A preparation method of high heat-resistant polybutene-1 composite pipe material for transporting high-temperature fluid

A high-temperature fluid, polybutene technology, applied in the field of polymer materials, can solve problems such as the inability to meet the use requirements, and achieve the effects of improving the crystal transformation rate, low reaction temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

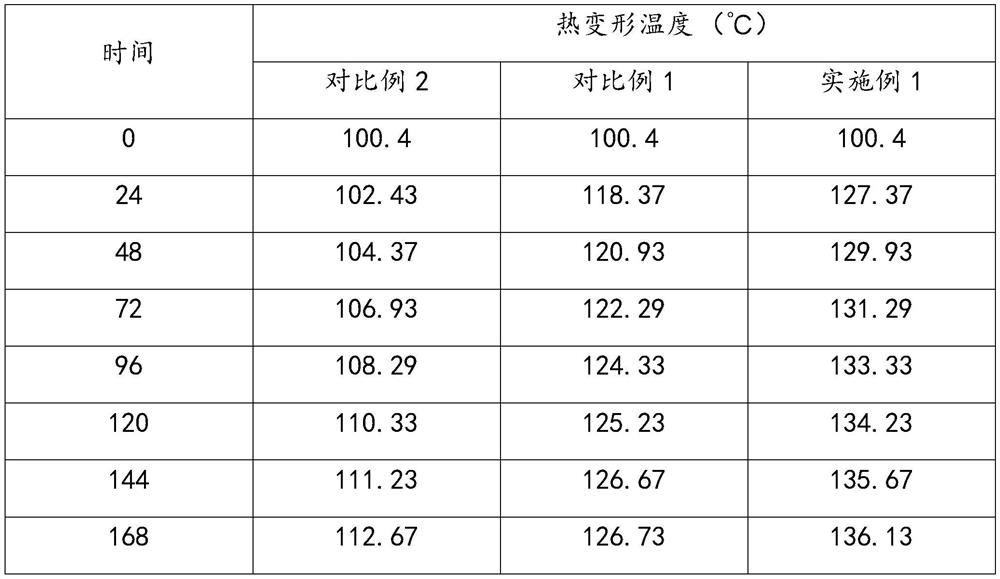

[0022] Add 5 g of bacterial cellulose powder with a particle size of 20 μm into 100 ml of 30% sulfuric acid solution, and stir vigorously for 10 min. After stirring, filter with suction and wash with water until neutral. Meanwhile, 5 g of bis[4-(1,1-dimethylethylbenzoyl-oxy)]aluminum hydroxide solid powder was dissolved in 100 ml of N,N-dimethylformamide at 130°C. The above solution was added to the bacterial cellulose powder treated with sulfuric acid, and stirred and reacted at 130°C for 8 hours. After the reaction, the white powder in the system was suction-filtered, washed with water, and dried. Mix 0.5g of the above-mentioned special additives with 1000g of PB-1 in a high-speed mixer, and shape them through extrusion, granulation, injection molding and other steps. At intervals of 24 hours, the heat distortion temperature (HDT) was measured according to GB / T1633-2000. The specific data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com