Preprocessing equipment for antimony pentachloride waste catalyst and processing method thereof

A waste catalyst, antimony pentachloride technology, applied in chemical instruments and methods, cleaning methods using liquids, combustion methods, etc., can solve the problem of lack of pretreatment of antimony pentachloride waste catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

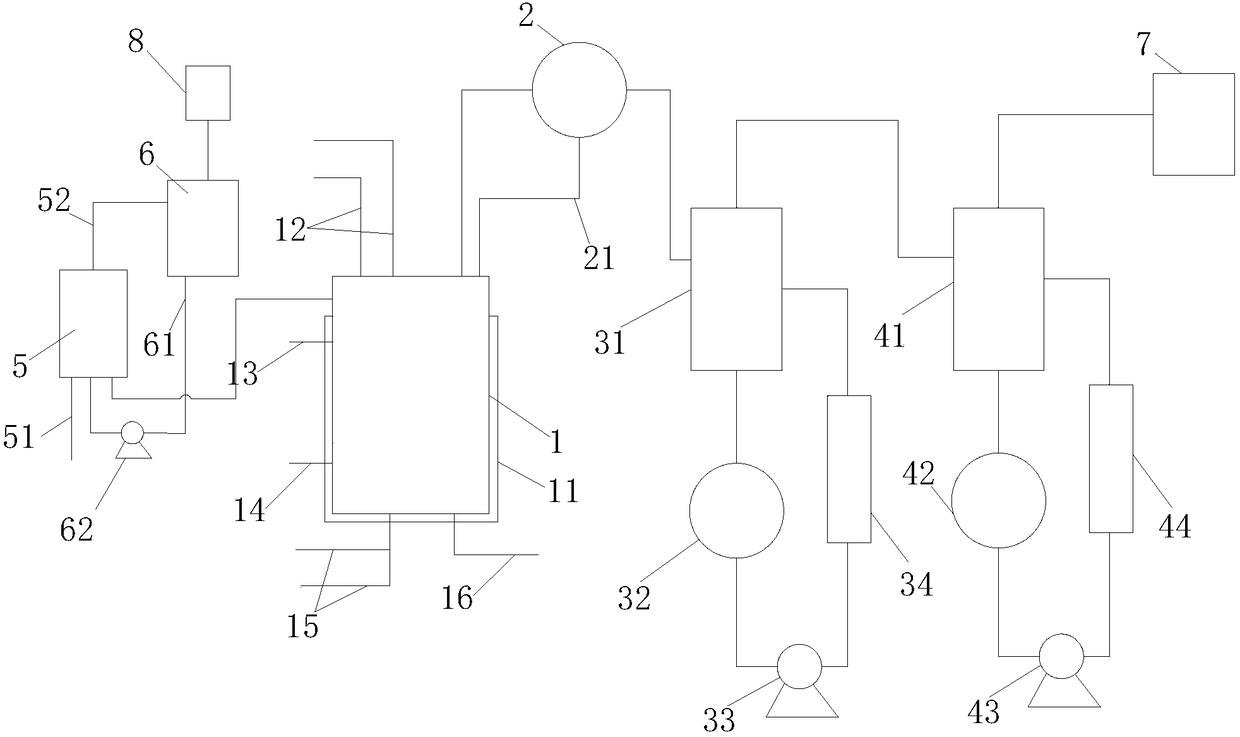

[0027] See figure 1 , the present embodiment discloses a pretreatment device for spent antimony pentachloride catalyst, comprising a catalyst treatment tank 1, the catalyst treatment tank 1 is connected to an organic matter treatment unit, and the organic matter treatment unit includes a reactor 5 connected in sequence and a finishing unit. Distillation tower 6, the top of the reactor 5 is connected with the rectification tower 6 through a pipeline one 52, the rectification tower 6 is connected with the organic matter storage tank 8, the reactor 5 is connected with the feed pipe three 51, and the feed pipe three 51 transport the spent antimony pentachloride catalyst and hydrofluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com