Patents

Literature

55 results about "Antimony pentachloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony pentachloride is a chemical compound with the formula SbCl₅. It is a colourless oil, but typical samples are yellowish due to impurities. Owing to its tendency to hydrolyse to hydrochloric acid, SbCl₅ is a highly corrosive substance and carbonizes non-fluorinated plastics.

Processes for hydrofluorination of 2-chloro-3,3,3-trifluoropropene to 2-chloro-1,1,1,2-tetrafluoropropane

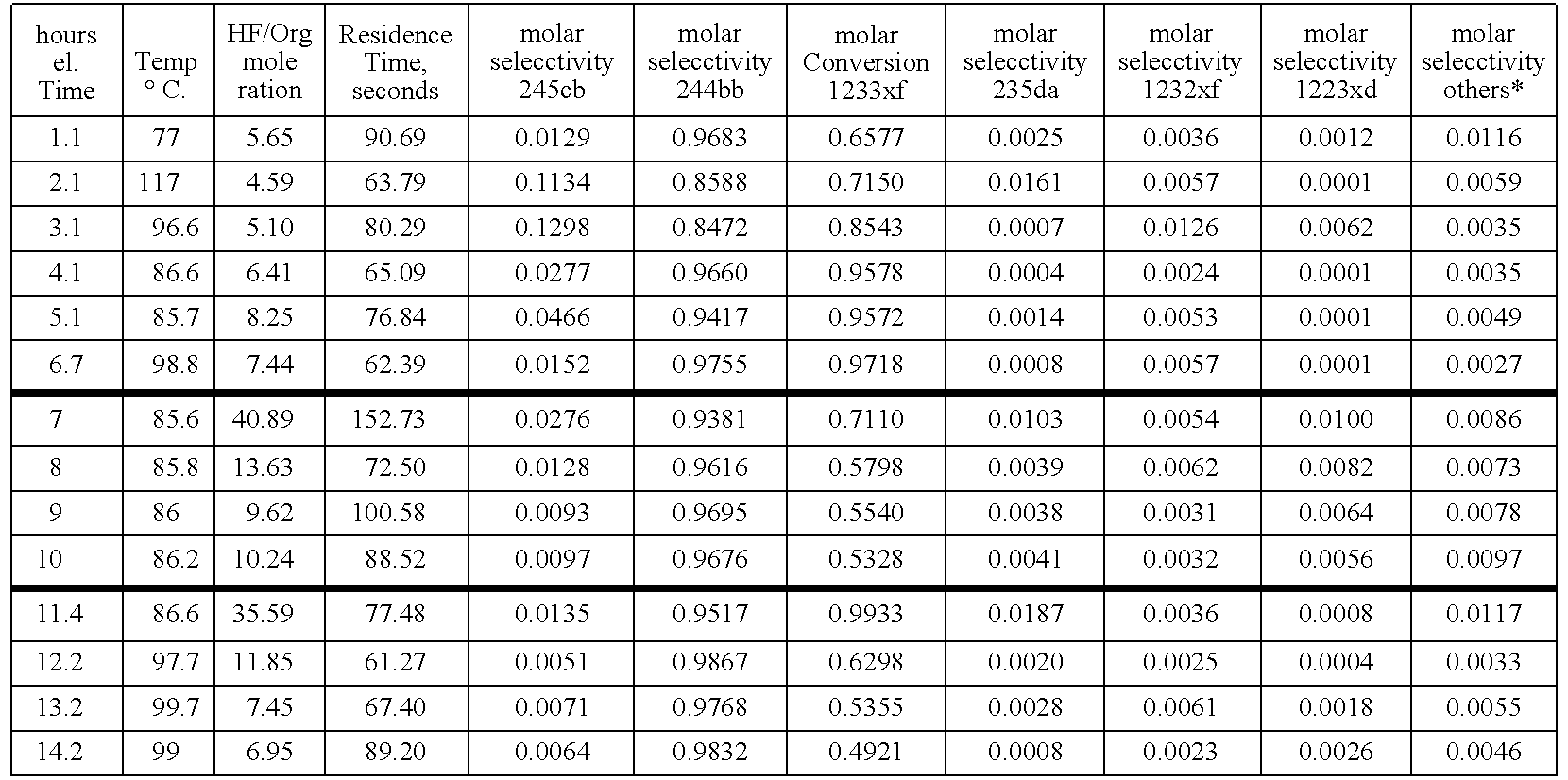

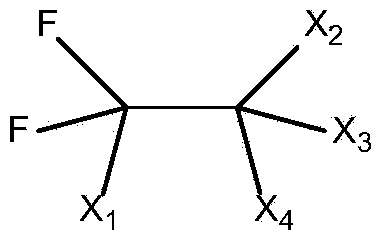

A process for making 2-chloro-1,1,1,2-tetrafluoropropane. The process has the step of contacting 2-chloro-3,3,3-trifluoropropene with hydrogen fluoride in the presence of a catalyst having about 25 to about 99.9 mole percent antimony pentachloride and about 0.1 to about 75 mole percent of a metal of a Lewis acid under conditions sufficient to form the 2-chloro-1,1,1,2-tetrafluoropropane. There is a second process for making 2-chloro-1,1,1,2-tetrafluoropropane. The process has the step of hydrofluorinating about 75 to about 99.9 mole percent 2-chloro-3,3,3-trifluoropropene and about 0.1 to about 25 mole percent of one or more other hydrocarbons having at least one chlorine atom in the presence of a catalyst of fluorinated antimony pentachloride under conditions sufficient to form the 2-chloro-1,1,1,2-tetrafluoropropane. There is yet another process for hydrofluorinating 2-chloro-3,3,3-trifluoropropene to 2-chloro-1,1,1,2-tetrafluoropropane. The process has the step of contacting the 2-chloro-3,3,3-trifluoropropene with hydrogen fluoride in the presence of a vapor phase catalyst under conditions sufficient to form the 2-chloro-1,1,1,2-tetrafluoropropane.

Owner:HONEYWELL INT INC

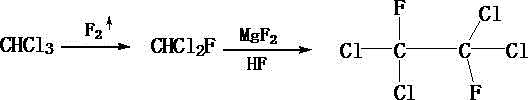

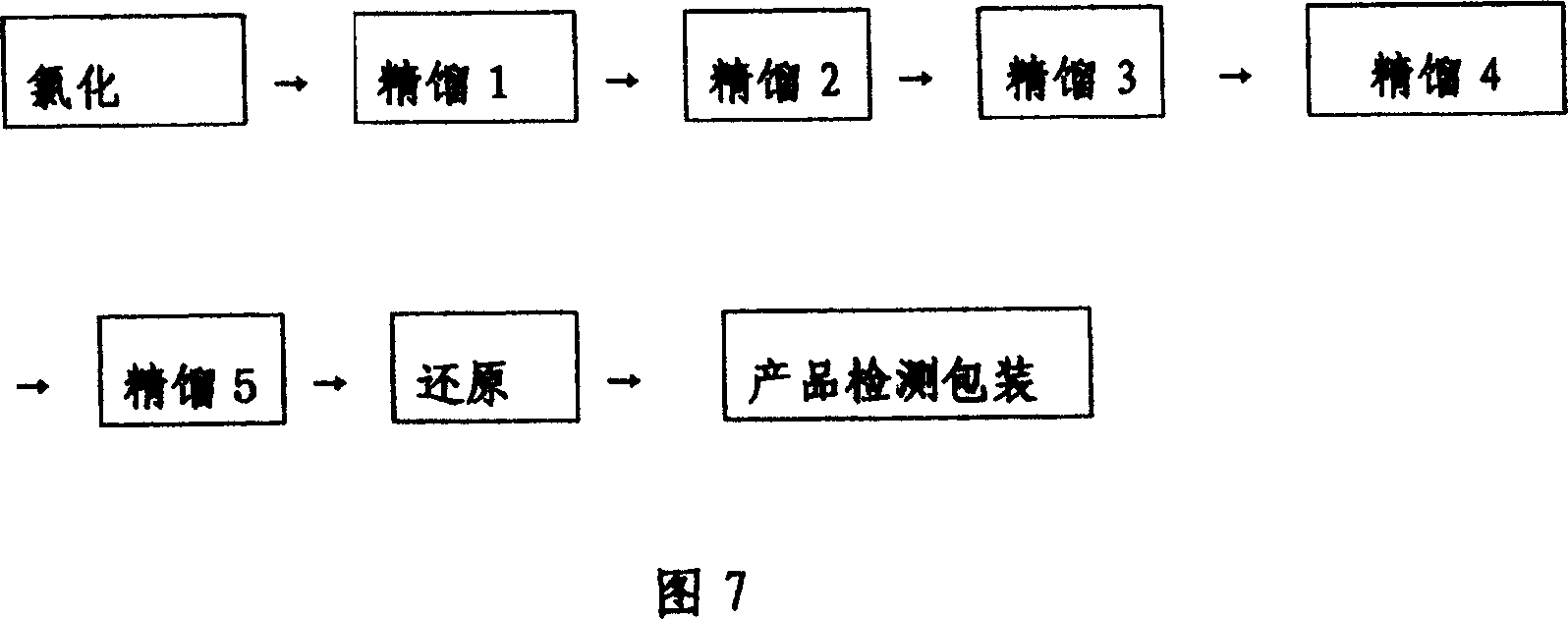

Preparation method of trifluoroacetic acid

InactiveCN103524325ALow costPreparation from carboxylic acid halideHalogenated hydrocarbon preparationCatalytic oxidationTetrachloroethane

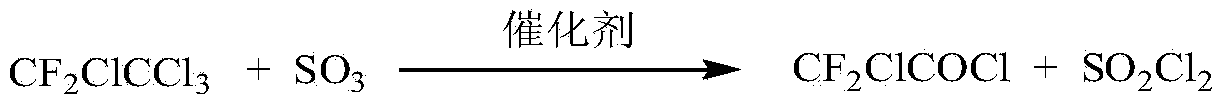

The invention discloses a preparation method of trifluoroacetic acid low in synthesis cost. The preparation method comprises the steps of (1) preparing 1,1-difluoro tetrachloroethane from 1,1-difluoroethane or chloride thereof through ultraviolet catalysis and a chlorine reaction; (2) implementing catalytic oxidation on the 1,1-difluoro tetrachloroethane to obtain 1,1-difluoro-1-chloroacetyl chloride, wherein in the catalytic oxidation, mol ratio of the 1,1-difluoro tetrachloroethane to an oxidizing agent is 1: (2-4), dosage of the catalyst is 0.5-5% of the total weight of an reactant, and reaction temperature is 50-70 DEG C; (3) carrying out hydrogen fluoride (HF) fluoridation on the 1,1-difluoro-1-chloroacetyl chloride under the catalyst to obtain trifluoroacetyl fluoride, wherein mol ratio of the 1,1-difluoro-1-chloroacetyl chloride to the HF is 1: (2-3), reaction temperature is 40-60 DEG C, and the catalyst is either antimony or antimony pentachloride; and (4) hydrolyzing the prepared trifluoroacetyl fluoride to obtain trifluoroacetic acid.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

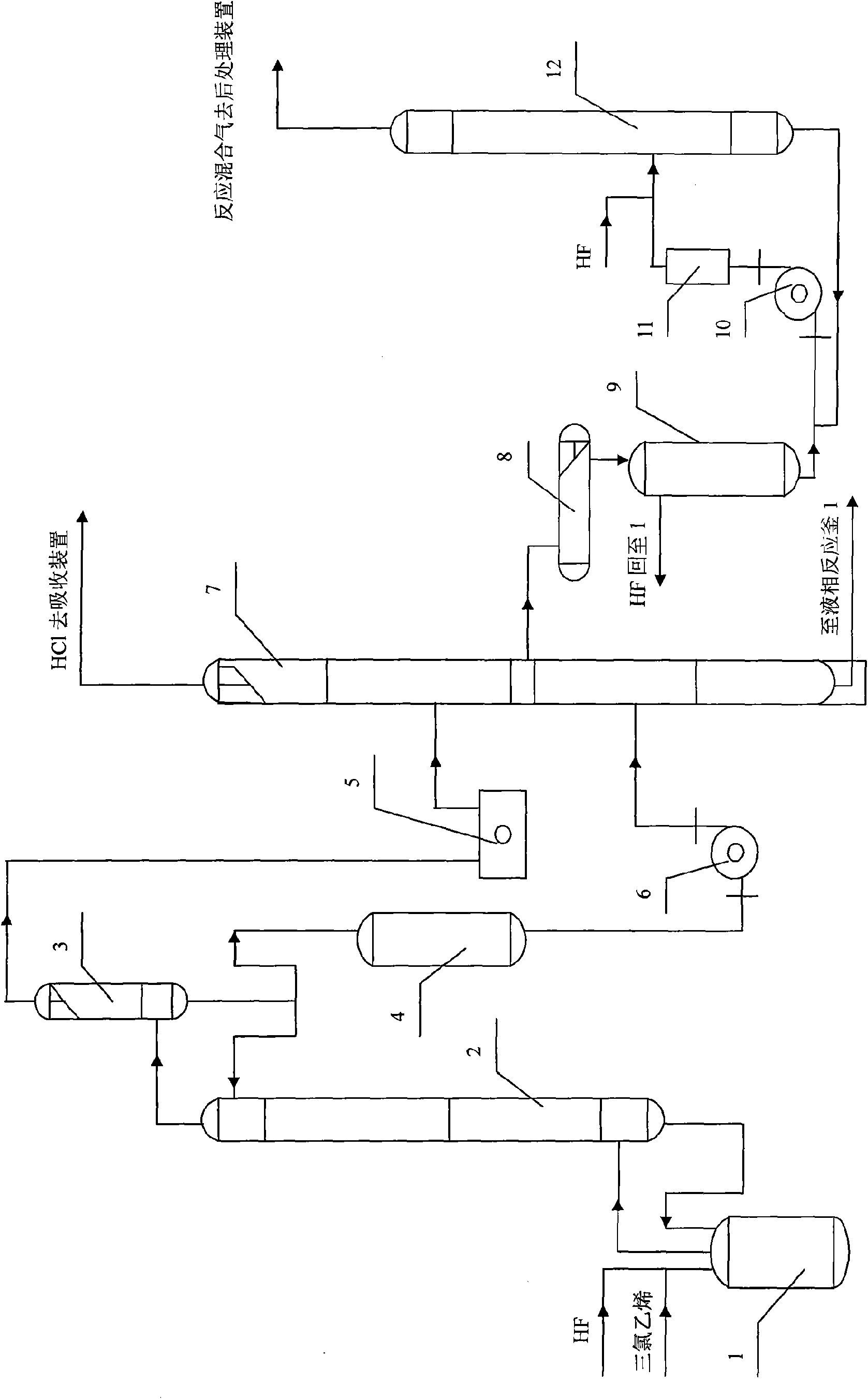

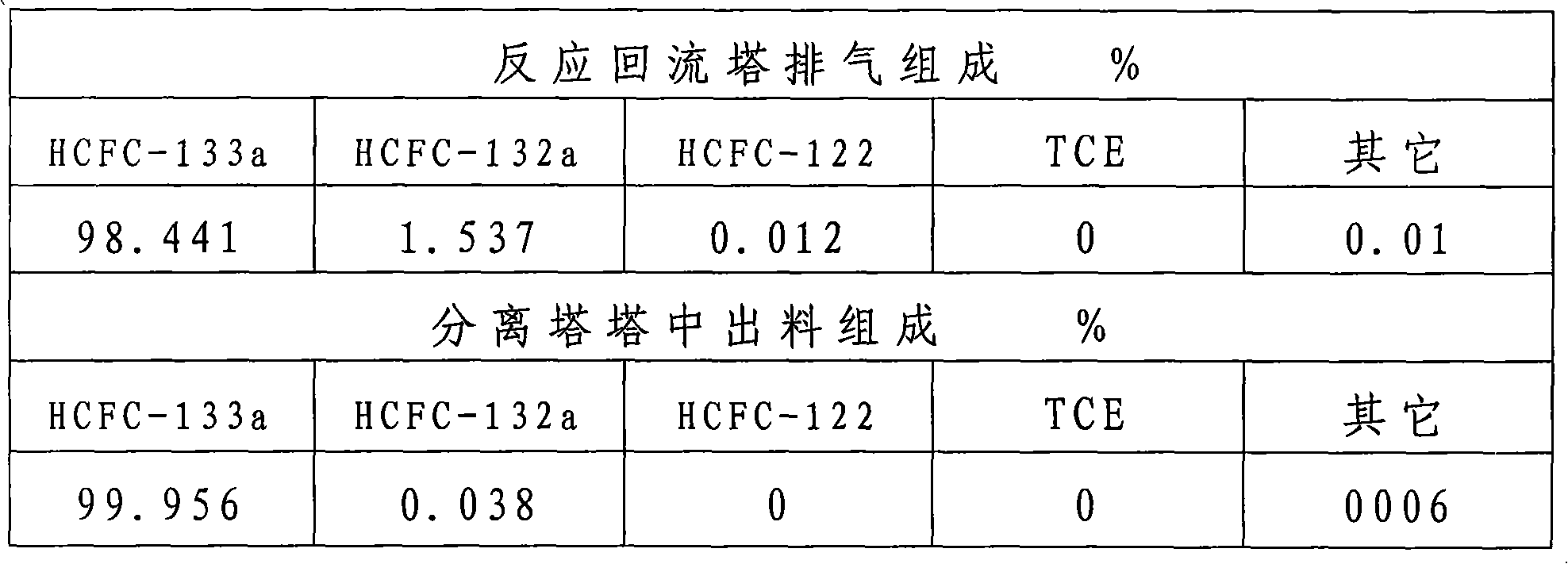

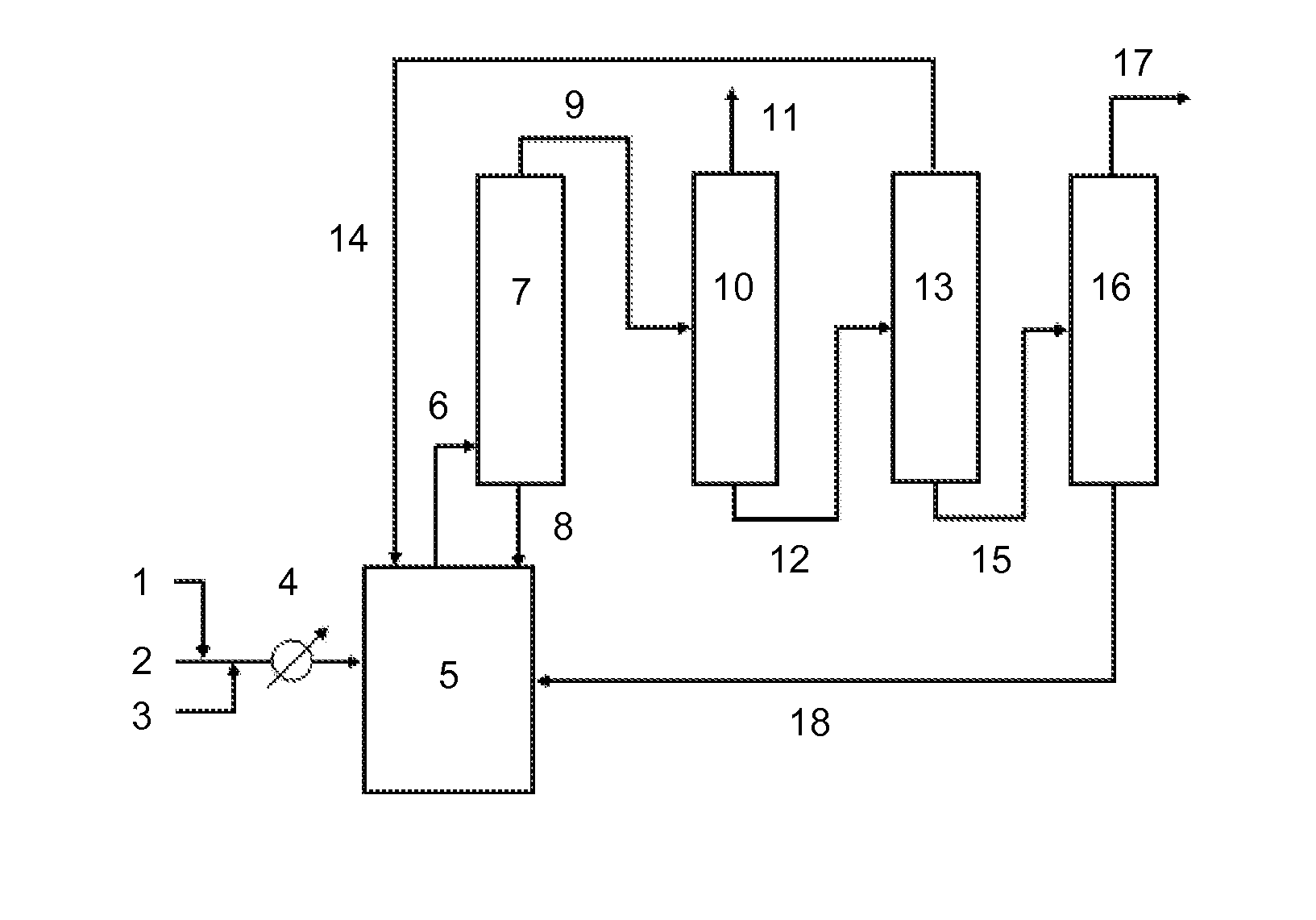

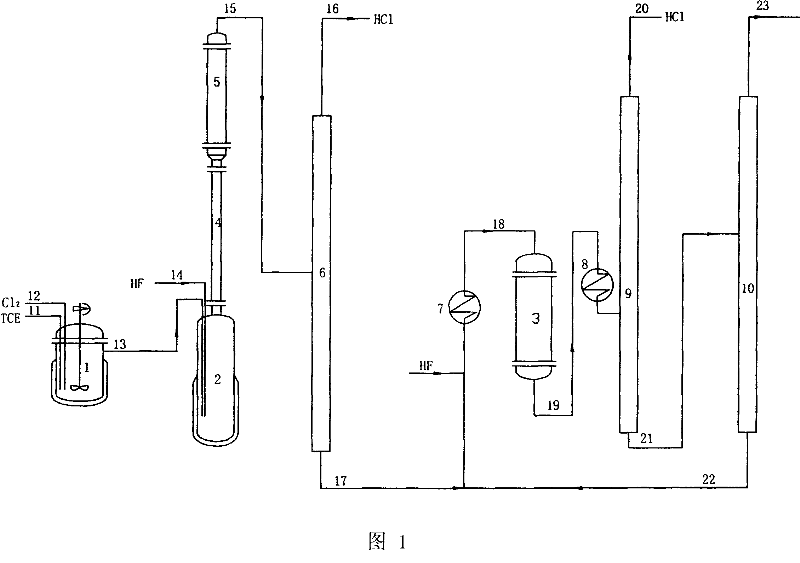

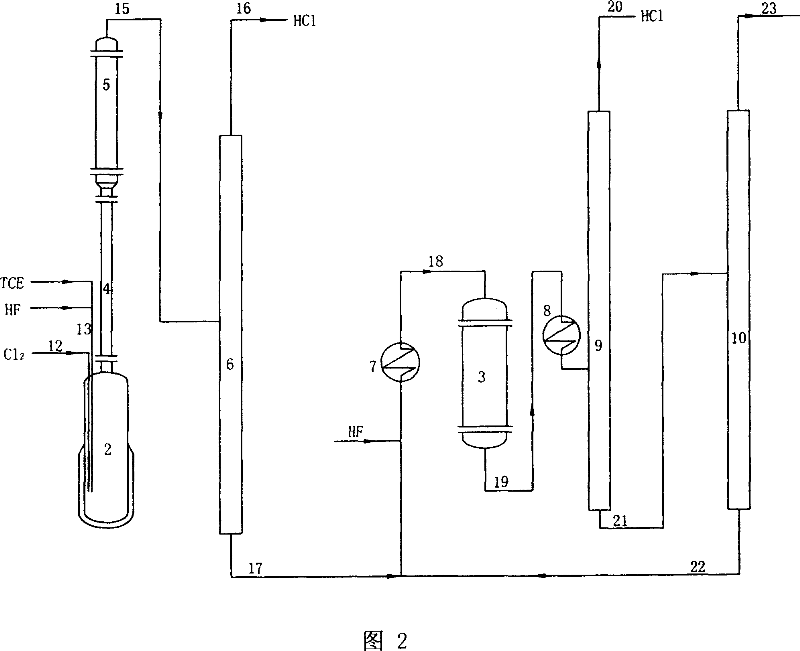

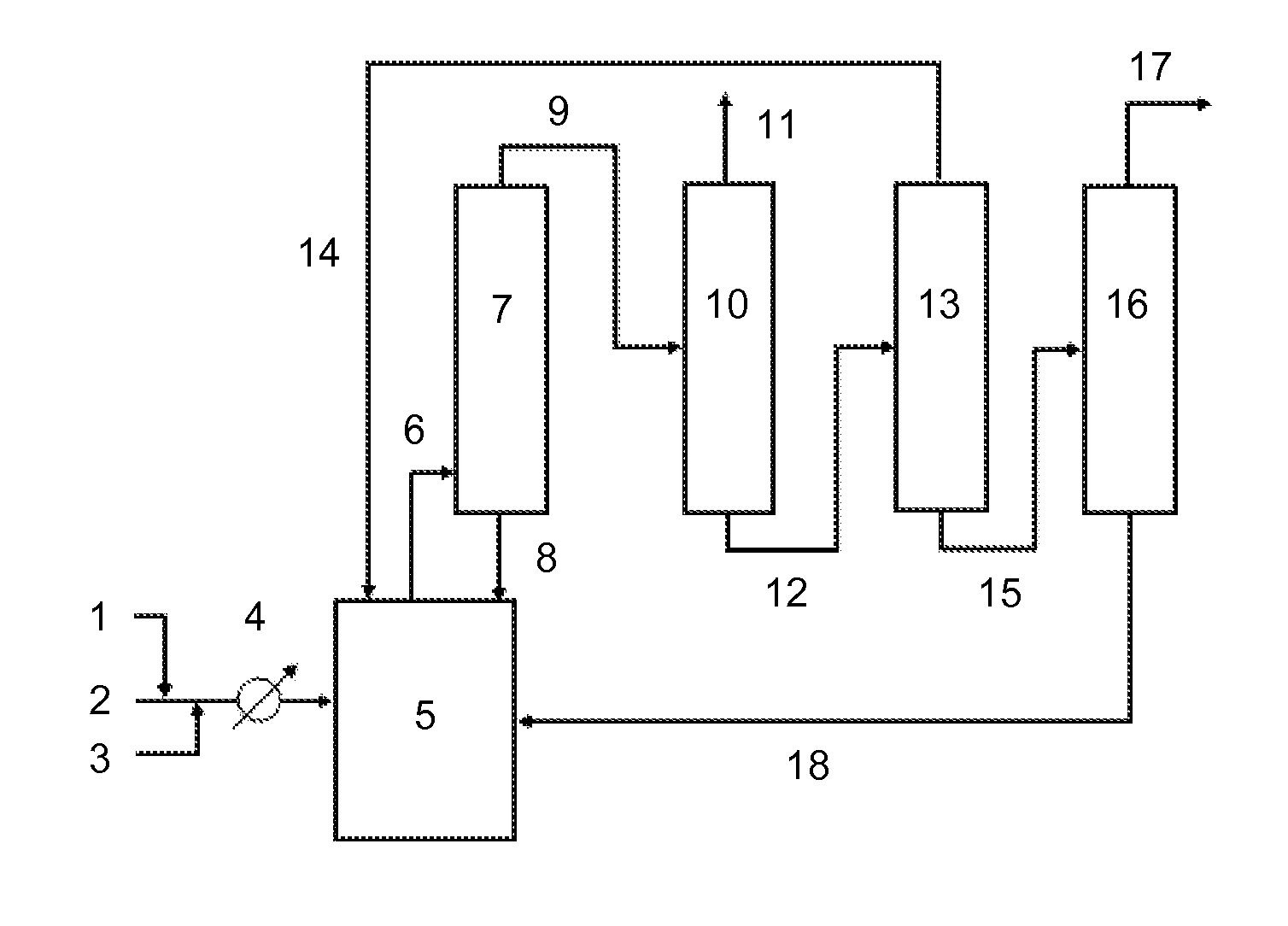

Producing process for synthesizing 1, 1, 1, 2-tetrafluoroethane by liquid phase-gas phase method

ActiveCN101648846AImprove conversion rateGood choicePhysical/chemical process catalystsPreparation by halogen replacementHydrogen fluorideAntimony pentachloride

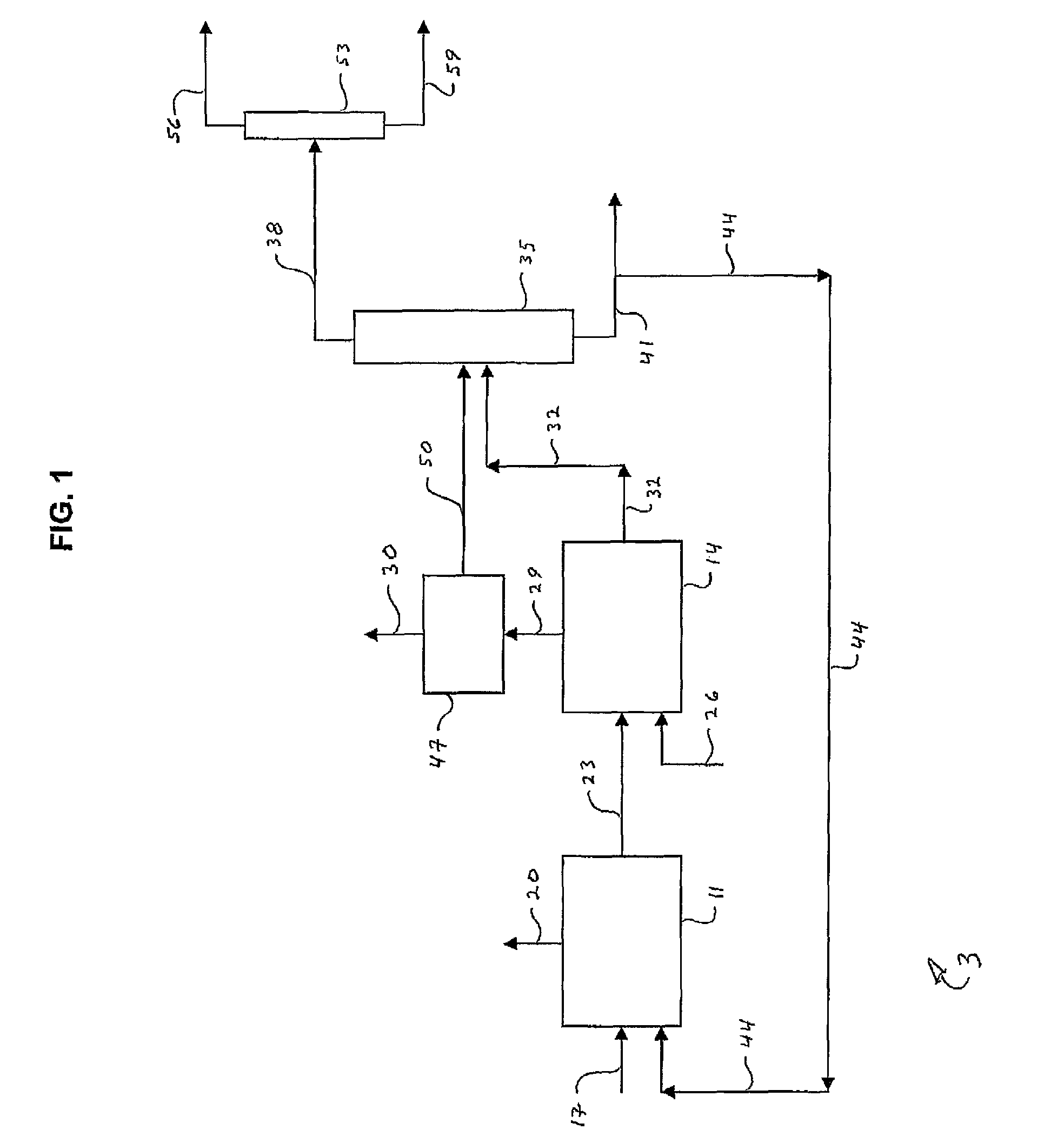

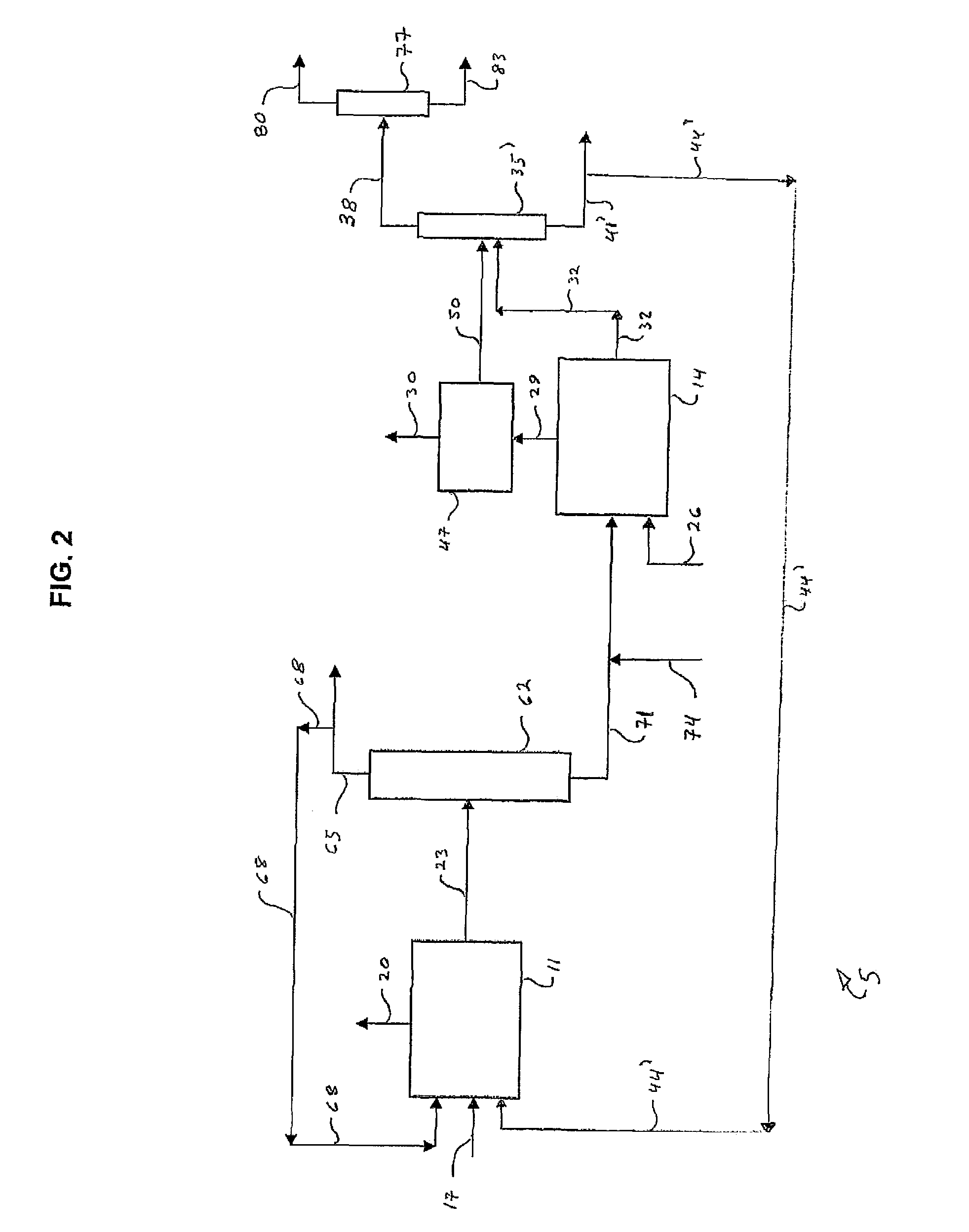

The invention discloses a producing process for synthesizing 1, 1, 1, 2-tetrafluoroethane by a liquid phase-gas phase method, comprising three steps: firstly, using trichloroethylene and hydrogen fluoride to synthesize 1, 1, 1-trifluoro-2- chloroethane by the liquid phase method under the action of a catalyst antimony pentachloride; sencondly, extracting and separating 1, 1, 1-trifluoro-2- chloroethane, hydrogen fluoride azeotrope, i.e. separating the mixed gas and the liquid phase coarse product obtained in the first step in a separating tower from a phase to another phase, separating the hydrogen chloride from the top of the tower, extracting the 1, 1, 1-trifluoro-2- chloroethane, hydrogen fluoride azeotrope from the tower, circulating a tower kettle with high-boiling to a liquid phase fluorinated reaction kettle; and thirdly, carrying out a gas phase fluorinated reaction on the 1, 1, 1-trifluoro-2- chloroethane obtained through the chromatography by a laminator and the hydrogen fluoride through a gasifier in the gas phase fluorinated reactor. The process has advantages of high conversion rate of the trichloroethylene, good selectivity, long service life of the catalyst, high yield, simple separating operation, low consumption and the like.

Owner:JIANGSU SANMEI CHEM

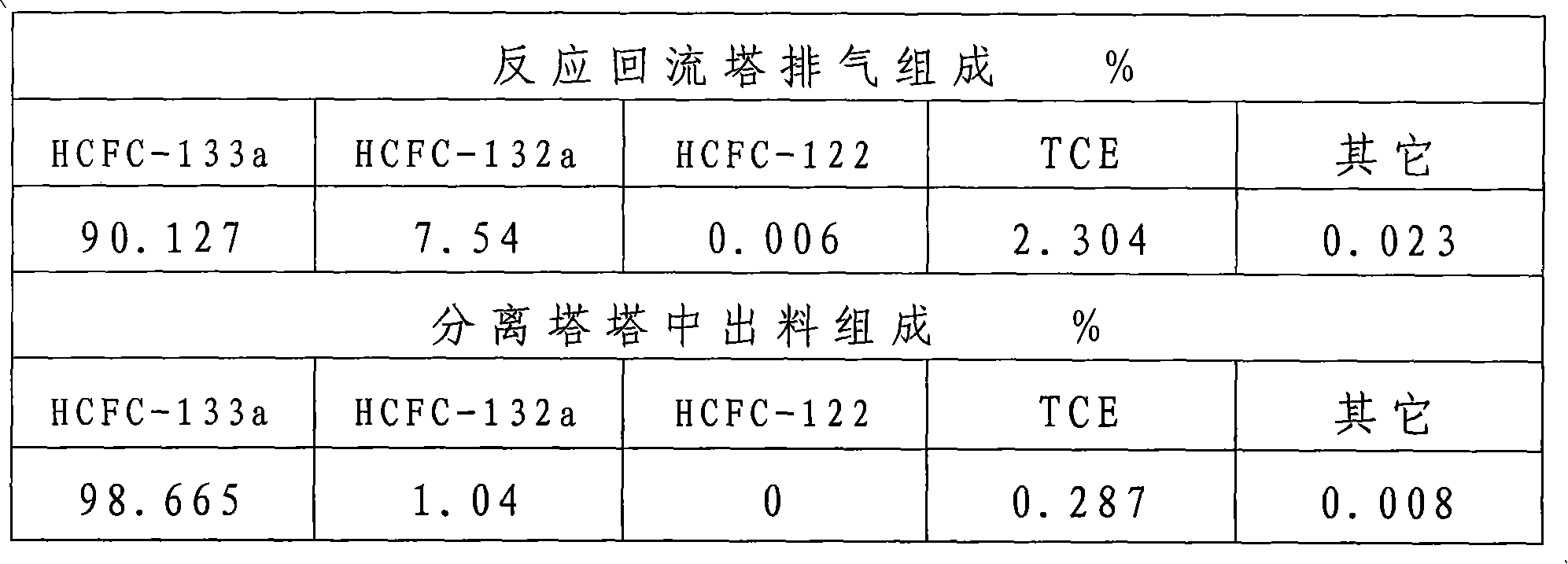

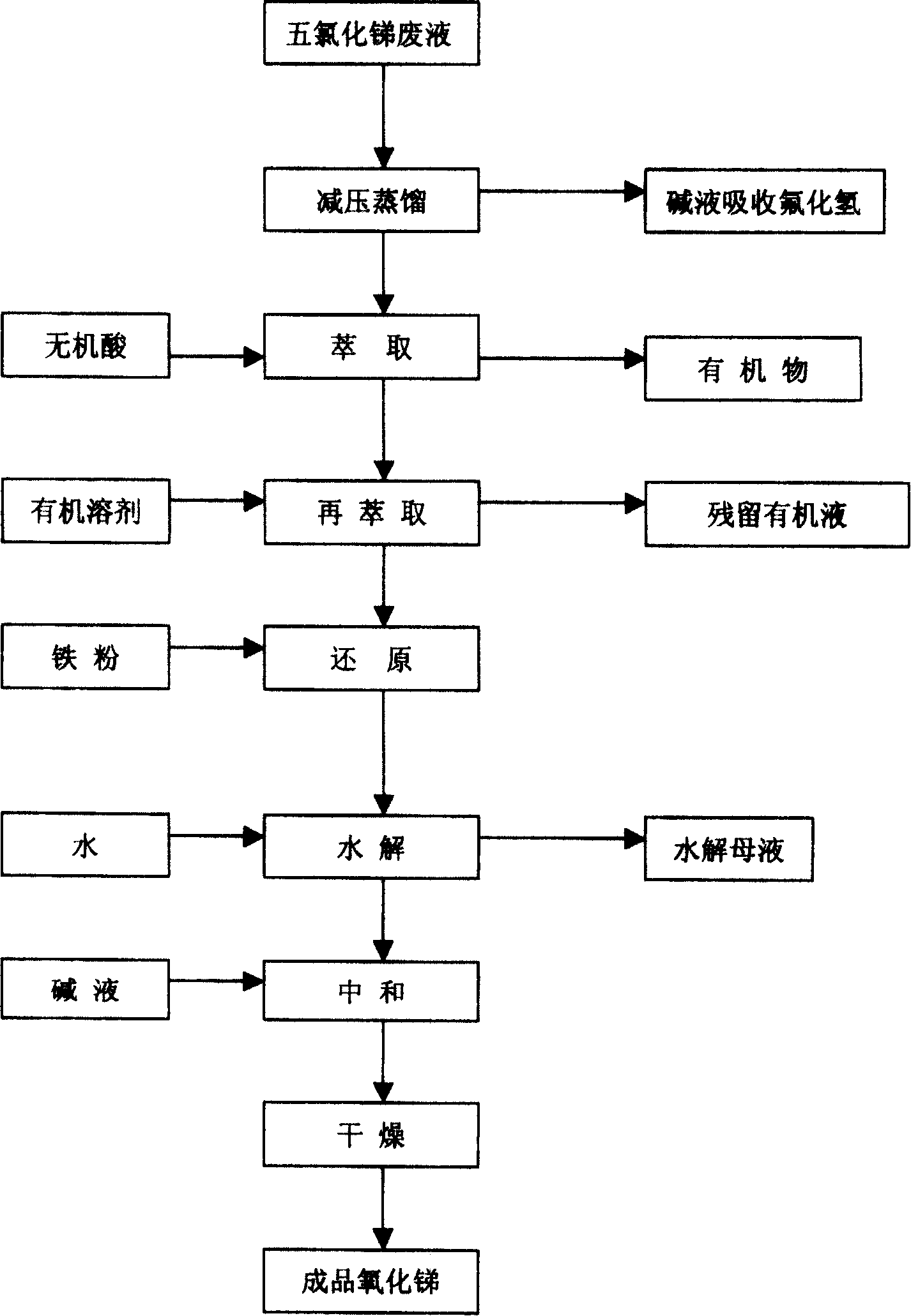

Method for recovering and making antimony oxide from antimony pentachloride solution

InactiveCN1733612AReduce dosageReduce consumptionAntimony compoundsLiquid solutions solvent extractionOrganic solventDecomposition

The invention relates to a method for recovering and making antimony oxide from antimony pentachloride solution which comprises the steps of pretreatment, reduction, hydrolytic decomposition, drying and neutralization, wherein the pretreatment consists of antimony pentachloride effluent liquor vacuum distillation, inorganic acid abstraction and organic solvent extraction.

Owner:JUHUA GRP

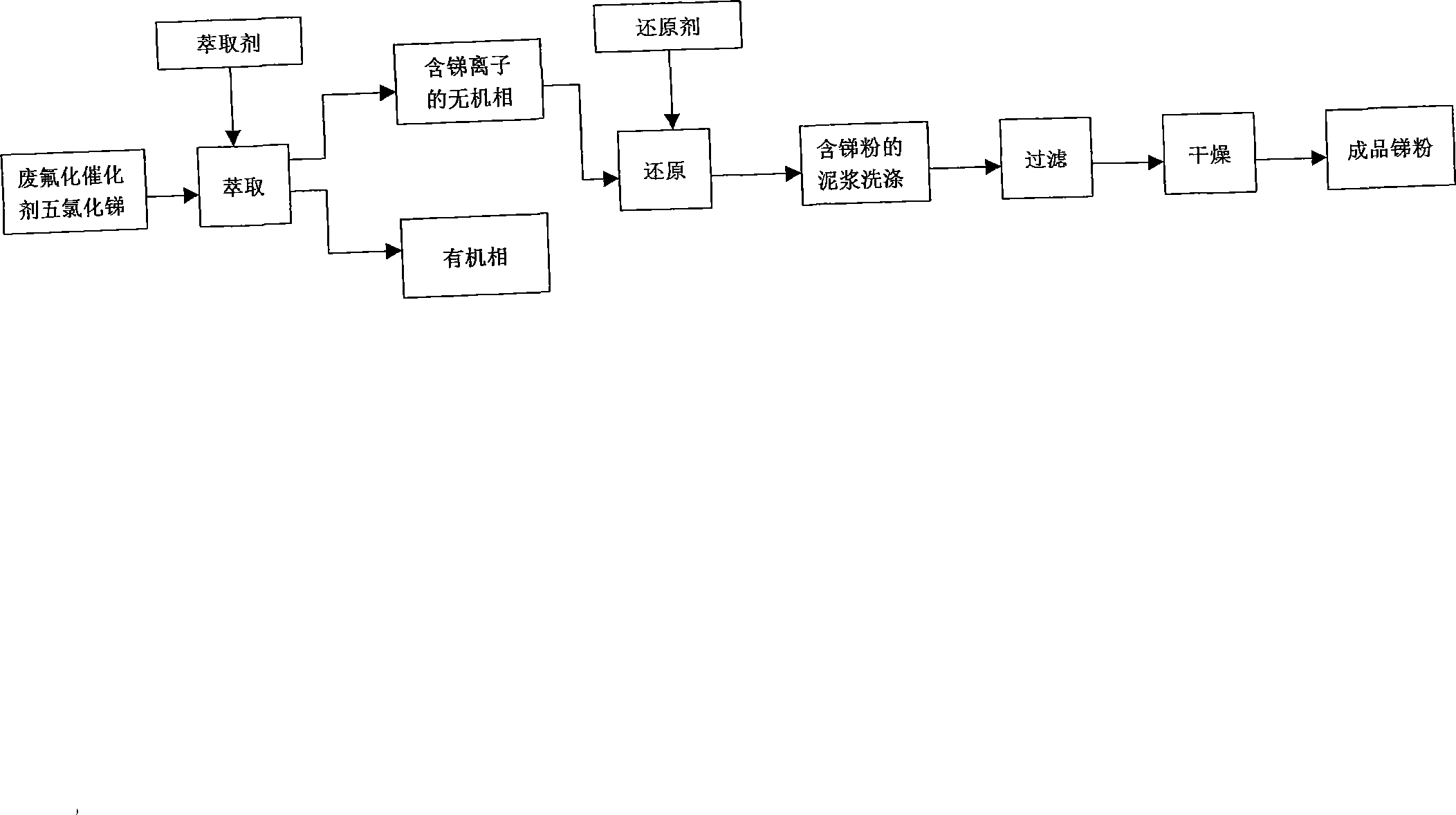

Method for reclaiming metal stibium from waste fluorination catalyst antimony pentachloride

InactiveCN101205571AReduce the impactEasy to handleProcess efficiency improvementAntimony pentachlorideMetal

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

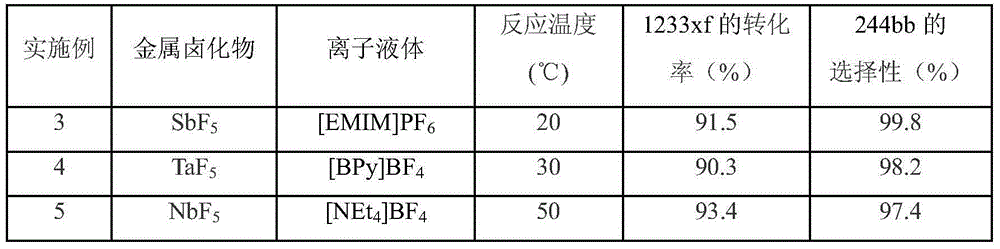

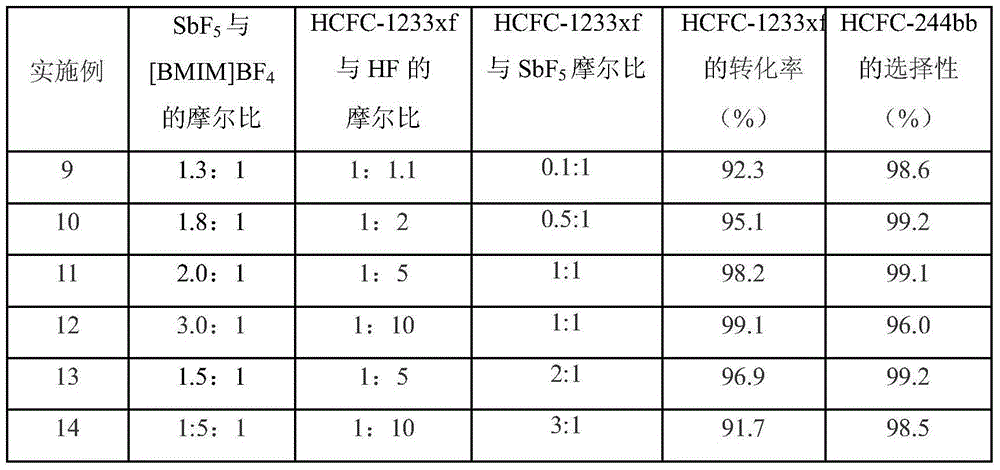

Method for preparing HCFC-244bb

InactiveCN104140354AImprove performanceLow reaction temperatureHalogenated hydrocarbon preparationReaction temperatureAntimony pentafluoride

The invention discloses a method for preparing HCFC-244bb. According to the method, 2-chloro-3, 3, 3-trifluoropropene is used as raw materials. The method comprises the following steps that, a metal halide and an ionic liquid are used as a catalyst, and fluorination is conducted on 2-chloro-3, 3, 3-trifluoropropene and a hydrogen fluoride solution, so that HCFC-244bb is prepared, wherein the metalhalide is antimony pentafluoride or antimony pentachloride or tantalum pentafluoride or tantalum pentachloride or niobium pentafluoride or niobium pentachloride, the general formula of ionic liquid is X+A-, X+ is positive ions of C1-C8 alkyl substitution type double-alkyl imidazole, pyridine and quaternary ammonium salt, A- is negative ions of tetrafluroborate negative ions or hexafluorophosphatenegative ions, the molar ratio between the metal halide and the ionic liquid is 1-3:1, the molar ratio between hydrogen fluoride and 2-chloro-3, 3, 3-trifluoropropene ranges is 1.1-10:1, and the reaction temperature ranges from 20 DEG C to 70 DEG C. The method for preparing HCFC-244bb has the advantages that the reaction temperature is low, the conversion rate is high, the selectivity is high, and chlorine is not needed in the reaction process. The method is used for preparation of HCFC-244bb.

Owner:XIAN MODERN CHEM RES INST

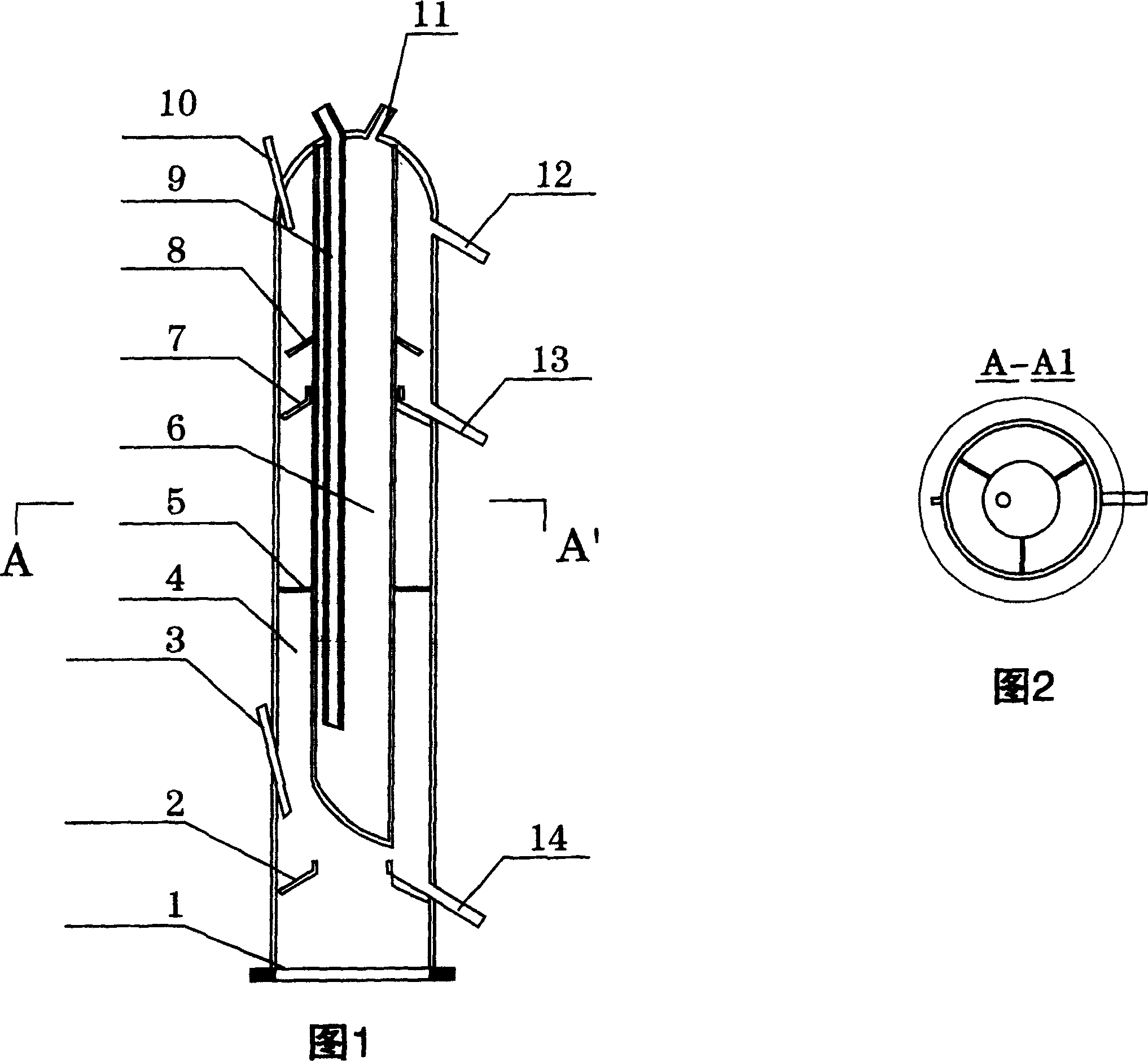

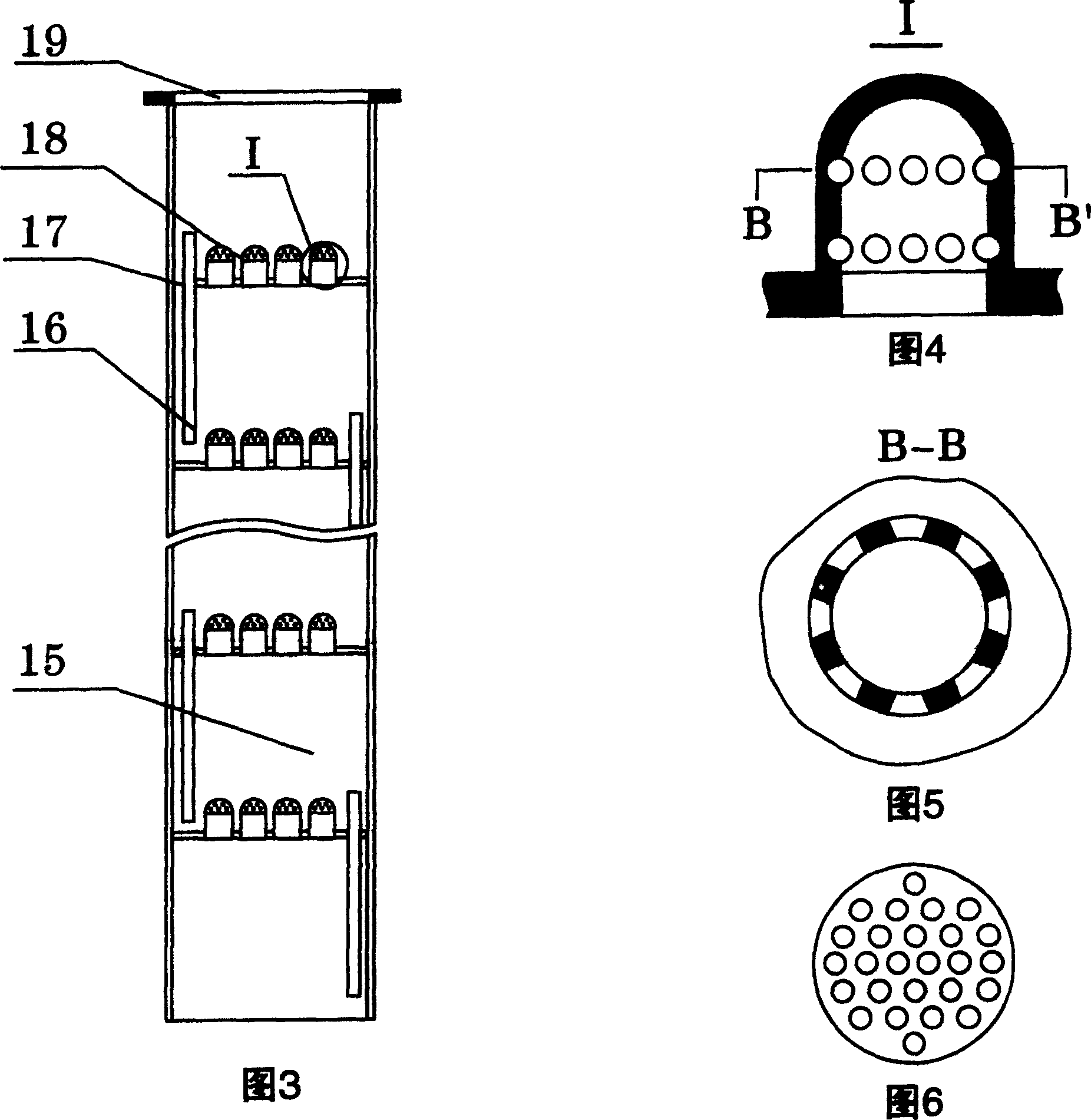

Metal antimony purifying method and apparatus

InactiveCN1676638AGuaranteed distillation effectImprove efficiencyAntimony compoundsProcess efficiency improvementHydrogenAntimony pentachloride

This invention discloses metal antimony purifying method and its mechanism. The method is to fill the industrial antimony in the chlorination tower; lead chlorine in the middle of the tower, heat at the 1 / 3 lower part of the tower to decompose antimony pentachloride; chloride and the superfluous mental blocks in the tower react to create antimony trichloride. The antimony trichloride in the storage tank automatically flows to re-boiling equipment and steam to go into rectification 1; through reflux control valve adjust flow amount of antimony trichloride and reflux amount, and the antimony trichloride goes into the re-boiler of rectification 2; the lower output mouth of the rectification tower arch is connected by the channel with the material interface of the storage tank that has two outputting mouths connected with the computation tank of reductive tank and re-boiler of sub-grade rectification system by the tube. The upper outputting mouth is connected with the residue tank by the pipeline; orderly connect the multi-grade rectification tower and continuously bring in the superfluous hydrogen and revert it and get 99.999%, 99.9999% and 99.99999% metal antimonies.

Owner:云南省通海大方科技有限公司

Norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and binary copolymerization method

The invention relates to a norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and a binary copolymerization method. The preparation method of the catalyst is characterized by comprising the following steps: in a container of dry inert gas atmosphere, dissolving antimony pentachloride and ligand in a first solvent; dropwise adding tetra-isopropoxy titanium at 200-300rpm, and then continuously stirring for 30-50 minutes at 30-50 DEG C to obtain an antimony-titanium complex catalyst; adding a norbornene monomer and a perfluoromethyl vinyl ether monomer in a molar ratio of 1:1 into an autoclave after repeated vacuumizing and nitrogen charge; adding a second solvent and dissolving; adding the antimony-titanium complex catalyst, and reacting for 1-6 hours at 30-120 DEG C and under the pressure of 0.1-8MPa; pouring the reaction product into an ethanol solution containing 4-5wt% of hydrochloric acid; washing the obtained precipitate with ethanol to neutrality; and performing vacuum drying to obtain a norbornene-perfluoromethyl vinyl ether binary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing sodium pyroantimonate by using waste antimony pentachloride as raw material

InactiveCN103114203ASimple processReduce material consumptionProcess efficiency improvementWater useAntimony

The invention discloses a method for preparing sodium pyroantimonate by using waste antimony pentachloride as a raw material. The method comprises the following steps of A, an extraction step, wherein a waste antimony pentachloride catalyst is extracted by using industrial water to obtain an organic phase and an inorganic phase, the inorganic phase is separated to obtain an antimony ion containing water solution, and the volume ratio of the waste catalyst to the industrial water is 1:0.5-1:2; B, an oxidation step, wherein the antimony ion containing water solution is oxidized by using hydrogen peroxide to obtain antimony oxidation liquid, and the hydrogen peroxide water using amount is 1-2 times of the theoretic using amount; and C, a neutralization step, wherein neutralization reaction on the antimony oxidation liquid is carried out by using sodium hydroxide water solution, a pH value of the reaction liquid is regulated to be between 7 and 13, and after the reaction is carried out for 10-300 minutes at 50-90 DEG C, cooling, filtering, washing and drying are performed to obtain sodium pyroantimonate. The method has the advantages of simple process, low material consumption, low cost, good quality of the product and environmental friendliness; the extraction ratio of antimony is more than 99.2 percent, and the highest is 99.85 percent; and the total yield of antimony is more than 98 percent, and the highest is 99.65 percent.

Owner:JUHUA GRP

Low temperature synthesis method for graphite fluoride

InactiveCN104591115AReduce the synthesis reaction temperatureLow reaction temperatureAntimony pentachlorideDecomposition

The invention discloses a low temperature synthesis method for graphite fluoride. The method includes: reacting graphite with antimony pentachloride at 300-400DEG C for 7h to prepare an antimony pentachloride graphite intercalation compound; and introducing a fluorine-nitrogen mixed gas into the reactor to carry out reaction for 5-10h, with the fluorine accounting for 12%-15% of the total volume of the fluorine-nitrogen mixed gas. The graphite fluoride synthesis reaction temperature is far below its decomposition temperature, thus avoiding the potential danger of explosion. Graphite fluoride can form in ordinary fluorination equipment, the reaction temperature control range is large and is easy to control. The production cost is low, and the output rate is high.

Owner:QINGDAO TAIHAODA CARBON MATERIAL

Method for preparing 4.4-dichlorodiphenyl sulfone by using sulfur trioxide

InactiveCN102304072AReduce generationLow reaction temperatureOrganic chemistryOrganic compound preparationChlorobenzeneReaction temperature

The invention discloses a method for preparing 4.4-dichlorodiphenyl sulfone by using sulfur trioxide, which comprises the following steps: dripping sulfur trioxide into chlorobenzene to perform a sulfonation reaction; after the sulfonation reaction is finished, adding dimethyl sulfoxide serving as a catalyst, heating, introducing nitrogen, dripping thionyl chloride to perform an acid halogenation reaction and absorbing sulfur dioxide and hydrogen chloride generated in an acid halogenation reaction process by using alkaline liquor; and after acid halogenation reaction is finished, adding antimony pentachloride serving as a catalyst, introducing nitrogen, and dripping chlorobenzene at room temperature to perform a Friedel-Crafts reaction to produce coarse 4.4-dichlorodiphenyl sulfone. Therefore, the method can effectively lower reaction temperature and reaction time, thereby saving production cost; in addition, nitrogen is introduced into the reaction solution in the whole reaction process, so the production of byproducts is reduced effectively. The 4.4-dichlorodiphenyl sulfone yield of the method may reach 98 percent.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

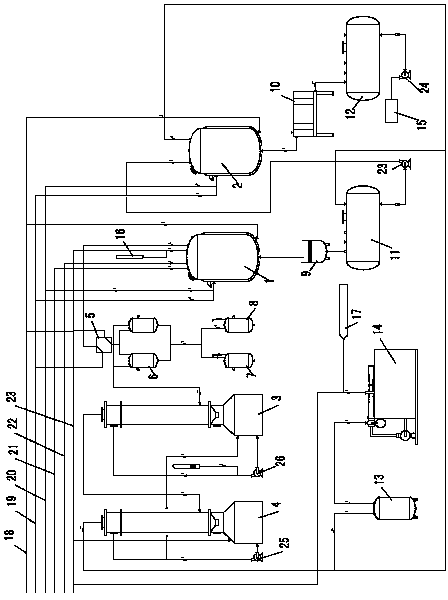

Antimony pentachloride waste liquid treatment system

ActiveCN103820645AThorough disposalGood effectWater contaminantsDispersed particle separationLiquid wasteFiltration

The invention provides an antimony pentachloride waste liquid treatment system. The antimony pentachloride waste liquid treatment system mainly comprises a primary reaction kettle and a secondary reaction kettle, wherein the primary reaction kettle is sequentially connected to a vacuum filtration machine, a first-stage filtrate tank, a first pipeline pump and the secondary reaction kettle; the secondary reaction kettle is sequentially connected to a filter press, a secondary-stage filtrate tank, a second pipeline pump and a wastewater treatment system; the primary reaction kettle is sequentially connected to a graphene condenser, a liquid distribution tank and a first-stage falling film absorption tower, and the liquid distribution tank is respectively connected to a dilute acid storage tank and a chloroform storage tank; the first-stage falling film absorption tower is sequentially connected to a fourth pipeline pump, the first-stage falling film absorption tower, a secondary-stage falling film absorption tower and a third pipeline pump; the secondary reaction kettle, the first-stage filtrate tank and the secondary-stage falling film absorption tower are connected to a vacuum buffer tank which is connected to a vacuum pump. The antimony pentachloride waste liquid treatment system can be used for recovering antimony oxide in waste liquid very well and collecting acid gas and chloroform generated in a reaction process and is complete in treatment and good in effect.

Owner:济南云水腾跃环保科技有限公司

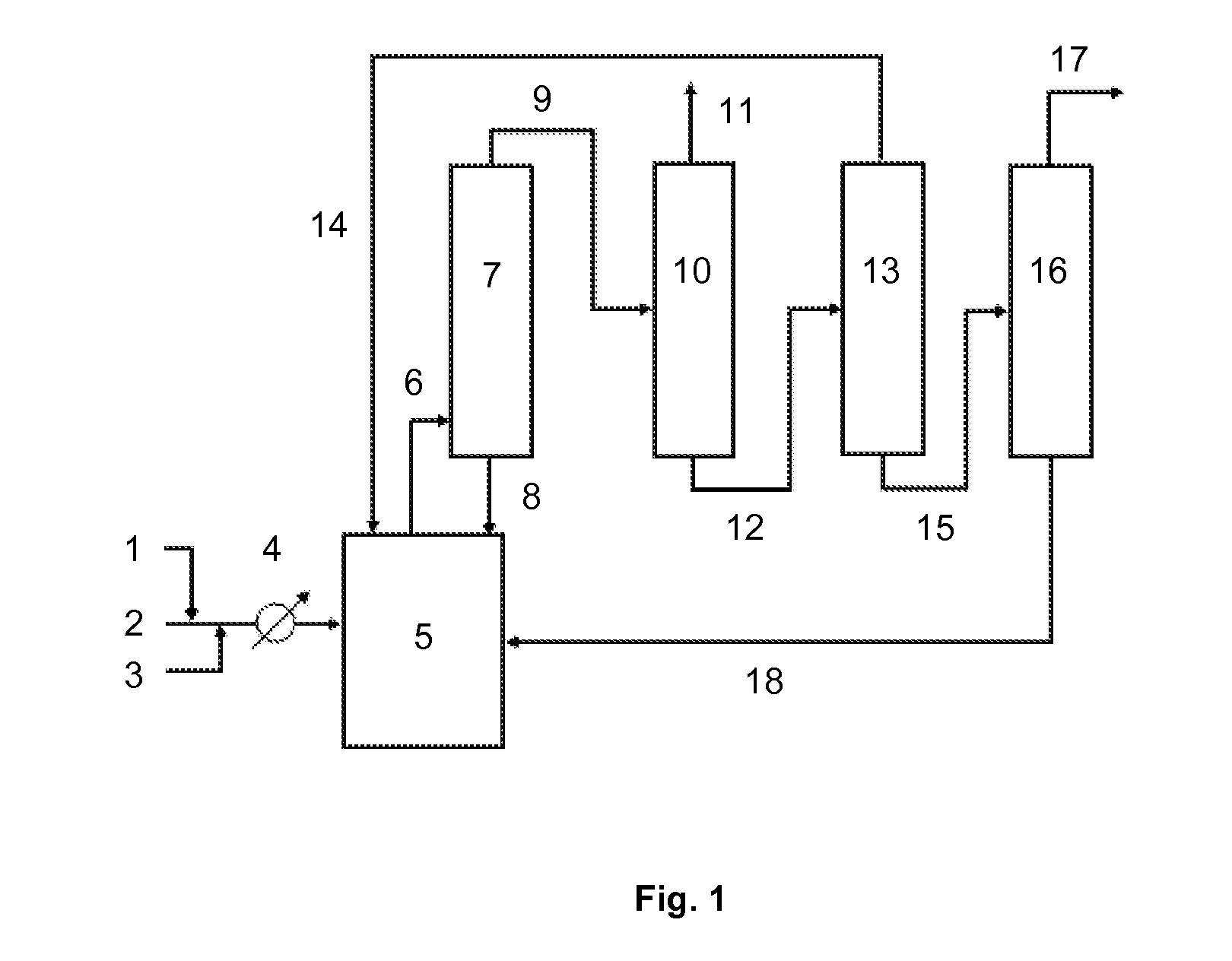

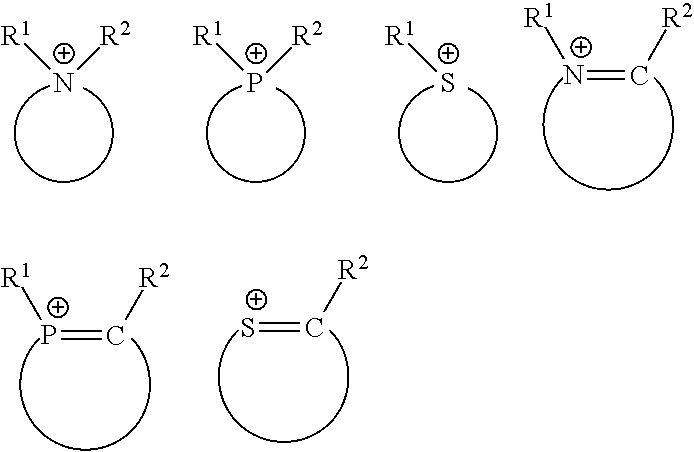

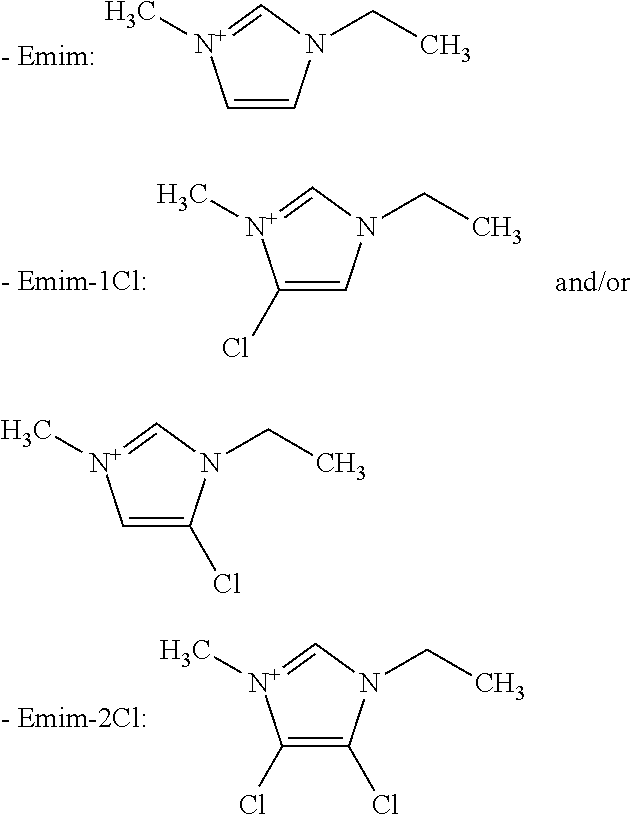

Method for producing difluoromethane

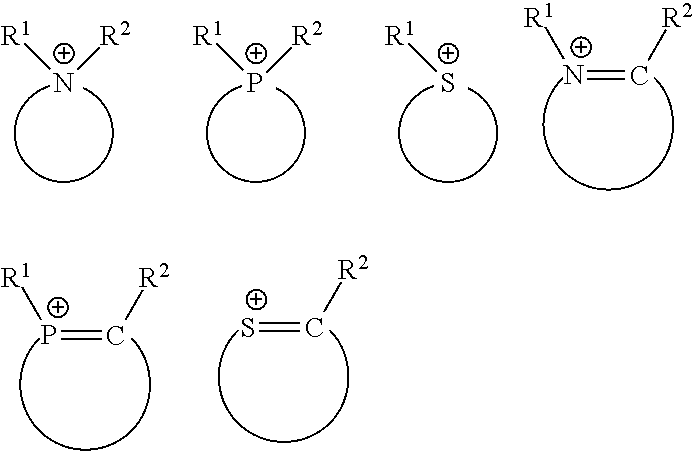

InactiveUS20150210617A1High selectivityHigh yieldGaseous chemical processesPreparation by halogen halide additionHydrogen fluorideQuaternary ammonium cation

A method for producing difluoromethane, including the catalytic reaction of dichloromethane with hydrogen fluoride in the liquid phase, in the presence of chlorine, and in the presence of an ionic liquid catalyst consisting of the product of the reaction of antimony pentachloride with an organic salt having the general formula X+A, where A is a halide anion or hexafluoroantimonate, and X+ is a quaternary ammonium cation, quarternary phosphonium or ternary sulfonium. Further, equipment suitable for implementing said method.

Owner:ARKEMA FRANCE SA

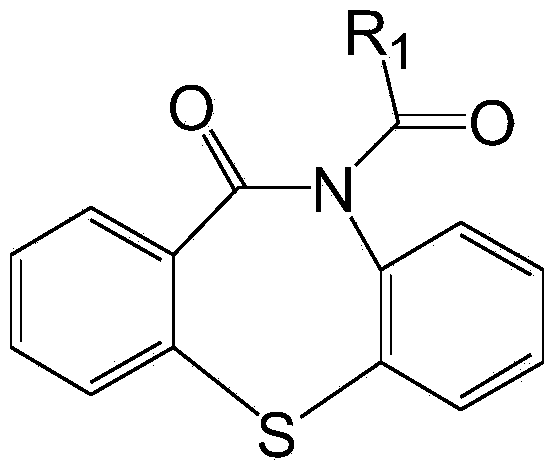

Method for increasing proportion of paradichlorobenzene in benzene chlorination product

InactiveCN103739441ARaise the ratioOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationBenzeneChlorobenzene

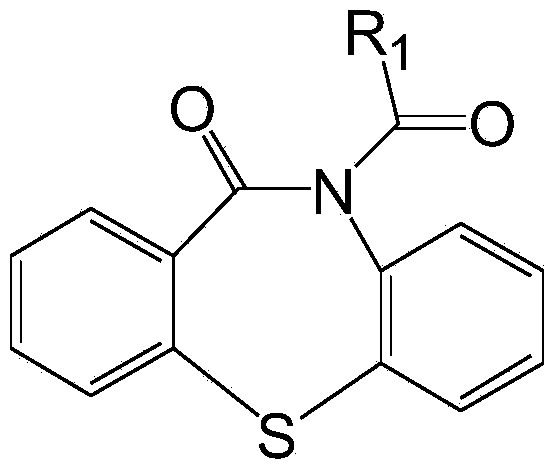

The invention discloses a method for increasing a proportion of paradichlorobenzene in a benzene chlorination product. The method comprises the steps: adding a combined catalyst in benzene, introducing chlorine under a stirring condition, to obtain the chlorination product with high paradichlorobenzene content, wherein the temperature of the whole process is controlled to be 50-80 DEG C, and the amount of the introduced chlorine is controlled to ensure that the conversion rate of the benzene is more than 99 percent and the conversion rate of chlorobenzene is more than 93 percent, and in addition, the combined catalyst comprises a main catalyst and a co-catalyst, the main catalyst is one of iron powder, ferric trichloride, aluminum trichloride, antimony trichloride, antimony pentachloride or tin tetrachloride, the co-catalyst is a dibenzo thiazepine organic matter, and the weight ratio of the main catalyst to the co-catalyst is 1:1. According to the method, the proportion of the paradichlorobenzene in the product is effectively increased, the ratio of the paradichlorobenzene to orthodichlorobenzene can reach 4.8, the content of the orthodichlorobenzene is less than 0.4 percent, and the content of phenyl polychloride is less than 1 percent.

Owner:SOUTHEAST UNIV

Dehydrofluorination catalyst

ActiveCN101637733AHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consistsof 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

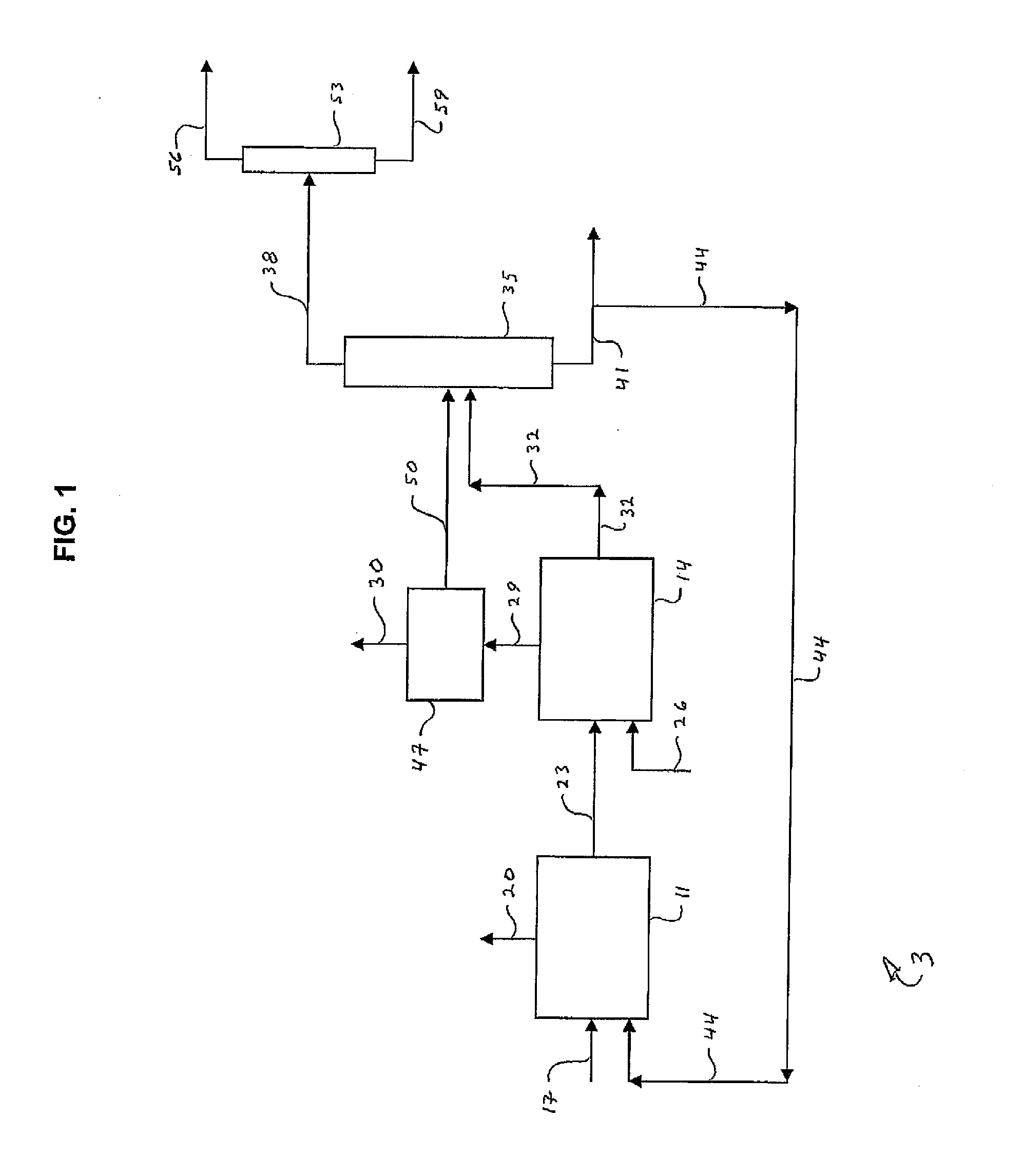

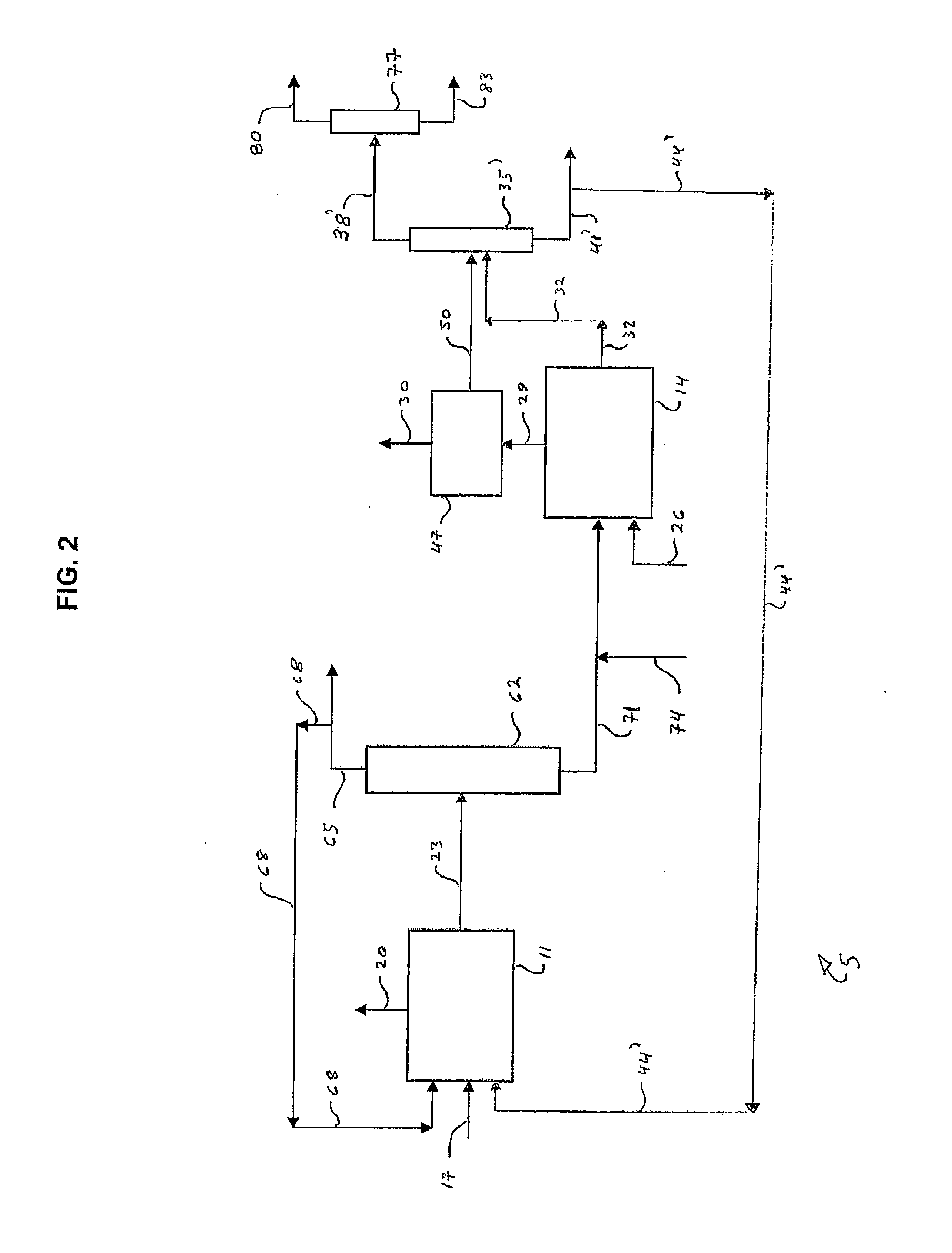

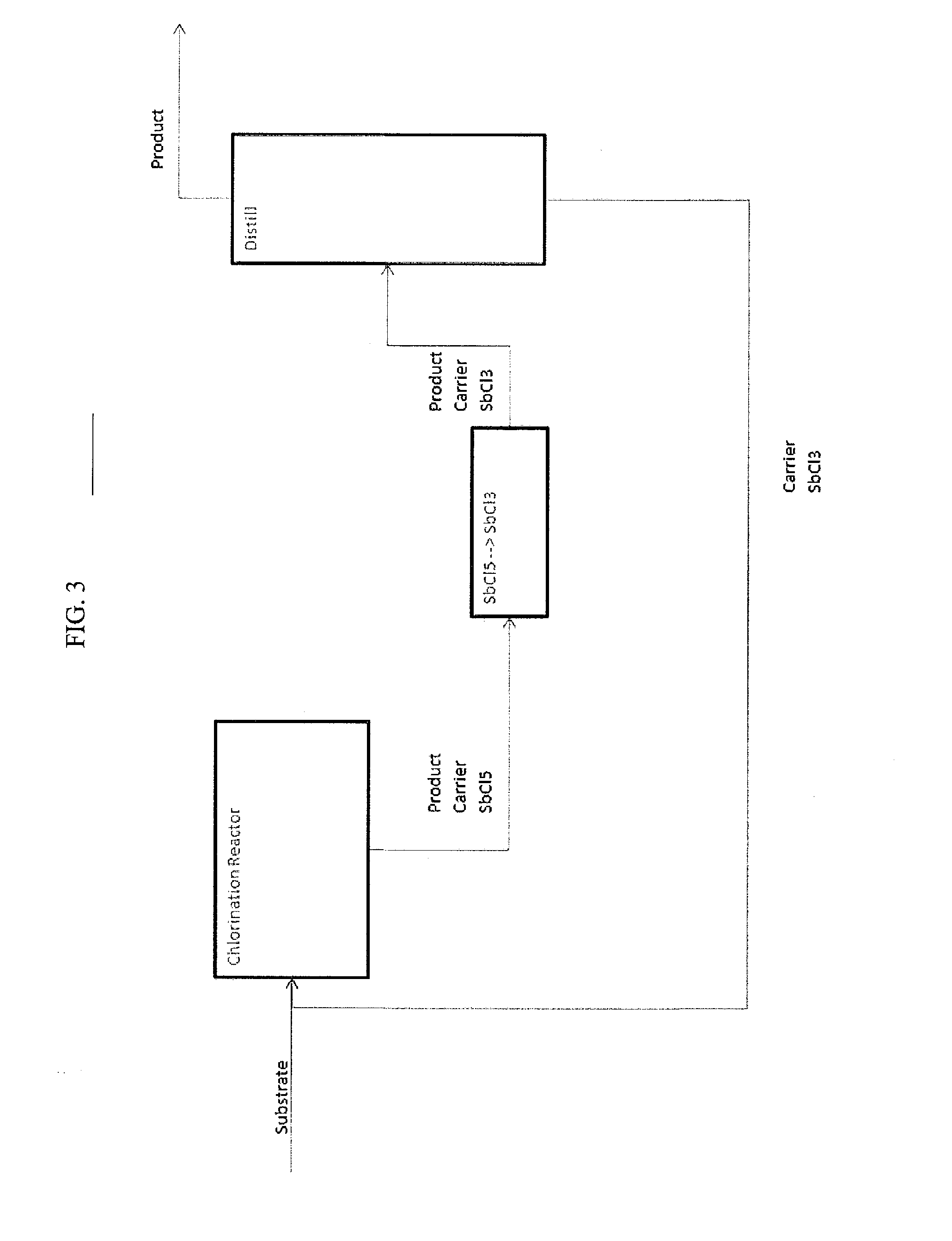

Processes for producing chlorinated hydrocarbons and methods for recovering polyvalent antimony catalysts therefrom

ActiveUS9289758B2Preparation by dehalogenationPreparation by hydrogen halide split-offAlkaneAntimony compounds

Owner:EAGLE US 2 LLC

Method for preparing loaded solid super acidic catalyst directly by microwave method

ActiveCN102614926AHigh catalytic hydrocracking activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTrimethylsilyl trifluoromethanesulfonatePtru catalyst

The invention relates to a method for preparing a loaded solid super acidic catalyst directly by a microwave method, and belongs to a method for preparing a super acidic catalyst. The method comprises the following steps of: (1) mixing and stirring NaHCO3 and a carbon nano tube in a weight ratio of 1:500 fully, and roasting in a microwave reactor to obtain a Na-loaded catalyst carrier; (2) heating the Na-loaded catalyst carrier by microwave radiation, adding a mixed solution of antimony pentachloride (SbCl5) and trimethylsilyl trifluoromethanesulfonate (F3CSO3Si(CH3)3) dropwise, stirring and immersing to obtain a suspension mixed solution; (3) filtering the suspension mixed solution to obtain a solid precursor and a mixed solution; (4) putting the solid precursor into the microwave reactor, heating by the microwave radiation, and roasting to obtain a solid super acidic catalyst prototype; and (5) performing operation for 1 to 5 times by taking the solid super acidic catalyst prototype as a raw material according to the steps (2), (3) and (4) to obtain the solid-loaded super acidic catalyst. The method has the advantages that: the loaded solid super acidic catalyst prepared by the microwave method is high in catalytic hydrocracking activity and selectivity.

Owner:CHINA UNIV OF MINING & TECH

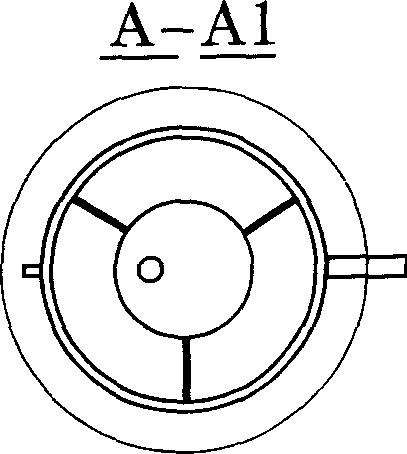

Preprocessing equipment for antimony pentachloride waste catalyst and processing method thereof

The invention discloses preprocessing equipment for an antimony pentachloride waste catalyst and a processing method thereof. The technical problem that the processing on the antimony pentachloride waste catalyst is lacked in the prior art is mainly solved. The preprocessing equipment for the antimony pentachloride waste catalyst disclosed by the invention comprises a reactor, wherein the reactoris connected with a rectifying tower; the rectifying tower is connected with a catalyst processing tank; the catalyst processing tank is connected with a gas-liquid separation tank; the gas-liquid separation tank is connected with a washing unit; the washing unit is connected with an alkali washing unit; the alkali washing unit is connected with a burning device. According to the preprocessing equipment disclosed by the invention, the problem is solved preferably, and the preprocessing equipment can be used for preprocessing the antimony pentachloride waste catalyst.

Owner:SINOCHEM LANTIAN HONEYWELL NEW MATERIAL CO LTD

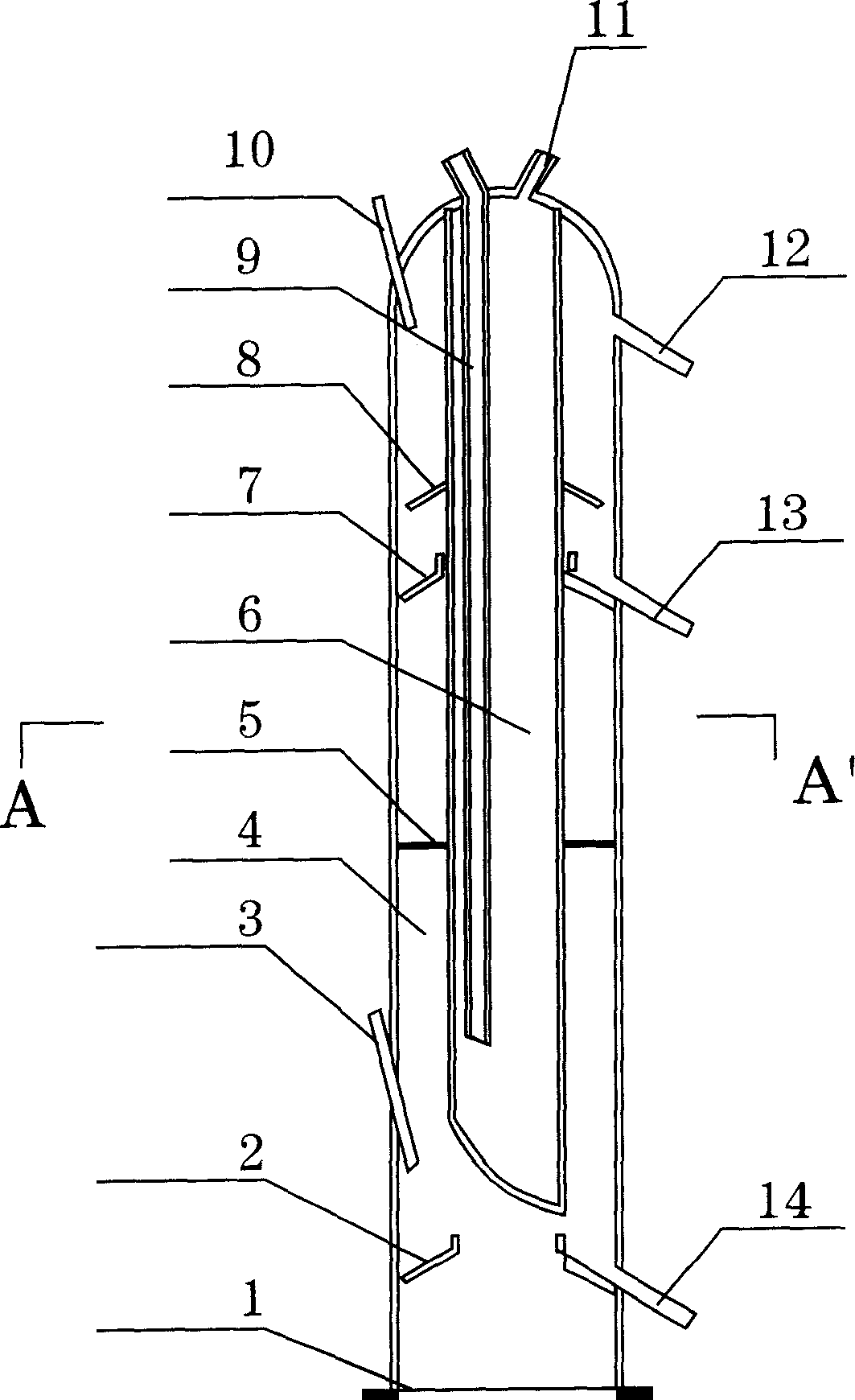

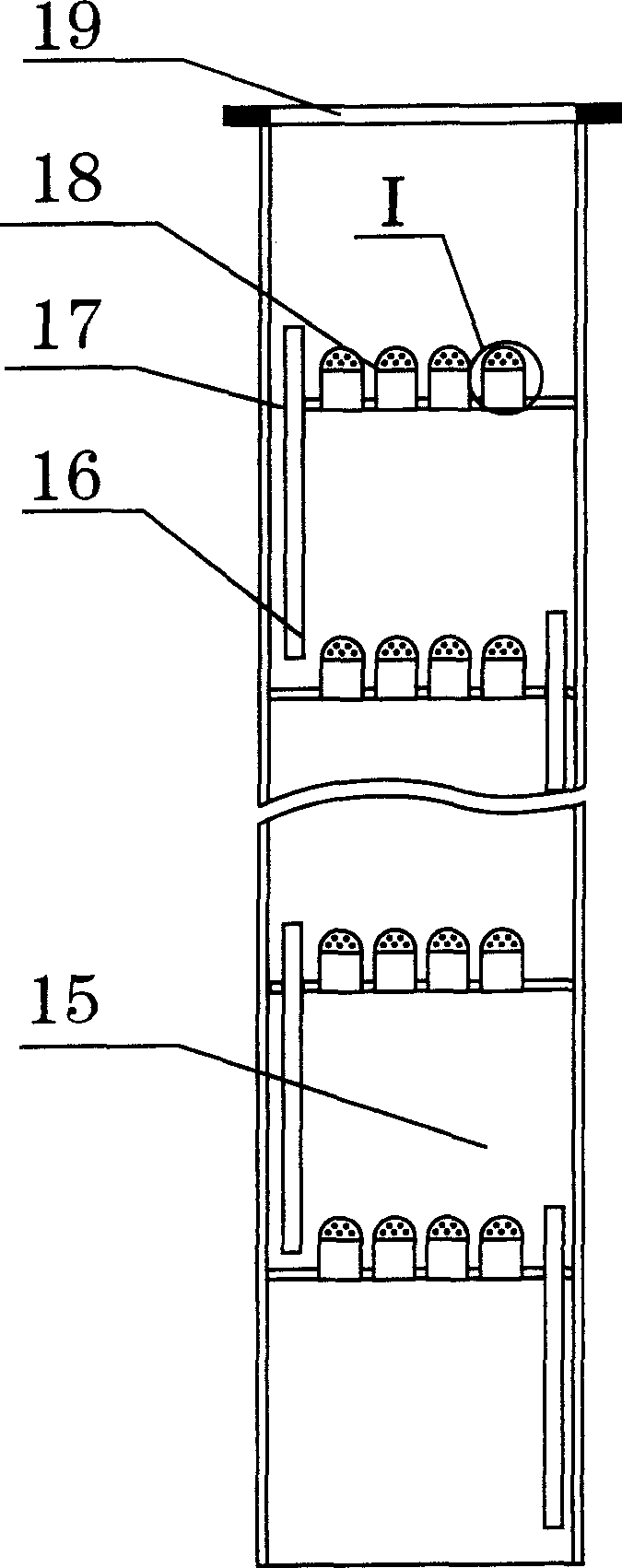

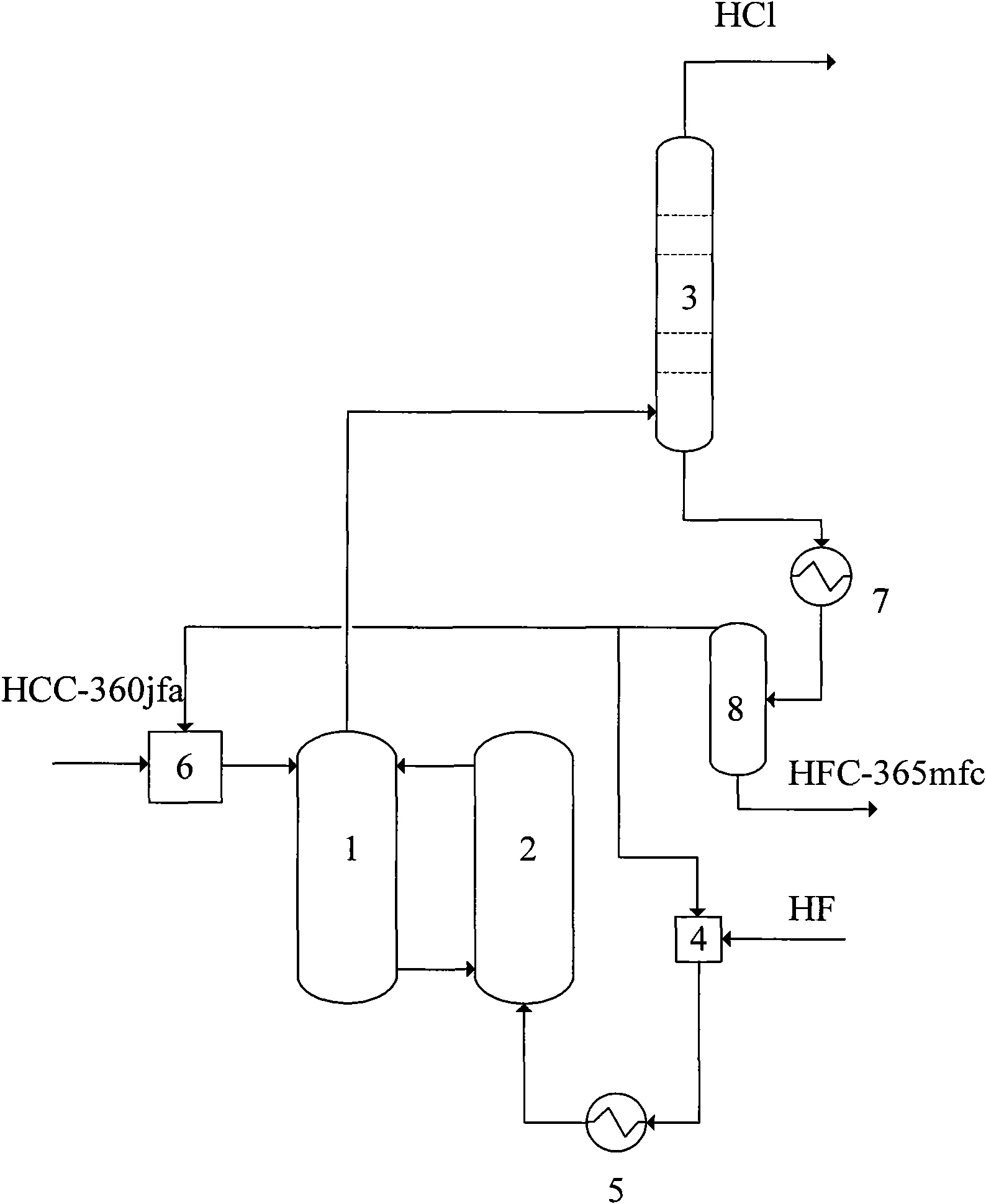

Preparation method of 1,1,1,3,3-pentafluorobutane

ActiveCN101913982BAchieve cycleRealize circular motionPreparation by halogen replacementHydrogen fluorideTetrachloride

The invention provides a preparation method of 1,1,1,3,3-pentafluorobutane, which comprises the following step of reacting 1,1,1,3,3,-pentachlorobutane with HF (Hydrogen Fluoride) in a liquid-phase fluorination reactor provided with a low-temperature reaction zone (1) and a high-temperature reaction zone (2) in the presence of a liquid-phase fluorination catalyst. The reaction conditions are as follows: the mol ratio of the HF to the 1,1,1,3,3,-pentachlorobutane is 6-15:1, the reaction pressure is 1.0-1.5 MPa, the reaction temperature of the low-temperature reaction zone is 60-90 DEG C, the reaction temperature of the high-temperature reaction zone is 90-140 DEG C, wherein the liquid-phase fluorination catalyst is antimony pentachloride or tin tetrachloride; the 1,1,1,3,3,-pentachlorobutane enters the low-temperature reaction zone (1) of the liquid-phase fluorination reactor; the fresh HF enters the high-temperature reaction zone (2) of the liquid-phase fluorination reactor and then enters a reaction system; and the circulating HF enters the low temperature reaction zone (1) and the high-temperature reaction zone (2) of the liquid-phase fluorination reactor simultaneously. The invention is used for the preparation of the 1,1,1,3,3-pentafluorobutane.

Owner:XIAN MODERN CHEM RES INST

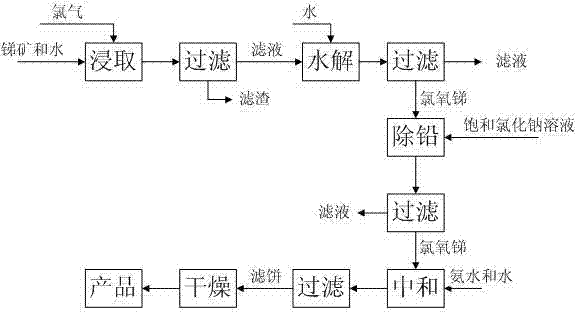

Process for producing cubic crystal antimony white from low-grade complex lead-antimony polymetallic ores

ActiveCN103614573ANo pollution in the processTake advantage ofProcess efficiency improvementEcological environmentResource utilization

The invention belongs to the technical field of hydrometallurgy, and in particular relates to a process for producing cubic crystal antimony white from low-grade complex lead-antimony polymetallic ores. The low-grade complex lead-antimony polymetallic ores (with antimony content of lower than 14.56 percent) are used as a raw material, and the cubic crystal antimony white is obtained by processes of extracting antimony in a chlorination leaching way to obtain an antimony chloride solution, performing hydrolysis to remove impurities, dropwise adding ammonia water for neutralization, adding a crystal form conversion agent and the like. According to the process, chlorine is used as a leaching agent, so that the advantages of antimony pentachloride serving as the leaching agent are achieved, the introduction of metallic impurity ions is also avoided, sulfur dioxide gas pollution and dust pollution are avoided, and the process is low in energy consumption and production cost and high in recovery rate and product quality; resources can be completely and comprehensively utilized, the resource utilization rate can be increased, waste emission can be reduced, and the ecological environment can be protected; the process is significant particularly for the treatment of low-grade complex antimony ores.

Owner:青海省化工设计研究院有限公司

Method for recovering and making antimony oxide from antimony pentachloride solution

InactiveCN100383053CReduce dosageReduce consumptionAntimony compoundsLiquid solutions solvent extractionOrganic solventDecomposition

The invention relates to a method for recovering and making antimony oxide from antimony pentachloride solution which comprises the steps of pretreatment, reduction, hydrolytic decomposition, drying and neutralization, wherein the pretreatment consists of antimony pentachloride effluent liquor vacuum distillation, inorganic acid abstraction and organic solvent extraction.

Owner:JUHUA GRP

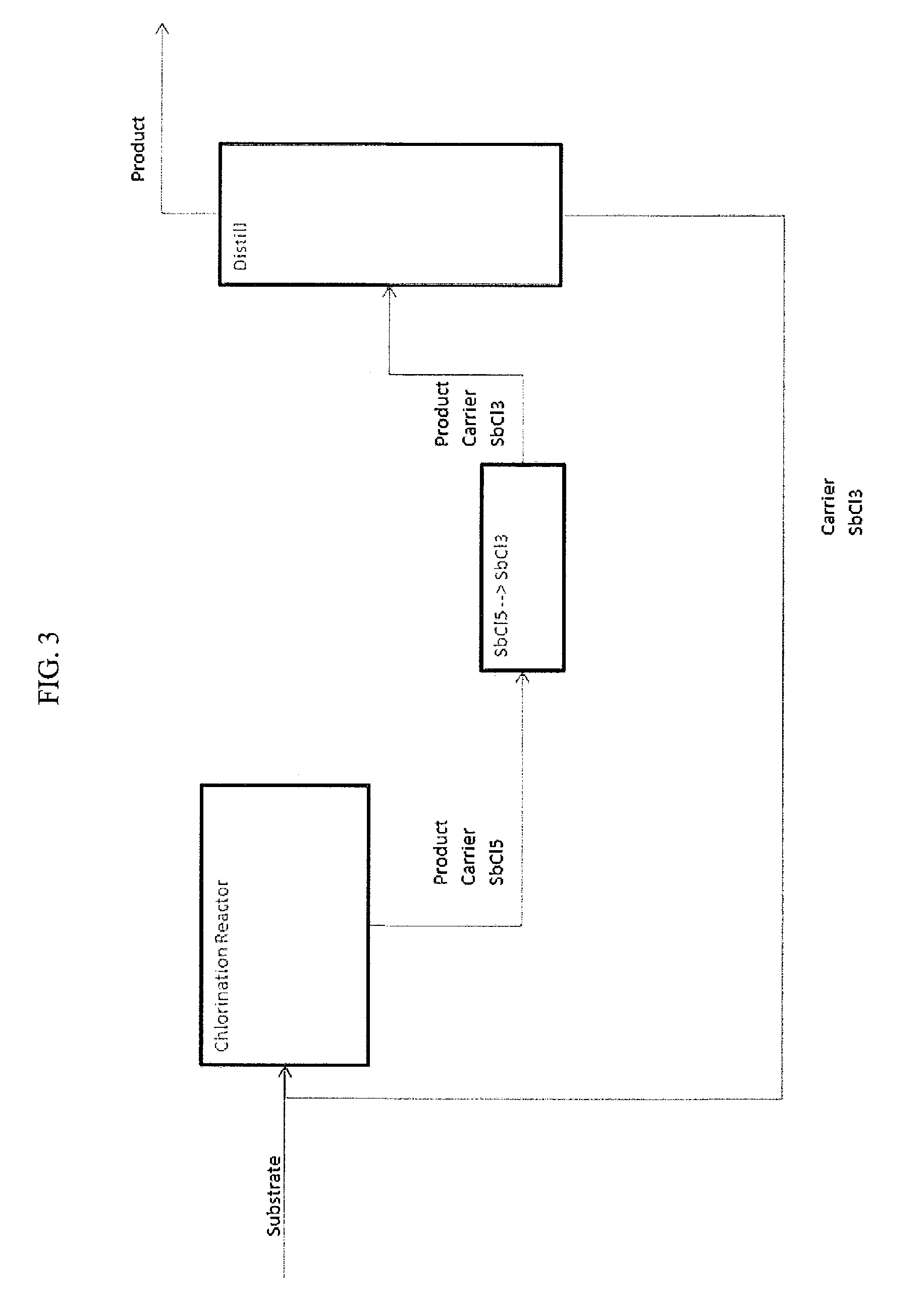

Processes for Producing Chlorinated Hydrocarbons and Methods for Recovering Polyvalent Antimony Catalysts Therefrom

ActiveUS20150045591A1Preparation by dehalogenationPreparation by hydrogen halide split-offAlkanePtru catalyst

The preparation of chlorinated hydrocarbons, such as pentachloropropanes, such as 1,1,1,2,3-pentachloropropane, from tetrachloropropanes, such as 1,1,1,3-tetrachloropropane, in the presence of a polyvalent antimony compound that includes a pentavalent antimony compound, such as antimony pentachloride, is described. Also described are methods for preparing optionally chlorinated alkenes, such as, tetrachloropropenes, from chlorinated alkanes, such as pentachloropropanes, in the presence of polyvalent antimony compound that includes a pentavalent antimony compound, as well as methods for recovering polyvalent antimony compounds from such processes.

Owner:EAGLE US 2 LLC

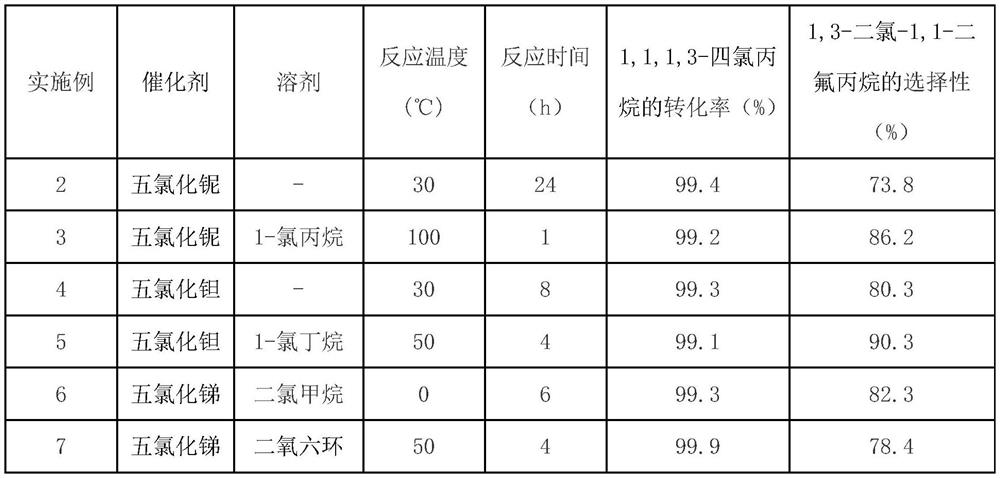

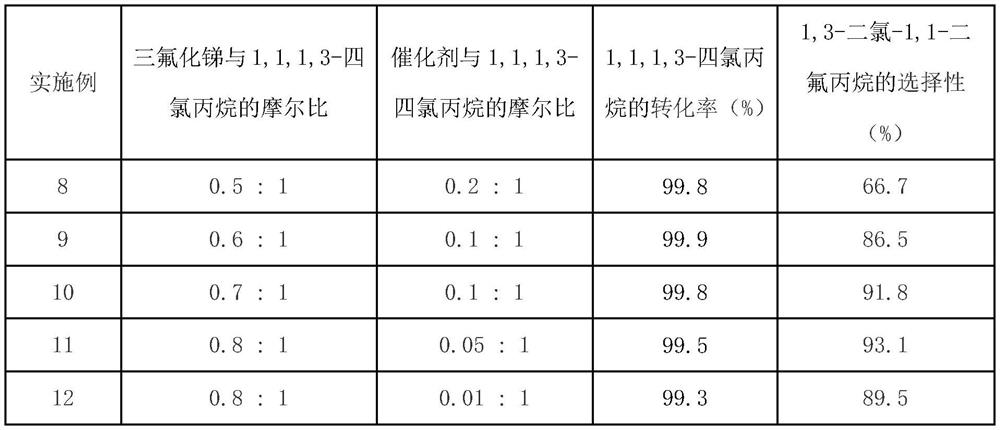

Preparation method of 1, 3-dichloro-1, 1-difluoropropane

ActiveCN114213211ARaw materials are easy to getImprove conversion ratePreparation by halogen replacementPtru catalystAntimony pentachloride

The invention discloses a preparation method of 1, 3-dichloro-1, 1-difluoropropane, and belongs to the technical field of fluorine-containing chemicals. Under the action of a lewis acid catalyst, in the presence or absence of a solvent, 1, 1, 1, 3-tetrachloropropane reacts with antimony trifluoride to generate 1, 3-dichloro-1, 1-difluoropropane, and the lewis acid catalyst is niobium pentachloride, tantalum pentachloride or antimony pentachloride. According to the preparation method of the 1, 3-dichloro-1, 1-difluoropropane, the raw materials are easy to obtain, the conversion rate is high, the 1, 3-dichloro-1, 1-difluoropropane can be prepared with high selectivity, and the selectivity can reach 90% under better conditions.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

Production of 1,1,1,2-tetrafluoroethykane and pentafuoethane simultaneously

InactiveCN100338001CReduce typesPreparation by halogen halide additionPreparation by halogen additionAntimony pentachlorideEther

Owner:浙江莹光化工有限公司

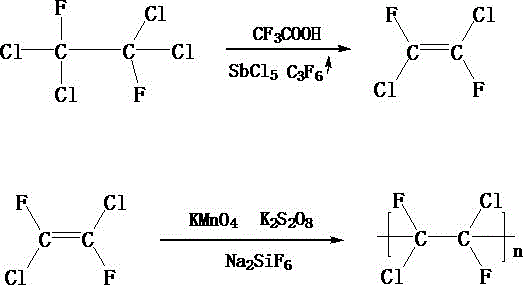

Synthesis method of polydifluorodichloroethylene

InactiveCN105601773AThe synthesis steps are simpleLow coefficient of linear expansionHexafluoropropyleneSynthesis methods

Owner:CHANGZHOU LANXU CHEM CO LTD

Norbornene and perfluoromethyl vinyl ether binary copolymerization catalyst and binary copolymerization method

The invention relates to a norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and a binary copolymerization method. The preparation method of the catalyst is characterized by comprising the following steps: in a container of dry inert gas atmosphere, dissolving antimony pentachloride and ligand in a first solvent; dropwise adding tetra-isopropoxy titanium at 200-300rpm, and then continuously stirring for 30-50 minutes at 30-50 DEG C to obtain an antimony-titanium complex catalyst; adding a norbornene monomer and a perfluoromethyl vinyl ether monomer in a molar ratio of 1:1 into an autoclave after repeated vacuumizing and nitrogen charge; adding a second solvent and dissolving; adding the antimony-titanium complex catalyst, and reacting for 1-6 hours at 30-120 DEG C and under the pressure of 0.1-8MPa; pouring the reaction product into an ethanol solution containing 4-5wt% of hydrochloric acid; washing the obtained precipitate with ethanol to neutrality; and performing vacuum drying to obtain a norbornene-perfluoromethyl vinyl ether binary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for recovering diantimony trioxide from monochlorodifluoromethane reaction residual liquid

InactiveCN110902719AReduce consumptionEmission reductionAntimony oxides/hydroxides/oxyacidsAntimony compounds preparationAntimony pentachlorideWater chlorination

The invention discloses a method for recovering diantimony trioxide from a monochlorodifluoromethane reaction residual liquid. The method comprises the following steps: 1, extracting: extracting wasteantimony pentachloride in a monochlorodifluoromethane reaction residual liquid in a hydrolysis kettle by using an extracting agent to obtain an antimony ion-containing aqueous solution, carrying outsteam stripping on the antimony ion-containing aqueous solution by using nitrogen with a flow rate of 100 L / min for 6 hours, and absorbing the steam stripping substance by using an alkaline solution;2, reducing: reducing the antimony ion-containing aqueous solution by using a reducing agent to obtain an aqueous solution containing trivalent antimony ions; 3, hydrolyzing: hydrolyzing the aqueous solution containing the trivalent antimony ions by using water to obtain a turbid liquid containing diantimony trioxide solid; and 4, carrying out suction filtration on the hydrolyzed turbid liquid containing the diantimony trioxide solid, and drying to obtain diantimony trioxide with a content of 99.9% and a particle size of more than 400 meshes and a hydrolysis mother liquor.

Owner:江苏梅兰化工有限公司

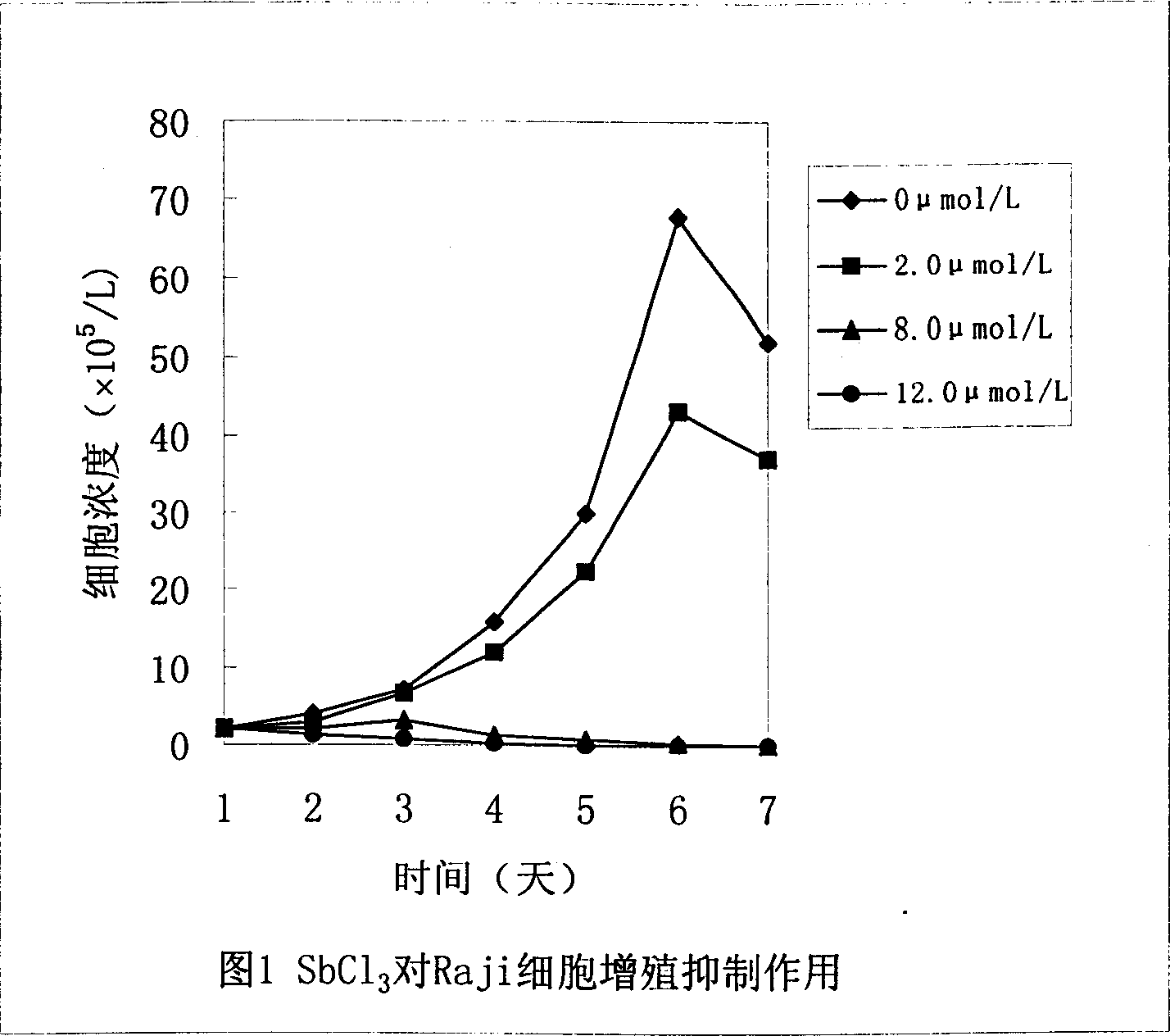

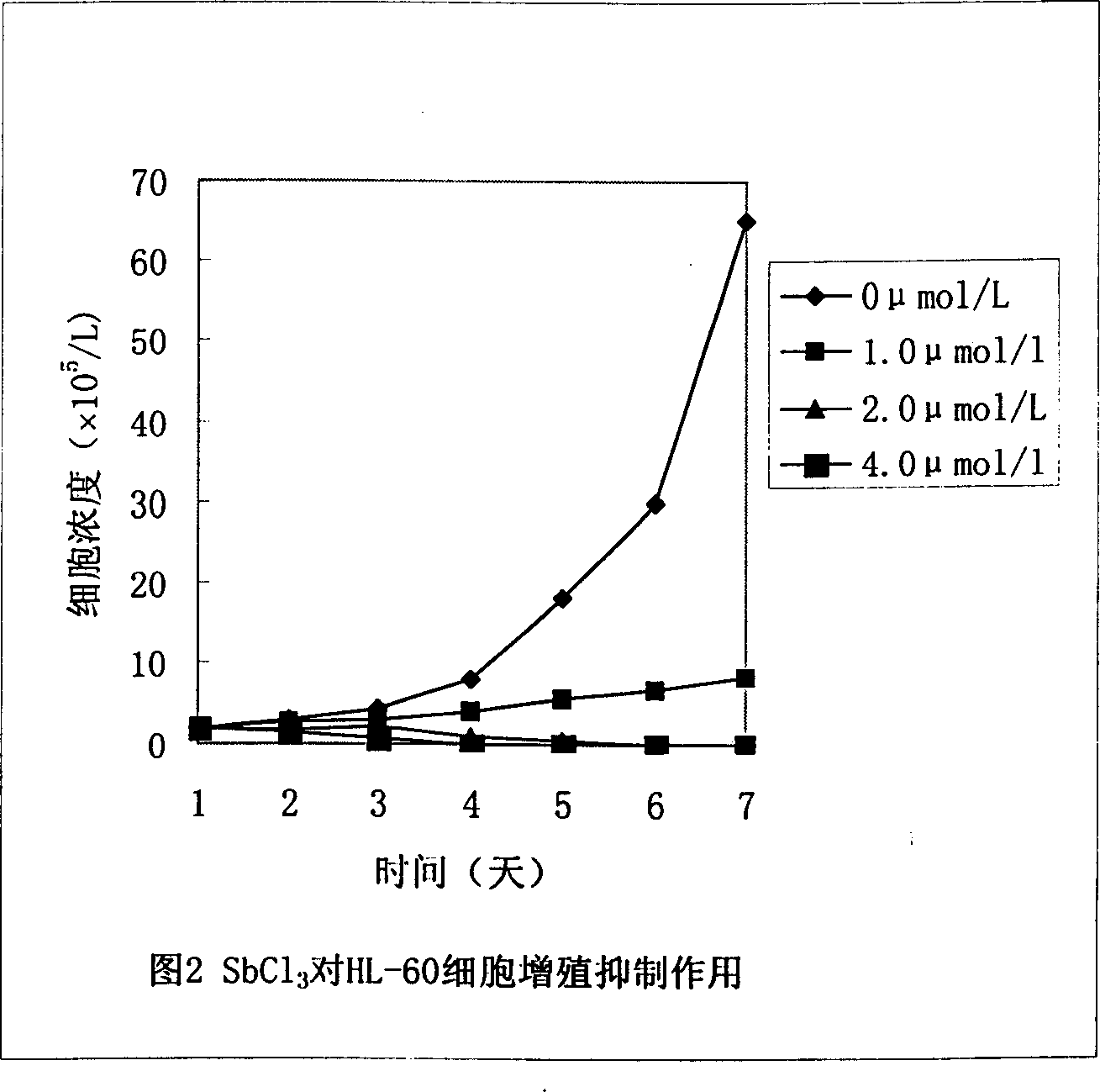

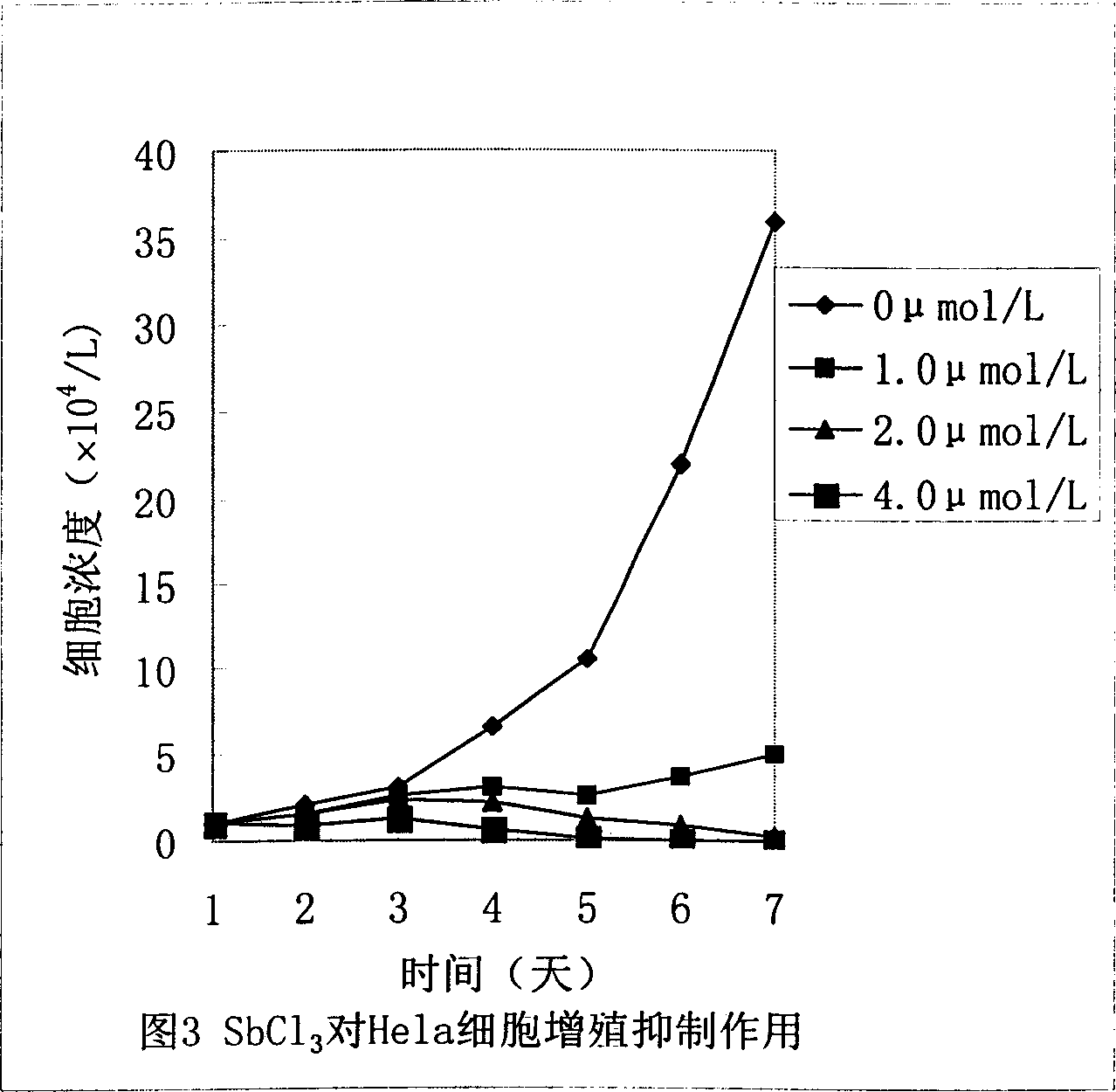

Antimony halide medicine composition for treating leukemia and lymphoma

InactiveCN1159017CSafe and effectiveEasy to buyHeavy metal active ingredientsAntineoplastic agentsMalignant lymphomaExcipient

The invented compound contains effective dose of antimony halide and medicinal carrier and / or excipient. The described antimony halide includes antimonous chloride, antimonous bromide, antimonous triiodide, antimonous fluoride, antimonous pentafluoride and antimony pentachloride, the active component in the described compound is one of the above-mentioned antimony halide or their combination. Said invention relates to adoption of antimony halide, special SbCl3 to cure various leukemia and malignant lymphoma.

Owner:苏州市第二人民医院

Method for producing difluoromethane

InactiveUS9428428B2Improve yieldHigh selectivityPreparation by halogen replacementChemical/physical/physico-chemical stationary reactorsQuaternary ammonium cationPhosphonium

A method for producing difluoromethane, including the catalytic reaction of dichloromethane with hydrogen fluoride in the liquid phase, in the presence of chlorine, and in the presence of an ionic liquid catalyst consisting of the product of the reaction of antimony pentachloride with an organic salt having the general formula X+A, where A is a halide anion or hexafluoroantimonate, and X+ is a quaternary ammonium cation, quarternary phosphonium or ternary sulfonium. Further, equipment suitable for implementing said method.

Owner:ARKEMA FRANCE SA

Metal antimony purifying method and apparatus

InactiveCN1325674CGuaranteed distillation effectImprove efficiencyAntimony compoundsProcess efficiency improvementHydrogenAntimony pentachloride

This invention discloses metal antimony purifying method and its mechanism. The method is to fill the industrial antimony in the chlorination tower; lead chlorine in the middle of the tower, heat at the 1 / 3 lower part of the tower to decompose antimony pentachloride; chloride and the superfluous mental blocks in the tower react to create antimony trichloride. The antimony trichloride in the storage tank automatically flows to re-boiling equipment and steam to go into rectification 1; through reflux control valve adjust flow amount of antimony trichloride and reflux amount, and the antimony trichloride goes into the re-boiler of rectification 2; the lower output mouth of the rectification tower arch is connected by the channel with the material interface of the storage tank that has two outputting mouths connected with the computation tank of reductive tank and re-boiler of sub-grade rectification system by the tube. The upper outputting mouth is connected with the residue tank by the pipeline; orderly connect the multi-grade rectification tower and continuously bring in the superfluous hydrogen and revert it and get 99.999%, 99.9999% and 99.99999% metal antimonies.

Owner:云南省通海大方科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com