Method for preparing low-temperature semi-solid phase of lithium ion battery positive material

A technology for lithium-ion batteries and cathode materials, which is applied in the field of low-temperature semi-solid phase preparation of cathode materials for lithium-ion batteries, can solve problems such as uneven mixing, uneven reaction, and unstable performance of batch products in solid-phase methods, and achieve Overcome the effects of large water treatment capacity, simple equipment, and excellent electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

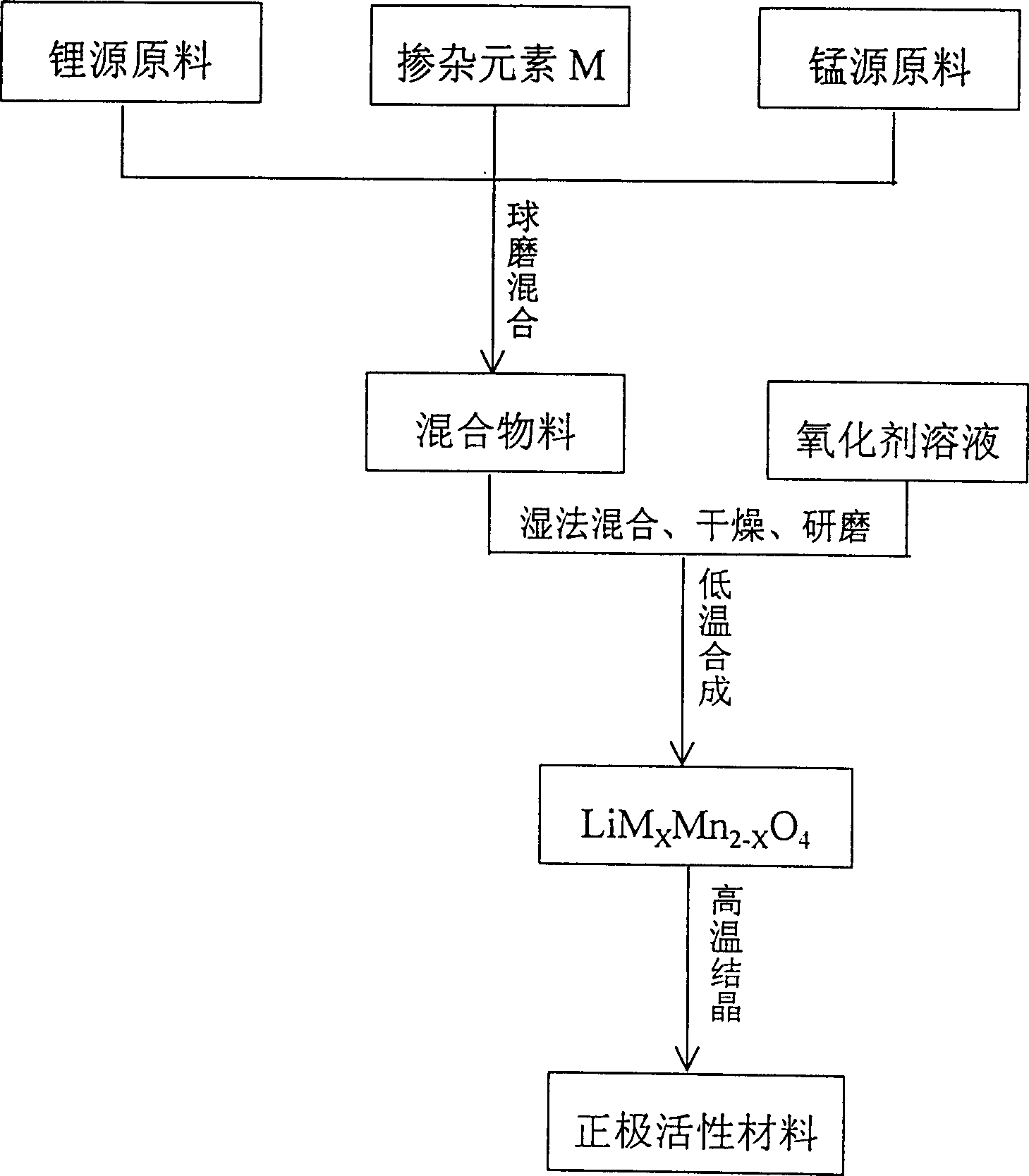

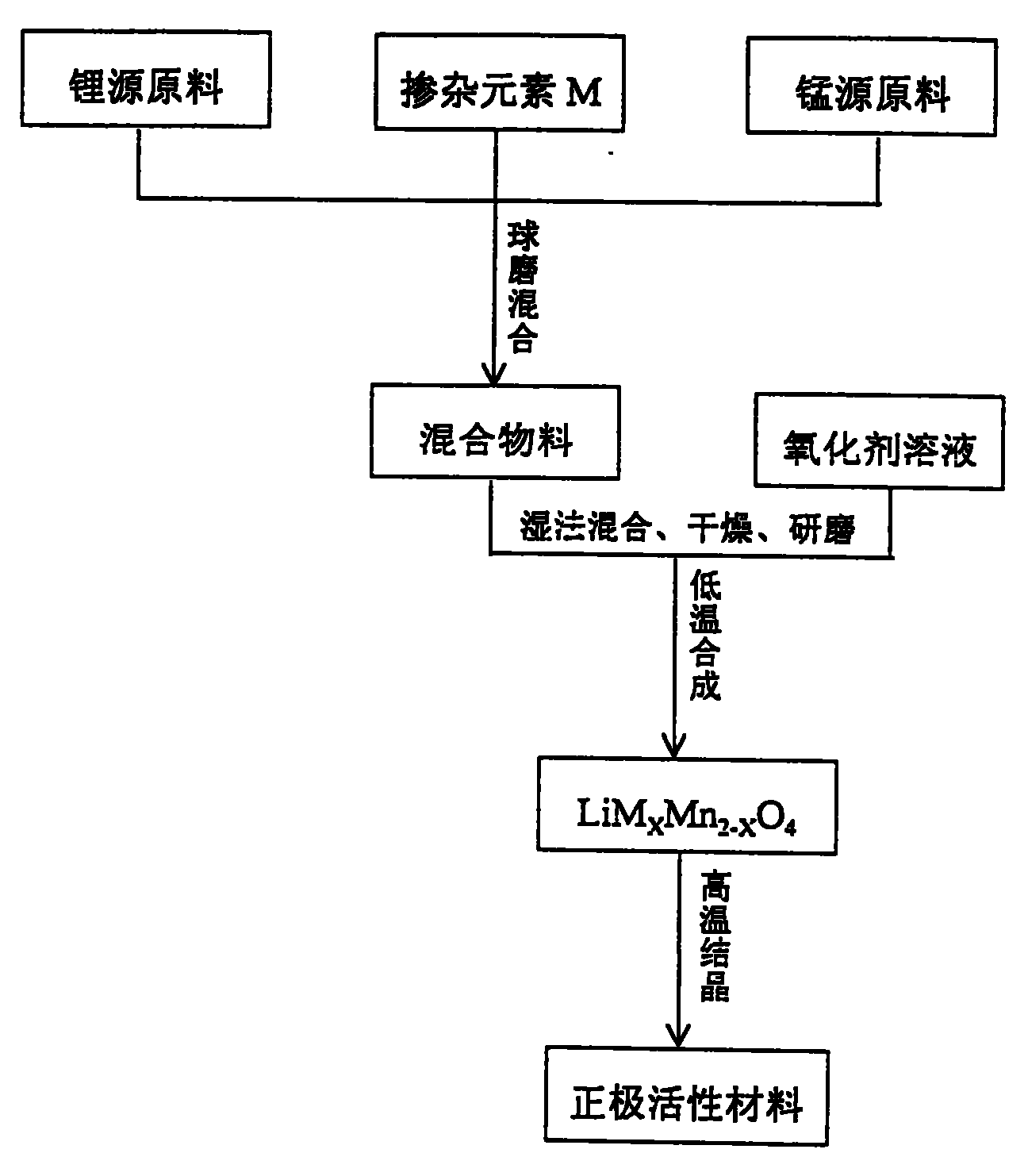

Method used

Image

Examples

Embodiment 1

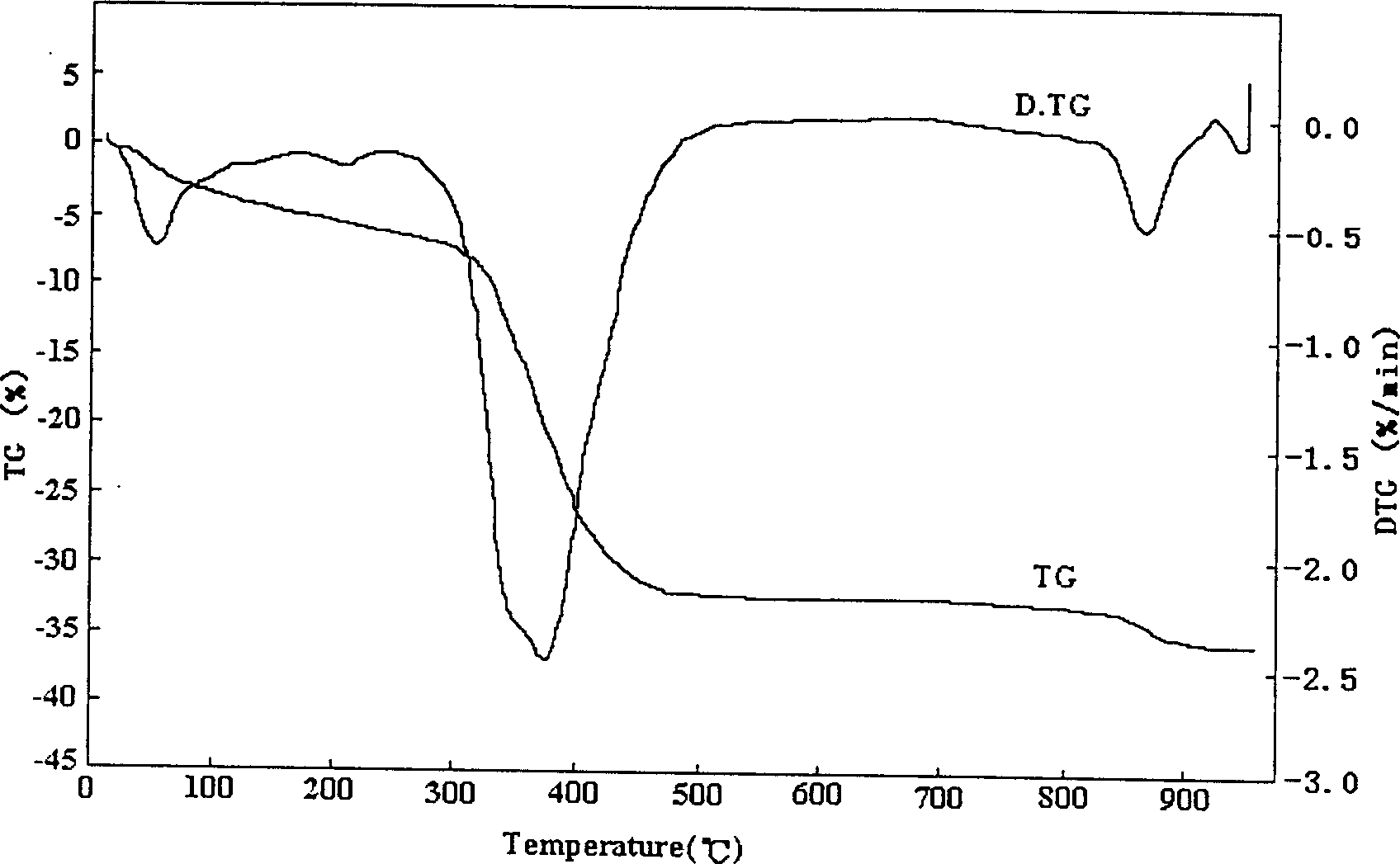

[0027] Example 1: Synthesis of pure spinel phase Li by low temperature semi-solid phase method 1.08 mn 2 o 4

[0028] Place 0.108mol (4.53g) of lithium hydroxide monohydrate and 0.200mol (22.99g) of manganese carbonate in a planetary ball mill, grind and mix evenly, then slowly add 8ml of 5% hydrogen peroxide aqueous solution, and mix the above wet materials After fully kneading and wet mixing, put it into a 60°C vacuum oven filled with water at the bottom, adjust the vacuum degree to control the humidity and dry slowly. The dried material is synthesized at a low temperature of 480°C for 10 hours, and then crystallized at a high temperature of 780°C for 5 hours. The resulting black powder is Li-ion battery cathode material Li 1.08 mn 2 o 4 .

Embodiment 2

[0029] Example 2: Synthesis of spinel phase LiCo by low temperature semi-solid phase method 0.1 mn 1.9 o 4

[0030] Put 0.1mol (4.19g) of lithium hydroxide monohydrate, 0.01mol of cobalt acetate (1.77g) and 0.19mol of manganese carbonate (21.84g) in a planetary ball mill and grind them evenly, then slowly add 6ml of 5% Hydrogen peroxide aqueous solution, fully knead the above wet materials, after wet mixing evenly, put it into a 60°C vacuum oven filled with water at the bottom, adjust the vacuum degree to control the humidity and dry slowly, and dry the materials at 520°C for 12 hours. Then crystallize at a high temperature of 800°C for 4 hours, and the obtained black powder is LiCo, the positive electrode material for lithium-ion batteries. 0.1 mn 1.9 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com