Antimony pentachloride waste liquid treatment system

A technology of antimony pentachloride and waste liquid, which is applied in metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve atmospheric environmental damage, health hazards of surrounding environment workers, neglect of acidic components and chloroform collection and Recycling and other issues, to achieve the effect of thorough disposal, good effect and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

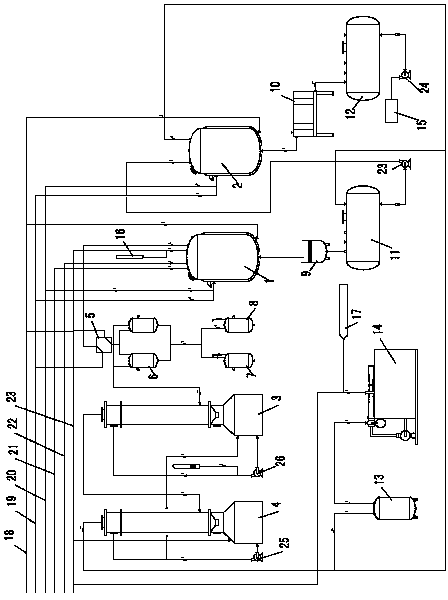

[0018] Such as figure 1 As shown, the antimony pentachloride waste liquid disposal system of the present invention comprises primary reactor 1, secondary reactor 2, primary falling film absorption tower 3, secondary falling film absorption tower 4, graphite condenser 5, separatory tank 6. Dilute acid storage tank 7, chloroform storage tank 8, vacuum suction filter 9, filter press 10, primary filtrate tank 11, secondary filtrate tank 12, vacuum buffer tank 13 and vacuum pump 14. The primary reactor 1 and the secondary reactor 2 adopt a conventional reactor structure, which is equipped with a stirrer and a jacket, and is equipped with a cooling circulating water pipeline and a steam heating pipeline. The inlet and outlet of the cooling circulating water pipeline are respectively connected to the The cooling water return pipe 18 is connected with the cooling water inlet pipe 19, and the steam heating pipeline is connected with the steam main pipe 20. The primary reactor 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com