Metal antimony purifying method and apparatus

A purification method, metal antimony technology, applied in the improvement of process efficiency, chemical instruments and methods, antimony compounds, etc., can solve the problems of difficult to control product indicators, uncontinuous production, difficult to grasp purification time, temperature, etc., to save Operating procedures and equipment, improving the efficiency of equipment use, and improving the effect of product technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

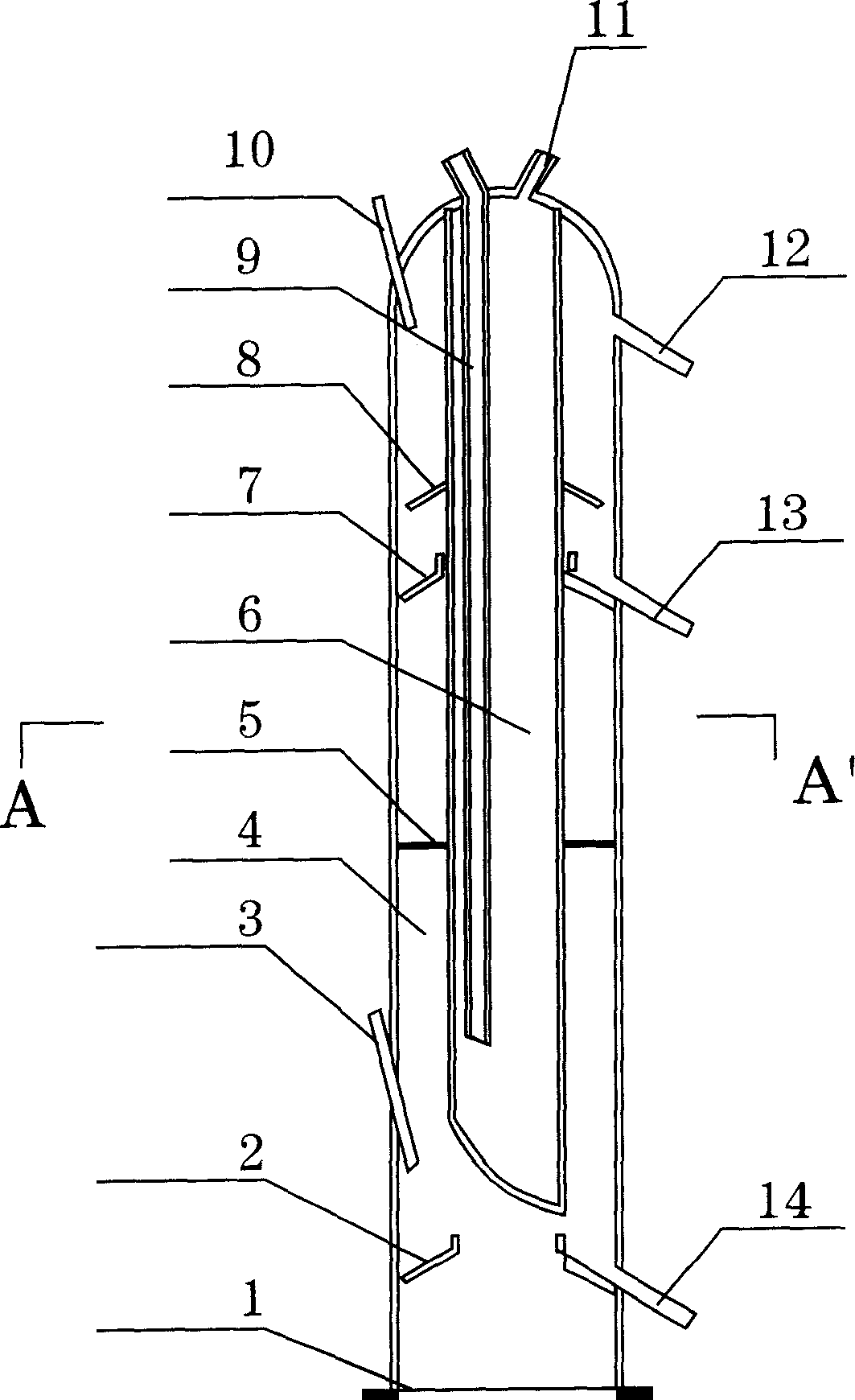

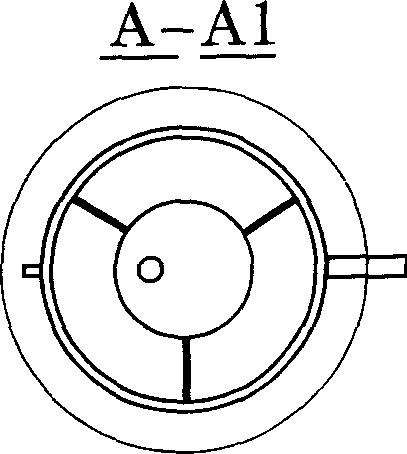

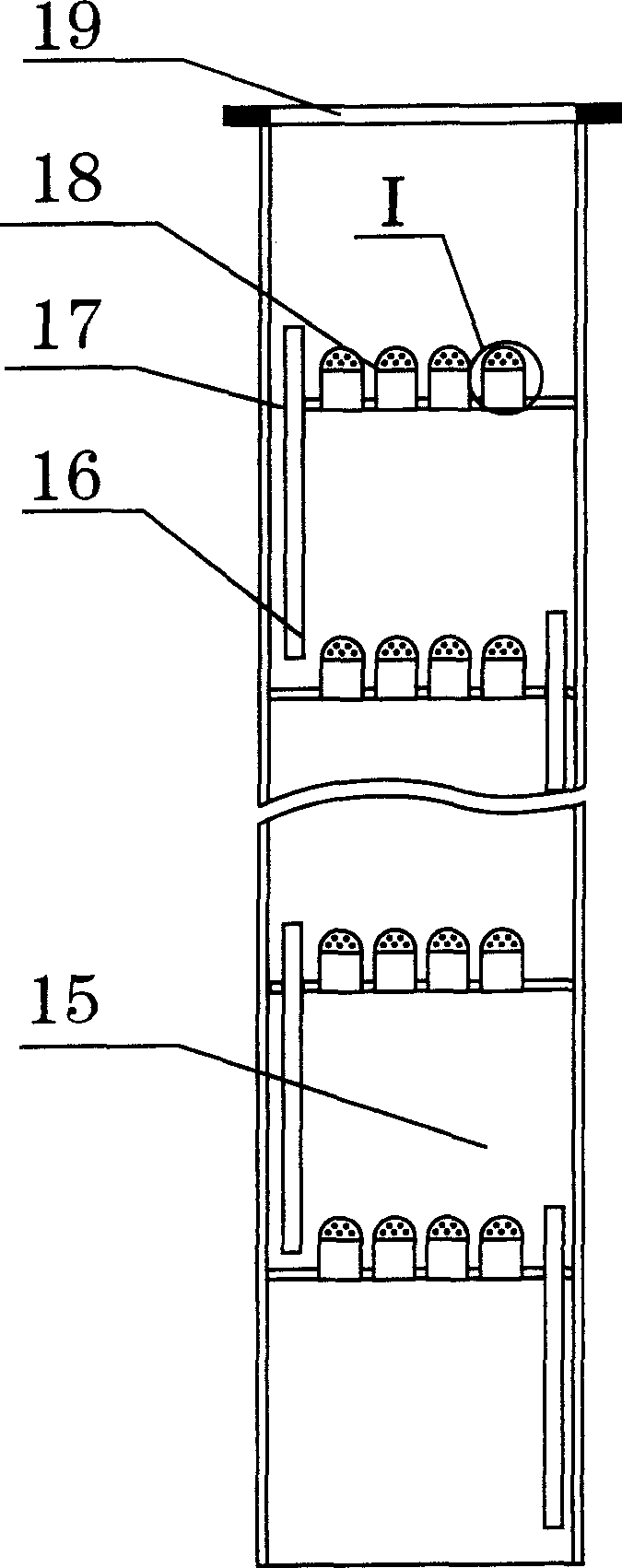

[0033]Crush 1# industrial antimony ingots into irregular blocks of φ20~30φ, put 200 kg in the chlorination tower, heat the lower section of the chlorination tower to 130°C, and continuously introduce chlorine gas at a rate of 0.5 cubic meters per hour to make the antimony The block gradually generates antimony trichloride, which flows from the outlet of the chlorination tower to the liquid storage tank, and puts the antimony trichloride into the reboiler of rectification 1 from the liquid storage tank at a speed of 5 liters per hour, and the reboiler The temperature of the lower part of the tower head is controlled to be 210°C, and the temperature of the upper part of the tower head is 150°C. Under normal pressure conditions, carry out continuous rectification, adjust the reflux valve so that the ratio of antimony trichloride outflow to reflux is 5.5:1. The flow goes to the reboiler of rectification 2. Continue rectification under the same temperature and pressure conditions ...

Embodiment 2

[0038] In Example 1, the antimony trichloride of rectification 2 was put into the reboiler of rectification 3 by the liquid storage tank, and the control conditions of temperature and pressure were the same as those of rectification 1, and continued rectification, adjusting the reflux valve to make The ratio of antimony trichloride outflow to reflux is 3.0:1, and the rectified antimony trichloride is put into the measuring tank in the reduction system through the liquid storage tank for standby use.

[0039] Use argon to drive out the air in the reduction tank, raise the temperature to 850°C, slowly introduce hydrogen, and at the same time, at a flow rate of 1 liter per hour, put the antimony trichloride in the metering tank into the reduction tank continuously, and adjust the amount of hydrogen. For 0.6 cubic meters per hour, continuously pass into the reduction tank to reduce antimony trichloride to metal antimony, and remove the material every 8 hours, that is, metal antimon...

Embodiment 3

[0043] In Example 2, the antimony trichloride of rectification 3 was put into the reboiler of rectification 4 by the liquid storage tank, and the control conditions of temperature and pressure were the same as rectification 1, and continued rectification, and the reflux valve was adjusted to make The ratio of antimony trichloride outflow to reflux is 2.0:1, and the rectified antimony trichloride is put into the measuring tank in the reduction system through the liquid storage tank for standby use.

[0044] The air in the reduction tank was purged with argon gas, and the temperature was raised to 850°C, and hydrogen was slowly introduced into the reduction tank. The amount of hydrogen was adjusted to 0.4 cubic meters per hour, and it was continuously fed into the reduction tank to reduce antimony trichloride to metal antimony, and the material was removed every 8 hours to obtain metal antimony 0.6, with a purity of more than 99.99999%, using a glow discharge mass spectrometer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com