Method for recovering and making antimony oxide from antimony pentachloride solution

A technology of antimony pentachloride and antimony oxide, applied in chemical instruments and methods, liquid solution solvent extraction, inorganic chemistry and other directions, can solve the problems of reducing hydrolysis rate, large consumption of sodium hydroxide and hydrochloric acid, environmental and human harm, etc. To achieve the effect of easy control of process conditions, low cost input, and low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

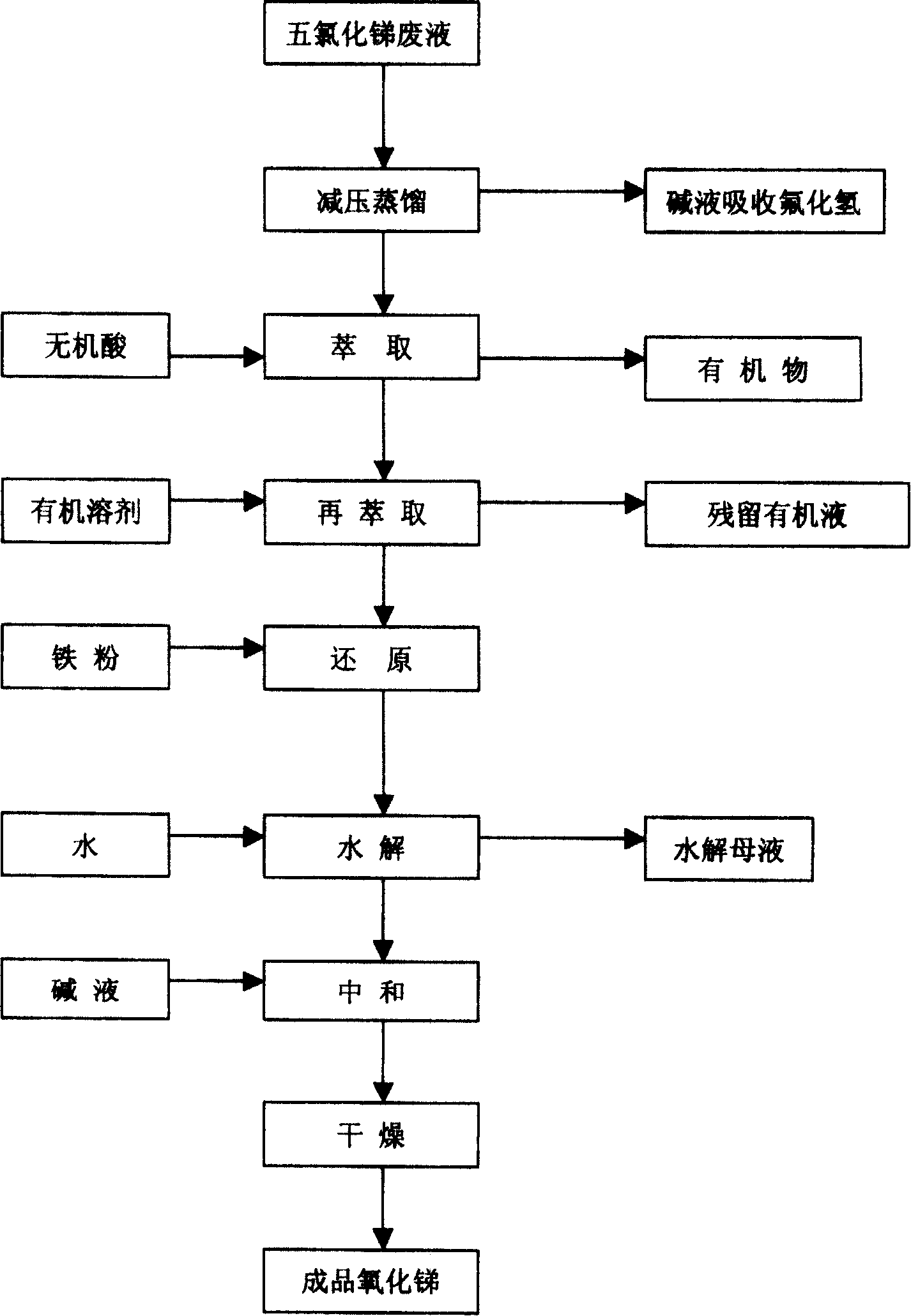

[0019] Embodiment 1: the present embodiment reclaims antimony oxide from 250ml antimony pentachloride waste liquid, combines figure 1 As shown in the process block diagram, proceed as follows:

[0020] Step 1: get the antimony pentachloride waste liquid of 250ml, wherein there are pentavalent antimony, trivalent antimony and antimony fluoride chloride (SbCl 5 -nFn, where n=1~5) and various organic substances with higher content of hydrogen fluoride and different boiling points, undergo vacuum distillation, the temperature during distillation is controlled at 20°C to 30°C, until no white smoke comes out, The distillate is directly absorbed with lye.

[0021] Step 2: After distillation, slowly add to 2.0mol / L hydrochloric acid. After cooling to room temperature, the solution is layered. After standing for 1.0 hour, separate with a separatory funnel and wash with 2.0mol / L hydrochloric acid. The organic phase. The ratio of the organic phase to the water phase is 1:2.5 (volume r...

Embodiment 2

[0027] according to figure 1 , follow the steps below:

[0028] In the step 1, the distillation temperature is changed to be controlled between 35° C. to 45° C., and the rest are the same as in Example 1. Step 3 and step 4 are the same as embodiment 1.

[0029] Step 2: Distillation is completed, slowly added to dilute hydrochloric acid, after cooling to room temperature, the solution is layered, separated with a separatory funnel after standing for 1.0 hour, and the organic phase is washed with hydrochloric acid with a concentration of 2.0mol / L. The amount of hydrochloric acid provided is insufficient, and the antimony salt in the spent catalyst is easily hydrolyzed, which makes it difficult to separate the antimony from the organic phase. Too much dilute hydrochloric acid will increase the amount of wastewater in the subsequent hydrolysis process, so the ratio of the aqueous phase to the organic phase is 3.2: 1 (volume ratio ).

[0030] Step 5: The neutralization process i...

Embodiment 3

[0032] according to figure 1 , follow the steps below:

[0033] In the step 1, the distillation temperature is changed to be controlled between 50° C. and 60° C., and the rest are the same as in Example 1. Step 3 and step 4 are the same as embodiment 1.

[0034] Step 2: Distillation is completed, slowly added to dilute hydrochloric acid, after cooling to room temperature, the solution is layered, separated with a separatory funnel after standing for 1.0 hour, and the organic phase is washed with hydrochloric acid with a concentration of 2.0mol / L. The amount of hydrochloric acid provided is insufficient, and the antimony salt in the spent catalyst is easily hydrolyzed, which makes it difficult to separate the antimony from the organic phase. Too much hydrochloric acid will increase the amount of wastewater in the subsequent hydrolysis process, so the ratio of the aqueous phase to the organic phase is 3.8:1 (volume ratio) .

[0035] Step 5: The neutralization process is to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com