Borate matrix fluorescent powder for white-light LED and preparation method of borate matrix fluorescent powder

The technology of phosphor and borate is applied in the preparation of a single-base phosphor for white light LED and the preparation field thereof, which can solve the problems such as difficulty in adjusting and controlling the phosphor powder ratio, decrease in luminous efficiency, and the like, and achieves low synthesis reaction temperature, The effect of good thermal stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

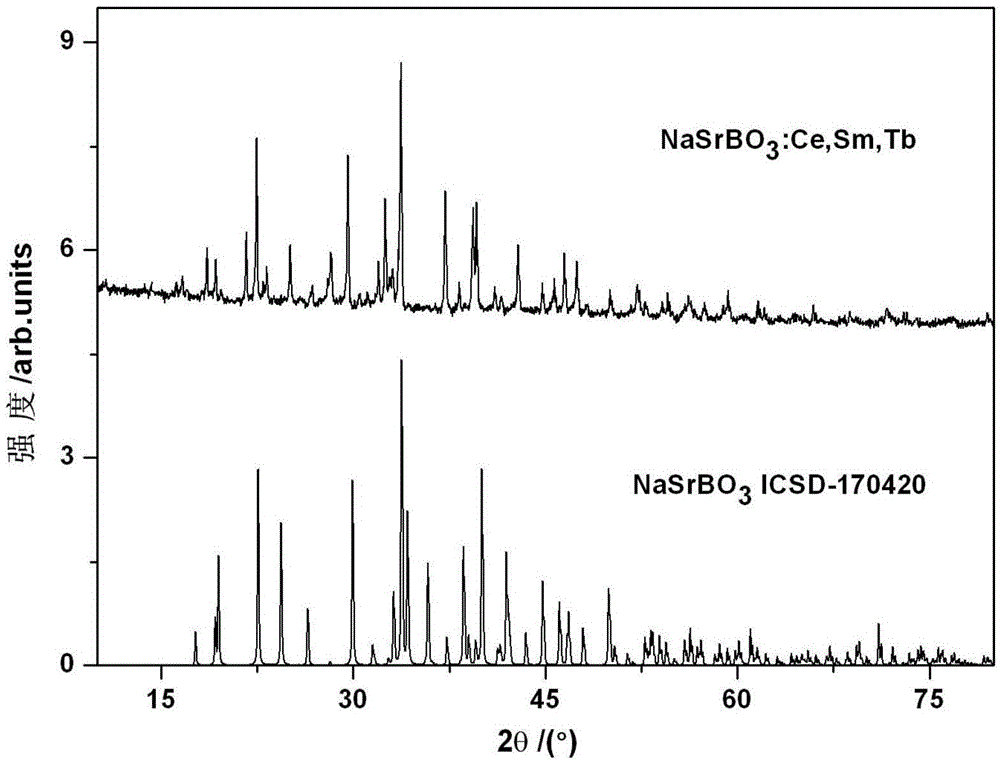

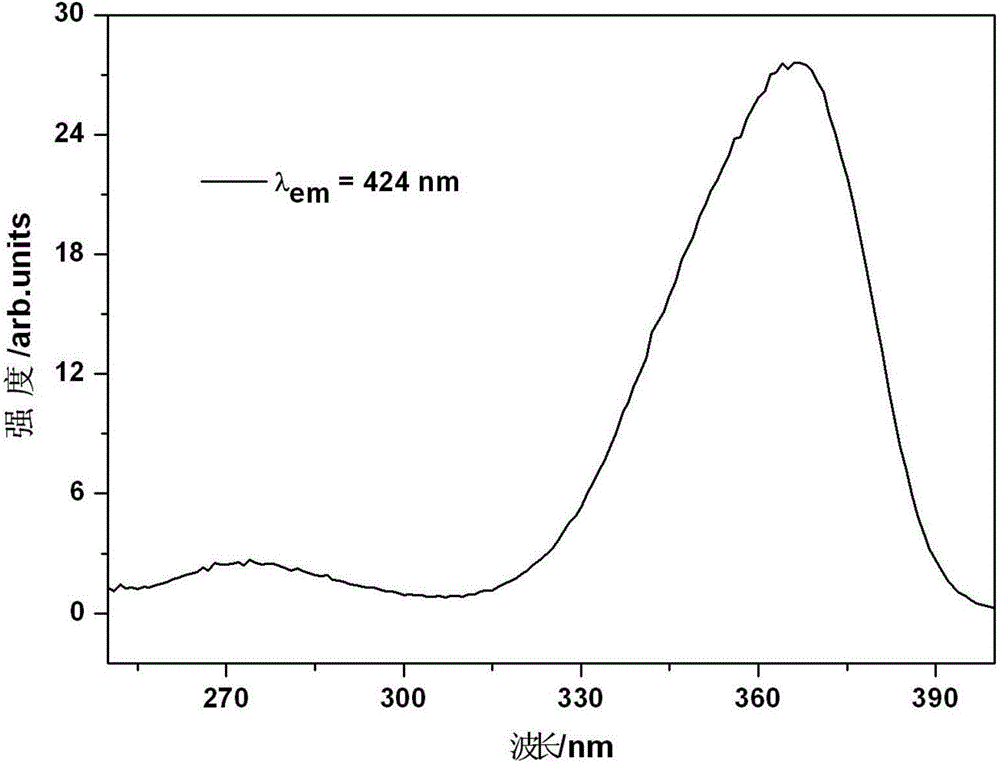

Method used

Image

Examples

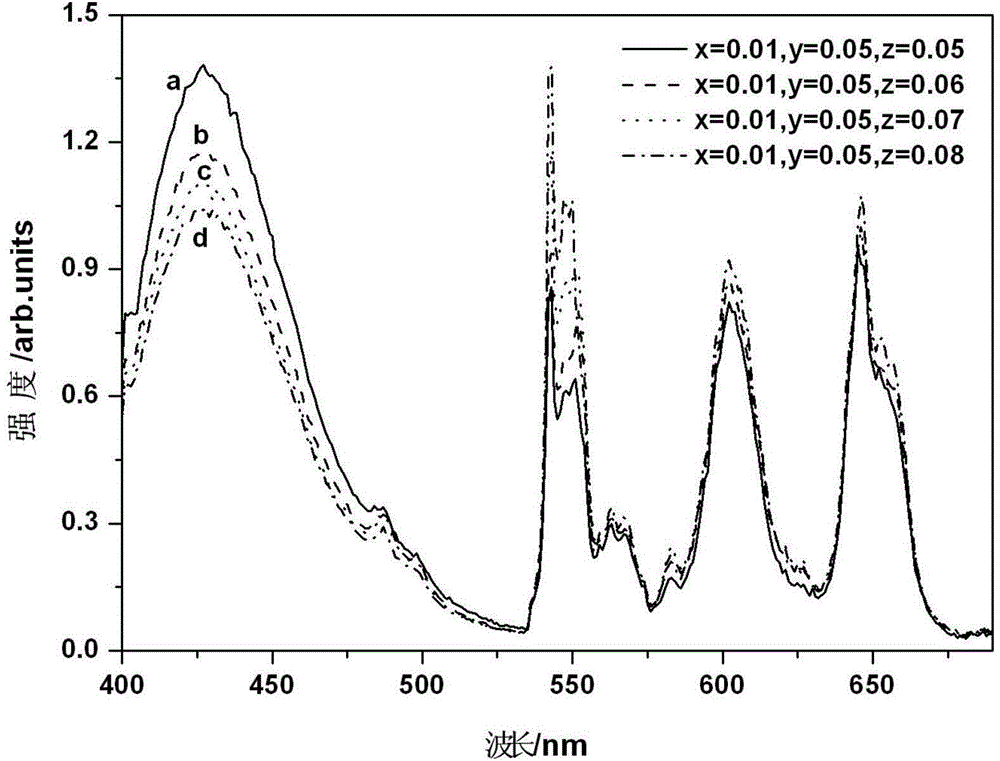

Embodiment 1

[0039] NaSr according to chemical composition 0.89 BO 3 :0.01Ce 3+ ,0.05Sm 3+ ,0.05Tb 3+ Take by weighing 0.5304g anhydrous sodium carbonate Na 2 CO 3 , 1.3144g strontium carbonate SrCO 3 , 0.6474g boric acid H 3 BO 3 , 0.0181g cerium oxide CeO 2 , 0.0872g samarium oxide Sm 2 o 3 , 0.0935g terbium oxide Tb 4 o 7 , into the agate mortar for preliminary mixing. Then add 2 times the volume of acetone, fully grind it in a ball mill jar for 30 minutes, then dry it in a drying oven for 1-5 hours, remove the acetone, transfer the dried raw material to a corundum crucible, and put it in a high-temperature muffle furnace. Calcining at 400-500°C for 10 hours; putting the semi-finished product obtained after the first sintering into an agate crucible for further grinding; Secondary sintering, reducing atmosphere is N 2 and H 2 Mixed gas, the calcination time is 8 hours; after the reaction is completed, naturally cool to room temperature, take out the sample and grind it, ...

Embodiment 2

[0042] NaSr according to chemical composition 0.88 BO 3 :0.01Ce 3+ ,0.05Sm 3+ ,0.06Tb 3+ Take by weighing 0.5307g anhydrous sodium carbonate Na 2 CO 3 , 1.2995g strontium carbonate SrCO 3 , 0.6478g boric acid H 3 BO 3 , 0.0172g cerium oxide CeO 2 , 0.0879g samarium oxide Sm 2 o 3 , 0.1131g terbium oxide Tb 4 o 7 , into the agate mortar for preliminary mixing. Then add 2 times the volume of acetone, fully grind it in a ball mill jar for 30 minutes, then dry it in a drying oven for 1-5 hours, remove the acetone, transfer the dried raw material to a corundum crucible, and put it in a high-temperature muffle furnace. Calcining at 400-500°C for 10 hours; putting the semi-finished product obtained after the first sintering into an agate crucible for further grinding; Secondary sintering, reducing atmosphere is N 2 and H 2 Mixed gas, the calcination time is 8 hours; after the reaction is completed, naturally cool to room temperature, take out the sample and grind it, ...

Embodiment 3

[0045] NaSr according to chemical composition 0.87 BO 3 :0.01Ce 3+ ,0.05Sm 3+ ,0.07Tb 3+ Weigh respectively 0.5306g of anhydrous sodium carbonate Na 2 CO 3 , 1.2849g strontium carbonate SrCO 3 , 0.6466g boric acid H 3 BO 3 , 0.0175g cerium oxide CeO 2 , 0.0879g samarium oxide Sm 2 o 3 , 0.1314g terbium oxide Tb 4 o 7 , into the agate mortar for preliminary mixing. Then add 2 times the volume of acetone, fully grind it in a ball mill jar for 30 minutes, then dry it in a drying oven for 1-5 hours, remove the acetone, transfer the dried raw material to a corundum crucible, and put it in a high-temperature muffle furnace. Calcining at 400-650°C for 10 hours; putting the semi-finished product obtained after the first sintering into an agate crucible for further grinding; Secondary sintering, reducing atmosphere is N 2 and H 2 Mixed gas, the calcination time is 8 hours; after the reaction is completed, naturally cool to room temperature, take out the sample and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com