Branched polymer-urea-glyoxal copolycondensation resin as well as preparation method and application thereof

A technology of dialdehyde copolycondensation resin and branched polymer, which is used in aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problem of insufficient crosslinking degree of synthetic resin and difficult crosslinking There are no problems in system and water resistance, and the effect of obvious energy saving effect, low synthesis reaction temperature and improved water resistance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

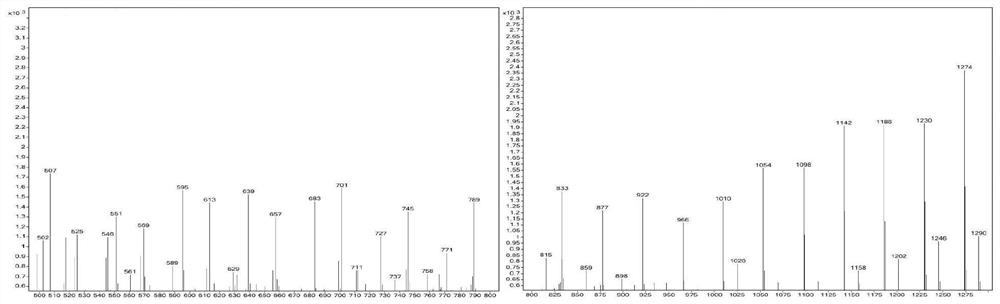

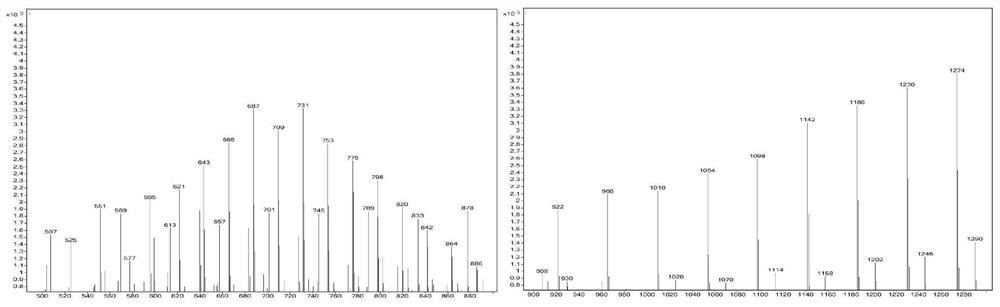

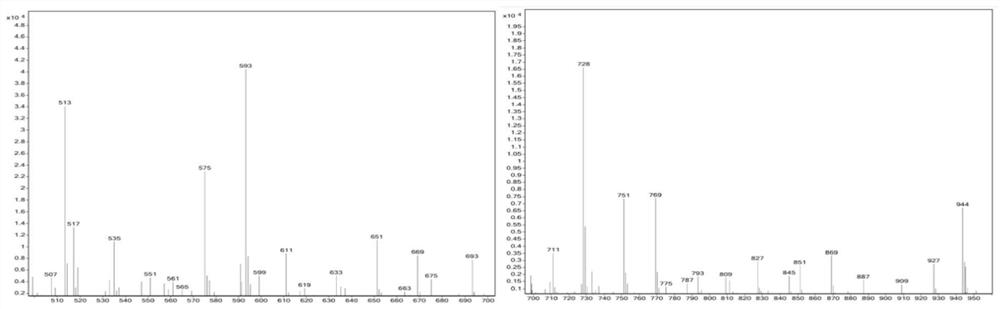

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides a preparation method of the above-mentioned branched polymer-urea-glyoxal co-condensation resin, comprising the following steps:

[0035] Step 1: making branched polyethyleneimine and urea undergo a grafting reaction to obtain a graft-modified branched polyethyleneimine polymerization product, which is denoted as HPEIU-1800;

[0036] Furthermore, HPEI is usually distinguished by average molecular weight, and the average molecular weight of HPEI products on the market is divided into 600, 800, 1800, 10,000, 70,000, etc. The above-mentioned HPEI is a commercially available product, the appearance is light yellow viscous liquid, the purity is above 95%, the pH value is 10-12, and it is stored at room temperature.

[0037] The average molecular weight of the branched polyethyleneimine used in the present invention is 1800. The reason for introducing HPEI is that the degree of cross-linking of urea-glyoxal co-condensatio...

Embodiment 1

[0049] (1) Under normal temperature conditions, the branched polyethyleneimine polymer with an average molecular weight of 1800 and urea (U1) are prepared according to the molar ratio of 1:6, and then added to the reaction vessel, and then condensed, refluxed, stirred, etc. Under the auxiliary device, continuously stir and heat to 95-100° C., and heat preservation reaction for 1 hour to prepare the grafted modified branched polyethyleneimine polymerization product. The discharged material is cooled and set aside, and it is recorded as HPEIU-1800.

[0050] (2) Under normal temperature conditions, take by weighing 100 grams of 40% glyoxal aqueous solution (G) and 25.86 grams of urea (U2) (molar ratio G:U2=1:1.6), join in the reaction vessel, Use 40% sodium hydroxide aqueous solution to adjust the pH value to 7.5-8.0, then heat the urea-glyoxal reaction system to 60°C under the conditions of heating in a water bath, stirring, and reflux, and keep the reaction for 1 hour, then hea...

Embodiment 2

[0052] (1) Under normal temperature conditions, the branched polyethyleneimine polymer with an average molecular weight of 1800 and urea (U1) are prepared according to the molar ratio of 1:8, and then added to the reaction vessel, and then condensed, refluxed, stirred, etc. Under the auxiliary device, continue stirring and heating to 95-100°C, and heat preservation reaction for 1 hour to prepare the grafted modified branched polyethyleneimine polymerization product, which is discharged to cool and set aside, which is designated as HPEIU-1800.

[0053] (2) Under normal temperature conditions, take 100 grams of concentration and be 40% glyoxal aqueous solution (G) and 24.37 grams of urea (U2) (molar ratio G:U2=1:1.7), join in the reaction vessel, Use 40% sodium hydroxide aqueous solution to adjust the pH value to 7.5-8.0, then heat the urea-glyoxal reaction system to 60°C under the conditions of heating in a water bath, stirring, and reflux, and keep the reaction for 1 hour, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com