Patents

Literature

42results about How to "Reduce the synthesis reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

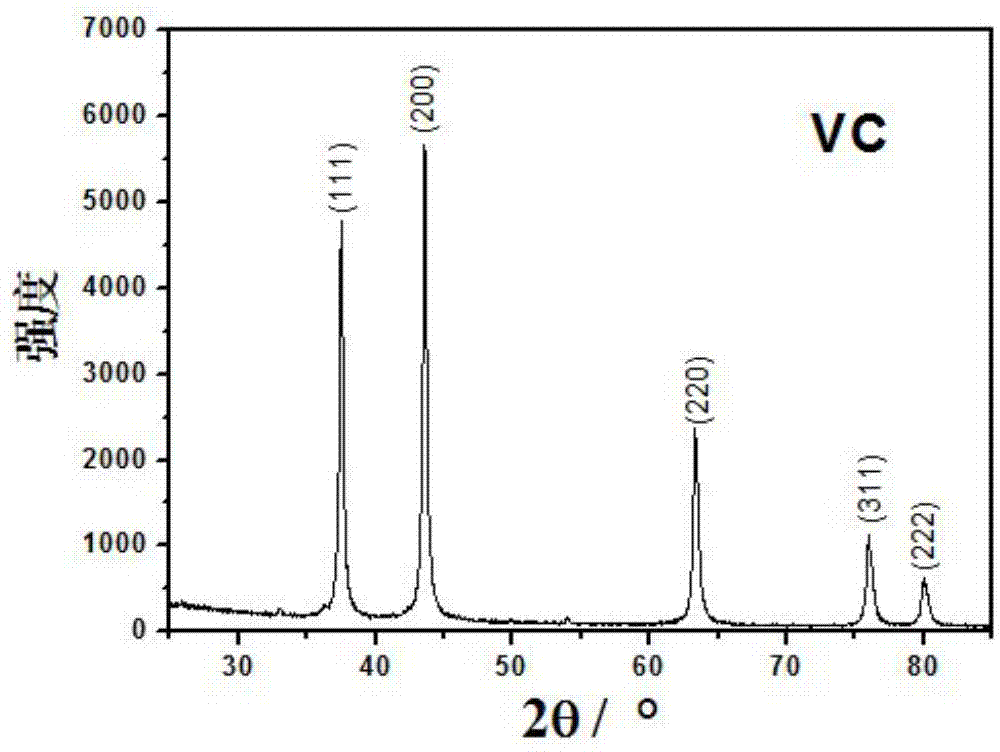

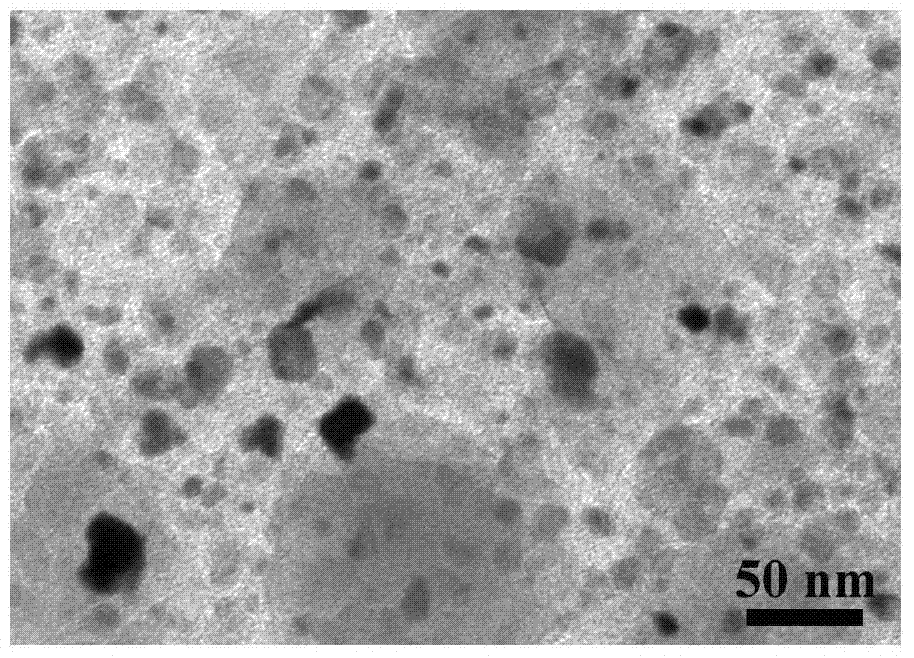

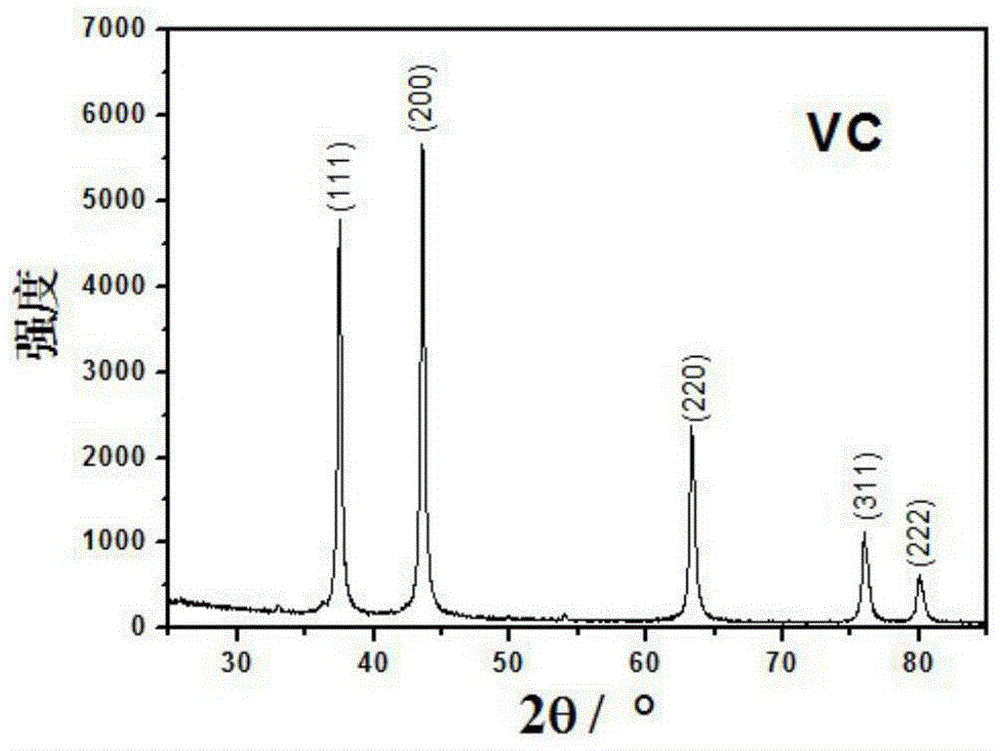

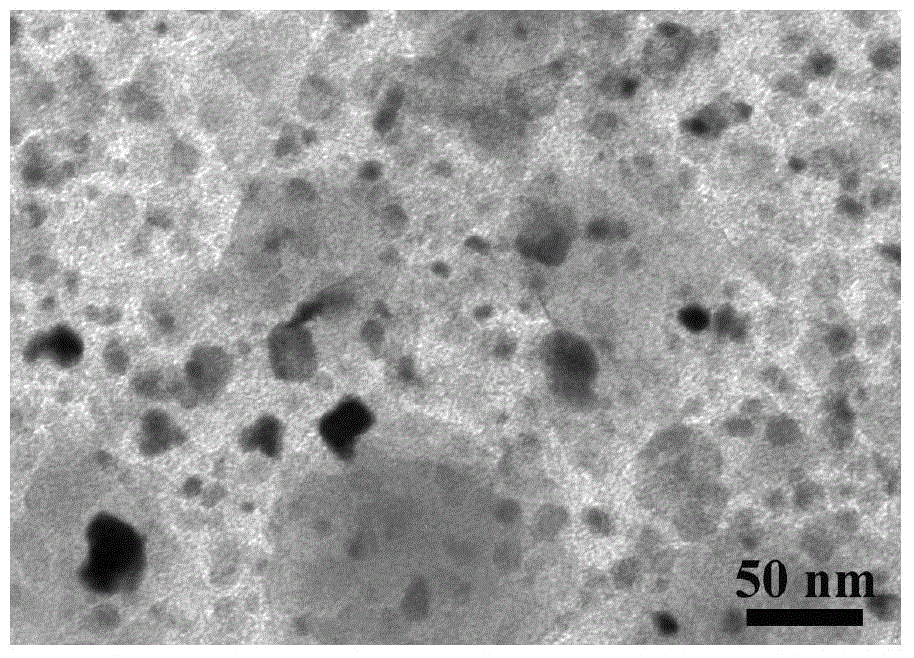

Method for producing nano-sized vanadium carbide powder

The invention relates to a method for producing nano-sized vanadium carbide powder, belonging to the technical field of preparing ceramic powder. The method comprises the following processes: (1) mixing a vanadium source, a carbon source and an auxiliary into a solution according to a certain proportion; (2) heating the solution, so that the solution is volatilized, concentrated and decomposed to obtain precursor powder containing the vanadium source and the carbon source; and (3) reacting the precursor powder for 1-5 hours at the temperature of 700-1300 DEG C under certain atmosphere. The method is simple in technology, low in cost, and easy to industrialize, and the obtained vanadium carbide powder has a particle size of less than 50nm, and good dispersity.

Owner:UNIV OF SCI & TECH BEIJING

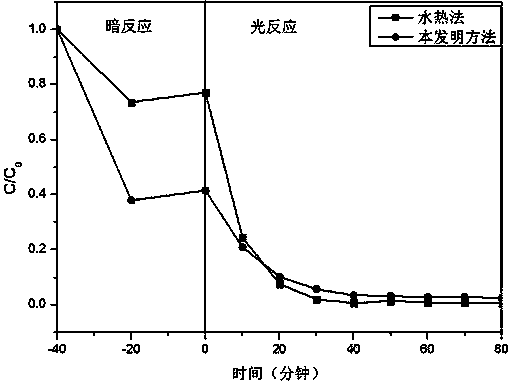

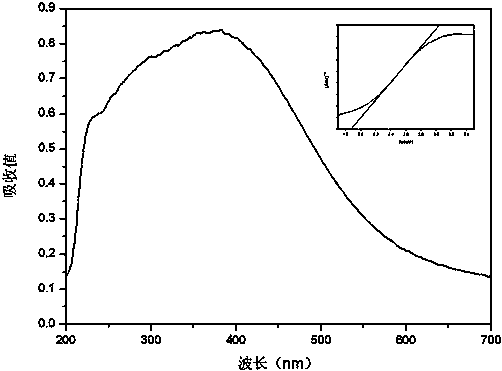

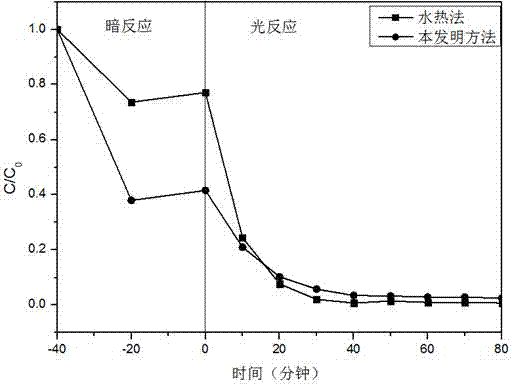

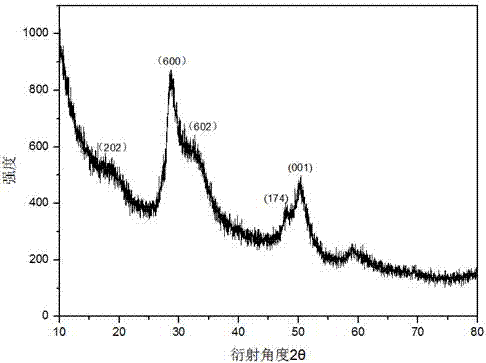

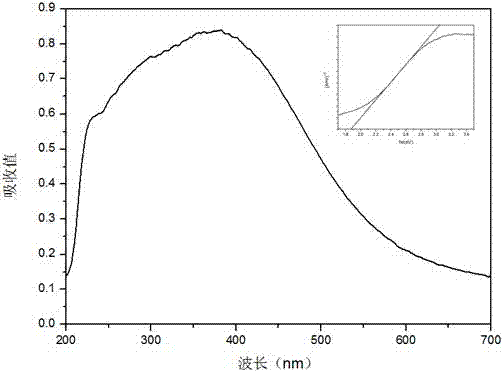

Method for preparing SnIn4S photocatalyst through low-temperature coprecipitation method

InactiveCN103657686AImprove photocatalytic performanceEfficient degradationCatalyst activation/preparationIndiumThiourea

The invention relates to a method for preparing a SnIn4S photocatalyst through a low-temperature coprecipitation method. The method is characterized by comprising the following steps: using soluble tin salt as a tin source, soluble indium salt as an indium source, thiourea or thioacetamide as a sulfur source, and methanol, ethanol, propanol and glycol as solvents, performing condensing refluxing at 60-90 DEG C, stirring at a constant speed, and reacting for 3-7 hours; cooling to room temperature, performing suction filtration on a sample, rinsing with deionized water and ethanol for three times, drying the obtained sample for 6-24 hours at 80-120 DEG C to obtain the SnIn4S photocatalyst with relatively higher activity. The SnIn4S photocatalyst can effectively degrade methyl orange, rhodamine B and other organic pollutants in visible light and reduce some heavy metal ions; the method has the significant advantages of simpleness, easiness, low reaction temperature, low energy consumption, short response time and high yield; the product of SnIn4S has very high photocatalytic performance.

Owner:NANCHANG HANGKONG UNIVERSITY

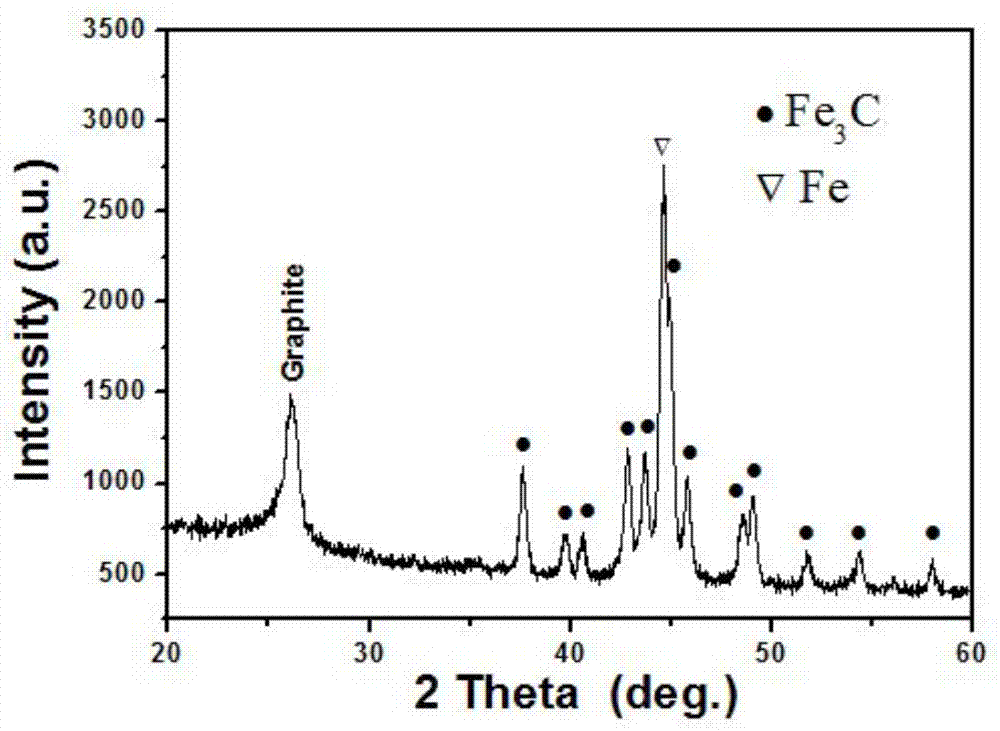

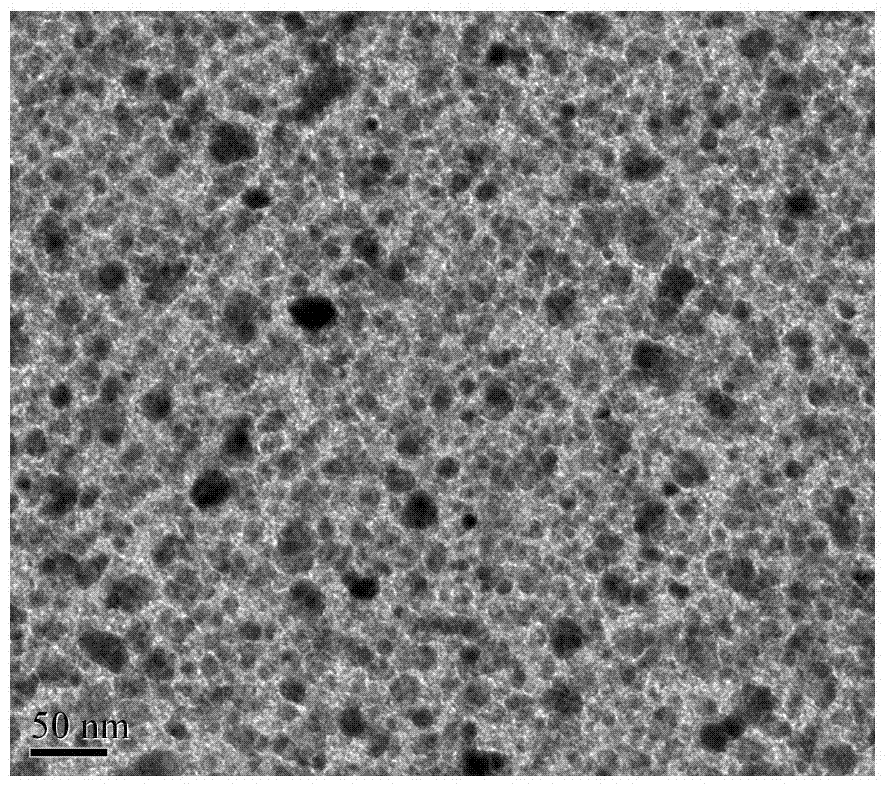

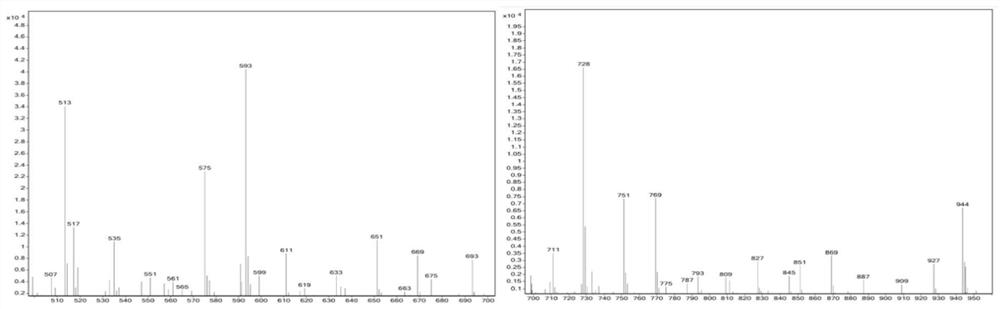

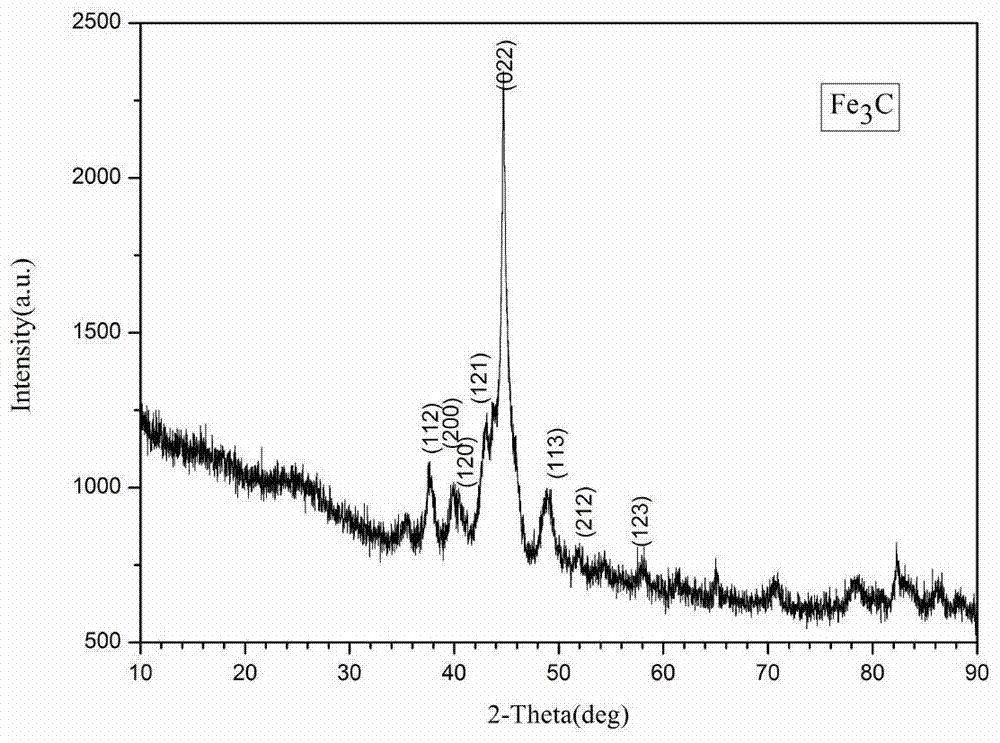

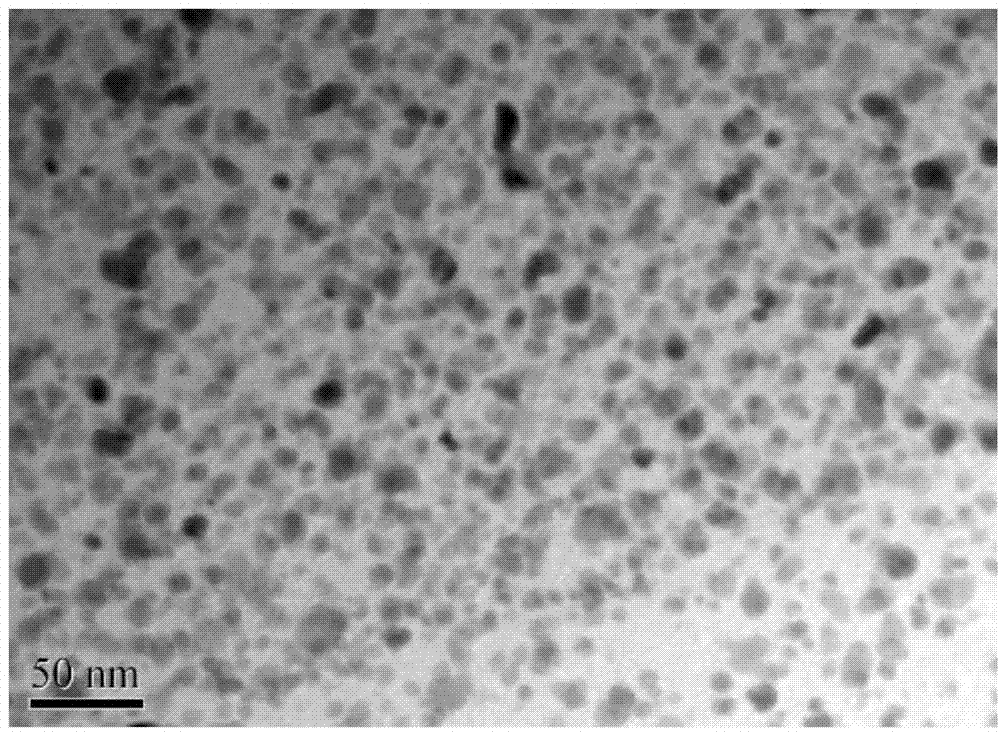

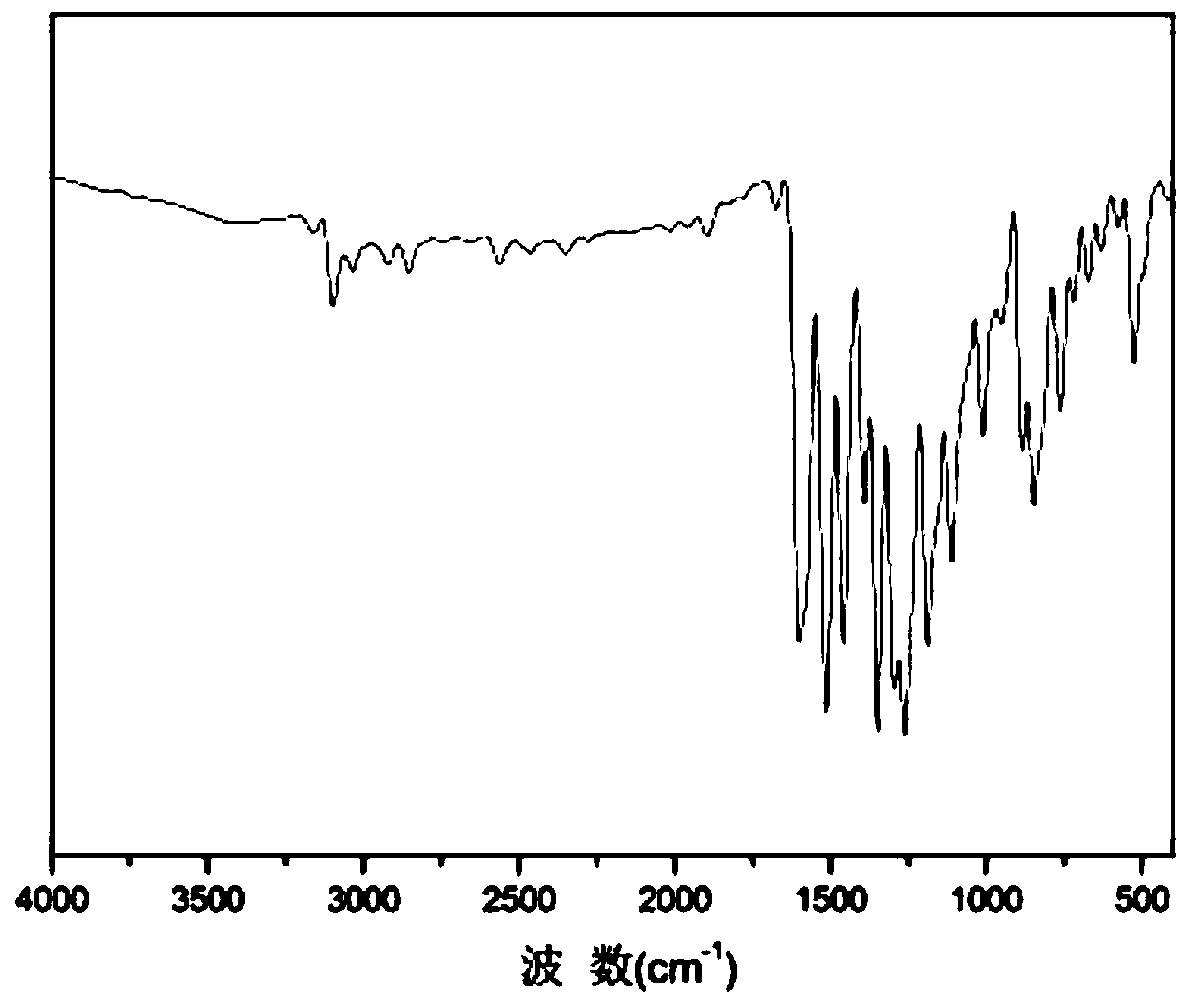

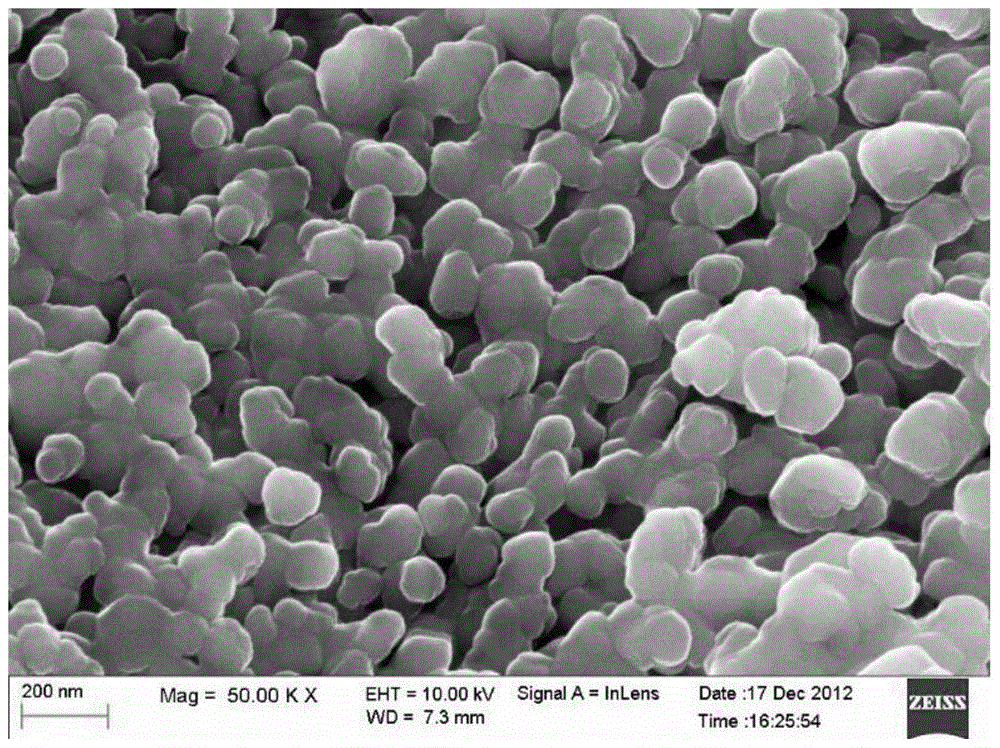

Production method of graphite/iron carbide/ iron nanocomposite

The invention relates to a production method of a graphite / iron carbide / iron nanocomposite and belongs to the technical field of magnetic nanopowder production. The production method includes the processes: (1) dissolving ferric nitrate, adjuvants and a water-soluble carbon source in distilled water according to a proper proportion; (2) heating and stirring, and reacting solution after volatilization and concentration so as to obtain precursor powder containing iron and carbon; (3) reacting the precursor powder at the temperature of 700-1100 DEG C under a certain atmosphere for 0.5-2 hours. Graphite / iron carbide, graphite / iron or graphite / iron carbide / iron can be obtained respectively by regulating process parameters. The production method is simple in process, low in cost and easy for industrial production, and the obtained graphite / iron carbide / iron nanocomposite with the size less than 50nm is good in dispersibility and high in saturation magnetization.

Owner:UNIV OF SCI & TECH BEIJING

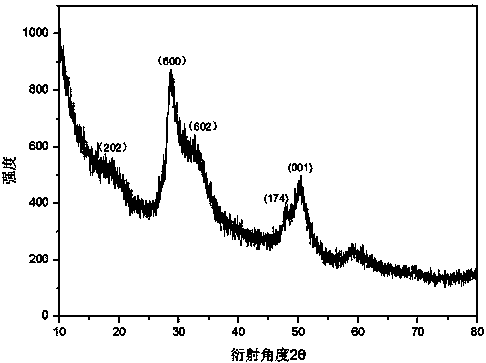

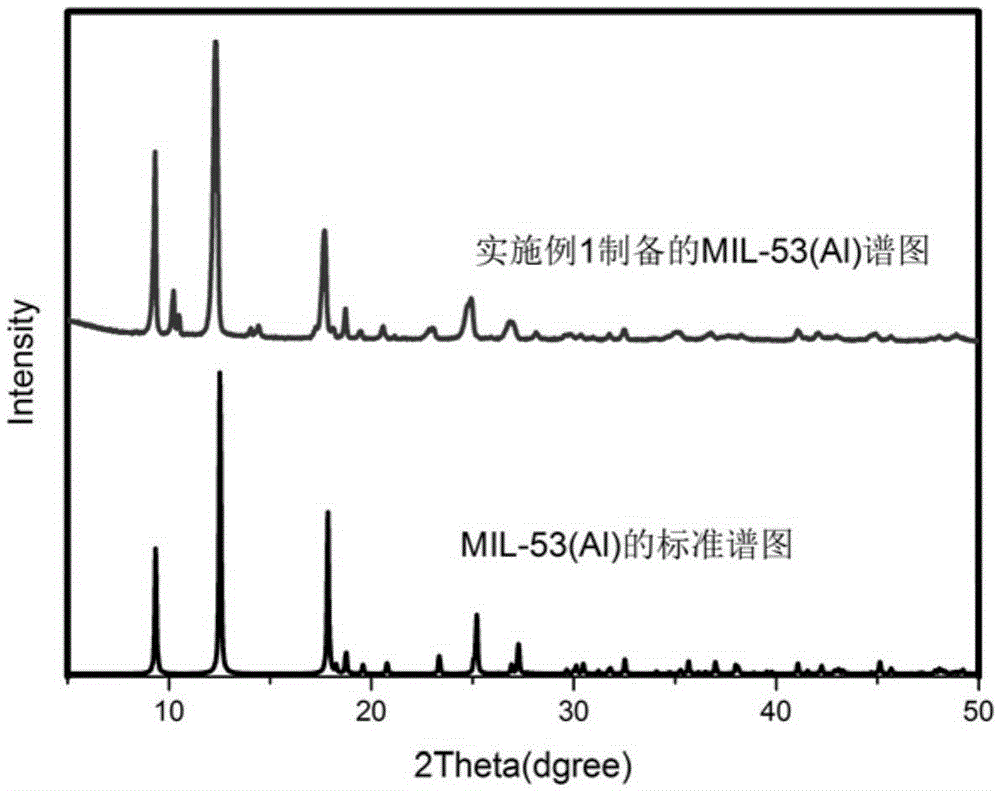

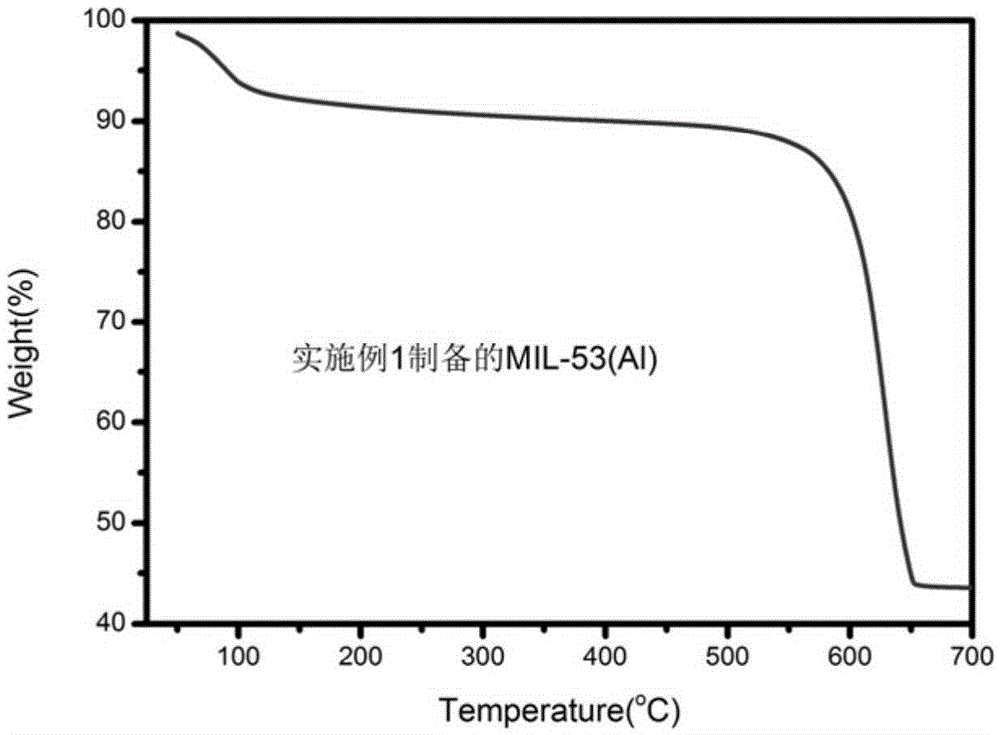

Synthesis method for metal organic framework material MIL-53 (Al)

ActiveCN105384762AExtended service lifeReduce the synthesis reaction temperatureGroup 3/13 element organic compoundsMetal-organic frameworkRaw material

The present invention belongs to the technical field of preparation of metal organic framework materials, particularly relating to a synthesis method for a metal organic framework material MIL-53 (Al) coordinated with aromatic organic carboxylic acid and aluminum. The structural formula of the metal organic framework material MIL-53 (Al) is Al (OH) [O2C-C6H4-CO2]. The method comprises the following steps: taking aluminum hydroxide and terephthalic acid as raw materials and acid as an auxiliary; preparing MIL-53 (Al) by a hydrothermal method; and activating at high temperature to obtain the metal organic framework MIL-53 (Al) with open channels. According to the method provided by the present invention, a water-insoluble metallic aluminum source is used as a precursor, and an acid auxiliary is used cooperatively; and compared with the existing synthesis method, the method has the advantages of low raw material cost, relatively mild conditions, energy conservation and environment protection and the like, solves the existing problem in a current MIL-53 (Al) synthesis process, and has a potential industrial production prospect.

Owner:TONGJI UNIV

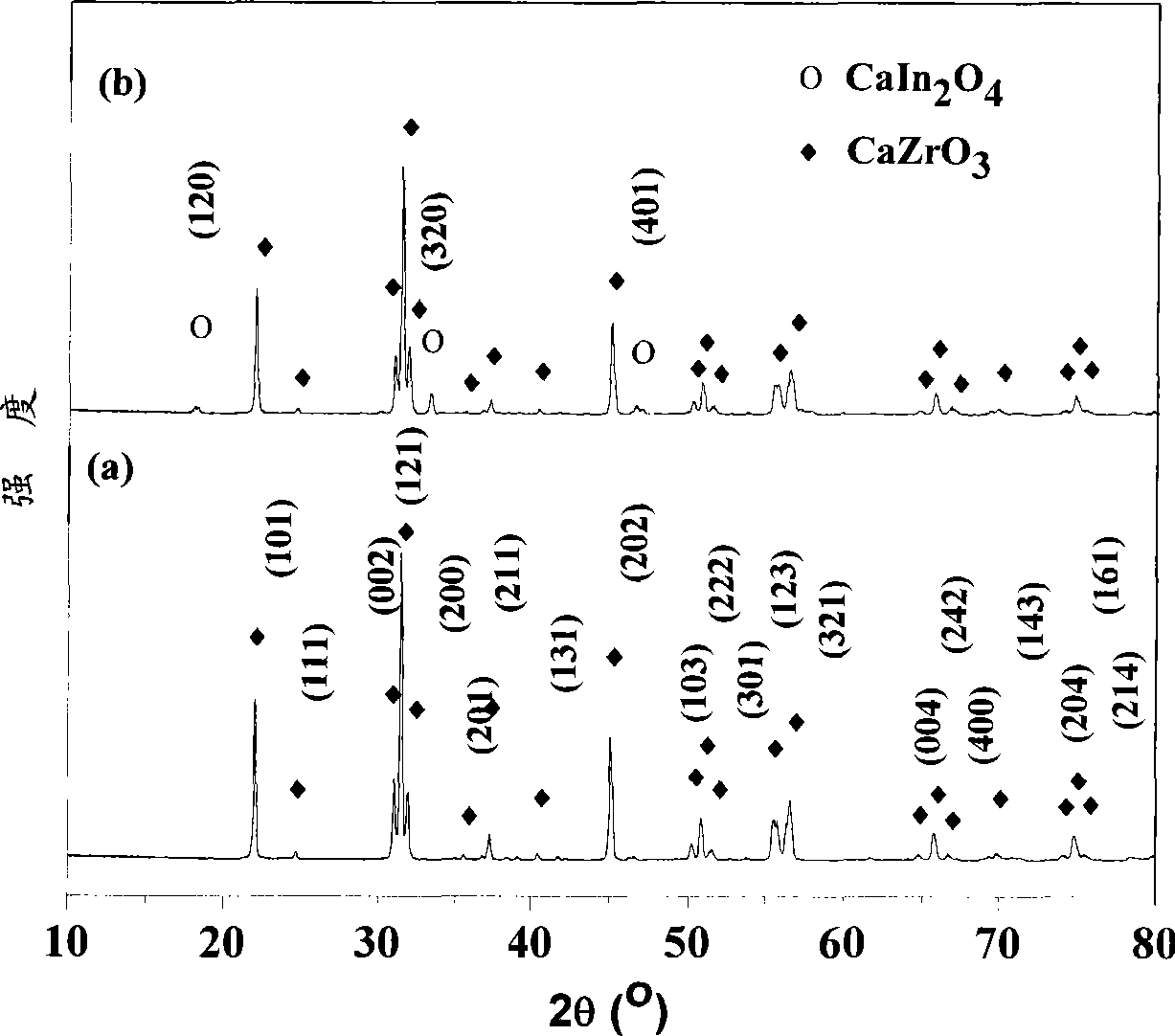

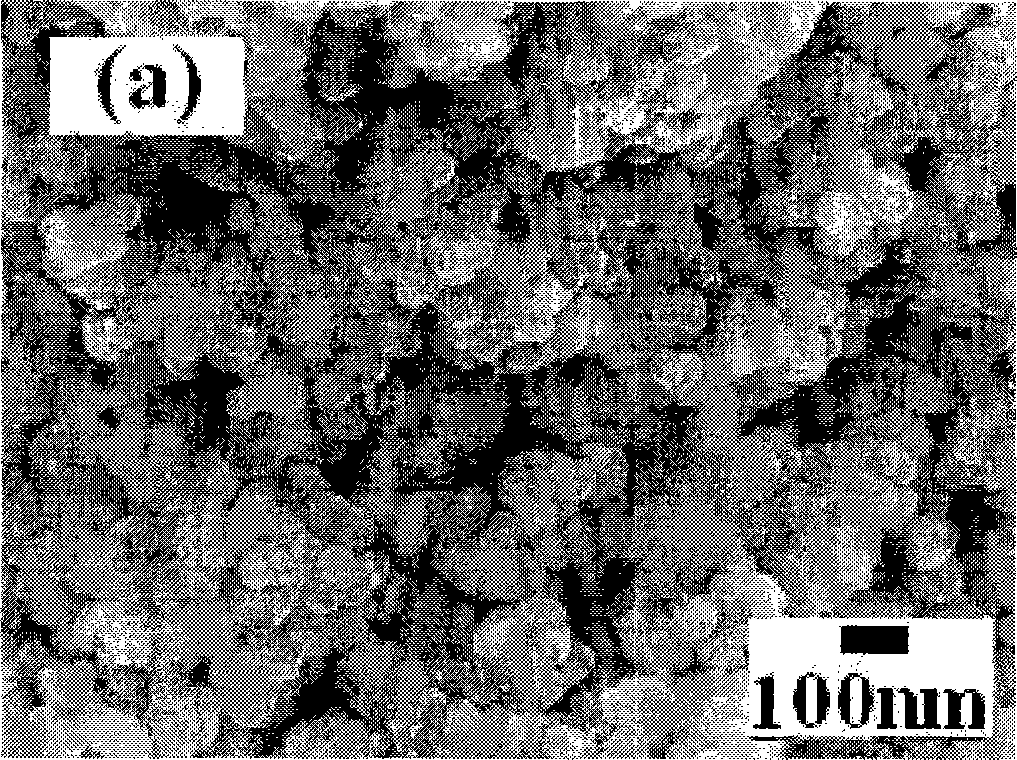

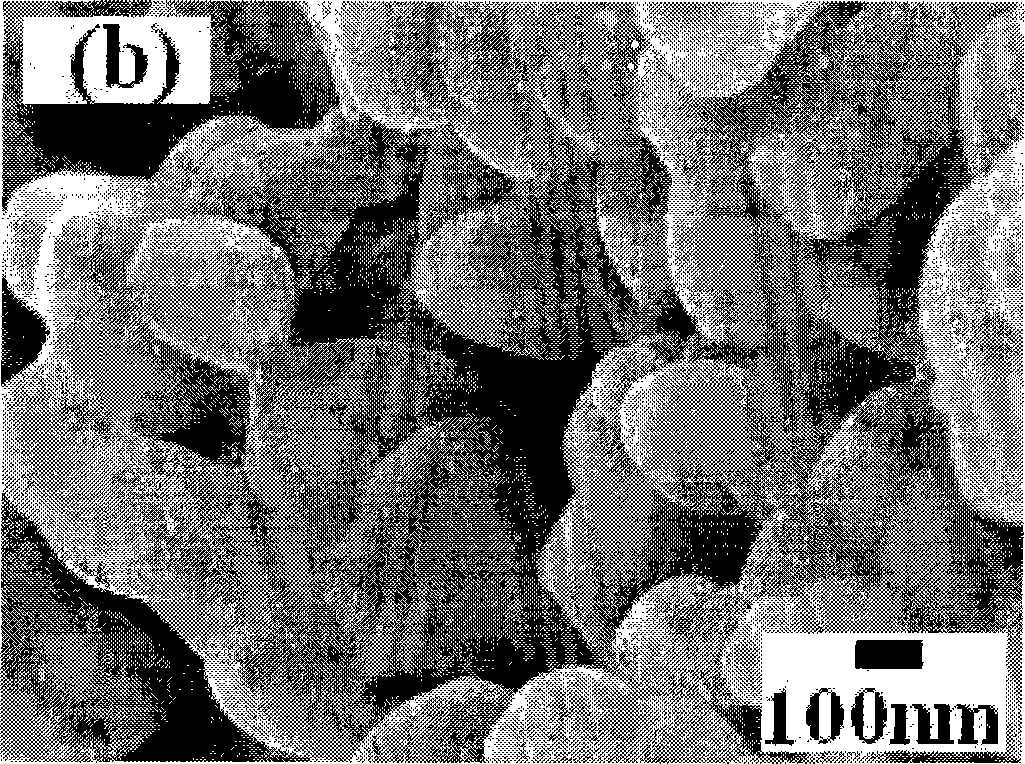

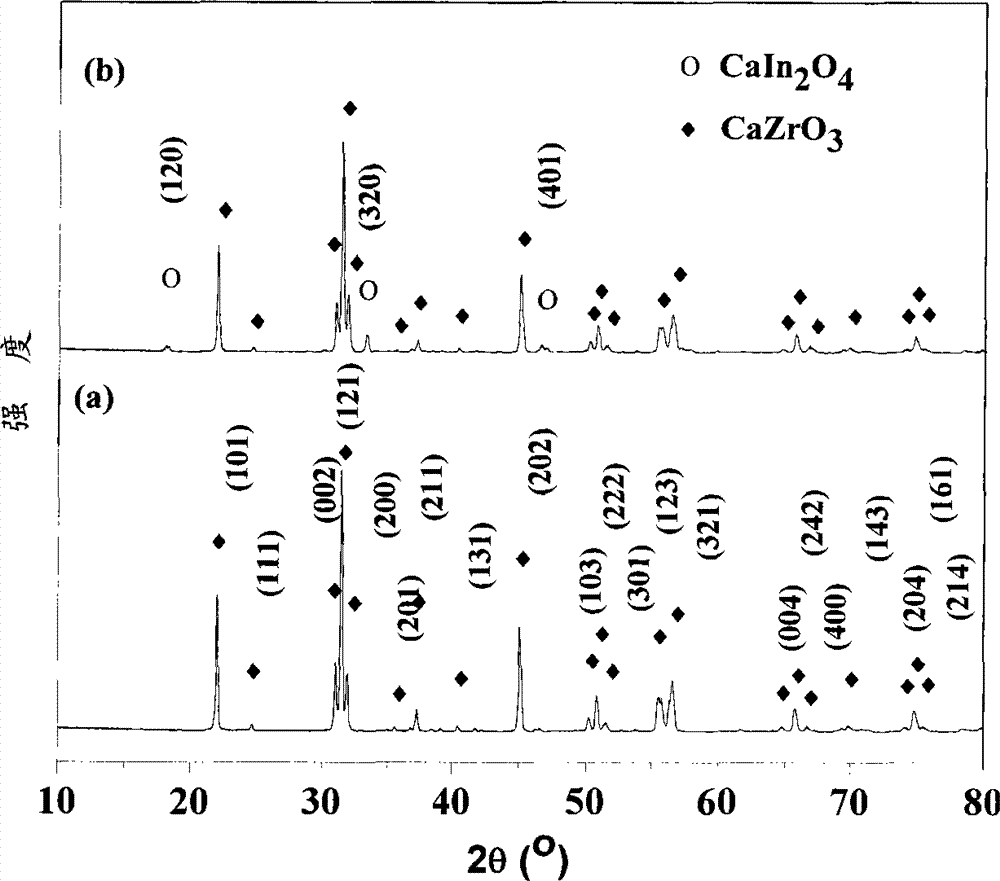

Method for low-temperature preparation of pure phase oxide material

The invention relates to a method for preparing pure phase oxide at low temperature, belonging to the material preparation technical field. The inventive method referrs the chemical formual of ABM<1-x>O3, (x=0.50-1.0), to dissolve the nitrates of cerium, zirconium, titanium or gallium into water, and slowly add the carbonate, oxalate, nitrate, acetate, basic hydroxide, hydroxide or oxide of calcium, barium, strontium, lead or lanthanide metal element into the solution to be dissolved completely, heats and mixes precursor solution in water bath or oil bath at 50-100DEG C, until the solution changes to gel, and reacts the gel at 1000DEG C for 2-10h, to obtain oxide materials of pure phase and high crystallinity. The method for preparing pure phase oxide at low temperature has simple process, easy operation, low cost, high product purity and easily accessible industrial production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

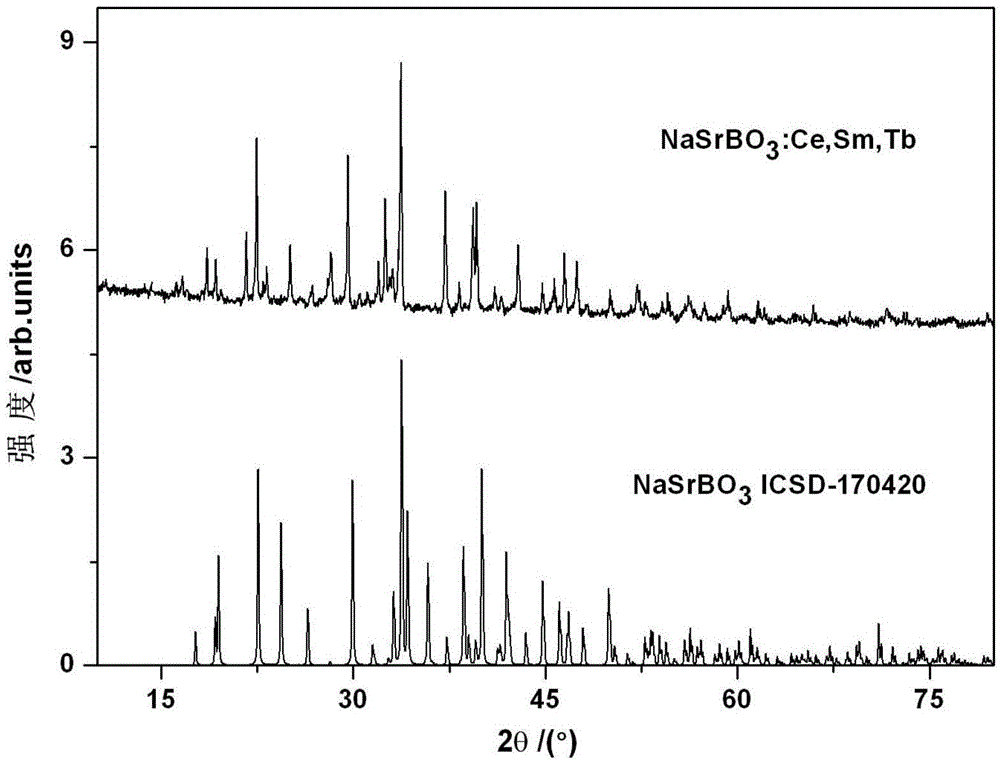

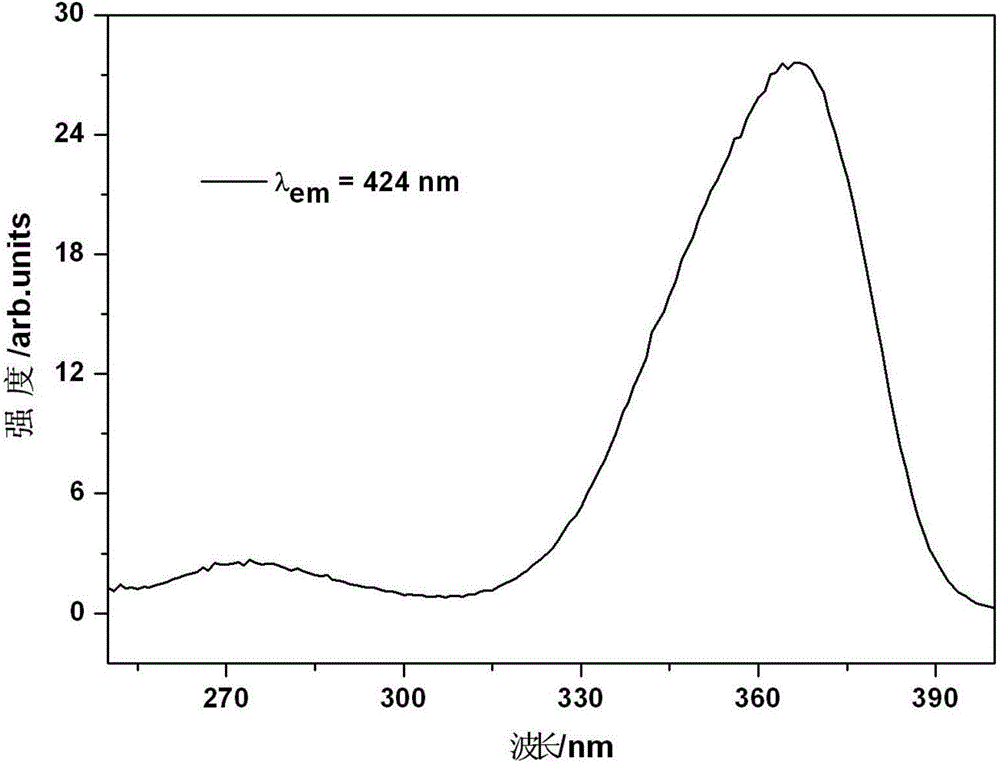

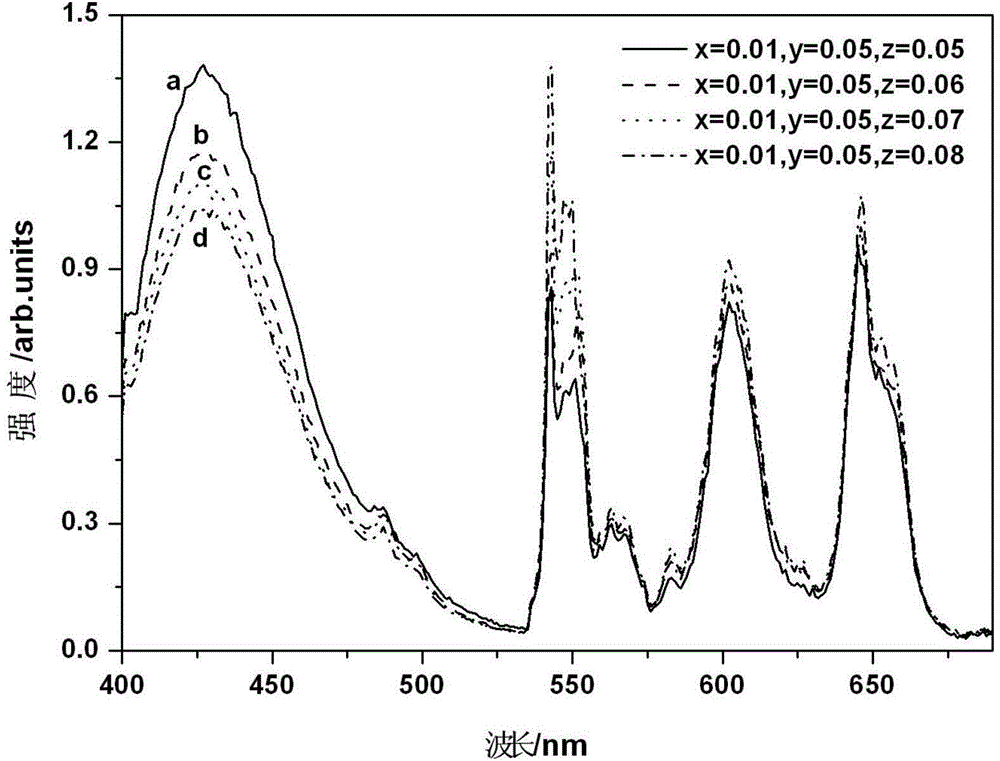

Borate matrix fluorescent powder for white-light LED and preparation method of borate matrix fluorescent powder

InactiveCN106147759AImprove luminous efficiencyImprove thermal stabilityEnergy efficient lightingLuminescent compositionsReaction temperatureThermal stability

The invention discloses borate matrix fluorescent powder for white-light LED and a preparation method of the borate matrix fluorescent powder. The preparation method is characterized in that NaSr1-x-y-zCexSmyTbzBO3 single matrix fluorescent powder is prepared by a high temperature solid phase method, 0<=x<=0.10, 0<=y<=0.40, 0<=z<=0.40, and the raw materials used by the preparation method are high-purity Na2CO3, SrCO3, H3BO3, CeO2, Tb4O7 and Sm2O3. The fluorescent powder can emit white light under ultraviolet excitation, and the purity of white light can be regulated by regulating doping Ce<3+>, Sm<3+> and Tb<3+> ion concentration. The borate matrix fluorescent powder and the preparation method have the advantages that the preparation method is simple in process and low in synthesizing reaction temperature, the chromaticity coordinates of the prepared NaSrBO3:Ce,Sm,Tb fluorescent powder can be regulated by regulating the doping concentration of the Ce<3+>, the Tb<3+> and the Sm<3+>, and the fluorescent powder is high in light emitting efficiency, good in thermal stability and promising in application prospect in white-light LED under ultraviolet excitation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

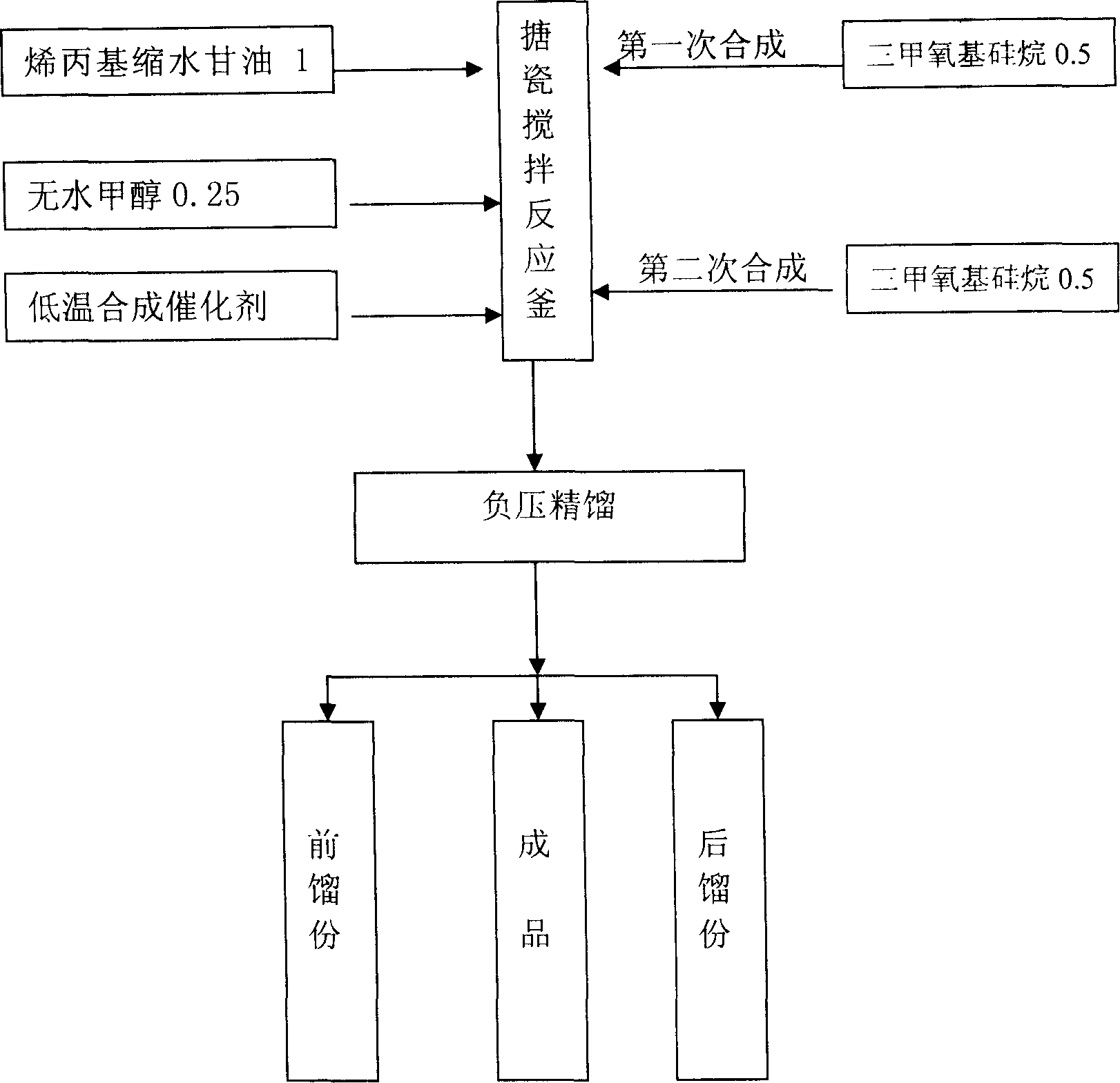

Process for synthesizing silicane coupling agent KII 560 at low temp.

InactiveCN100999531AReduce the synthesis reaction temperatureReduce manufacturing costGroup 4/14 element organic compoundsSilanesPhotochemistry

The present invention discloses low temperature process of synthesizing silane coupler KH-560. The process adopts anhydrous methanol as activating material, and low temperature synthesizing catalyst of alcohol solution of chloroplatinic acid compounded with chloroplatinic acid isopropyl alcohol and acetylacetone, so that it has low synthesis temperature, 65-80 deg.c, of allyl diglycidyl ether and trimethoxyl silane. The present invention has low power consumption, effective separation between high boiling point matter and low boiling point matter, low production cost and high product purity and yield.

Owner:樊福定

Low temperature synthesis method for graphite fluoride

InactiveCN104591115AReduce the synthesis reaction temperatureLow reaction temperatureAntimony pentachlorideDecomposition

The invention discloses a low temperature synthesis method for graphite fluoride. The method includes: reacting graphite with antimony pentachloride at 300-400DEG C for 7h to prepare an antimony pentachloride graphite intercalation compound; and introducing a fluorine-nitrogen mixed gas into the reactor to carry out reaction for 5-10h, with the fluorine accounting for 12%-15% of the total volume of the fluorine-nitrogen mixed gas. The graphite fluoride synthesis reaction temperature is far below its decomposition temperature, thus avoiding the potential danger of explosion. Graphite fluoride can form in ordinary fluorination equipment, the reaction temperature control range is large and is easy to control. The production cost is low, and the output rate is high.

Owner:QINGDAO TAIHAODA CARBON MATERIAL

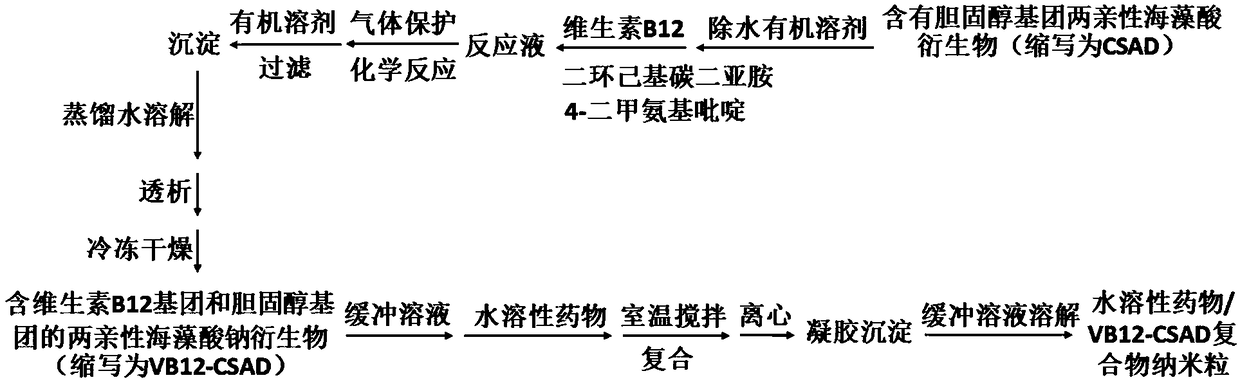

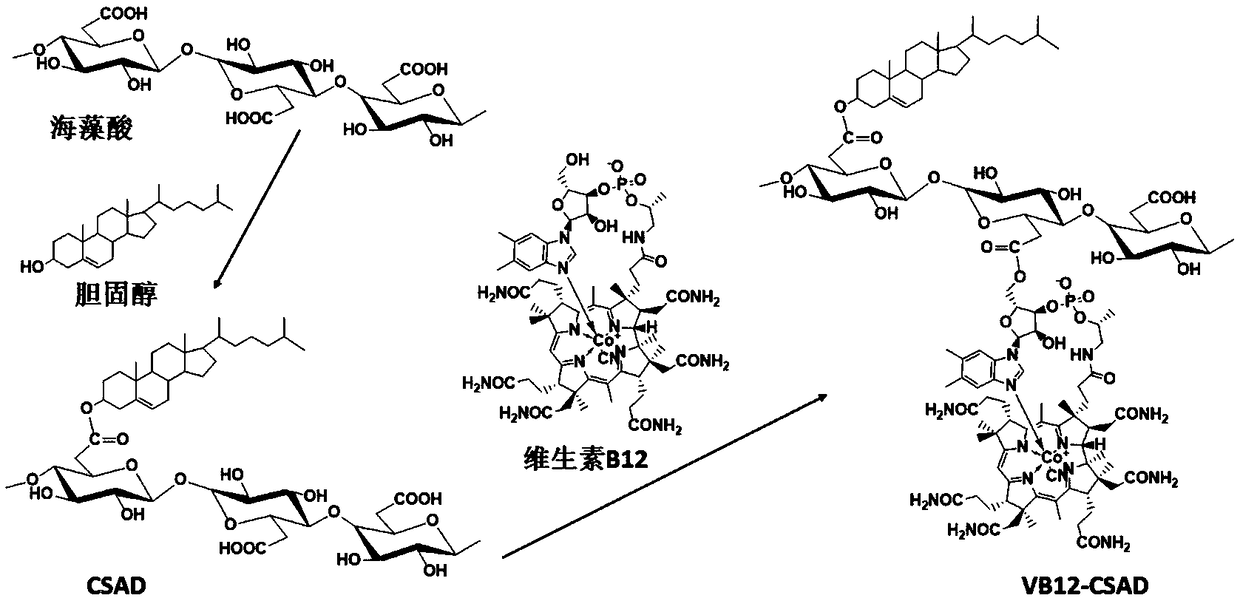

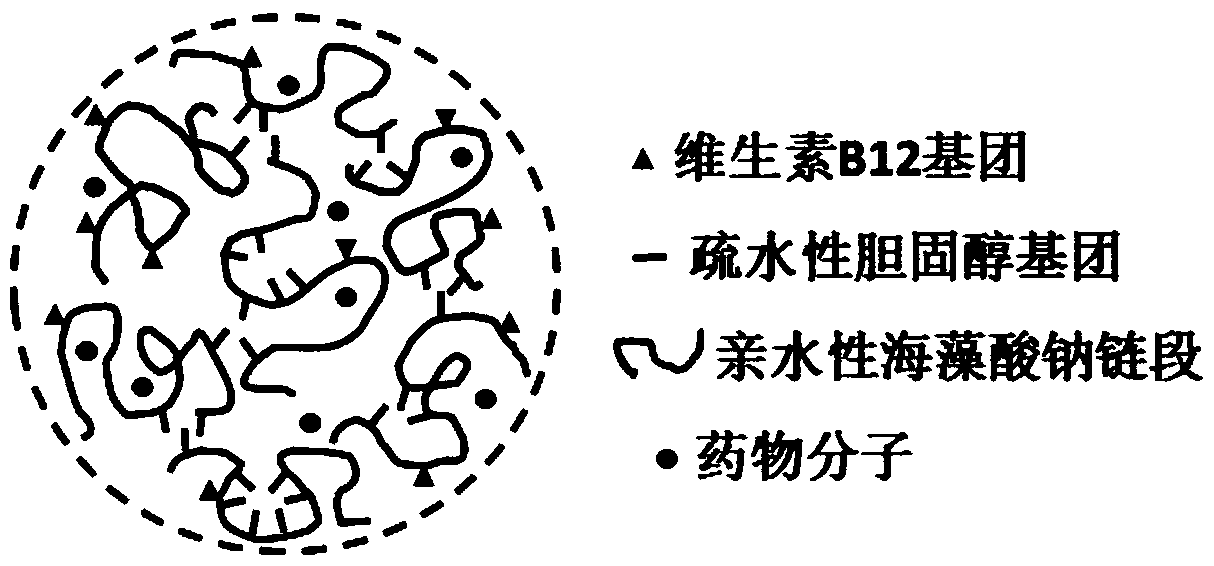

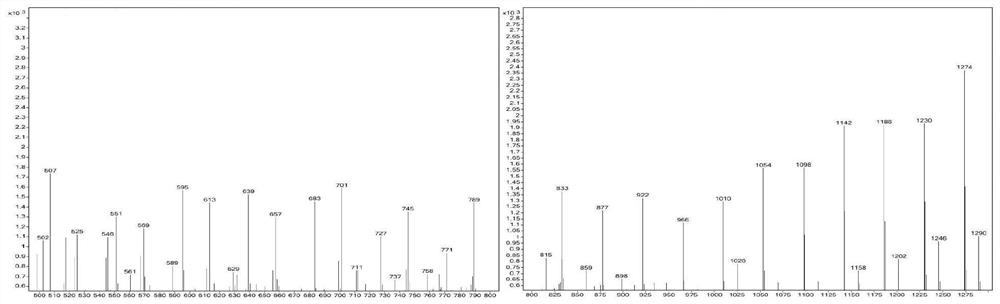

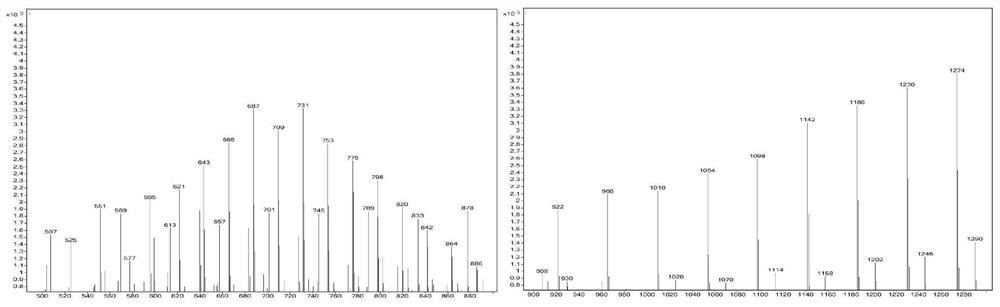

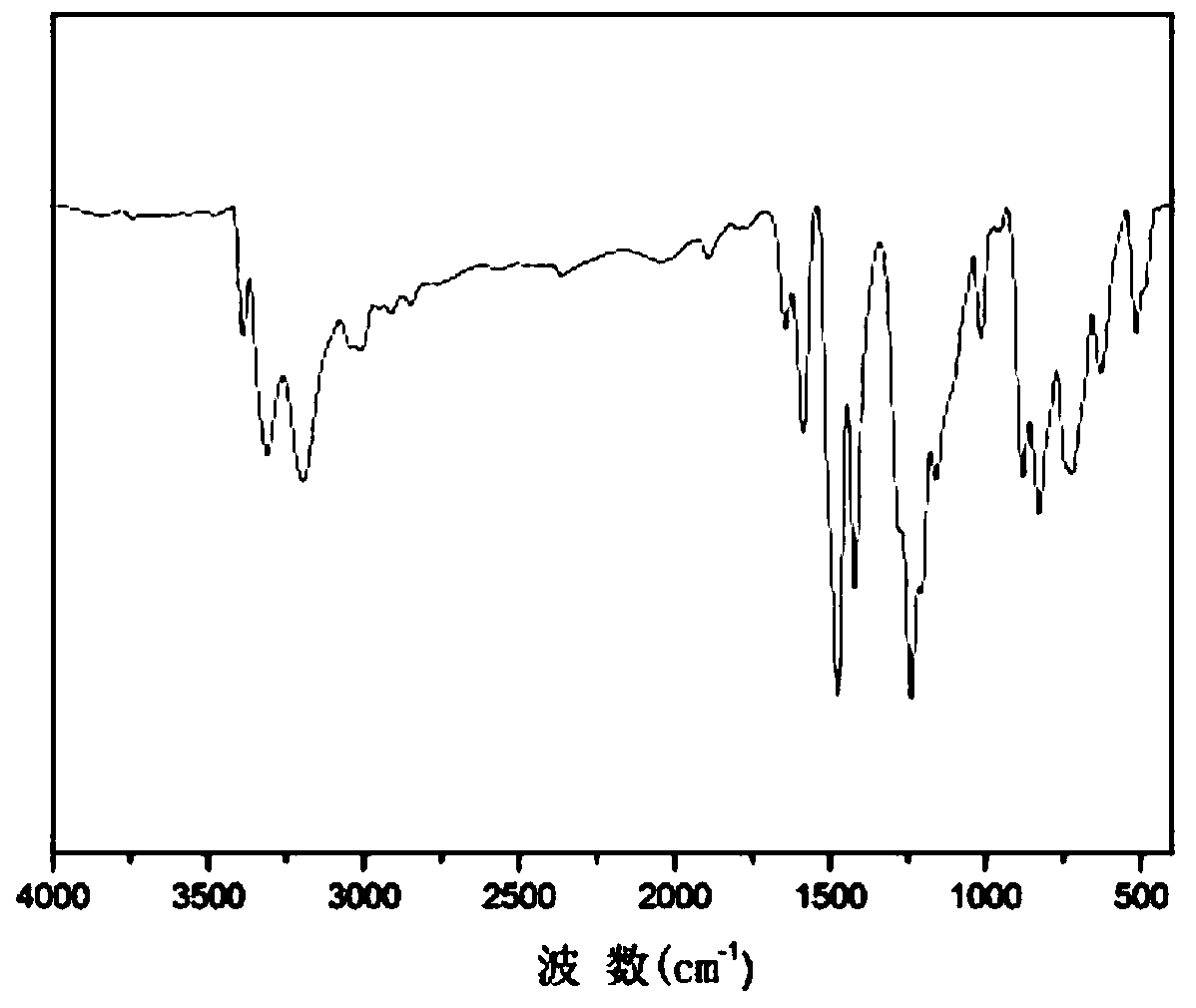

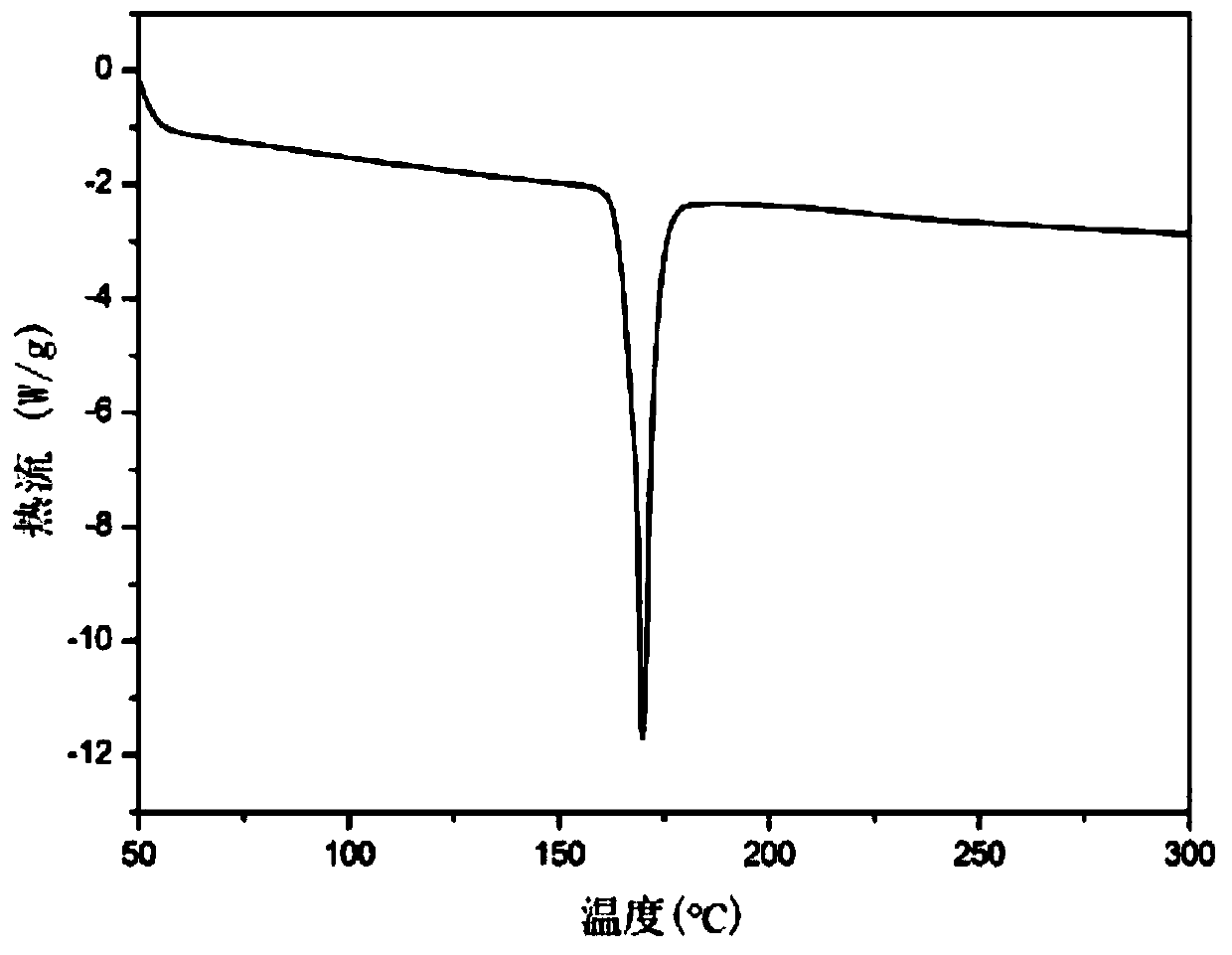

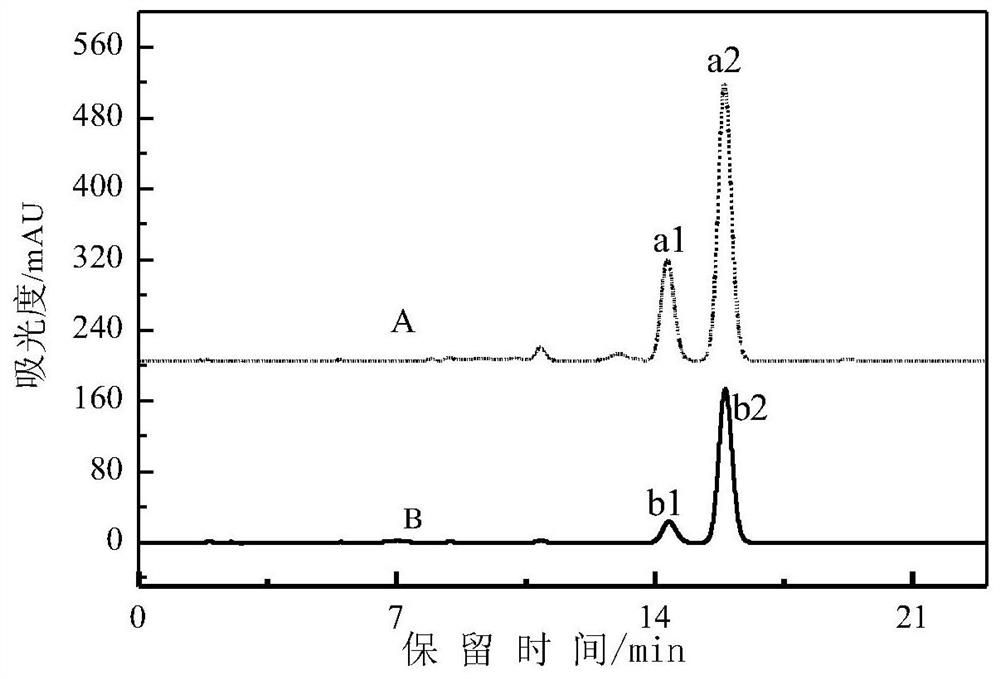

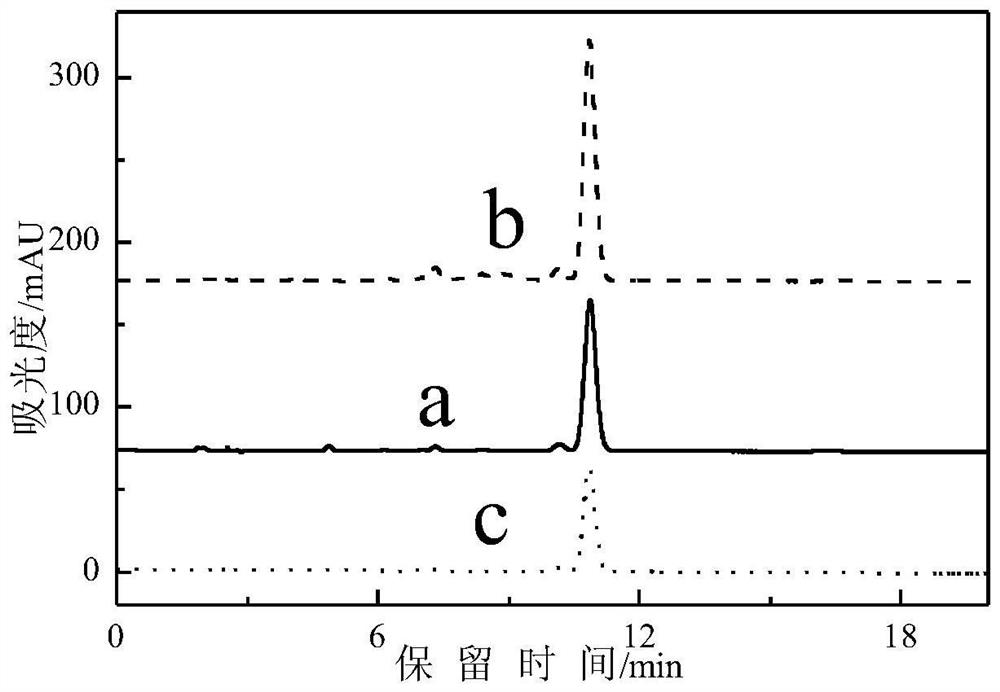

Vitamin B12 group containing amphiphilic sodium alginate derivative and preparation method and application thereof

InactiveCN109053927APrevent leakageImprove stabilityOrganic active ingredientsPeptide/protein ingredientsIntestinal structureCholesterol

The invention discloses a vitamin B12 group containing amphiphilic sodium alginate derivative and a preparation method and application thereof. Particularly, the derivative is an amphiphilic sodium alginate derivative containing a vitamin B12 group and a cholesteryl group. The derivative has a compound structure formula represented by a formula (I) shown in the description. The vitamin B12 group containing amphiphilic sodium alginate derivative (VB12-CSAD) is prepared through subjecting a cholesteryl containing amphiphilic alginic acid derivative (CSAD) to a reaction with vitamin B12. The reaction conditions of synthesis of the VB12-CSAD are mild, and thus, the maintaining of bioactivity of the vitamin B12 is facilitated; the VB12-CSAD is high in stability in a digestive tract system; thesmall-intestine targeted absorption performance is high, so that the vitamin B12 group containing amphiphilic sodium alginate derivative is advantageously used as an oral-application nano-preparationfor small-intestine targeted absorption and has a relatively good application prospect in the aspect of improving safety and bioavailability of oral application drugs.

Owner:SUN YAT SEN UNIV +1

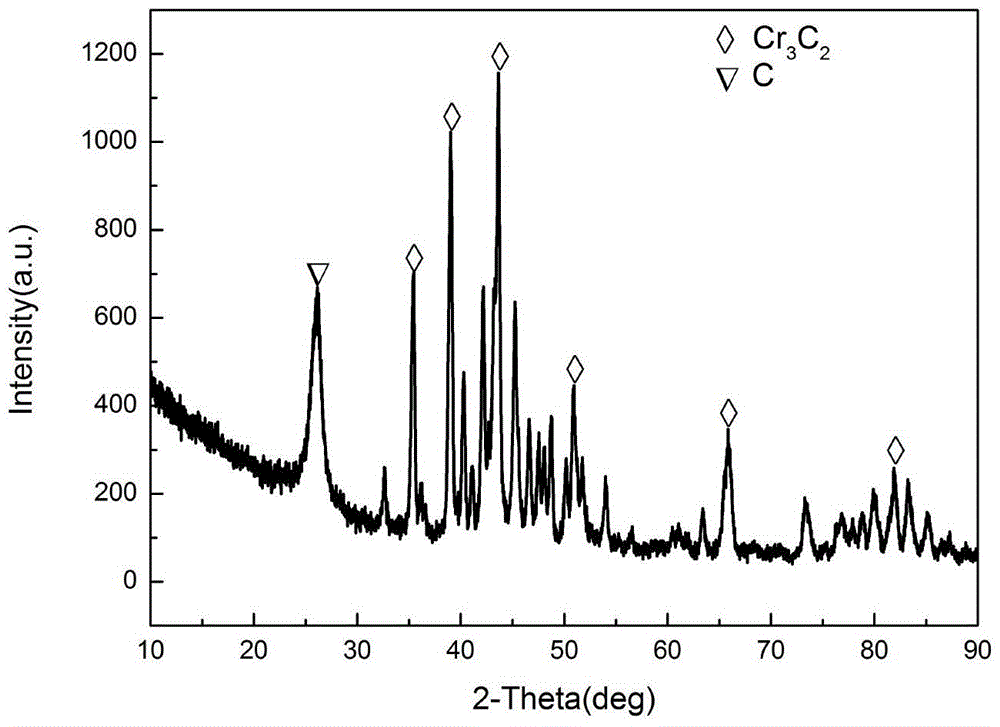

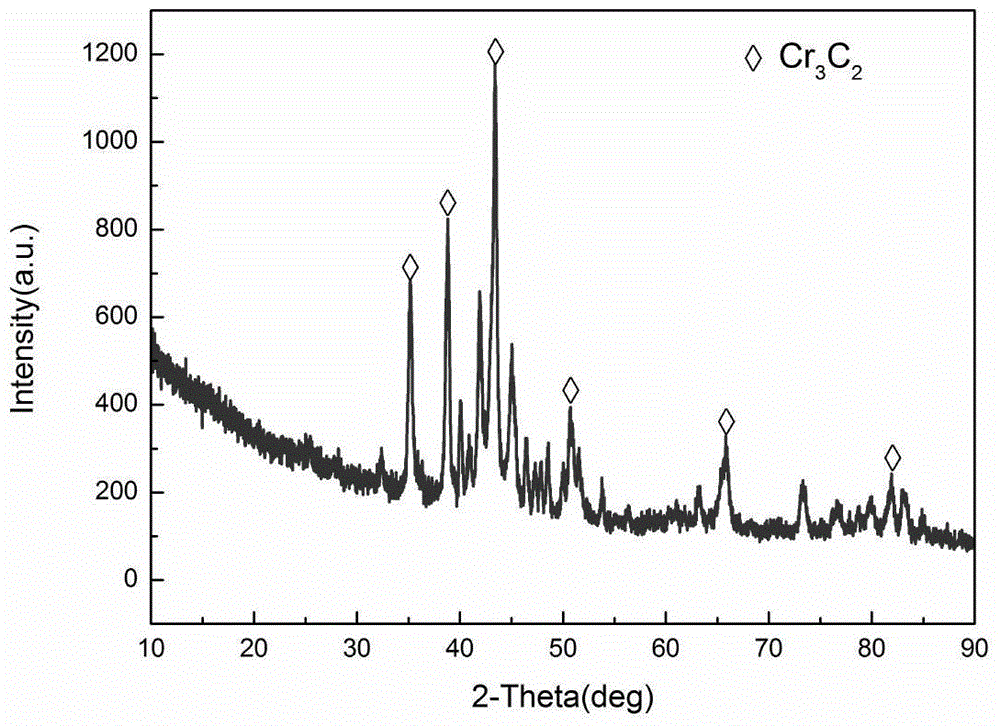

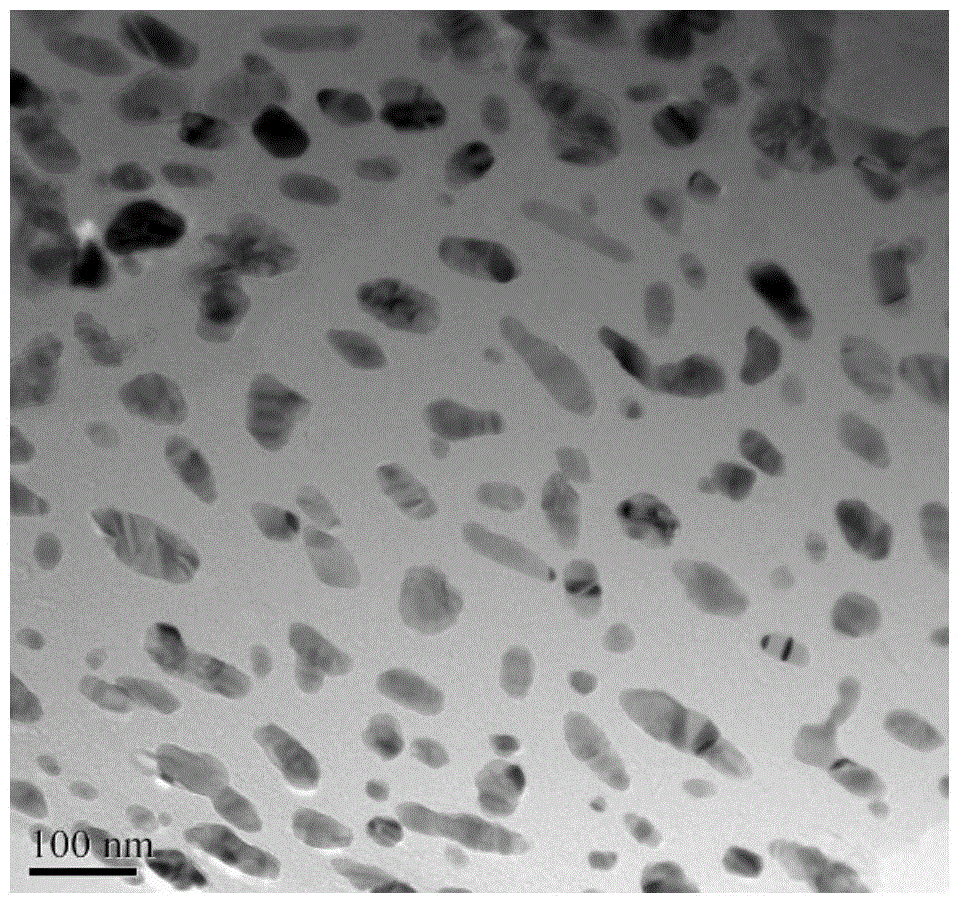

Preparation method of chromium carbide/carbon nano composite material with mesoporous structure

The invention relates to a preparation method of a chromium carbide / carbon nano composite material with a mesoporous structure and belongs to the technical field of composite material preparation.The preparation method includes: (1), mixing chromium source, glycine and additives (carbon source, ammonium nitrate and the like) according to a certain proportion to form a solution; (2), heating while stirring, and decomposing after volatilizing and concentrating the solution to obtain precursor powder; (3), subjecting the precursor powder to reaction for 0.5-2 h within a temperature range of 700-1200 DEG C in certain protection atmosphere.The preparation method is simple in process, low in cost and easy for industrial production, and the chromium carbide / carbon nano composite material obtained by the method is uniform in particle distribution and high in dispersity.

Owner:UNIV OF SCI & TECH BEIJING

Solvent-free method for preparing 1,3-propane sultone

The invention discloses a solvent-free method for preparing 11,3-propane sultone. According to the method, propenol and ammonium sulfite are used as reaction raw materials; and deionized water is adopted as medium. The preparation method comprises the following steps: stirring ammonium sulfate and deionized water; at 20-50 DEG C, preparing a mixed solution from acrolein, an initiator and deionizedwater, dropwise adding the mixed solution into a beaker, and carrying out catalytic reaction to generate an aqueous solution of 3-hydroxypropylammonium sulfonate; adding calcium hydroxide to carry out alkalization reaction, after alkalization is completed, adding concentrated sulfuric acid for acidification treatment to obtain 3-hydroxypropanesulfonic acid and solid calcium sulfate, and performing filtration to obtain an aqueous solution of the 3-hydroxypropanesulfonic acid; carrying out concentration and reduced pressure rectification to obtain a target product; adding a certain amount of calcium hydroxide and water into kettle residues, performing hydrolysis to obtain an aqueous solution of calcium 3-hydroxypropanesulfonate, adding concentrated sulfuric acid for acidification treatment,performing filtration to obtain an aqueous solution of 3-hydroxypropanesulfonic acid, and carrying out concentration and reduced pressure rectification to obtain the target product. The method has the advantages of simple process, simple raw materials, no solvent and no waste, and the yield can reach 95%.

Owner:江苏瀚康新材料有限公司

Preparation method of nano chromium carbide powder

InactiveCN105731459ASmall granularityGood dispersionMaterial nanotechnologyCalcium carbideChromium carbideNanometre

The invention relates to a preparation method of nano chromium carbide powder, which belongs to the technical field of nano powder preparation. The process is as follows: (1) make a solution of chromium nitrate, glycine and carbon source according to a certain ratio; (2) heat and stir, the solution is volatilized, concentrated and then decomposed to obtain the precursor powder; (3) the precursor powder is heated at 600 Within the temperature range of ~1000°C, react in a certain protective atmosphere for 0.5-3 hours. The invention has the advantages of simple process, low cost and easy industrial production, and the particle size of the obtained chromium carbide powder is less than 100nm, and the dispersibility is good.

Owner:UNIV OF SCI & TECH BEIJING

A kind of method for preparing indium tin sulfide photocatalyst by low temperature co-precipitation method

InactiveCN103657686BImprove photocatalytic performanceEfficient degradationCatalyst activation/preparationIndiumThiourea

Owner:NANCHANG HANGKONG UNIVERSITY

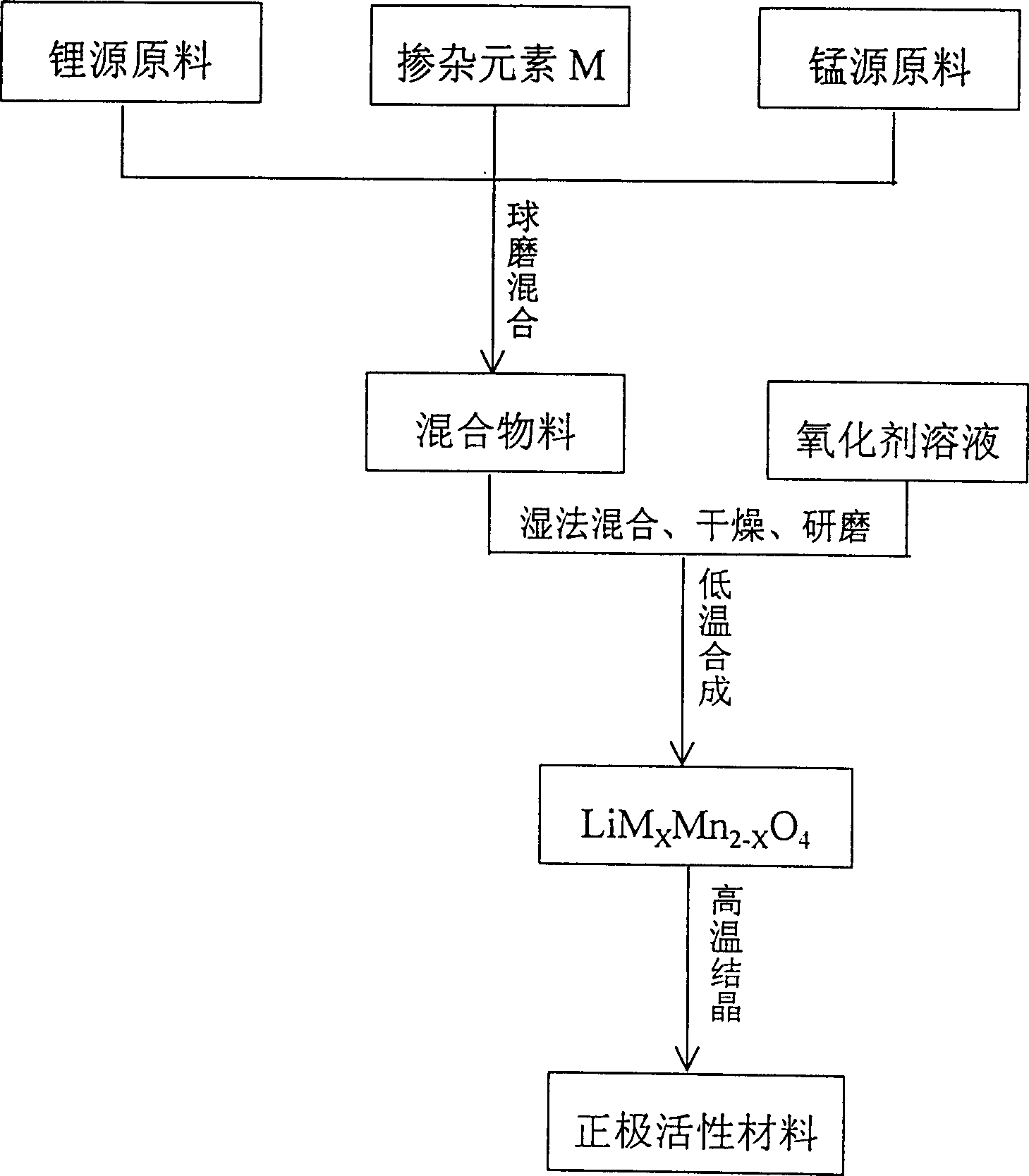

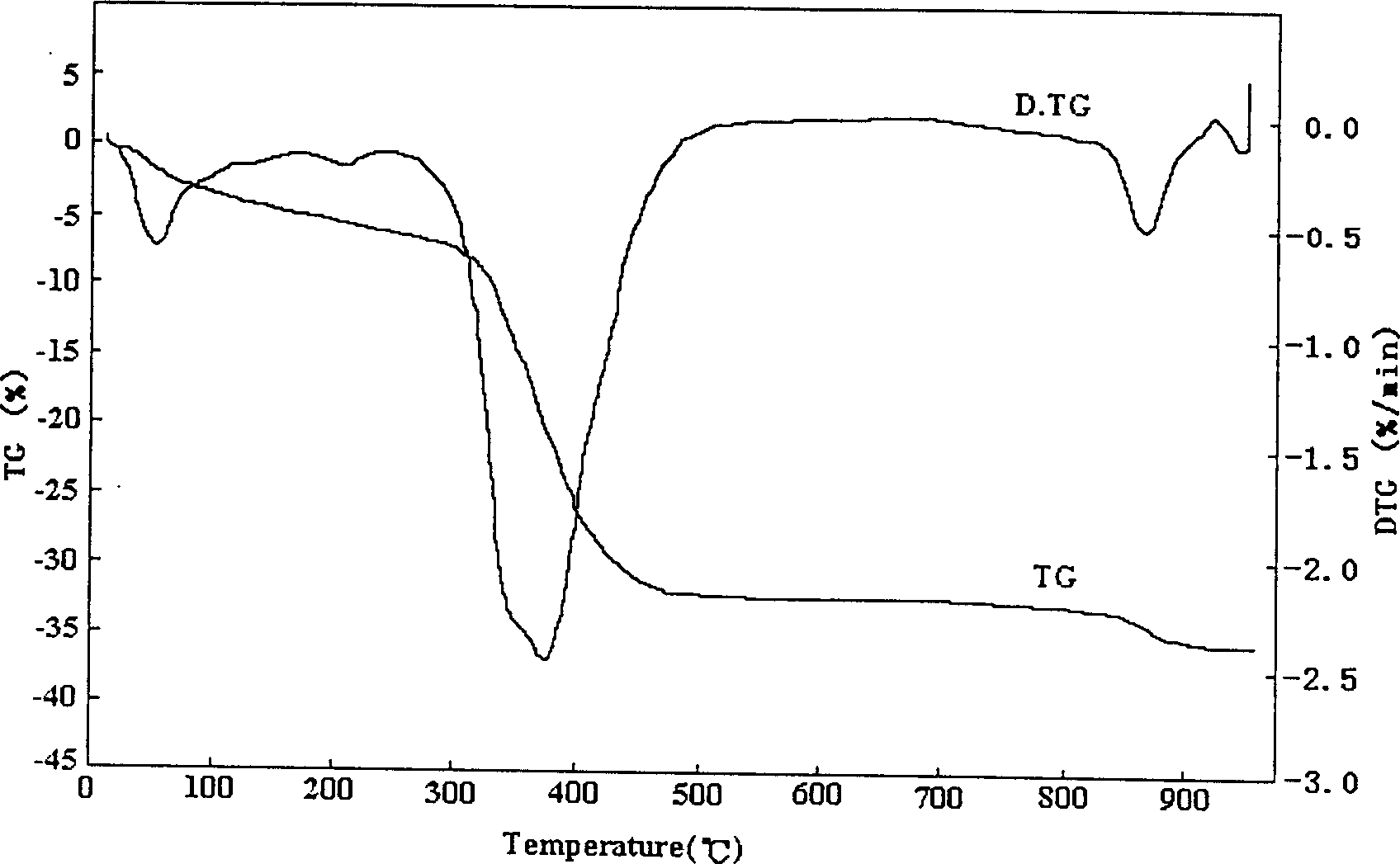

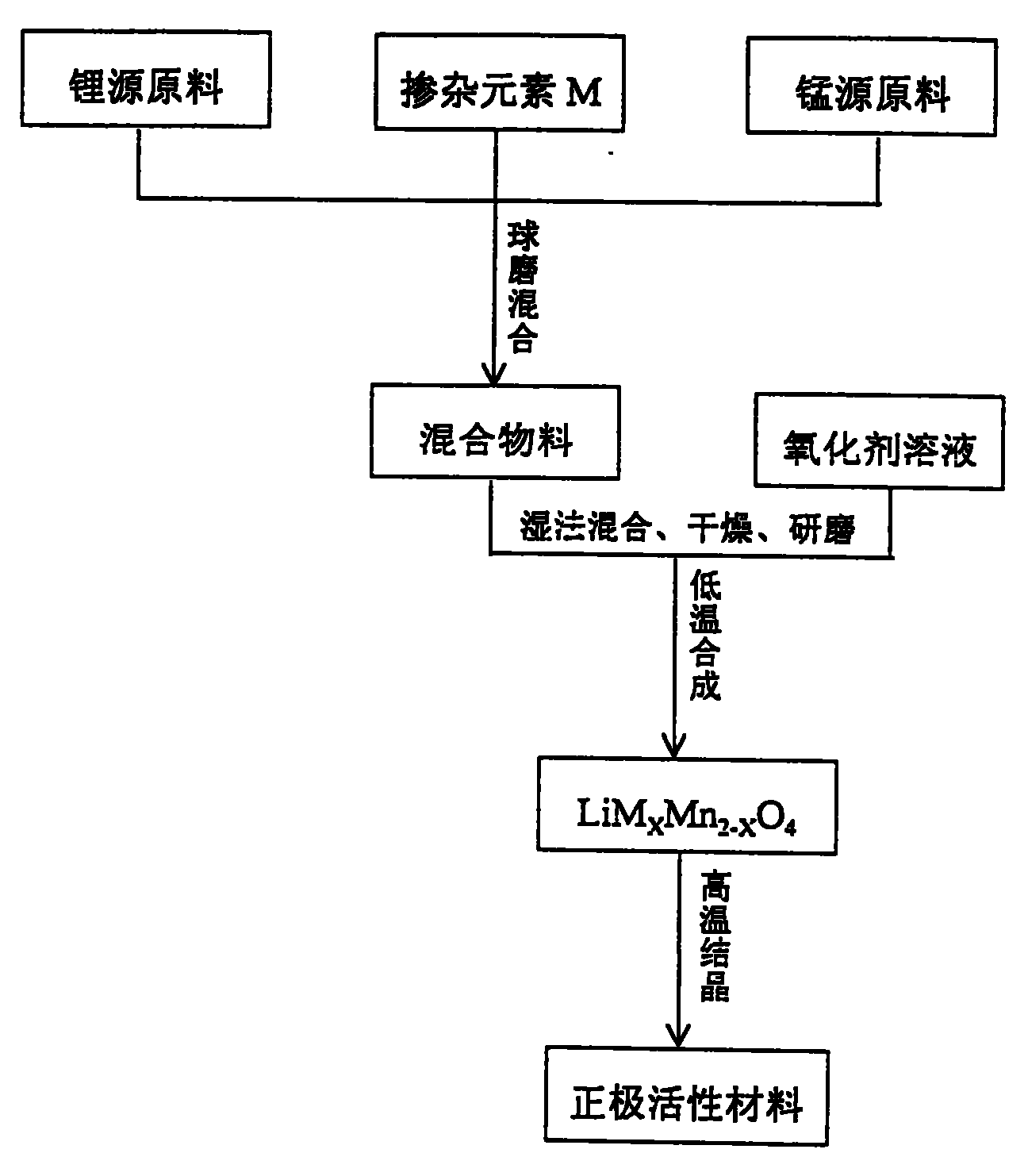

Method for preparing low-temperature semi-solid phase of lithium ion battery positive material

InactiveCN1274038CEnsure mixing uniformityAvoid inhomogeneityElectrode thermal treatmentGel electrodesPhysical chemistrySemi solid

The method includes steps: according to proportion, mixing material of manganese source, material of doped elements and material of lithium source; carrying out preliminary treatments for the said materials; after wet mixing, synthesizing material of positive pole under 350 deg.C - 500 deg.C low temperature; carrying out crystallizing qualified treatment in 700 deg.C -900 deg.C high temperature for short time so as to obtain material of positive pole of lithium ion battery in pure phase and high crystal quality. Reserving strongpoint of solid phase method, accepting merit of liquid phase and overcoming shortcoming of pure solid phase method, the invention possesses features of cheap materials, fine electrochemical performances, simple equipment, non toxic matter produced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of method of producing nano vanadium carbide powder

Owner:UNIV OF SCI & TECH BEIJING

Branched polymer-urea-glyoxal copolycondensation resin as well as preparation method and application thereof

ActiveCN113336908AImprove water resistanceMeet the use requirementsAldehyde/ketone condensation polymer adhesivesPolymer scienceAdhesive

The invention provides a branched polymer-urea-glyoxal copolycondensation resin and a preparation method thereof, and the preparation method comprises the following steps: 1, carrying out grafting reaction on branched polyethyleneimine and urea to obtain a grafted modified branched polyethyleneimine polymerization product marked as HPEIU-1800; 2, mixing a glyoxal aqueous solution with urea, adjusting the pH value to 7.5-8.0, carrying out a heating and thermal insulation reaction, adding the HPEIU-1800 synthesized in the step 1, and continuing the heating and thermal insulation reaction to obtain a target product. Due to the introduction of the branched polymer, the obtained resin has excellent bonding strength and water resistance. And no formaldehyde or organic solvent is used as synthetic raw materials, so the resin does not release formaldehyde and has excellent environmental protection property. The invention also provides an application of the resin in a wood adhesive.

Owner:SOUTHWEST FORESTRY UNIVERSITY

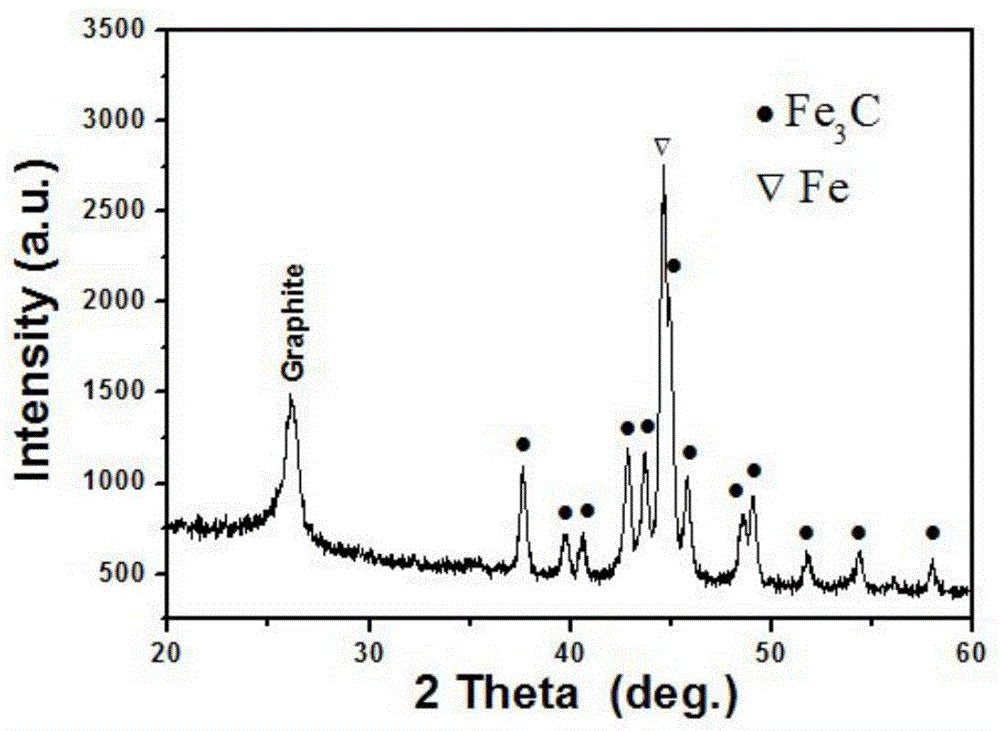

Production method of nanometer iron carbide powder

The invention relates to a preparation method of nanometer iron carbide powder and belongs to the technical field of preparation of nanometer powder. The preparation method comprises the following technological steps: (1) mixing ferric nitrate, glycine and a carbon source at a certain ratio to form a solution; (2) heating, stirring, volatilizing, concentrating and decomposing the solution to obtain precursor powder; and (3) allowing the precursor powder to react for 0.5-3 hours in a certain atmosphere at the temperature of 500 to 800 DEG C. The preparation method disclosed by the invention is simple in process, low in cost and easy for industrial production, and the obtained iron carbide powder particles are smaller than 30nm in particle size and good in dispersity.

Owner:UNIV OF SCI & TECH BEIJING

Diamine monomer containing pyridazine group and its preparation method and application

The invention provides pyridazine-group-containing diamine monomer and a preparation method and application thereof and belongs to the technical field of organic synthesis. The preparation method includes: adopting a nucleophilic substitution method to enable a dihydroxyl compound containing flexible group or asymmetric structure or bulky side group to react with chlorine-containing nitro pyridazine to obtain a dinitro intermediate containing a pyridazine structure, and reducing the dinitro intermediate to obtain diamine monomer containing a pyridazine structure; enabling the diamine monomer to react with dianhydride, and performing thermal imidization to obtain a high-performance heterocyclic polyimide film. The high-performance heterocyclic polyimide film maintains excellent thermal performance and mechanical performance that polyimide has originally, has solubility and photopermeability improved remarkably and has wide application prospect.

Owner:JILIN UNIV

Preparation method of resorcinol formaldehyde resin for modified rubber adhesive

The invention discloses a preparation method of a resorcinol formaldehyde resin for a modified rubber adhesive, which comprises the following steps: a) adding p-alkylphenol and polyformaldehyde into an organic solvent, and stirring uniformly at 40-70 DEG C; b) dropwisely adding an alkali solution, and keeping the temperature for 1-4 hours; c) heating the product obtained in the step b) to 80-100 DEG C, keeping the temperature for 2-4 hours, and cooling to 90 DEG C below; d) adding an acidity regulator into the product obtained in the step c), stirring, adding resorcinol, heating to 100-150 DEG C, and reacting under reflux for 2-5 hours; and e) removing the organic solvent from the product obtained in the step b), and starting granulation when the softening point of the product is 99-109 DEG C to obtain the granular resorcinol formaldehyde resin. The method uses polyformaldehyde instead of the formalin, and has the advantages of simple material feeding and lower risk.

Owner:SHANGHAI LUCKY BIOLOGICAL & CHEM TECH +1

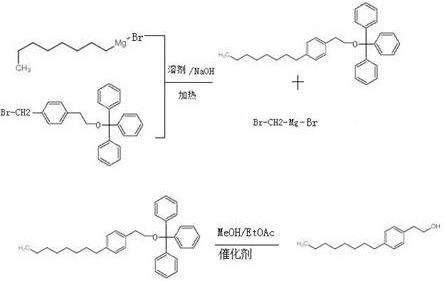

Preparation method of 4-octylphenethyl alcohol

InactiveCN111978154AHigh yieldLow costOrganic compound preparationHydroxy compound preparationGrignard reagentPhenethyl alcohol

The invention relates to the technical field of preparation of 4-octylphenethyl alcohol, in particular to a preparation method of 4-octylphenethyl alcohol. The method comprises the following operationsteps of 1, synthesizing a Grignard reagent R1-Mg-X1, wherein R1 is octyl, X1 is halogen (Cl, Br or I), and R1-X1 and magnesium powder react in anhydrous ether or tetrahydrofuran (THF) to prepare theGrignard reagent R1-Mg-X1; and 2, carrying out an alkylation reaction on R2-CH2-X2 and the R1-Mg-X1 to obtain R2-CH2-R1 and X1-Mg-X2, wherein R2 is phenethyl alcohol, X2 is halogen (Cl, Br or I), andR2-CH2-R1 is the product 4-octylphenethyl alcohol. The specific technological process is as follows: R2-CH2-X2 + R1-Mg-X1-R2-CH2-R1 + X1-Mg-X2, wherein R1 is octyl, X1 is halogen (Cl, Br or I), R2 isphenethyl alcohol, and X2 is halogen (Cl, Br or I). The method has the advantages of few byproducts, high yield, low cost and relatively low synthesis reaction temperature, is beneficial to industrial production, has low environmental pollution, and implements green production.

Owner:南京康德祥医药科技有限公司

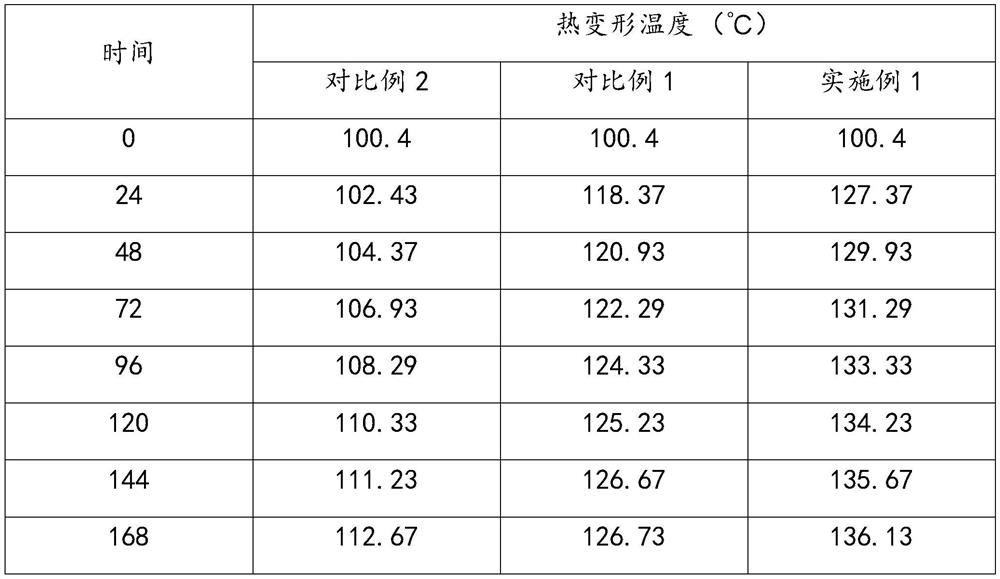

A preparation method of high heat-resistant polybutene-1 composite pipe material for transporting high-temperature fluid

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

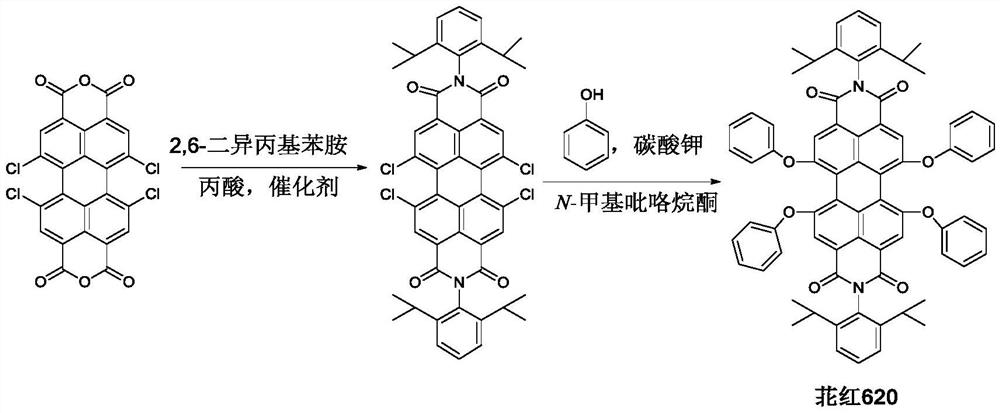

A kind of synthetic method of perylene red dye perylene red 620

ActiveCN109096790BReduce the synthesis reaction temperatureHigh purityAnthracene dyesLuminescent compositionsImidePtru catalyst

The invention discloses a synthetic method of perylene red 620 as perylene red dye. The method is characterized by comprising the following steps: 1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylicdianhydride is taken as a raw material and subjected to a reaction with 2,6-diisopropylanilineby catalysis of a catalyst under protection of inert gas, and the intermediate N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic diimide is obtained; the intermediate is subjected to a reaction with phenol, and a crude perylene red 620 product is obtained; the crude product is washed and subjected to other processing, and perylene red 620 with higher purity is obtained. After introduction of the catalyst, synthetic reaction temperature of the intermediate is reduced, and reaction time is shortened by 2 / 3; the original column chromatographic process is replaced with a cooling, standing and suction filtration method, and accordingly, purity of the intermediate isimproved; the method has the characteristics of safe and reasonable process, simple processing steps, high yield, low cost, high product purity and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Low-temperature synthesis method of polyfluorocarbon

InactiveCN109721052AReduce the synthesis reaction temperatureWide range of reaction temperature controlGraphiteDecompositionAntimony pentachloride

The invention discloses a low-temperature synthesis method of polyfluorocarbon. The low-temperature synthesis method comprises the steps: reacting graphite with antimony pentachloride to prepare an antimony pentachloride graphite intercalation compound, wherein the reaction temperature is 300-400 DEG C, and the reaction time is 7 h; and introducing a fluorine-helium mixed gas to a reactor, and carrying out a reaction for 5-10 h, wherein fluorine in the fluorine-helium mixed gas accounts for 12%-15% of the total volume of the mixed gas. The synthesis reaction temperature of polyfluorocarbon isfar lower than the decomposition temperature of polyfluorocarbon, so that potential explosion hazards are avoided; polyfluorocarbon can be formed in common fluorination equipment, the control range ofthe reaction temperature is relatively wide, and the reaction temperature is easy to control; and the production cost is relatively low, and the yield is relatively high.

Owner:李倩

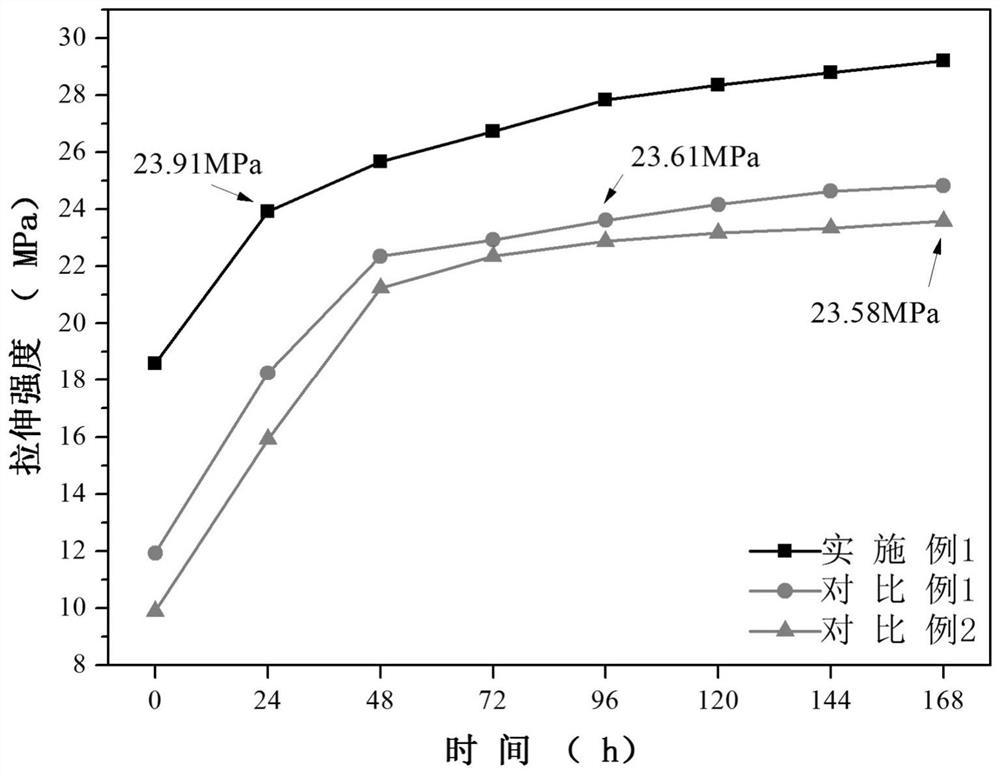

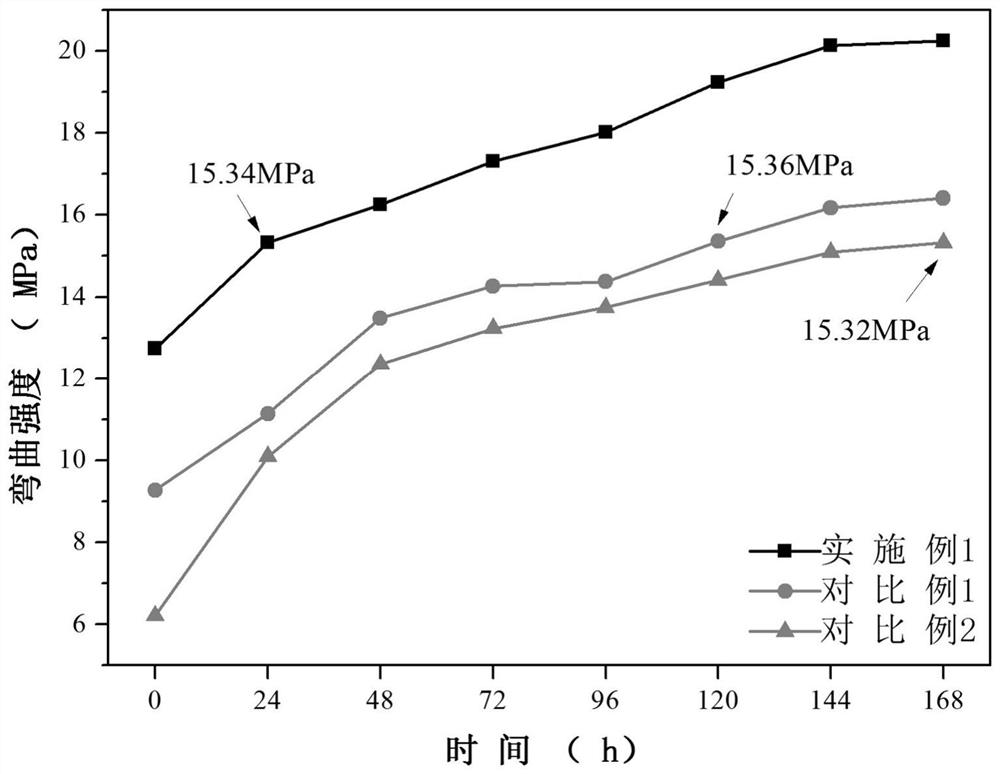

A preparation method of a special auxiliary agent for improving the mechanical properties of polybutene-1 in the initial stage of molding and the application of the special auxiliary agent

The invention relates to a method for preparing a special auxiliary agent for improving the mechanical properties of polybutene-1 at the initial stage of molding and the application of the special auxiliary agent, which belongs to the technical field of polymer materials, and specifically comprises the preparation of aryl phosphate hydroxyaluminum salt solid powder Put it in an organic solvent according to a certain proportion, stir and dissolve at 100°C-130°C until it is completely dissolved, and obtain mixture A; add bacterial cellulose powder to mixture A to obtain mixture B; Acid anhydride, stirred for 4-10 hours; after the reaction, the reacted substance was suction-filtered, then washed repeatedly with methanol at 50-60°C, and the obtained white powder was dried to obtain polybutene-1 Special auxiliary agent, the special auxiliary agent prepared by the present invention is mixed with polybutene-1, which can make the mechanical properties of polybutene-1 reach the mechanical properties of crystal form I at the initial stage of molding, meet the use requirements, and then reduce production costs.

Owner:山西艾德赛恩绿色产业研究院有限公司

A kind of preparation method of resorcinol formaldehyde resin for alkylphenol modified rubber adhesive

InactiveCN103936951BFeeding is simpleSimple processAldehyde/ketone condensation polymer adhesivesOrganic solventAdhesive

The invention discloses a preparation method of a resorcinol formaldehyde resin for an alkylphenol modified rubber adhesive, which comprises the following steps: a) adding alkylphenol and polyformaldehyde into an organic solvent, and stirring uniformly at 40-70 DEG C; b) dropwisely adding an alkali solution, and keeping the temperature for 1-4 hours; c) heating the product obtained in the step b) to 80-100 DEG C, keeping the temperature for 2-4 hours, and cooling to 90 DEG C below; d) adding oxalic acid into the product obtained in the step c), stirring, adding resorcinol, heating to 100-150 DEG C, and reacting under reflux for 2-5 hours; and e) removing the organic solvent from the product obtained in the step b), and starting granulation when the softening point of the product is 99-109 DEG C to obtain the granular resorcinol formaldehyde resin. The method uses polyformaldehyde instead of the formalin, and has the advantages of simple material feeding and lower risk.

Owner:SHANGHAI LUCKY BIOLOGICAL & CHEM TECH +1

Method for low-temperature preparation of pure phase oxide material

The invention relates to a method for preparing pure phase oxide at low temperature, belonging to the material preparation technical field. The inventive method referrs the chemical formual of AB<x>M<1-x>O3, (x=0.50-1.0), to dissolve the nitrates of cerium, zirconium, titanium or gallium into water, and slowly add the carbonate, oxalate, nitrate, acetate, basic hydroxide, hydroxide or oxide of calcium, barium, strontium, lead or lanthanide metal element into the solution to be dissolved completely, heats and mixes precursor solution in water bath or oil bath at 50-100DEG C, until the solution changes to gel, and reacts the gel at 1000DEG C for 2-10h, to obtain oxide materials of pure phase and high crystallinity. The method for preparing pure phase oxide at low temperature has simple process, easy operation, low cost, high product purity and easily accessible industrial production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

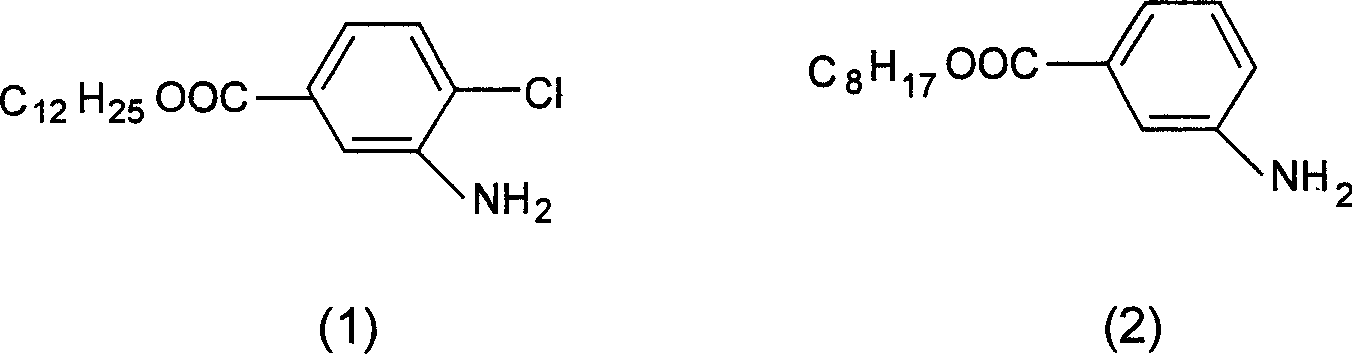

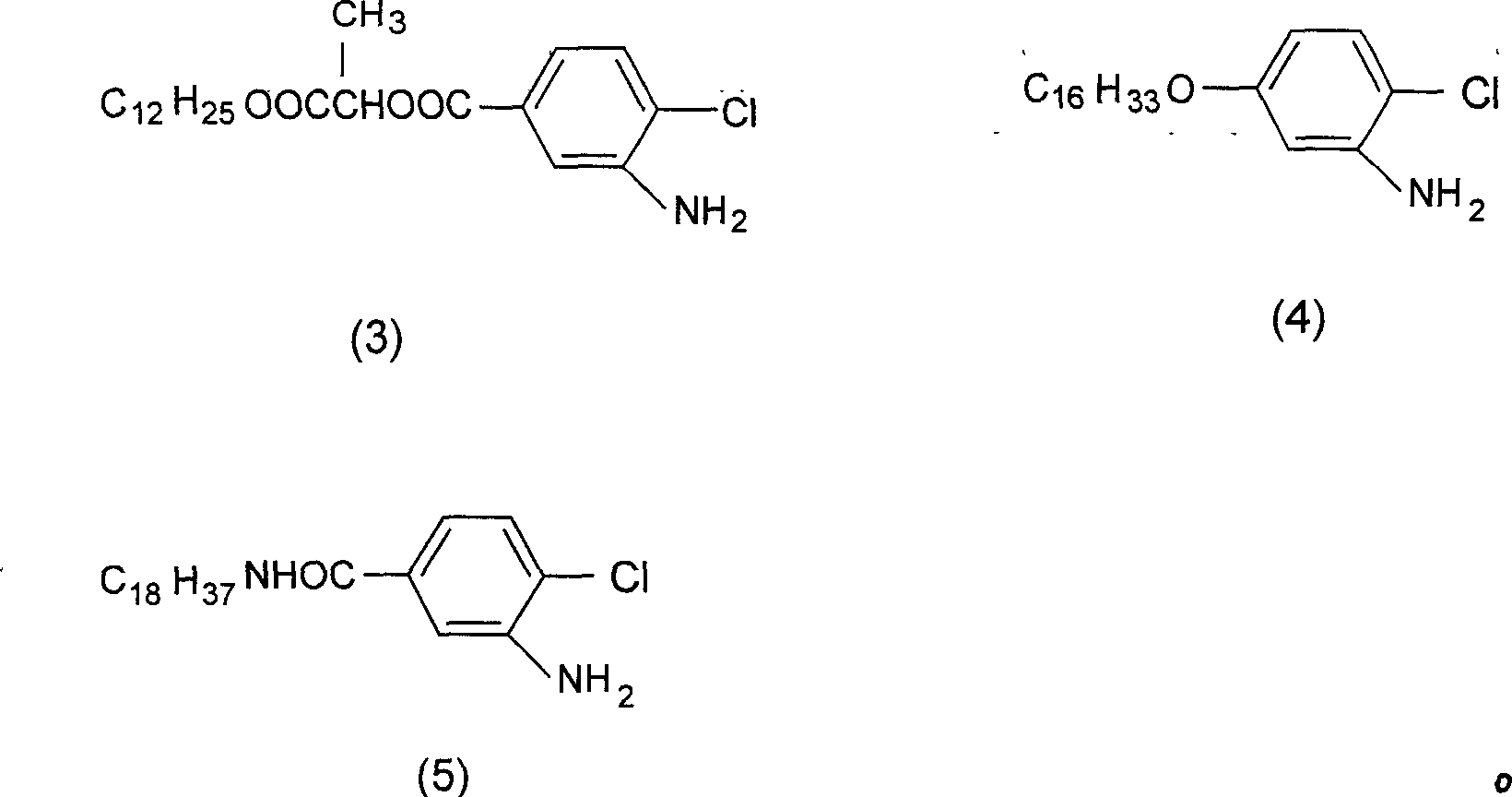

Preparing process of propane diamide compound

InactiveCN1164567CReduce the synthesis reaction temperatureShort reaction timeOrganic compound preparationCarboxylic acid amides preparationMalonic acidPhosphor

The present invention provides the preparation process of propane diamide compound. The propane diamide compound is prepared through adding malonic acid, amine and solvent, heating to 60-65 deg.c dropping phosphor trichloride and reaction at the said temperature for 1.5-2 hr. The general reaction expression is 2RNH2+HOOCCH2COOH+PCl3-R-NHCOCH2COLNH-R+H3PO3+HCl. The preparation process of present invention has short reaction period, low reaction temperature and high yield. The propane diamide compound product can be used to release compound parent substance for development inhibitor and development promoter.

Owner:CHINA LUCKY FILM CORP

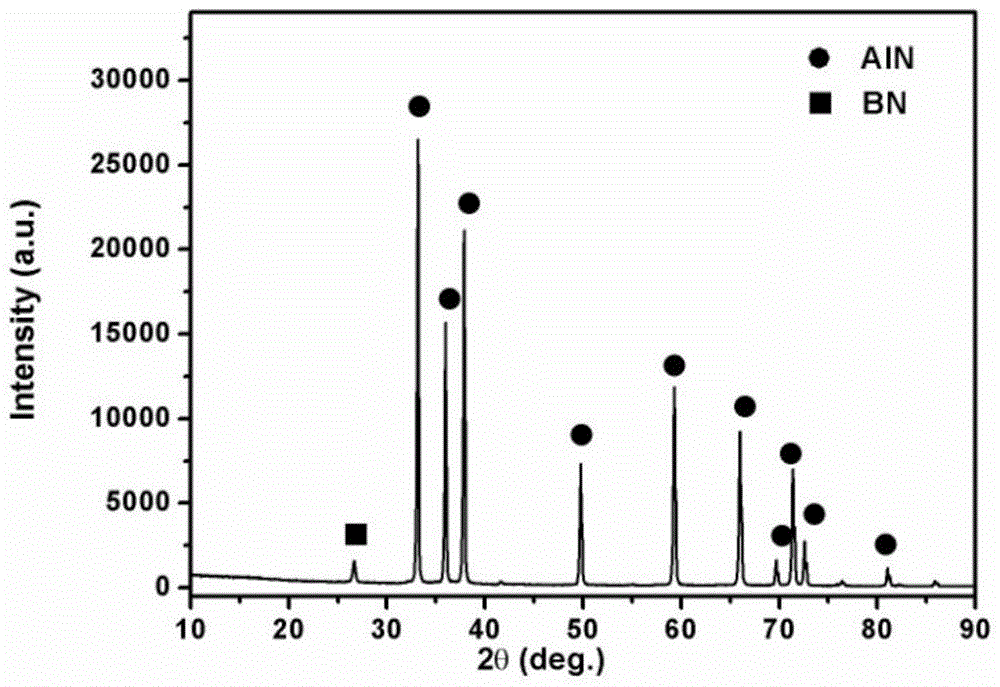

A kind of preparation method of aluminum nitride/boron nitride composite ceramic powder

ActiveCN104725049BSimple processCraft quickNitrogen-metal/silicon/boron binary compoundsComposite ceramicGranularity

The invention discloses a preparation method of aluminum nitride / boron nitride composite ceramic powder, and belongs to the technical field of preparation of ceramic powder. The preparation method comprises the following specific steps of with aluminum source, boron source, amine organism, waters soluble carbon source and assistant agent as raw materials, preparing a solution according to a certain ratio, heating and stirring, volatilizing and concentrating the solution, and reacting to obtain precursor powders; reacting the precursor powders for 2-4h in a flowing nitrogen atmosphere at 1300-1700 DEG C, heating the reacted powders for 1-3h in air at 500-650 DEG C so as to obtain the aluminum nitride / boron nitride composite ceramic powder. The preparation method is applicable for synthesizing high-purity high-dispersion and high fine granularity under a lower reaction temperature condition, the operation is simple, the cost is low, and the industrial production is prompted.

Owner:UNIV OF SCI & TECH BEIJING

A kind of preparation method of resorcinol formaldehyde resin for modified rubber adhesive

The invention discloses a preparation method of a resorcinol formaldehyde resin for a modified rubber adhesive, which comprises the following steps: a) adding p-alkylphenol and polyformaldehyde into an organic solvent, and stirring uniformly at 40-70 DEG C; b) dropwisely adding an alkali solution, and keeping the temperature for 1-4 hours; c) heating the product obtained in the step b) to 80-100 DEG C, keeping the temperature for 2-4 hours, and cooling to 90 DEG C below; d) adding an acidity regulator into the product obtained in the step c), stirring, adding resorcinol, heating to 100-150 DEG C, and reacting under reflux for 2-5 hours; and e) removing the organic solvent from the product obtained in the step b), and starting granulation when the softening point of the product is 99-109 DEG C to obtain the granular resorcinol formaldehyde resin. The method uses polyformaldehyde instead of the formalin, and has the advantages of simple material feeding and lower risk.

Owner:SHANGHAI LUCKY BIOLOGICAL & CHEM TECH +1

A kind of production method of graphite/iron carbide/iron nanocomposite material

The invention relates to a production method of a graphite / iron carbide / iron nanocomposite and belongs to the technical field of magnetic nanopowder production. The production method includes the processes: (1) dissolving ferric nitrate, adjuvants and a water-soluble carbon source in distilled water according to a proper proportion; (2) heating and stirring, and reacting solution after volatilization and concentration so as to obtain precursor powder containing iron and carbon; (3) reacting the precursor powder at the temperature of 700-1100 DEG C under a certain atmosphere for 0.5-2 hours. Graphite / iron carbide, graphite / iron or graphite / iron carbide / iron can be obtained respectively by regulating process parameters. The production method is simple in process, low in cost and easy for industrial production, and the obtained graphite / iron carbide / iron nanocomposite with the size less than 50nm is good in dispersibility and high in saturation magnetization.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com