Filtering and distilling equipment for fine chemical organic synthesis

An organic synthesis and fine chemical technology, applied in the field of filter distillation equipment for fine chemical organic synthesis, can solve the problems of waste of resources, inconvenient collection and treatment of impurities, poor condensation effect, etc., to ensure accuracy, convenient collection and processing, and guarantee The effect of the distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

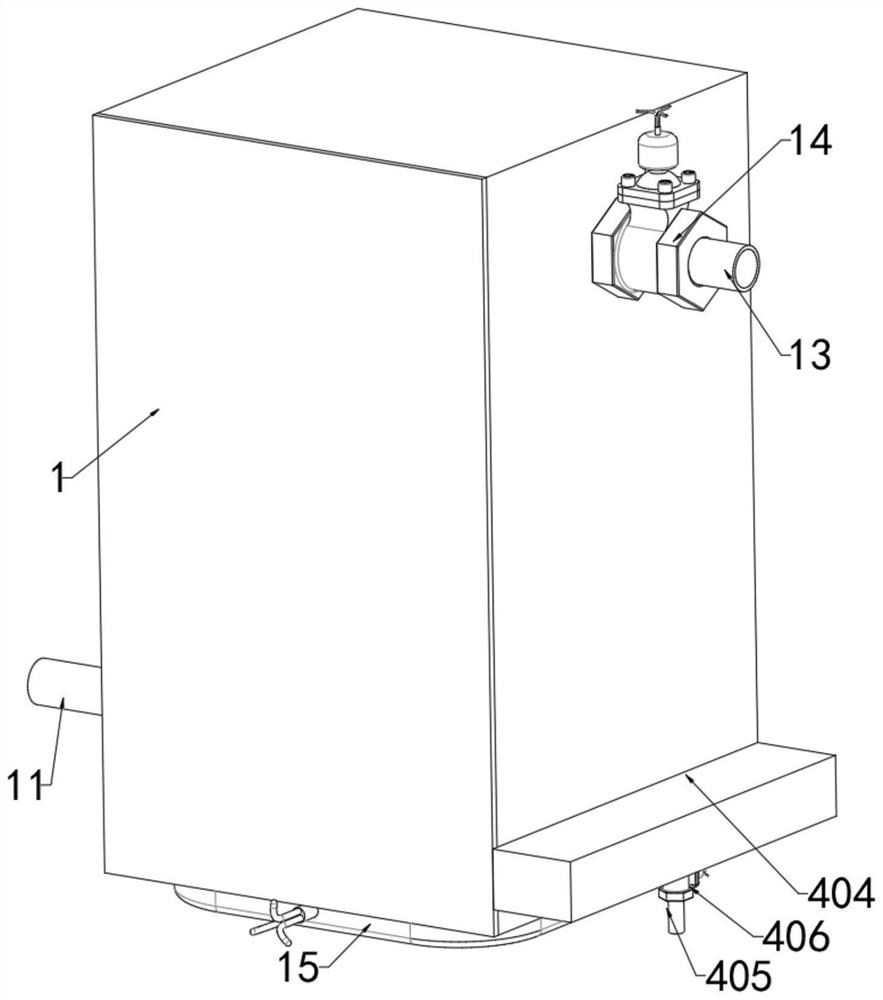

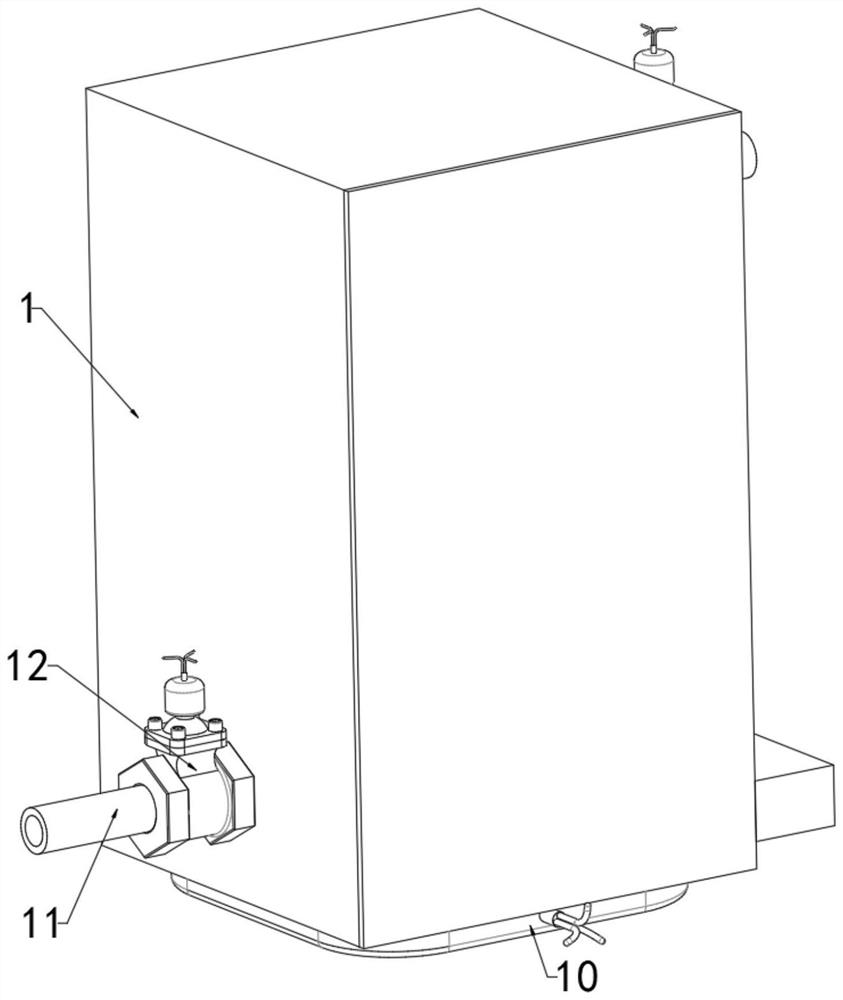

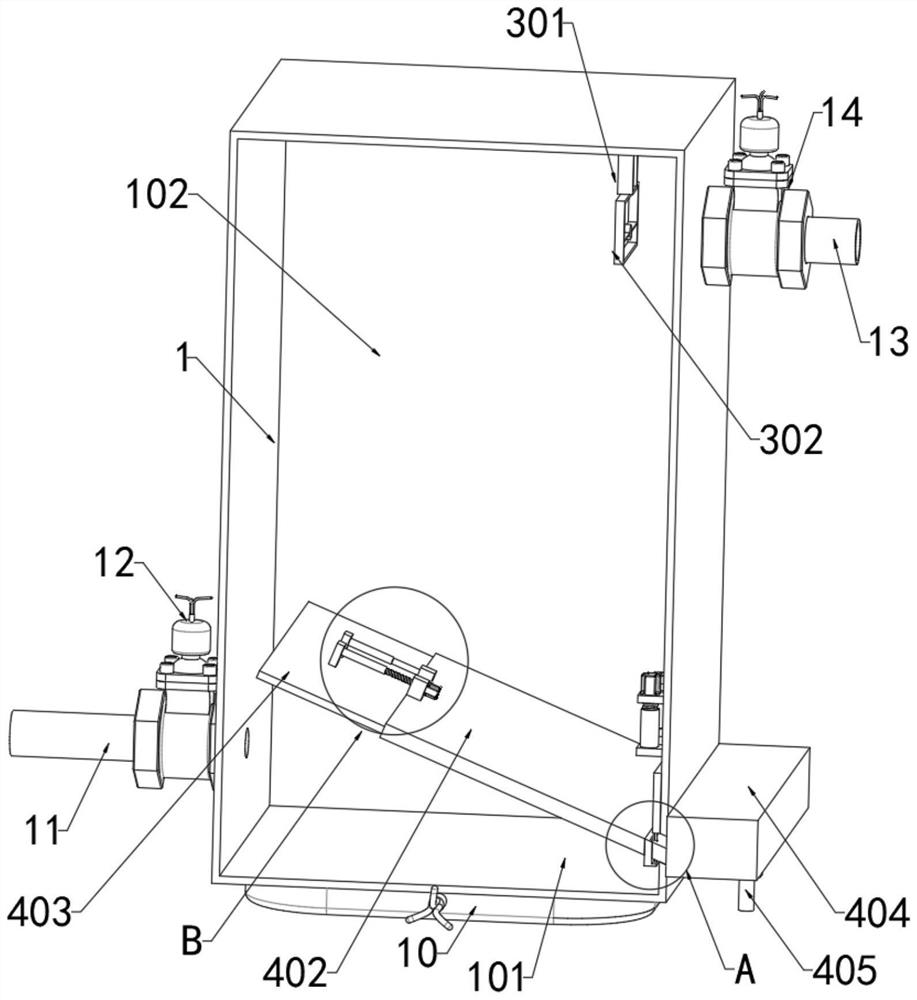

[0040]The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0041] Fine chemical industry is a general term for the production of fine chemicals, referred to as "fine chemicals". It can be divided into fine organic chemical products, fine inorganic chemical products, fine biochemical products and fine polymer chemical products. Organic synthesis refers to the use of simple and easy-to-obtain raw materials to generate organic compounds with specific structures and functions through organic reactions. Filter distillation equipment can distill and filter organic compounds during processing.

[0042] After in-depth investigation and research on the distillation process, the inventor found that the existing filter distillation equipment for fine chemical organic synthesis has poor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com