0051] Melt 2400Kg (18.75kmol) industrial naphthalene in the naphthalene melting kettle, put the liquid industrial naphthalene in the molten state into the sulfonation kettle, add 2659Kg (26.59kmol) concentrated sulfuric acid to carry out sulfonation at 120~160°C (naphthalene: concentrated sulfuric acid=1 : 1.4), sulfonated for about 3 hours, poured into the hydrolysis kettle to cool down to 120°C, added 1100Kg tap water to the kettle for hydrolysis reaction for 45-60min, cooled down after hydrolysis, poured into the condensation kettle, and added dropwise 1400Kg of 37% formaldehyde at about 80°C (17.27kmol) to carry out the condensation reaction, the dropwise addition is completed at 100°C and the condensation reaction is about 5 to 6 hours. After cooling down, put 525Kg of calcium hydroxide into the neutralization tank and stir for one hour, then add 3000Kg of liquid sodium hydroxide (concentration 30%) to adjust the pH value to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com