A kind of synthetic method of perylene red dye perylene red 620

A synthesis method and red dye technology, which are applied in the field of synthesis of perylene red dye perylene red 620, can solve the problems of long synthesis time, affecting the production and application of perylene red 620, and high reaction temperature, and achieve low cost, strong practicability, and high-quality products. The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

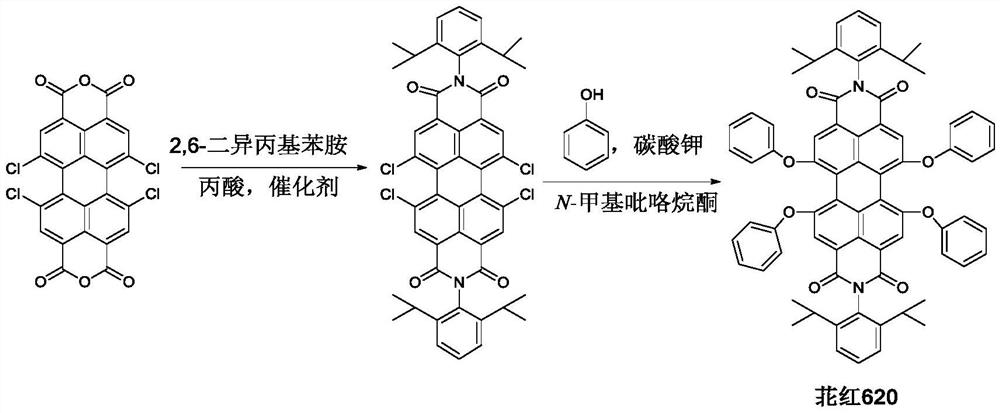

[0038] A method for synthesizing perylene red dye perylene red 620, namely a method for efficiently synthesizing and purifying perylene red dye perylene red 620, is carried out according to the following steps:

[0039]a. Efficient preparation of N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide :

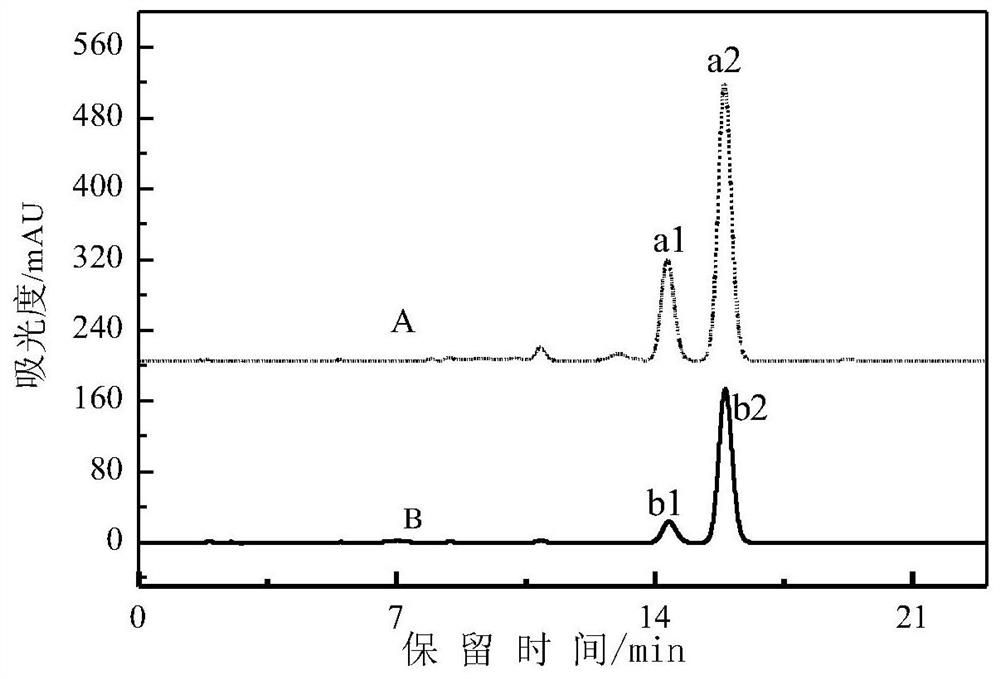

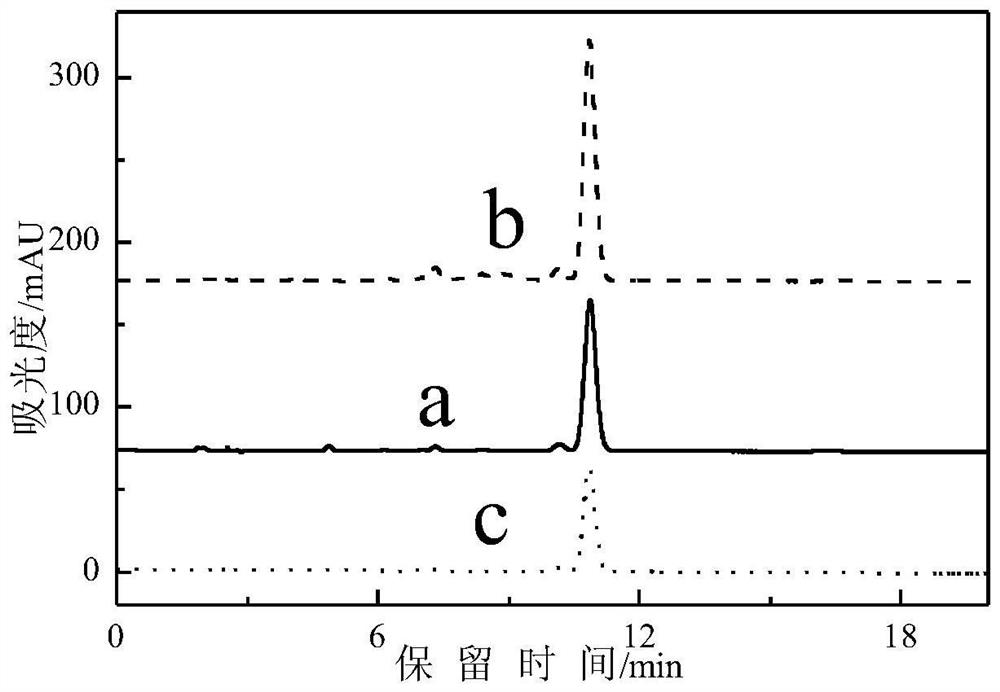

[0040] Under the protection of inert gas, 10mmol 1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic dianhydride, 40mmol 2,6-diisopropylaniline and 0.1mmol zinc chloride were added to In 1300mmol propionic acid, react at 120°C for 8 hours, stand at 25°C for 12 hours, filter with suction, wash with water until the filtrate is neutral, and dry at 80°C to obtain orange powder N,N'-bis(2,6-diisopropyl Base) phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide 7.2g, the yield was 85%, and the purity was 91%;

[0041] b. Preparation and efficient purification of perylene red 620:

[0042] 10mmol N,N'-bis(2,6-diiso...

Embodiment 2

[0045] A method for synthesizing perylene red dye perylene red 620, namely a method for efficiently synthesizing and purifying perylene red dye perylene red 620, is carried out according to the following steps:

[0046] a. Efficient preparation of N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide :

[0047] Under the protection of inert gas, add 10mmol 1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic dianhydride, 40mmol 2,6-diisopropylaniline and 0.1mmol anhydrous zinc acetate Add 1300mmol propionic acid, react at 125°C for 8 hours, stand at 25°C for 12 hours, filter with suction, wash with water until the filtrate is neutral, and dry at 80°C to obtain N,N'-bis(2,6-diiso Propyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide 7.5g, yield 88%, purity 92%;

[0048] b. Preparation and efficient purification of perylene red 620:

[0049] 10mmol N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4...

Embodiment 3

[0052] A method for synthesizing perylene red dye perylene red 620, namely a method for efficiently synthesizing and purifying perylene red dye perylene red 620, is carried out according to the following steps:

[0053] a. Efficient preparation of N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide :

[0054] Under the protection of inert gas, add 10mmol 1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic dianhydride, 40mmol 2,6-diisopropylaniline and 0.1mmol zinc acetate dihydrate Add 1300mmol propionic acid, react at 115°C for 8 hours, stand at 25°C for 12 hours, filter with suction, wash with water until the filtrate is neutral, and dry at 80°C to obtain N,N'-bis(2,6-diiso Propyl)phenyl-1,6,7,12-tetrachloro-3,4,9,10-perylenetetracarboxylic acid diimide 7.3g, yield 86%, purity 92%;

[0055] b. Preparation and efficient purification of perylene red 620:

[0056] 10mmol N,N'-bis(2,6-diisopropyl)phenyl-1,6,7,12-tetrachloro-3,4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com