Method for preparing SnIn4S photocatalyst through low-temperature coprecipitation method

A technology of indium tin sulfide light and co-precipitation method, which is applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of long reaction time, high reaction temperature, and high energy consumption, and achieve synthesis The effect of low reaction temperature, mild preparation conditions and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 1.2 mmol of tin chloride and 4.8 mmol of indium chloride into 90 mL of ethanol solution and stir, then add 12 mmol of thioacetamide, and stir until the solution is transparent.

[0018] (2) Transfer the solution to a 150 mL single-necked flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 60 o C, the water bath time is 3 hours.

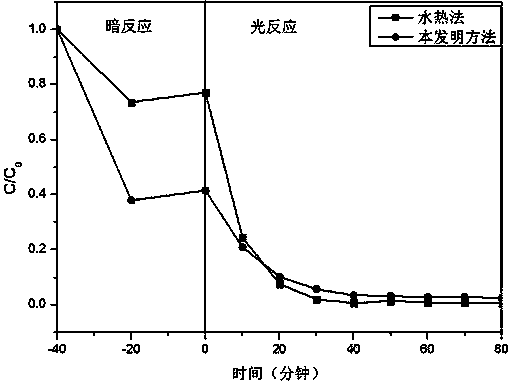

[0019] (3) The sample after the water bath was suction filtered and washed three times with deionized water and ethanol, and the obtained sample was at 80 o C for 24 hours. Then take it out, let it cool naturally, and grind it. The resulting product is an indium tin sulfide photocatalyst, which can completely degrade methyl orange within 50 minutes.

Embodiment 2

[0021] (1) Add 1.2 mmol of tin chloride and 4.8 mmol of indium chloride into 90 mL of ethanol solution and stir, then add 12 mmol of thioacetamide, and stir until the solution is transparent.

[0022] (2) Transfer the solution to a 150 mL single-necked flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 90 o C, the water bath time is 7 hours.

[0023] (3) The sample after the water bath was suction-filtered and washed three times with deionized water and ethanol. o C for 6 hours. Then take it out, let it cool naturally, and grind it. The resulting product is an indium tin sulfide photocatalyst, which can completely degrade methyl orange within 40 minutes.

Embodiment 3

[0025] (1) Add 1.2 mmol tributyltin chloride and 4.8 mmol indium nitrate to 90 mL ethylene glycol solution and stir, then add 12 mmol thioacetamide and stir until the solution is transparent.

[0026] (2) Transfer the solution to a 150 mL single-necked flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 60 o C, the water bath time is 3 hours.

[0027] (3) The sample after the water bath was suction filtered and washed three times with deionized water and ethanol, and the obtained sample was at 80 o C for 24 hours. Then take it out, let it cool naturally, and grind it. The resulting product is an indium tin sulfide photocatalyst, which can completely degrade methyl orange within 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com